A jack is a special device that is used to lift heavy loads and fix them at the desired height. The use of this mechanism is indispensable when repairing a car during the process of changing a wheel.

A hydraulic jack is considered the most convenient and effective when performing various types of work. The working force is achieved thanks to a piston, which is driven under pressure generated by hydraulic oil. However, during operation, the equipment may fail. You can assemble the device and repair a hydraulic jack yourself at home.

How does a hydraulic jack work?

A hydraulic jack is an easily transportable device that has maximum lifting capacity compared to other similar mechanisms. It is also distinguished among its peers by its durability.

Appearance

Operating principle

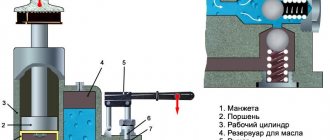

Externally, several details are visible:

- Cylinder - it contains a piston and two sections with working fluid.

- A pump that pumps liquid. It is connected to the cylinder by valves.

- Lever arm.

- Reference point.

The mechanism is very simple, as is the design, due to the small number of parts. It is worth considering the function of additional elements:

- The base is what the pump is mounted on. The base must have a large area to compensate for the mechanical pressure when lifting the load.

- Reserve tank - connected to the cylinder, it houses a lever system and a pump.

- The piston rises due to the flow of oil.

- Plunger - limits the height of the piston lift.

Jack parts

The jack is located below the object being lifted and does not require ropes, ropes, fasteners and other auxiliary parts. But it won’t be possible to hold an object suspended for a long time - the device serves solely for lifting.

How do the models differ?

The main distinguishing feature of jacks is their load capacity, pick-up and lifting height. With a focus on them, device models change. For example, the lifting height depends on the distance between the base and the support point. There are also some peculiarities in the lifting principle.

Another quality is wear resistance. Car enthusiasts for home use once a year and repair services need different mechanisms.

Trolley type

The entire mechanism is located on a frame, which is attached to the wheels. The compact and mobile trolley type can be used even in hard-to-reach places. The system of levers and pistons is located horizontally, making it easy to place the device under any load (for example, a car) and lift it at any angle. Additional details in the rolling model:

- 2 wheels,

- suction and discharge pump,

- lifting platform,

- frame instead of base,

- lever - you must press it to start the pump, which will transfer hydraulic oil through the valves into the cylinder.

Trolley type

Bottle type

A simple version with a vertical cylinder. A distinctive feature is its small size with a high load capacity - from 2 to 50 tons. The pick-up height in bottle jacks usually starts from 15 cm and ends at 30 cm. The height is adjusted using a screw located in the upper base of the rod. The bottle type is designed in such a way as to prevent slipping during operation. For this purpose, the supporting part is made corrugated.

Each jack comes with a handle, which makes it easier to use the mechanism. Those units that can withstand loads of 30 tons or more have an additional second handle. By doubling the length, the weight that the bottle jack can lift increases.

Bottle type

There are other types:

- Pneumatic - a cushion is installed, connected to a source of compressed air, for example, a stationary compressor. Used when the gap between the object and the surface is small. It is also possible to use it when the support is unstable - for example, in swampy areas, sand, snow. This jack can withstand loads of up to 6 tons.

- Screw - compact, standard jack for cars. Load capacity - up to 15 tons.

- Rack and pinion – has maximum lifting height. A fastening mechanism moves along the rail, which snaps into place and rises like a ladder along with the load. Can withstand 20 tons.

A jack handle is a mechanical lever that is used to pump fluid. Electric drive means that the mechanism has an automatic built-in pump. Repairing the electric version requires special equipment, while the bottle and rolling mechanical types can be repaired yourself.

Advantages and disadvantages of this type of jacks

Like any technical device, a rolling jack has both its advantages and disadvantages. Let's start with the first ones. So, their advantages include:

- High coefficient of efficiency (efficiency). With its help, you can lift a car of considerable weight with minimal physical effort.

- High load capacity. This was made possible by the use of a horizontal cylinder and a removable handle.

- Slow lifting ensures neat operation and safety. And the shut-off valve ensures that the load is secured at any selected height.

- The presence of a support platform provides good stability and safety.

- Convenience and ease of use of the jack.

- Be careful and clean when working with the jack. The operator does not need to lie down on the ground or garage floor in order to place the jack under the car.

What types of breakdowns happen and what causes them?

Hydraulic jacks are the most durable. Their malfunction may be caused by improper operation or wear of individual parts. A common problem is lifting weights that exceed the unit's capabilities. Then you can observe the following “symptoms”:

| What is observed | Where is the breakdown? | Why did it break? | What to do |

| Stop | In a cylinder | Not enough oil, filters may become clogged | Disassemble the device. Fill the oil compartments, clean the filters |

| Piston does not rise | In a cylinder | Lack of pressure due to lack of sufficient working fluid | Add liquid |

| The rise is very slow or, conversely, jerky | In a cylinder, system with working fluid | Air has entered the jack, which negatively affects the operation of the piston. | It is necessary to add liquid and remove air through the tubes |

| Low pressure | Valves | The springs have weakened |

Read also: Uoni 13 55 decoding what 55 is

Valves are separated from the compartments

Valves are dirty

If possible - repair or cleaning

In other cases, it is necessary to disassemble the mechanism and put it back together so that the following conditions are met:

- The valves fit tightly.

- Sufficient amount of working fluid in the departments.

- There is no air in the system.

Air injection mechanism

If we are talking about using the device in a garage, or using it in a tire shop, then there is only one option. This is a compressor that runs on 220 volts. By the way, there are models of pneumatic jacks that can also use a compressor that pumps no more than 2 atmospheres and operates from the on-board vehicle network of 12 volts, but this option is good in nature when there are no other options for hanging the car.

A garage needs a reliable and efficient compressor, although almost all modern models provide a pressure of 6 atmospheres, which is quite sufficient for the operation of an air spring from a truck.

DIY repair

A hydraulic jack rarely breaks down seriously, most often the problem is contamination, valves or lack of fluid. All of these are easy to repair, as well as fixing the more rare problem of leaking.

Valve failure

Attention is paid to how the valves fit into the seats. If the contact is loose, check the springs, which may have weakened. The valves could be clogged, so you need to remove the dirt with a damp piece of cloth, then dry thoroughly. If the contamination is severe, for example due to oil, then rinse with gasoline or kerosene. Then dry with compressed air.

Jack diagram

If the valves are deformed, they must be replaced with new ones.

Liquid leak

Occurs with mechanical damage and breakage of parts. It is necessary to completely disassemble the jack, simultaneously checking metal parts, for example, the piston, for corrosion. Elements, in particular the rod, are checked for deformation. Damaged parts are replaced with new ones.

It is recommended to drain all the oil and wash the jack and parts with kerosene. Old cuffs and sealing gaskets are replaced with new ones.

How to remove air or dirt

Air accumulation is inevitable during continuous operation. In the same way, dirt gets inside the working cavity.

The air is eliminated when changing the oil. Dirt is removed with a sediment removal solution.

Disassembled jack

How to fill oil correctly

It is the lack of oil in the jack that leads to its poor performance. Fortunately, such a breakdown is easy to fix - you just need to add liquid. However, you should know what exactly to add.

High-quality fluid will ensure long-term operation of the mechanism:

- Industrial types of industrial oil. But not types I30A, I40A, I50A - they are too viscous.

- Brake fluid is excessively hygroscopic, that is, it absorbs water vapor. And water will eventually lead to corrosion and failure.

- Branded hydraulic fluids are manufactured specifically for brake and lifting systems.

- The water jack won't last long, but it will work.

After the fluid has been selected, it is necessary to carry out preparatory work to replace it.

First, the old fluid is drained. To do this, unscrew the plug and pump the device. Next, the jack is washed with cleaning fluid, which can be purchased at a hardware store. The solution is poured and drained. Before adding new oil, there should be no foreign liquid in the jack.

How to unscrew the plug

Afterwards, the jack is set to the lowest position, and the screw-cock is turned to the “Drain” position. Oil is poured. The required level is indicated by a mark on the jack.

After the first filling, the plug is closed and the jack is run 5-6 times. The plug is opened again and oil is poured in. It is necessary to repeat several times until the oil stops leaving.

After the final filling of the oil, a test distillation of the liquid is performed again to get rid of air. To do this, the jack is pumped - raised and lowered - until pressure appears. Excess air is released through special tubes; oil must be added in its place as it exits.

Device and principle of operation

The choice of a particular device directly depends on the conditions in which it will be used. This can be not only a large car service center, but also a small private garage. Many car enthusiasts have already appreciated the benefits of a convenient design. Such models can be installed anywhere, that is, even in areas adjacent to the service station. They are capable of lifting a fairly large mass to a decent height. Some models have additional attachments that significantly expand their functionality.

Thus, it was previously established that one of the main components of a hydraulic jack is the cylinder. The required force is obtained due to the pressure difference in the main cylinder and the actuator cylinder. It is worth paying attention to a certain design feature of such devices. The fact is that the hydraulic cylinder is not vertical, but horizontal. Of course, this does not in any way affect the principle of operation of the mechanism. There are several other design features of such devices.

Their rod does not rest directly on the car body. It rests on a lever that rests on the surface of the car. Why use such a complex mechanism when you can control the position of the cylinder with a simple vertical jack?

The answer to this question is actually quite simple. This device is easier to roll under the car than its vertical counterpart. This is due to the same design features of models of this type. If you have a car with a low chassis, you need to use this device to raise it to a certain height.

It is worthwhile to dwell in detail on the topic of a walking hydraulic lift. Thus, it is a four-wheeled stroller that can easily pass under almost any car. These wheels are rigidly fixed to the frame. The hydraulic drive is located on the frame. In a horizontal position, the piston rod is supported by a special vertical mechanism, which is attached to a lifting platform. Vehicle lifting is provided.

The mechanism for converting horizontal movement into vertical movement can be different. Most often this is a rotary gear. But this is not the only way of transformation. Much more complex mechanisms can be used here.

The entire operation of the mechanism is based on the movement of a special handle. The hydraulic jack itself slides under the car. Then the working mechanism starts. The drive creates a certain pressure in the cylinder, with which the car rises. The main work is done by the actuator and direct valve. If the pressure in the system needs to be reduced slightly, the knob can be turned. As a result, the check valve opens, releasing air from the system.

A jacked vehicle or other device is lowered. There are also alternative models of mechanisms. They have an air release check valve right next to the handle. To relieve excess pressure, just install the handle on it, having first removed it from its place. This is how a hydraulic car jack works. Its design is simple and original. It is for this reason that such mechanisms are chosen.

Jack characteristics table.

Recommendations for use

After finishing use, the jack must be freed from loads. The device should be stored in a warm and dry place. Due to excess moisture, the mechanism may rust, and cold will negatively affect the quality of the oil. It is recommended not to work with a jack in severe frost.

Loads on the device should not exceed those for which it is designed.

With constant use, pumping (oil change) should be carried out every 2-3 months. For rare use - once every six months.

Thus, in the event of a hydraulic jack failure, it is necessary to check 3 components:

- Quality and quantity of liquid.

- Presence of air bubbles in the system.

- Contamination, loose valve fit.

In most situations, to solve all problems with the device, it is enough to clean it and change the oil.

Good day everyone!

During the previous replacement of the pads, my favorite, dearly cherished jack broke, which had been chosen for a long time to replace the diamond in the previous car and reinforced after the gears were shifted in the upper part. The old one was also strengthened in the lower part.

It is reinforced with the same half-inch barrels, at the ends of which a centimeter groove was cut for easier installation inside the jack foot. The studs were removed and their place was taken by powerful Soviet bolts with washers and grommets (not to be confused with Chinese crap from hardware stores)). Now there is nothing to break in the jack, the metal is thick and durable, it will help you out on the road.

Since diamond jacks are still tools for emergency use only, a 3-ton rolling jack was purchased.

Read also: How to make a potato digger with your own hands video

I decided to take a chance and took a rolling jack “Service Key” for restoration, catalog number 75040, load capacity 3t, lifting height 150-530mm

, although at the same time there was an opportunity to purchase a new 2-ton “Avtovirazh” AV-076002 for 1300 in Chumadan.

But 3 tons is still 3 tons! In addition, a large and massive jack is more suitable for working with Qashqai. The jack was received in a non-working condition, according to the former owner, “it doesn’t rise all the way and who the hell knows what’s wrong with it...”. So what did I do? The first thing I did was disassemble it completely and wash it.

There was no oil in the jack. Filled it up. Choked from the plunger. The rod began to twitch and... nothing. The first experience was unsuccessful.

I monitored the Internet. I read and looked at everything about jacks, rolling jacks and others))). On the drive I found information about a similar jack from SarEcks

.

I contacted him, then three more owners of 2 tons and samodelkin689

,

Godmask82

and

COSWORTH23

. Thank them very much for their response and participation. But the design of those jacks was similar, but the plunger pump was still different from mine. It was decided to buy new seals. Shopping trips for passenger cars yielded nothing. The store bought rubber rings for Belaz-Kamaz trucks with a reserve.

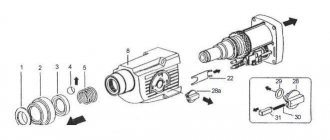

Balls from bearings of various diameters were found, and a BiC automatic ballpoint pen was disassembled in order to obtain a spring. Next, I will write strictly to the point, for those who are faced with repairing a jack. I've seen enough lyrics on the Internet and haven't found any specifics that apply to my jack. There are 4 balls in the jack

.

These are valves. Moreover, one of them is located in the plunger channel leading to the main (working) cylinder (check valve). IT DOESN'T COME OUT

! The second ball with a diameter of 3 (or 4) mm is located in the bypass valve. The third ball with a diameter of 6.5 mm is in the bypass valve. The fourth, with a diameter of 6 mm, is located at the base of the main cylinder, in a recess and must be pressed with a spring (like from a ballpoint pen) 8 mm long. The other end of the spring rests against a large washer, which simultaneously serves as a seal for the main (working) cylinder. Often no one knows about this necessary spring, but if it is missing, the jack may not work!

When inserting the piston, the twisted working cylinder should not leak at the point of contact with this washer. In my jack, half of the shut-off valves were missing and the plunger pump was leaking. 2 new rings were installed on the plunger: one in its regular place, the second, I moved the plastic ring into the formed groove. Those. The result was three seals for the plunger rod: the piston itself and two rings. A paronite washer is installed under the screw-in pump housing for sealing instead of the old steel one.

Now the pump does not flow. In the large piston, the O-ring is replaced with a ring of the same diameter, but thicker.

That's all the work done. The jack works great.

The car can easily be lifted half a meter on 2 wheels.

I hope this description helps someone. If you have any questions, I will be happy to answer. Peace and goodness to everyone.

When lifting heavy objects to a small height, a special technical device of a hydraulic, pneumatic or mechanical type is used. The operation will be performed by a small but strong device known as a jack. It is possible to repair a rolling hydraulic jack yourself.

Main design parameters

Every person who decides to purchase a rolling hydraulic jack should definitely think about what design parameters are important to him. This refers to its structure and technical characteristics.

The main characteristic of the device is its load capacity. It most often starts from 2 tons, but you can find models that can work from 750 kg. They are specially designed for small-sized equipment, namely motorcycles and ATVs. Models with a carrying capacity of 3, 5 and 10 tons are considered standards for ordinary cars.

For owners of an ordinary passenger car, a carrying capacity of 2 tons will be sufficient. It can be easily placed in the garage, and, if necessary, even taken on the road.

Diagram of a park hydraulic jack.

Fans of SUVs should consider models that have a more substantial carrying capacity. It should start from 3 tons, of course, if this value does not exceed the mass of the device itself.

Not only load capacity is an important characteristic of such devices. Each model has its own lifting range. It usually varies from a minimum value of approximately 100 mm to a maximum value of approximately 500 mm. You definitely need to consider what ground clearance your car has. It is worth taking into account the distance not only from the body to the ground, but also from the heel of the device to the body.

How does a hydraulic jack work?

By design, compact lifting mechanisms are divided into several types, each of which has individual characteristics. The hydraulic parameters of all elements of the model are reliable, have sufficient load capacity and durability.

When choosing a model, it is necessary to take into account the operational features of the device, permissible loads on the mechanisms, scope of application and how to properly fill the unit with oil. For example, the following types of jacks are suitable for a car repair shop:

- rolling;

- bottle;

- manual;

- electric

- hooked

- diamond

Product performance depends on product design, operating conditions, operating load, and ambient temperature. If in a rolling jack the entire load falls on the support frame, then the design of a bottle-type hydraulic jack provides for the presence of a vertical cylinder shaped like a bottle. The device has compact dimensions, reliability and high performance, and is often included in vehicle equipment.

Among all the presented models of lifting mechanisms, the bottle jack is the most popular due to the ability to apply little effort when lifting a heavy load. Restoring the device's functionality can be done at home; to repair other types of devices, the help of a professional workshop is required.

Jack operating diagram

Professional rolling jacks differ in size and load capacity. As a rule, the valve is controlled by turning the handle, which is very convenient during operation. But the principle of operation of all hydraulic jacks is the same, so it is more convenient to use the diagram - after all, despite the size and type of products, they have the same causes of breakdowns.

The force created by the plunger is transmitted through the oil used as the working fluid to the piston connected to the rod. In this case, oil is pumped from the front cavity of the jack cylinder to the rear cavity (from the plunger side). The bypass channel is closed, and the inlet and discharge valves allow the oil to move only towards the rear cavity, that is, the jack works like a pump. When the bypass needle (which is a pointed threaded rod) is opened, oil can flow back into the front cavity through the bypass channel. If at this moment the jack is under load, the piston rod will sink into the cylinder. The performance of the jack is ensured by compliance with three conditions:

- Tight fit of valves to seats.

- Required oil level.

- No air bubbles in the oil.

Scope of application

A do-it-yourself manual lift greatly simplifies repair, maintenance and tuning work related to vehicles and will help in the construction and restoration of capital structures. The presence of a compact jack eliminates the need for the car owner to visit a service center or buy a factory-made device. The lifting forces of the mechanism allow the following manipulations with the load:

- fix;

- move;

- lift up.

When planning the manufacture of a jack, it is necessary to take into account that the device cannot lift loads “from the floor”; in its design it is impossible to adjust the level of lowering; the mechanism must be transported only in a vertical position. The hydraulic system requires constant maintenance.

Read also: How to use a screwdriver with a battery indicator

When working on the device, you should also take into account that the factory jack will work cyclically, and in the event of a breakdown, repair measures will require significant financial costs. A device assembled in your garage, in case of failure, can be replaced with another device of your own assembly, but its degree of reliability is reduced several times.

Principles of hydraulics

For the practical implementation of the portable lift scheme, the hydraulic jack is equipped with a system designed on the principle of communicating vessels. The operating principle of the device consists of the following operations:

- the injection pump supplies liquid from the reserve vessel to the main one;

- the working process creates pressure inside the system;

- pressure moves the piston.

Due to the fact that the design contains a small number of parts, maintenance and repair of the device does not require the use of special tools and production equipment. All elements of the device have a significant service life.

The rolling hydraulic jack contains a reserve tank with a lever system, a working piston cylinder with a plunger, and a support part to compensate for the mechanical pressure that occurs when lifting a load. The jack device ensures that the load is lifted to an allowable height equal to the distance between the base and the top of the piston.

The design of a rolling jack includes three important components, the functionality of which is determined by the force loads on the moving parts of the device. The operating principle of the components is similar to other types of compact lifting equipment, the design of which contains:

- piston;

- frame;

- liquid medium (machine oil);

- levers;

- plungers;

- valves

To pump a bottle-type jack, a mechanical force is applied to the levers, which can be increased due to the valves. The plunger transfers oil to the receiver through the movement of the piston; the return of the liquid medium and the return of the piston to its original position is carried out after opening the valve and transferring the oil to the reserve tank.

Filtered machine oil is used as a bottle-type working fluid, which allows you to work with objects weighing up to 100 kg. The main advantage of the device is the large size of the support platform . The hydraulic lifting device of the bottle model is produced in two modifications:

- single-rod units of simple design (used in the repair of cars, cars, in construction, for bending and cutting pipes);

- two-rod vertical and horizontal mechanisms.

According to the physical and mechanical characteristics, the principle of operation of devices of different models is aimed at ensuring the convenience of repairing cars, trailers, supporting structures, fencing elements and other objects that have a weight that is too heavy for a person to carry.

Modification of the rolling jack

Modifying the jack can be useful if you need to lift a load to a greater height, exceeding the factory specifications of the device. Also, modifications can quickly and easily solve the safety problem of the lifting mechanism. This can be solved by installing a clamp in the jacking platform. Both easy upgrade options are explained and shown below.

Increasing lift height

The low lift height may limit the jack's range of use for vehicles with high suspension. In such situations, tool owners may be interested in knowing how to increase the height of the rolling jack. A simple stop extension can be made from scrap materials. The guide below uses a brake cylinder from a Zhiguli, but you can use a regular thick-walled pipe of a suitable diameter.

First of all, you should prepare the adapter by welding a transverse plate to the top of the pipe in which you need to drill a hole for fixing (with the standard diameter).

Next, unscrew the bolt to which the thrust bowl of the rolling jack is attached. We remove the stop from its place and place an extension on it, with the drilled plate facing down. We place the previously removed bowl on top of the structure. We take a long bolt the diameter of the holes, thread it through the thrust bowl and pipe, and then tighten it with a nut.

Such jacks, with useful modifications in the form of increasing the lifting height, become useful for lifting SUVs and minibuses. At the same time, the added part (cylinder) remains a removable part of the mechanism, because it can be removed if necessary by unscrewing the bolt back.

Installing the retainer

So that when lifting the car you do not have to install an additional support to securely fix the car, a small modification of the rolling jack is required, which requires a minimum of time and materials.

We drill one 14 mm wide hole on both sides of the jack (approximately in the middle, opposite the central part of the rising piston mechanism of the jack).

We take a steel rod Ø 14 mm (we used a hinge rod for a rotary connection) with a pre-cut thread and a nut of the appropriate size for it. We raise the jack and fix the lifting part of the mechanism by inserting the kingpin into the holes made in the middle. Secure with a nut.

After these changes, the kingpin inserted into the jack will prevent the lifted car from lowering in the event of a sudden breakdown (failure) of the jack due to the opening of the exhaust valve. A more visual representation of this modernization is demonstrated in the following video.

Source

When the device is broken

If the lifting mechanism breaks down, the work on repairing the technical equipment stops completely. The cause of device failure may be improper operation, foreign objects or air entering the hydraulic system. When using the lever, the piston movement may not be smooth enough and the oil pressure may decrease.

Depending on which node does not perform functions, a sequence of measures is developed to eliminate the cause. Cleaning the mechanisms from clogging, adding fluid, replacing the valve and pumping the piston system will help restore the performance characteristics of the device. Any cause of failure can be identified after removing the housing cover; if mechanical damage to parts is detected, then it is better to replace the old jack with a new one.

Unit repair

If there is an oil leak, it is recommended to find the damaged area on the housing, seal it and fill in a fresh portion of filtered oil. All measures related to restoring the operating condition of components must be carried out in accordance with the manufacturer's instructions.

If the manual mechanism refuses to lift the load, the cause may be insufficient fluid volume, excess air in the cylinder, rust particles, or rod deformation.

Bleeding the hydraulic jack after adding or replacing engine oil will help eliminate the problems; you will also need to repair the valves by replacing the gaskets.

To do this, you need to unscrew the cylinder cover screws, remove the drain valve and piston, clean the inside of the cylinder from dirt, clean the drain valve, and check the tightness of the ball to the hole under the valve. It is prohibited to use old used oil. It must be drained by bleeding the lever. The mechanisms are washed with kerosene. After this, the gaskets and cuffs are replaced, and fresh working fluid is added.

After assembling and refueling the unit, it is necessary to test the hydraulic system under load to detect leaks and the presence of an air lock in the system. Air can be released through the drain valve. The pumping procedure and maintenance of the unit are simple. The owner of the device can independently cope with the repair of the lifting device, repair the lever, and at home, pour oil into the hydraulic system.

Unlike a lift assembled at home, a factory jack has high power and efficiency of up to 80%, ease of operation, and can withstand working loads of up to 200 tons. A hydraulic device made from improvised means will cost less, but it must be done by a specialist who understands hydraulics.