Interskol rotary hammers, according to statistics, are reliable tools. Failures are recorded much less frequently than with the more popular Makita, Bosch, and Hitachi models.

The main rule: choose a model that is designed for loads and designed to perform the planned work.

Using hammer drills for their intended purpose in accordance with operating requirements allows you to operate Interskol rotary hammers for a long time.

But, like any tool, various malfunctions appear in hammer drills that will require you to repair the hammer drill yourself, especially if it is no longer under warranty.

To repair Interskol rotary hammers and troubleshoot problems, you need to carefully study the structure of the tool, its circuit, and lubrication charts. Any repair of an Interskol hammer drill begins with disassembling it. Read more about this.

Disassembly and assembly of gearbox P710

Repair instructions for the gearbox of rotary hammers P710 Interskol, BPR 241 SPARKY , P1-750-RE, P2-850-RE Fiolent

Dismantling

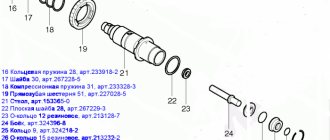

Remove in sequence: - special ring 1, - release sleeve 2, - ring 3, - ball 4, - spring 5. Pull the bearing shield out of housing 8 by 3-4 mm, remove switch 28a. Remove the bearing shield from the housing. Remove in sequence: - clamp 31, - spring 30, - ring 29. Remove closing spring 22.

Remove in sequence: - spring 21, - locking bar 20, - front switching bar 17, - rear switching bar 18, - spring 19 from the axle.

Remove washers 10, 16 and 55, spindle assembly and intermediate shaft 50 from bearing shield 24. Remove washer 43 and springs 42. Remove bearing 51. Remove gasket 26. If necessary, remove from bearing shield 24: bearing 23, bearing 52. Note: Washer 10 serves to ensure mounting distances and may be missing on some machines.

Remove ring 11, washers 12, spring 13 and gear wheel 14. Remove cylinder 40 with piston 38. Remove piston 38 from cylinder 40. Remove ring 37 from spindle 15. Remove sequentially: - catch sleeve 35, - rubber washer 34, - impact intermediate body 33. If necessary, remove rings 32, 36, 39. Remove axle 41 and washers 27.

Remove, in sequence, the intermediate shaft gear 44 and the switching bushings 45 and 46. Remove the large intermediate gear 49 and the swing bearing 48 from the intermediate shaft 47. Tools: rack press, gasket, mandrel.

Apply grease 5 to the intermediate shaft 47 in an amount of about 1 g. Press in successively the swing bearing 48 and the large intermediate gear 49. Assemble in sequence the switching bushing 46 and the gear wheel of the intermediate shaft 45. Tools: rack press, bushing (pipe) with inner diameter 8 mm.

1. Apply grease to the cylinder bore 40. 2. Assemble washers 27 and axle 41. 3. Insert ring 39 into piston bore 38. 4. Apply grease to the cylinder bore and to the piston. 5. Insert piston 38 into cylinder 40.

1. Install rings 32 on the intermediate striker 33. 2. Insert ring 36 into the channel of the clamping sleeve 35. 3. Place in sequence: - spindle gear wheel 14, - spring 13, - washers 12, - ring 11 on spindle 15. Into the spindle in series insert: - intermediate striker 33, - rubber washer 34, - clamping sleeve 35, - ring 37. Note: Clamping sleeve 35 is inserted with a large chamfer into ring 37. Tools: rack press, pliers and mandrel for pressing ring 37, sleeve for pressing ring eleven

Install the intermediate switch bar 18 on the switch bar 17 and the spring 19 so that the spring is between the intermediate switch bar 18 and the switch bar 17, as shown in the figure. On axis 53 install sequentially: - spring 21, - locking bar 20, - switching bar 17 together with intermediate switching bar 18 and spring 19.

Install bearing 23 and bearing 52 on bearing shield 24. Install the spindle assembly on the bearing shield and measure the mounting clearance. With a gap of 92.38. 92.7 install washer pos. 10. With a gap of 92.7. 93.32 - washer pos. 10 is not installed.

Insert the cylinder with piston 40 into the bearing assembly shield 54.

Install the bearing assembly 51 on the intermediate shaft 50. Assemble the bearing shield 54, the intermediate shaft assembly and the bearing assembly 51 so that the thrust bearing axis fits into the hole of the cylinder axis, as shown in the figure.

Place gasket 26 on the bearing shield. Install the switching mechanism SW on the bearing shield so that the fork of the switching bar fits into the channel of the switching sleeve. Assemble washers 55 and 16 and spindle assembly SP in sequence. Note: Rotate the switching sleeve so that its cams are in contact with the end surface without entering the channels of the thrust bearing 48.

Assemble: - washer 10 (if necessary, see point 10), - washer 43, - springs 42. Place locking spring 22 on the bearing shield.

On switch 28 install: - ring 29, - spring 30, - lock 31.

Install the gearbox on the shield, leaving a distance of 3-5 mm before final closing. Install switch 28 on the gearbox so that the pin fits into the slot of the intermediate switch strip. Smoothly turn switch 28 to the “impact drilling” position, while simultaneously pressing the gearbox until the gearbox is completely closed. Insert spring 5 and ball 4 into the spindle. Apply grease 3 to ring 3 and insert into release sleeve 2. Insert release sleeve into the spindle.

Operating mode switch The switch should move easily, without tightening, and the end positions should be clearly fixed.

1. Initial position for gearbox assembly The gearbox is installed in a vertical position. Mutual arrangement of parts and assemblies: - centering bushings 9 are installed in the shield, - pins of the rear shifting bushing 46 are not engaged with the swing bearing, - the fork of the rear shifting bar 18 is engaged in the channel of the rear shifting bushing 46, - the fork of the front shifting bar 17 is engaged in the channel of the bushing front shifting bar 45, - the gear wheel of the intermediate shaft 44 is engaged in the front shifting bushing 45. The free movement of the front shifting bar 17 and through it the front shifting bushing 45 is checked - through several compressions and releases of the spring 19.

2. Assembling the gearbox with the housing The closing spring 22 is pressed into the inside of the gearbox and the gearbox housing kit 8 is installed on the gearbox. In this case, it is necessary to orient the spindle kit so that it fits into the needle bearing in the housing. The gearbox housing 8 is held with one hand so as not to allow it to completely close the gearbox; a stroke of 4-5 mm remains. In this case, it should be in the following position: - through the hole for the switch, the channel formed by the front and rear switching strips should be visible; — the fork of the closing spring 22 must coincide (without going in) with the hole for the switch.

The hammer blow has disappeared - what to do?

As you know, nothing lasts forever. And reliable equipment breaks down. Somehow, in the midst of work, he stopped hammering. The machine was working in rotation mode, but the shock suddenly disappeared.

The gearbox was disassembled and the cause of the breakdown was identified. The bushing in the barrel body, in which the firing pin directly carries out the impact work, was broken. As a result, the striker became jammed in the fragments of the collapsed bushing.

The service center advised to replace the barrel completely. It turned out that the bushing is pressed into the barrel at the manufacturer and is not supplied separately. I had to buy a whole new barrel.

In this article we will tell you how to put the hammer drill into working condition yourself after this, in general, simple breakdown. If you have the skills to repair power tools and the desire not to pay someone your hard-earned money, then we take the tool and start disassembling the machine.

Tools

You will need two ordinary flathead screwdrivers and one Phillips head screwdriver. One of the flat-head screwdrivers should be thin and narrow, no more than 4 mm wide. You will also need a wire hook to remove the retaining ring. It can be made from a bicycle spoke, the main thing is that the wire is rigid and does not bend easily. You will also need a rubber mallet or wooden mallet.

Work process

Disassembling the hammer drill should begin by removing the protective rubber cap - boot. It can be easily removed, just grab it with your fingers and pull it off the barrel.

Removing the boot

Then, by pressing on the plastic cover and squeezing the spring of the SDS + mechanism, remove the retaining ring with a screwdriver.

Using a screwdriver, remove the stopper

The cover is removed from the barrel, and behind it, compressing the spring again, we pull out the retaining ball along with the spring and the figured washer.

Remove the cover

Disassembling the SDS mechanism

After which the operating mode switch is disassembled. Under the cover that holds the red locking button, there is a special slot for a screwdriver. By inserting a screwdriver into this groove and prying the cover slightly, first from one edge and then from the other, carefully remove it. You should not apply significant effort here; the lid is still plastic and may break. The red button along with the spring is removed from the switch body, and it is moved to the left all the way, just beyond the drilling mode. It is from this position that it is removed from the gearbox. For this operation, the switch must be lightly picked up with thin screwdrivers on both sides and removed along with the rubber o-ring.

Removing the rotary hammer mode switch

Now the gear box is removed. Using a Phillips screwdriver, unscrew the four bolts connecting the box to the stator housing. Then, holding it with your hand, you need to lightly hit the end of the barrel with a mallet so that the box comes off the gearbox.

Removing the gearbox

After removing the box, remove the barrel from the gearbox. It comes off easily.

Pull the barrel out of the gearbox

Use a rag to remove old grease, wash the barrel with gasoline or kerosene and wipe dry.

Broken bushing

So, as mentioned above, it was necessary to completely change the entire barrel. However, this item purchased at the service center turned out to be “as naked as a falcon.” That is, there was absolutely nothing on it and all the parts from the old barrel had to be moved to a new “blank”.

The most difficult operation was removing the firing pin from the barrel body. There are special holes in the barrel body through which the locking ring can be seen. This ring holds the firing pin with rings and rubber dampers in the body seat. Inserting a thin screwdriver into the hole, bend the ring slightly. We do this first on one side and then on the other. The stopper should come out of the groove.

Using two screwdrivers, compress the stopper

Then, from the inside, using a homemade wire hook, we pull the stopper out into the light of day.

Using a wire hook, remove the stopper from the inside.

Next, remove the striker with washers and rubber rings. For assembly, it is necessary to remember or sketch the location of all rings and washers. If something goes wrong, photographs and drawings from the article will help.

Now you need to remove the gear from the shaft. After pressing on the washer and compressing the spring, use a thin screwdriver to remove the retaining ring from the groove. After removing it, remove the washer, spring and gear from the barrel.

Assembly and lubrication of the Interskol hammer drill

Rotary hammers are quite unpretentious in maintenance. To maintain the working condition of the Interskol rotary hammer, it is necessary to promptly change the lubricant in the gearbox whenever the worn out carbon brushes of the electric motor are replaced.

Old grease must be removed; it is preferable to remove it with special detergents used in service centers. But a home craftsman can get by just fine with a solution of a mixture of kerosene and gasoline. Assembling an Interskol hammer drill with your own hands is a fairly simple technological process. You just need to read the disassembly instructions, the diagram, and the spare parts catalog. Before assembly, prepare new or repaired and cleanly washed parts, a new O-ring repair kit, lubricants, tools and auxiliary materials. Don't forget about proper preparation of the workplace and its lighting.

New lubricant is applied to cleanly washed parts and only that which is recommended for this unit.

When adding new lubricant, do not overdo it: excess lubricant during operation of the hammer drill is often squeezed out through the gearbox housing and leads to destruction of the seals.

Before assembling parts, check the internal surfaces for roughness. The surface must be polished to a mirror finish. At low roughness, abrasion of the rubber sealing rings occurs more intensely. Details about the repair of the Interskol rotary hammer.

Replacing brushes

If it’s time to change the brushes in a hammer drill, you can take the tool to a service center for this task, or you can do it yourself, which is quite easy. Replacement at a service center has a number of advantages:

- High-quality work if it is a specialized center

- Original parts for your tool model

- Extending the warranty if the period has not yet expired

- In addition to replacing the broken part, the service usually inspects the entire internal important parts, cleans them and lubricates them

Along with the advantages, repairing power tools at a service center also has disadvantages:

- If there is no guarantee, the work will be paid for

- Repairs will take time, you'll have to wait

- Service is not always close

If you are not satisfied with the indicated inconveniences of repairing a tool in a specialized center, it is better to complete the task yourself.

The process of replacing parts is carried out in stages:

- The hammer drill, which is disconnected from the socket, must be unscrewed to remove the top cover.

- After this, using a small screwdriver, you need to easily hook the brush holder, remove it and remove the old parts.

- Insert new ones into the holder, press them to the edges, and place them in place inside the hammer drill.

- Check that the brushes reach the contacts for smooth operation of the power tool.

- Close the lid and secure it with screws.

Read also: Cold salting of hot peppers for the winter

Tips from experts when repairing a rotary hammer

When replacing brushes yourself, experts recommend:

- When one is erased, both must be replaced.

- During repairs, it is also necessary to clean the collector from dust and carbon deposits.

- When replacing a part, it is better to grind it to the collector using fine-grained sandpaper

- It is better to install components that match the tool model

Replacing hammer drill brushes is a simple process that can be easily done at home.

A rotary hammer, like any electric tool, requires careful treatment, proper operation and timely preventive maintenance. If these standards are neglected, the device may fail without exhausting its service life. In case of some malfunctions, you can repair a hammer drill yourself, but to eliminate breakdowns associated with the electrical part of the engine, you will need the help of a specialist.

General principles of the assembly process of Interskol rotary hammers

The assembly of Interskol rotary hammers can be divided into several stages:

- Installation of rubber sealing rings.

- Assembly of individual units.

- Assembling blocks.

- Assembling the electrical part.

- Checking the functionality of the power tool.

All Interskol rotary hammers consist of several large blocks:

- Mechanical block of the shock unit.

- Intermediate shaft block.

- Gear block.

- Stator block.

- Control circuit block.

Selection of lubricants

Domestic manufacturers have developed special lubricants for lubricating hammer drills. The lubricant is divided according to the operating conditions of the units. To lubricate gearboxes, rolling bearings and clutches, it is recommended to use lubricants specially designed for these components.

Conventionally, lubricants are divided into three categories:

- For particularly loaded components, such as the impact mechanism, gearbox, intermediate shaft.

- For lubrication of drill shanks.

- For lubricating rubber O-rings.

It is advisable to use Tsiatim-221 as a lubricant for rubber sealing rings, which does not destroy rubber.

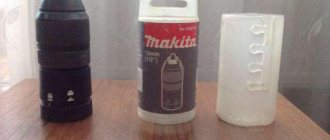

Special lubricants are used for gearboxes of Interskol rotary hammers.

Domestic lubricant for rotary hammer gearboxes

Before installing rubber sealing rings on parts, they must be lubricated with a lubricant inert for rubber that can withstand temperatures up to +120 ºС.

It is recommended to use not only a lubricant that is inert for rubber, but also one that provides high sealing during operation. Among domestic lubricants, pay attention to Tsiatim-221.

Domestic lubricant for rubber sealing rings in rotary hammers

To securely grip the tool and easily remove it at the end of the work, it is recommended to use a special bundle for shanks.

Domestic lubricant for rotary hammer drills

Assembling the shock unit block

For Interskol hammer drills, the impact unit block consists of a barrel and parts of the impact mechanism.

Let's consider the assembly of the impact unit using the example of the barrel of the Interskol 26/800ER hammer drill.

The impact mechanism consists of industrial mass pos. 16, barrel pos. 37, striker pos. 45 and piston pos. 47.

The shock impulse is created due to the reciprocating movement of the piston pos. 47 in the barrel pos. 36. The striker, pos. 45, moves inside the piston and transmits the impulse to the industrial mass, pos. 16. But the industrial mass transmits the shock impulse to the tool receiver position 12. In the above circuit there is another device that smoothes the magnitude of the shock impulse from the striker to the industrial mass. The device is called a striker catcher, pos. 42.

Barrel assembly

The gear pos. 35 is put on the barrel pos. 36, on the other side the cam bushing pos. 38 and the gear-cam bushing connection is fixed with needle rollers pos. 37 and a retaining ring pos. 34.

The gear is pressed by a spring, pos. 33, a washer, pos. 32, is put on the barrel, and everything is secured with a retaining ring, pos. 31.

The barrel is inserted into the body, pos. 18, into which the cuff, pos. 19, is first inserted, the roller bearing, pos. 20, and the bushing, pos. 21, are pressed in.

Barrel, firing pin, catcher before assembly

The barrel assembly ends with the installation of the firing pin and catcher inside after lubricating the internal surfaces. The installation of the catcher in the barrel body is secured with a locking ring.

Piston assembly

Piston assembly pos. 47 begin by installing a pin, pos. 48, and two rings, pos. 49, on it. The finger acts as a driver from the rolling bearing pos. 60. A firing pin, pos. 45, with a pre-installed sealing ring, pos. 46, is inserted into the piston.

Before inserting the firing pin into the piston, the inner surface of the piston must be checked for roughness. There should be no traces of scratches on the surface.

After lubricating the inner surface of the piston with a thin layer of Tsiatim-221, insert the firing pin inside.

The hammer drill does not hit well - what is the reason?

If the power tool does not work completely, then the most likely failure of the electrical components - cable, button, brushes, electric motor. If the drilling mode is functioning, but the hammer drill begins to chisel poorly (or has stopped completely), the following breakdowns are most likely:

- damage to the floating (“drunk”) bearing – usually its cage cannot withstand it and is destroyed – or to the crank mechanism in “barrel” models;

- wear of the rubber rings of the piston or striker that need periodic replacement;

- failure of the impact mechanism. Most often, incorrect use of the tool leads to the splitting of the steel striker, as a result of which the blow becomes weaker and finally disappears;

- wear of the splines located on the clutch clutch intermediate shaft;

- destruction of the elements included in the piston group - liner and/or piston.

Interskol rotary hammers, according to statistics, are reliable tools. Failures are recorded much less frequently than with the more popular Makita, Bosch, and Hitachi models.

The main rule: choose a model that is designed for loads and designed to perform the planned work.

Tool Receiver Assembly

In the design of the Interskol P-26/800ER rotary hammer, the working tool is inserted into a special tool receiver and clamped in a chuck.

Details of the quick-release chuck and tool receiver of the Interskol P-26/800ER hammer drill

The tool receiver, item 12, is easy to assemble.

The assembled industrial mass assembly, pos. 16, is inserted into the internal part of the receiver. On the industrial mass you must first put on the bushing pos. 15, cuff pos. 14, rubber ring pos. 13. Before assembly, be sure to lubricate the rubber o-ring and the inside of the barrel receiver with Tsiatim-221 lubricant.

The assembled tool receiver is inserted into the barrel, pos. 36.

Intermediate shaft assembly

In Interskol P-26/800ER rotary hammers, the intermediate shaft is a complex assembly.

Assembling the intermediate shaft is not difficult.

First, the components of the rolling bearing opz.60 are assembled. A needle bearing, pos. 61, and a combined gear wheel, pos. 62, are inserted into the bearing.

Details of the shaft of the Interskol P-26/800ER rotary hammer before assembly

The assembled unit is inserted into the housing, pos. 53, while simultaneously installing the piston, pos. 47. Before installation, the rolling bearing driver is inserted into the pin pos. 48.

The installed intermediate shaft is fixed with a bracket pos. 50.

Installing the Retaining Bracket

Assembling the impact mechanism assembly

At the next stage, the gear shaft pos. 58 is installed in the intermediate shaft with the switch arm pos. 55 put on it.

The assembled unit is lubricated with gear lubricant.

All that remains is to put the barrel, pos. 36, on the piston.

Lubricate the gearbox gears with the recommended lubricant and cover the outer gearbox cover, pos. 18.

Design features of the SDS-plus type keyless chuck

Let's start with the differences in the design of the quick-release chuck mounting assembly.

The principle of disassembling keyless chucks is almost the same for all rotary hammers.

Interskol hammer drills use a quick-release chuck of the SDS-plus type. To work with an Interskol hammer drill, you must use a tool with an SDS-plus shank.

Disassembling the keyless chuck

Let's look at disassembling the keyless chuck using the example of the Interskol P-26/800ER hammer drill.

Having installed the hammer drill on the back of the handle, you need to remove the protective sleeve pos. 1, remove the washer pos. 2 and remove the locking ring pos. 3.

Next, remove the washer pos. 4 and the retaining ring pos. 5. At the next stage, the pressure sleeve pos. 6 is removed.

To release the fixing ball pos. 8, you must press the special washer pos. 9. Take out the ball, take out the conical spring pos. 10.

The design of the quick-release chuck for the Interskol P-30/900ER hammer drill contains fewer parts. But the disassembly procedure remains the same.

The quick-release chucks for the Interskol P-600ER and P-710ER rotary hammers are almost identical and are disassembled in an identical sequence.

Keyless chuck for rotary hammer Intersol P-30/900ER

The parts of the quick-release chuck for Interskol P600ER and P710ER rotary hammers are dismantled in the following sequence:

- the special ring pos. 1 is removed;

- release sleeve position 2 is released;

- press the special ring pos. 3 and take out the ball pos. 4;

- the spiral spring pos. 5 is removed.

For all Interskol rotary hammers, to remove the gear housing, you must first remove the mode switch.

Dismantling the mode switching handle in the Interskol P-26 hammer drill

Having tilted the hammer drill to one side, turn the mode knob pos. 28 counterclockwise until it stops while pressing the button pos. 26. Remove the handle from the hammer drill body.

Never switch the mode knob while the hammer drill is running.

Installing the mode switch knob

Place the Interskol hammer drill on its side to free access to the hole for installing the mode switch handle.

The handle is easy to install. You just need to get the antennae into the grooves of the switch. The handle is inserted in the opposite position to “impact+drilling”, rotated at an angle of 15º and secured with a latch by pressing the white button.

The installed button is rotated clockwise to check that it operates correctly.

Stator assembly assembly

The stator assembly of the Interskol P-26/800ER hammer drill is no different from the stator assembly of any other hammer drill.

The stator pos. 74 is inserted into the stator housing, secured with screws pos. 73 and closed with a diaphragm pos. 72.

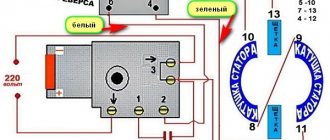

Electrical assembly diagram

The rotor pos. 69 is inserted into mesh with the helical gear of the intermediate shaft.

Assembling the housing of the Interskol P-26/800ER hammer drill

The assembly of the Interskol P-26/800ER hammer drill is completed by installing the stator housing cover pos. 77.

Assembly of rotary hammer housings Interskol P-26/800ER

Installing the brush holder and carbon brushes

Having secured the housing cover, proceed to installing the brush holder pos. 81. Installing the brush holder does not cause any difficulties.

Install carbon brushes, pos. 83, into the brush holder, secure them with spiral pressure springs, pos. 84.

All that remains is to insert the switch button pos. 87, connect the wires to the stator terminals, and hide the wires in the handle of the hammer drill.

Checking the functionality of the Interskol P-26/800ER hammer drill

After assembling the Interskol hammer drill, make sure that the rotor shaft rotates easily by twisting it behind the tool receiver.

Inspect the correctness and uniformity of the carbon brushes. Connect the instrument to a 220 V network.

Turn on the hammer for a short time and inspect the sparking of the carbon brushes.

Install the protective cover pos. 85.

The assembly of other models of Interskol rotary hammers is practically no different and is shown in the video below.

WRCBUX.RU

Tools for the garden and home

Assembling the Hammer Interskol P 710er

- General principles of the Interskol drilling rig assembly process

- Lubricant selection

- Assembling the impact block

- Tool Receiver Assembly

- Intermediate node

- Impact assembly

- SDS keyless installation

- Setting the Mode Knob

- Stator assembly

- Interskol P-26/800ER hammer drill assembly

- Video assembly stamps Interskol

- INTERSKOL P-18 / 450ER rotary hammer assembly

- INTERSKOL P-22 / 600ER rotary hammer assembly

- INTERSKOL P-26 / 800ER hammer drill assembly

- INTERSKOL P-600ER rotary hammer assembly

- INTERSKOL P-710ER hammer assembly

Hammers are quite easy to maintain. To maintain the working condition of the Interskol punch, it is necessary to promptly change the gearbox lubricant every time you replace worn motor carbon brushes.

Old grease must be removed without fail, preferably using special detergents used in service centers. But the homeowner copes well with kerosene and gasoline. Self-installation of Interskol drill bit. it's a simple process. You just need to read the disassembly instructions, diagram, spare parts catalog. Before assembly, prepare new or repaired and cleaned parts, a new seal repair kit, lubricants, tools and accessories. Do not forget about proper preparation of the workplace and its lighting.

The new lubricant fills the cleaned parts and only those that are recommended for this block.

Apply new lubricant, do not overdo it: excess grease during hammer operation is often squeezed out through the gear housing and leads to destruction of the seals.

Before assembling the parts, check the internal surfaces for roughness. The surface must be polished to a mirror finish. At low roughness, abrasion of rubber seals occurs more intensely. Read more about repairing an inter-skor drill.

General principles of the Interskol drilling rig assembly process

The assembly of interspeed drills can be divided into several stages:

- Installation of rubber seals.

- Assembly of individual units.

- Mounting blocks.

- Assembling the electrical part.

- Checking the functionality of the power tool.

All Interskol seeders consist of several large blocks:

- Mechanical shock assembly unit.

- Intermediate shaft block.

- Transmission.

- Stator block.

- Block control unit.

To lubricate rotary hammers, domestic manufacturers have developed special lubricants. The lubricant is divided in accordance with the operating conditions of the units. To lubricate the gearbox, rolling bearings and clutch, it is recommended to use lubricants specifically designed for these units.

Typically, oils are divided into three categories:

- For particularly loaded units, such as impact mechanisms, gearboxes, gear shafts.

- For lubricating the drill shank.

- For lubricating rubber seals.

It is recommended to use Qiatim-221, which does not attack rubber, as a lubricant for rubber seals.Special gear oils are used for gearboxes in Interskol wells.

Homemade lubricant for hammer drills

Before installing rubber seals on a workpiece, they should always be lubricated with an inert lubricant that can withstand temperatures up to 120°C.

It is recommended not only to use fatty inert rubber, but also to ensure high tightness during operation. For domestic lubricants, look for Tsiatim-221.

Household lubricant for sealing rubber rings in hammer drills

To securely grip the tool and easily pull it out at the end of work, it is recommended to use a special shaft shank.

Household drill lubricant

For Interskol rotary hammers, the impact block consists of a cylinder and parts of the impact mechanism.

Let's look at the assembly of the striking element using the Interskol 26/800ER barrel as an example.

The impact mechanism consists of an industrial mass of pos. 16, barrel pos. 37, attacker pos. 45 and piston pos. 47.

The shock impulse is created by the reciprocating motion of the piston postures. 47 in barrel pos. 36. Intruder village. 45 moves inside the piston and gives impulse to the industrial mass pos. 16. But the industrial mass already transmits the shock impulse to the instrument device pos. 12. In this circuit there is another device that smoothes the magnitude of the shock pulse from the striker to the industrial mass. The device is called an intruder, pos. 42.

Design features of the Bosch 2-24 rotary hammer

It is best to start repairing a Bosch 2-24 rotary hammer by becoming familiar with the circuit and design features of the tool being adjusted. The operating principle of the Bosch 2-24 rotary hammer is similar to the operating principle of the Bosch 2-20 rotary hammer.

The torque is transmitted to the tool mounting shaft, simultaneously with the transmission of the shock impulse. The hammer drill has three operating modes: drilling with impact, drilling without impact, impact.

The helical gear of the rotor pos. 803 transmits torque to the helical gear of the intermediate shaft pos. 826.

Design of the intermediate shaft of the Bosch 2-24 rotary hammer

The intermediate shaft of a Bosch 2-24 rotary hammer consists of a rolling bearing assembly, pos. 830, a clutch, pos. 823, and a switching part, pos. 44. Most often, the clutch fails. The teeth in it wear out. Repair of the coupling consists of correcting the profile of the engagement tooth in the coupling and on the intermediate shaft.

Impact mechanism barrel shaft design

The barrel shaft of the impact block is designed to transmit a rotational impulse with simultaneous movement of the striker.

Rotation is transmitted from the spur gear of the intermediate shaft to the large spur gear pos. 22 of the barrel shaft pos. 821.

The reciprocating motion is transmitted through the driven bearing pos. 830, the impact piston pos. 26, the striker pos. 27, the impact bolt pos. 28 to the drill fixed in the chuck pos. 756.

The design is a shaft, hollow on one side. Parts are installed on the shaft on both sides.

From the side of the cartridge mounting, a spur gear, pos. 22, is installed on the shaft and fixed on the shaft using a roller, pos. 88, and pressed against the shaft collar with a spring, pos. 80. The spring itself is fixed with a locking ring pos. 85.

The following is inserted into the cavity of the impact block barrel shaft: the assembled impact bolt pos. 28 and the impact piston. The striker pos. 27 is inserted into the impact piston pos. 26 with a new rubber ring pos. 73 placed on it. All rubber products are lubricated with the recommended lubricant.

Malfunctions of the hammer shaft shaft

Due to the weakening of the spring force and the locking roller falling out, the gear may rotate on the shaft. This manifests itself in the disappearance of the torque with the presence of a shock pulse.

The rotary hammer hammers, but does not drill.

When rubber products (sealing rings) wear out, the hammer drill stops working in the “Slotting” mode. This happens gradually. The impact force weakens as the rubber rings wear. The thing is that from the drunk bearing the movement is transferred to the impact piston pos. 26, in which the striker pos. 27 creates air pressure and acts on the impact bolt pos. 28.

The hammer drills, but does not chisel.

If you apply a lot of force when operating a hammer drill, this can lead to the destruction of the impact bolt and jamming of the striker in the impact piston. Such malfunctions can only be eliminated by completely replacing the failed part. Learn more about troubleshooting a Bosch rotary hammer.

Video: Assembling the Interskol P 710er Hammer

You may also like

At pos.36, place the barrel on the gear pos.35, on the other hand, the cam bushing pos.38 and the camshaft bushing connection, attach the needle rollers pos.37 and the retaining ring pos.34.

The gear is pressed by the spring pos. 33, washer pos. 32 rests on the barrel, and everything is secured with a locking ring pos. 31.

The trunk is inserted into the body pos. 18, in which the cuff pos. 19 pre-inserted roller bearing pos. 20 and sleeve pos. 21 is pressed.

Barrel, attacker, hunter before assembly

The barrel assembly is completed by installing the firing pin inside and gripping it after lubricating the internal surfaces. The hunter's installation in the barrel is secured with a locking ring.

Piston Assembly Poses 47 Start by installing pos. 48 and two rings pos. 49. The finger acts as a lever to support the rolling stock. 60. Hairpin village. 45 with pre-installed sealing ring pos. 46 is inserted into the piston.

Before inserting the hammer into the piston, the inside surface of the piston should be checked for roughness. There should be no scratches on the surface.

After lubricating the inner surface of the piston with a thin layer of Cyatim-221, insert the hammer inside.

Rotary hammer repair Interskol

A hammer drill is one of the most important tools in the arsenal of a person doing repairs. That is why it is popular for carrying out construction work of increased complexity. To use a hammer drill competently, you need to know its structure and have basic skills in its repair and preventive maintenance. Construction equipment stores have a wide range of products. The company occupies one of the leading positions in sales volumes of rotary hammers. One of the models is the P 710ER, the maintenance of which will be described below.

Interskol hammer drill design

The tool can operate in three modes: drilling, impact and drilling with impact.

The SDS plus chuck helps you quickly change attachments for work. The safety clutch can prevent tool breakage if the drill gets stuck in the material. The hammer drill has one speed and rotation speed adjustment. Additional features of the tool include an additional handle, a depth limiter and a power button lock.

All rotary hammers of the company are assembled according to the same scheme. There are three main blocks: impact reducer block, power supply, stator block.

These mechanisms have their own characteristics for different groups of instruments.

Disassembling the hammer drill

Let's start with the keyless chuck. The disassembly process consists of the following points:

- Removing a special ring

- Eating another special ring and ball

- Removing the Coil Spring

Removing the release sleeve

In order to remove the gear housing, you first need to remove the mode shift knob.

Then the barrel, firing pins and firing pins are disassembled. The intermediate shaft is disassembled in the order of the following parts. The electrical part consists of three blocks - a rotor, a stator and a control circuit with carbon brushes. All blocks are disassembled in detail. After this, the hammer drill can be considered completely disassembled.

Mechanical problems

Mechanical damage is a little more difficult: a hammer drill consists of many parts, so it may not even be possible to immediately determine the cause of the breakdown. The main thing is to closely visually examine what remains to be done by our client on the parts, and after identifying a breakdown, carefully remove it. Here are the main possible damages that can be repaired at home.

The device turns on, but does not hammer.

- Switch. Most devices are equipped with operating mode switches. myth mechanism and prone to breakdowns. If the hammer drill has stopped hammering, the most likely reason is that the switch fingers are worn out. During operation, they are constantly in contact with rotating parts, which leads to wear.

- The extension of the latch holding it in the gearbox housing has broken, which facilitates spontaneous switching of modes. Of course, do not change the latch, if this problem does not bother you, the hammer drill works in any case.

Change the switch. If there is no suitable switch, and work cannot be paused, then, of course, turning the worn part 180 degrees, you can continue working.

- Cartridge. This part of the mechanism is subject to greater load, which leads to its breakdown. If this happens to the cartridge, it should be replaced. The only thing that extends its service life is preventive maintenance: washing it off dust with gasoline, cleaning it from dirt, etc.

- Compressor ring and striker. Their breakdown sometimes occurs due to enormous loads. When pressed hard, the stroke of the striker is reduced, which leads to malfunction. If it breaks, there is only one way out - replace it.

- Gearbox. If the gearbox malfunctions, it is necessary to carefully disassemble it and check it one by one, leaving the parts to our client. The most vulnerable point of the gearbox is of course the bearing. First we check its integrity. If necessary, we change it. On the contrary, it is intact, the reason may be in the landing site. It can wear out and hold the bearing poorly. Then you will have to change the hammer housing itself. Of course, the gearbox gears will become unusable. It’s easy to identify them visually, but they can’t be repaired—you’ll have to replace them.

- Oil leak. If there is a leak (it must be emphasized that this happens infrequently), the oil seal should be replaced. It is located in the neck of the body.

- Operation may also be affected by dirt. This is indicated by a crackling sound or a grinding sound. To avoid similar problems, frequently clean and lubricate the inside of the hammer drill. It is important to use only type 1 lubricant, the same one that was used previously.

Do-it-yourself hammer drill repair

The tool can only be repaired after the allotted warranty period has expired.

Mechanical damage is much more difficult to fix than problems with the electronic unit. Establishing the cause of a breakdown takes time - you need to inspect all the mechanisms. After this, you can fix the problem. If the device turns on, but does not perform the chiselling function, then the breakdown may lie in the operating mode switch. Worn switch fingers may indicate a problem. Wear occurs due to constant contact with rotating mechanisms.

There is also such a thing as a breakage of the extension of the latch that holds it inside the gearbox. The mode can be switched arbitrarily. However, this does not affect the performance of the tool.

If this malfunction does not cause much trouble for the owner, then you just need to turn the switch exactly 180 degrees.

The hammer drill's keyless chuck experiences the heaviest loads; if it breaks, you need to purchase a new one and replace it. To extend the life of this mechanism, you just need to regularly clean it from dust and dirt that accumulates during operation.

Repair of rotary hammer P 710ER

The general rules also apply to the P 710ER model. It is necessary to disassemble the tool according to the established instructions, then identify the problem in operation,, if possible, eliminate it in full and reassemble it according to the same scheme.

The main malfunctions of a rotary hammer and their external signs

All unit malfunctions can be divided into 2 groups: mechanical and electrical.

Mechanical breakdowns

If any mechanical malfunction appears in the hammer drill, its presence can be determined by ear (noise increases, a grinding sound appears).

You may also experience increased vibration or an unpleasant odor emanating from the unit body.

So, mechanical failures include the following:

- failure of the device operating mode switch;

- worn rubber bands of the striker and striker;

- failure of the impact mechanism;

- failure of the unit barrel due to wear;

- breakage of gear teeth;

- the chuck breaks, causing the drill to fly out.

Electrical faults

Malfunctions associated with the electrical part of the hammer drill may also be accompanied by an unpleasant odor from the device body and sparking. You may also notice that the engine gets hot and hums quickly without turning over, or that it emits smoke.

Electrical failures of the device include the following:

- the device does not turn on;

- breakage of the start button;

- brush wear;

- collector clogged;

- violation of electrical contacts;

- burnout of the stator or rotor winding of an electric motor.