Types of steel ropes

Cables are twisted or twisted products made from steel, synthetic and organic threads. In the production of steel products, galvanized high-carbon wire with a cross-section of 0.4–3 mm is used, which has a significant margin of strength under tensile loads (from 130 to 200 kgf/mm2).

The metal threads used in the manufacture of products come in several grades. Wire of category B has the best strength characteristics; raw materials of grades I and II are considered to be of lower quality. Before determining what load a cable of 5 mm or other thickness can withstand, you should take into account that, regardless of the quality of the material, ropes differ in design and come in three types:

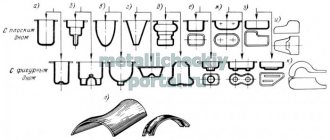

- Single lay - made from one strand with wire of the same section. Their elements are twisted around one of the metal threads in up to 4 layers. Steel cables are marked as a sum of numbers indicating the number of wires in the weave. For example, 1+9+9 means that there are 19 wires in the rope, one of which is located in the central part, 9 twists in the first layer and 9 in the second.

- Double lay - made of several strands, applied in 1-2 layers around the core. For the core, twisted wire, organic or mineral materials are used, which improve the strength of the steel cable and prevent strands from falling inside the product. Most often, such products are used for cable work.

- Triple lay - made of several cables. As with double lay, they have a core, but are made from wire of a smaller cross-section and are used where increased flexibility of the ropes is required (usually for cable work).

Wire located in different layers can have a point, linear or point-linear contact. When establishing what load a cable with a diameter of 6 mm or another thickness can withstand, you need to take into account that ropes with point contact (TC) are relevant only for minor pulsating loads. Products with linear touch (LT) have a wide range of applications, while products with point-line touch (PLT) are used in places where LT cannot provide the recommended safety margin.

In the manufacture of products, cross lay is usually used. The wire in its outer layer has a different direction, which guarantees a stronger weave and ease of operation. At the request of customers, manufacturing plants can produce other types of lay, such as single-sided and combined.

In addition to being classified by design, ropes are classified according to the degree of twist and can be flexible or rigid. The latter are characterized by higher tensile strength, since they are produced from a small number of metal threads of large diameter. To compare the flexibility of certain modifications, you can use the table.

| View | Design | Flexibility factor |

| Single strand | 1x19 | 5 |

| 1x37 | 7 | |

| LK-O | 6x19+1 | 12 |

| TK | 6x19+1 | 15 |

| TLK-O | 6x37+1 | 21 |

| Triple lay | 6x6x7+7 | 27 |

Steel rope GOST 2688 80 (6*19+OC), 6-strand rope, type LK-R with organic core

| Rope diameter | Weight of lubricated rope | Marking group, N/mm2 (kgf/mm2) | Price including VAT rub./meter | ||

| 1770 (180) | |||||

| mm | kg. / 1000m | Breaking force of the rope as a whole, kN, not less | Breaking force of the rope as a whole, KG, not less | Black in grease | Galvanized |

| 4,1 | 64,1 | 9,75 | 995 | 23,94 | 28,46 |

| 4,8 | 84,4 | 12,8 | 1306 | 27,03 | 33,15 |

| 5,1 | 95,5 | 14,6 | 1490 | 28,39 | 34,84 |

| 5,6 | 116 | 17,8 | 1816 | 33,04 | 36,57 |

| 6,2 | 141 | 21,1 | 2153 | 35,19 | 41,37 |

| 7,6 | 211 | 32,3 | 3296 | 43,99 | 52,33 |

| 8,3 | 256 | 38,1 | 3888 | 50,22 | 59,69 |

| 9,1 | 305 | 45,4 | 4633 | 56,45 | 67,13 |

| 9,6 | 358 | 53,4 | 5449 | 60,71 | 74,28 |

| 11 | 461 | 68,8 | 7020 | 72,21 | 90,87 |

| 12 | 527 | 78,5 | 8010 | 81,68 | 102,79 |

| 13 | 596 | 89 | 9082 | 88,63 | 111,46 |

| 14 | 728 | 108 | 11020 | 104,78 | 131,82 |

| 15 | 844 | 125 | 12755 | 116,99 | 147,13 |

| 16,5 | 1025 | 152 | 15510 | 138,36 | 174,16 |

| 18 | 1220 | 181 | 18469 | 163,49 | 205,63 |

| 19,5 | 1405 | 209 | 21327 | 185,4 | 233,23 |

| 21 | 1635 | 243 | 24796 | 211,86 | 266,67 |

| 22,5 | 1850 | 275 | 28061 | 238,53 | 300,2 |

| 24 | 2110 | 314 | 32041 | 269,09 | 338,52 |

| 25,5 | 2390 | 356 | 36327 | To order | To order |

| 27 | 2685 | 399 | 40714 | To order | To order |

| 28 | 2910 | 434 | 44286 | To order | To order |

| 30,5 | 3490 | 520 | 53061 | To order | To order |

| 32 | 3845 | 573 | 58469 | To order | To order |

| Check the availability of our products with managers, contact numbers: (495) 221-76-96, (495) 255-24-68 | |||||

Tensile strength parameters of steel cables

To establish what load a steel cable can withstand, it is important to take into account that its choice is determined by two main parameters - breaking and working strength.

Tensile strength

Breaking strength refers to the minimum force on a rope at which it will break. If it is necessary to determine this value of a steel cable, the tensile characteristics are taken from GOST or determined using the formula:

R=Kd2, where

- K – safety factor;

- d – diameter, mm.

The coefficient K when calculating the breaking load of cables is unchanged and is selected depending on the type of specific product. So, if you need to find out the value of a single-strand type product, use the figure 70. For a rope with one organic core, take the number 40, with several cores - 34.

Steel rope GOST 7668-80 (6x36+OS), double lay, type LK-RO with organic core

| Rope diameter | Weight of lubricated rope | Marking groups, N/mm2 (kgf/mm2) | Price including VAT rub. / meter | ||

| 1770 (180) | |||||

| mm | kg. / 1000m | Breaking force of the rope as a whole, kN, not less | Breaking force of the rope as a whole, KG, not less | Black in grease | Galvanized |

| 11,5 | 513 | 75,1 | 7663 | 93,15 | 113,85 |

| 13,5 | 696 | 101 | 10306 | 112,02 | 141,01 |

| 15 | 812 | 116 | 11837 | 126,17 | 158,83 |

| 16,5 | 1 045 | 150 | 15306 | 150,85 | 195,57 |

| 18 | 1 245 | 175 | 17857 | 177,03 | 229,47 |

| 20 | 1 520 | 215 | 21939 | 207,83 | 269,44 |

| 22 | 1 830 | 258 | 26327 | 235,09 | 304,68 |

| 23,5 | 2 130 | 304 | 31020 | 272,30 | 353,00 |

| 27 | 2 800 | 396 | 40408 | 350,37 | 453,86 |

| 31 | 3 655 | 517 | 52755 | 449,73 | 582,68 |

| 33 | 4 155 | 588 | 60000 | 510,73 | 662,14 |

| 36,5 | 4 965 | 703 | 71735 | 605,39 | 784,88 |

| Check the availability of our products with managers, contact numbers: (495) 221-76-96, (495) 255-24-68 | |||||

How are operating strength indicators calculated?

The strength of cables and ropes for production purposes is regulated by the relevant GOSTs:

- GOST 2688-80 – steel ropes, cables, slings for cranes (construction, metallurgical), installations in mines;

- GOST 3068-88 – ropes and cables for road, construction equipment, lifting and transport mechanisms, earth-moving equipment;

- GOST 7668-80 – universal steel cables for metallurgical, industrial lifting works, construction;

- GOST 7669-80 – cables and ropes for winches, excavator buckets, mine hoists;

The strength of a steel cable is determined by two criteria:

- tensile strength of cables is a calculated value that determines at what minimum loads the steel cable begins to fail;

- working strength or permissible force is an indicator of operational capabilities, optimal loads on the cable under which it can be operated for a certain period without breaks or destruction. This indicator determines what working loads are permissible for a steel rope.

Tensile and working strength depends on production technology, design, and degree of rigidity. The higher the rigidity of the cable, the higher the tensile strength.

Permissible load when using steel cable

The permissible load (AM) of steel ropes is calculated depending on their diameter. This value is measured in kilonewtons, with 1 kN equaling 100 kg. The permissible value for steel cables of different diameters is calculated as follows:

- for a rope with a diameter of 2 mm this value will be 0.47 kN;

- a product with a diameter of 3 mm has an allowable value of 1.06 kN;

- a thickness of 4 mm determines a DN of 1.88 kN;

- for a diameter of 5 mm this value will be 2.94 kN;

- with a thickness of 6 mm, the permissible value is 4.24 kN;

- a thickness of 8 mm determines a load of 7.52 kN;

- for a rope with a thickness of 10 mm, the DN is 1.74 kN.

The breaking load (FL) (the force required to break the cable) will also depend on the diameter of the product:

- for a rope with a diameter of 2 mm, the breaking load will be 2.35 kN;

- a product with a thickness of 3 mm has a pH of 5.29 kN;

- a thickness of 4 mm determines a breaking force of 9.41 kN;

- for a cable with a thickness of 5 mm this value will be 14.70 kN;

- with a product thickness of 6 mm, the pH is equal to 21.20 kN;

- a diameter of 8 mm determines a load of 37.60 kN;

- for a 10 mm product, pH is equal to 58.80 kN.

Application area

The use of steel rope can be found in various fields. This can be as a cable for mounting a tent and cable-stayed roof structures to suspension bridges and television and radio towers.

Different applications for wire ropes place different demands on strength, abrasion and corrosion resistance. To meet these requirements, the cable is made of materials such as:

- Stainless steel. Used where corrosion is a major factor.

- Galvanized carbon steel. It is used where strength comes first and corrosion resistance is less important.

The wire (one element) can have a cross-section of up to 3 mm. This is enough to withstand loads of up to 200 kgf/mm2. Steel cables and ropes differ in terms of lay, which can be single, double or triple. The arrangement of the wire in different layers has one of the following tangents:

- point (usually used for minor intermittent loads);

- linear (used in many areas);

- point-linear (used for additional strength).

Types of cables by material of manufacture

The material used in the production of this product largely determines its technical characteristics. Manufacturers offer steel and synthetic products.

Steel cables for cargo winch

The central part is a smooth organic core that gives the product flexibility. The braid is made of double lay wire. In different layers of strands, the diameter of the steel wire can be the same or different. The braid gives the rope high strength. Steel cables are often standard equipment on automotive traction devices.

Multilayer construction provides:

- high resistance of the product to various types of loads, exposure to aggressive environments, abrasion, temperature changes;

- minimal risk of rupture when the winch cable is strongly tensioned;

- no flattening during operation;

- long operational period.

Disadvantages - significant weight per linear meter, risk of injury when steel strands break, poor resistance to corrosion processes.

Synthetic products

In the production of these products, composite materials are used, which combine different types of synthetic threads. The most popular are Kevlar ropes. The finished product combines high strength, not inferior to that of steel ropes, with a lower specific weight. Synthetic products are often used to complete traction devices produced by foreign manufacturers.

- combination of strength and low weight per linear meter;

- safety for the user;

- in the unfolded state – no twisting;

- Convenient use - you can work with this product without gloves.

Disadvantages - high cost, inconvenience of use at subzero temperatures, rapid loss of strength at high temperatures. A wet synthetic rope wound on a drum turns into a monolithic piece of ice in the cold. The new Kevlar rope has greater strength than steel rope of the same diameter. But synthetic products wear out much faster than metal ones. Another difficulty when using synthetics is the need for constant protection from ultraviolet radiation, which causes its rapid aging.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 13

Steel cable type TK in 133 wires with a metal core

(GOST 3067-55)

| Cable diameter, mm | Estimated weight of 100 linear meters of cable, kg | Estimated tensile strength of cable wires, kg/mm 2 | ||||||||

| 120 | 130 | 140 | 150 | 160 | 170 | |||||

| Rope breaking strength, kg | ||||||||||

| 9,0 | 33,35 | 3830 | 4150 | 4470 | 4790 | 5110 | 5430 | |||

| 9.75 | 39.45 | 4540 | 4920 | 5295 | 5675 | 6055 | 6435 | |||

| 10,5 | 45,36 | 5210 | 5650 | 6080 | 6520 | 6960 | 7390 | |||

| 12.0 | 59,27 | 6810 | 7380 | 7950 | 8500 | 9090 | 9640 | |||

| 13,5 | 74,95 | 8620 | 9360 | 10000 | 10 750 | 11450 | 12150 | |||

| 15,0 | 92.50 | 10600 | 11 500 | 12400 | 13300 | 14150 | 15000 | |||

| 16,5 | 111.9 | 12 850 | 13900 | 15000 | 16100 | 17 150 | 18200 | |||

| 18,0 | 133,1 | 15300 | 16550 | 17850 | 19 100 | 20400 | 21650 | |||

| 19,5 | 156,3 | 17950 | 19450 | 20 950 | 22450 | 23950 | 25500 | |||

| 21,0 | 181,4 | 20850 | 22600 | 24350 | 26050 | 27800 | 29550 | |||

| 22,5 | 207.4 | 23800 | 25800 | 27800 | 29800 | 31800 | 33750 | |||

| 24,0 | 236,8 | 27200 | 29500 | 31 750 | 34050 | 35300 | 38550 | |||

| 25,5 | 267,5 | 30750 | 33300 | 35 900 | 38 450 | 41050 | 43600 | |||

| 27,0 | 299,3 | 34400 | 37 300 | 40 150 | 43 050 | 45 900 | 48750 | |||

| 30,0 | 370,0 | 42550 | 46100 | 49650 | 53200 | 56 750 | 60 300 | |||

| 33.0 | 447,7 | 51 500 | 55800 | 60100 | 64400 | 69700 | 73000 | |||

| 36,0 | 532,6 | 61 250 | 65400 | 71 500 | 76600 | 81 700 | 86700 | |||

| 39.0 | 625,7 | 71 950 | 78800 | 84000 | 89650 | 95600 | 102000 | |||

| 42,0 | 724,7 | 83400 | 90100 | 97300 | 104000 | 110500 | 118000 | |||

| 45,0 | 833,1 | 95600 | 103 500 | 111500 | 119500 | 127500 | 135500 | |||

| 48,0 | 947,4 | 109000 | 118000 | 127000 | 136000 | — | — | |||

| 52,5 | 1133.6 | 130500 | 141000 | — | — | — | — | |||

| 57,0 | 1336,3 | 153500 | 166000 | — | — | — | — | |||

| 60,0 | 1481,2 | 164500 | 178000 | — | — | — | — | |||

- Notes.

1) GOST 3067-55 provides for the production of cables with a diameter of 3 mm and

with a design tensile strength of all cables and above 170

kg 1mm2,

namely: 180, 190, 200, 210, 220, 240, 250, 260.

Table 14

Steel cable type LK-0 in 42 wires with an organic core

(GOST 3069-55)

| Cable diameter, mm | Estimated weight of 1 0 linear meters of cable, kg | Estimated tensile strength of cable wires, kg/mm 2 | ||||||||

| 120 | 130 | 140 | 150 | 160 | 170 | |||||

| Rope breaking strength, kg | ||||||||||

| 2,1 | 1,54 | 270 | 242 | |||||||

| 2,3 | 1.83 | — | — | — | 277 | 287 | ||||

| 2,5 | 2,14 | — | 297 | 317 | 337 | |||||

| 2,7 | 2.49 | — | 345 | 368 | 392 | |||||

| 2,9 | 3.05 | — | — | — | 423 | 451 | 479 | |||

| 3,2 | 3.66 | 474 | 508 | 543 | 576 | |||||

| 3.5 | 4,37 | . | 566 | 606 | 646 | 687 | ||||

| 3,8 | 5.09 | 658 | 706 | 752 | 800 | |||||

| 4,7 | 7,91 | 952 | 1030 | 1 090 | 1 160 | 1230 | ||||

| 5.6 | 11,44 | 1260 | 1370 | 1 470 | 1580 | 1690 | 1 790 | |||

| 6,5 | 15,54 | 1720 | 1860 | 2010 | 2150 | 2290 | 2430 | |||

| 7,5 | 20,32 | 2250 | 2430 | 2620 | 2820 | 3000 | 3 190 | |||

| 8,5 | 25,68 | 2840 | 3 080 | 3320 | 3560 | 3800 | 4040 | |||

| 9.5 | 31,70 | 3510 | 3800 | 4100 | 4 390 | 4 690 | 4980 | |||

| 10,5 | 38,36 | 4250 | 4610 | 4960 | 5320 | 5670 | 6030 | |||

| 11,5 | 45,63 | 5060 | 5490 | 5910 | 6320 | 6750 | 7 170 | |||

| 12,5 | 53,58 | 5940 | 6440 | 6940 | 7440 | 7930 | 8420 | |||

| 13.5 | 62,19 | 6900 | 7470 | 8050 | 8630 | 9160 | 9740 | |||

| 14,5 | 71,07 | 7890 | 8550 | 9160 | 9830 | 10500 | 11 150 | |||

| 15,0 | 81,17 | 8980 | 9740 | 10500 | 11250 | 12000 | 12750 | |||

| 36,0 | 91,67 | 10 100 | 10950 | 11 800 | 12700 | 13550 | 14400 | |||

| 17,0 | 102,5 | 11350 | 12300 | 13250 | 14200 | 15150 | 16100 | |||

| 19,0 | 126.8 | 14050 | 15200 | 16400 | 17550 | 18750 | 19900 | |||

| 21 0 | 153,4 | 17000 | 18400 | 19800 | 21 250 | 22650 | 24100 | |||

| 22,5 | 182,5 | 20200 | 21 900 | 23600 | 25300 | 27 000 | 28700 | |||

| 24,5 | 214,4 | 23 800 | 25 750 | 27750 | 29750 | 31700 | 33700 | |||

| 26,5 | 248,3 | 27500 | 29850 | 32150 150 | 34400 | 36750 | 39050 | |||

| 28,0 | 285,5 | 31650 | 34350 | 36 950 | 39600 | 42250 | 44900 | |||

- Notes.

1) GOST 3069-55 provides for the production of cables with a design tensile strength above 170 kg/m2,

namely: a) cables of all specified diameters up to 180 and 190

kg/mm

b) cables with diameters from 2.1 to 2.3

mm

180 190 200, 210, 220. 230, 240, 250 and 260

kg/mm2,

c) cables with a diameter from 2.5 to 2.9

mm

180, 190, 210, 230 and 240

kg/mm2.

See Tables for plant ropes

Further.