Steel 12Х18Н10Т (Х18Н10Т) corrosion-resistant chromium-nickel steel of austenitic class

Substitutes: Steel 08Х17Т, Steel 08Х18Т1, Steel 15Х25Т, Steel 10Х14Г14Н4Т, Steel 08Х18Н10, Steel 12Х18Н9Т, Steel 08Х18Н10Т, Steel 08Х18Г8Н2Т, Steel 08Х22Н6Т, Steel 12Х17Г9AN 4, Steel 08Х18Н10ГТ, Steel 12Х18Н10ГТ, Steel 08Х18Н12Б, Steel 03Х23Н6, Steel 03Х17АН9

Steel 12 X 18N10T is used in the food, oil, chemical industries, mechanical engineering, fuel and energy complex and other industries. It is used for the manufacture of stainless steel containers designed to operate under high pressure, the production of welded equipment and parts intended for contact with oxidizing environments, solvents, and acids of moderate concentration. It is also often used in cryogenic technology, heat exchange, and capacitive equipment.

One of the varieties of products made from steel 12 X 18N10T is wire with a diameter of 0.3 mm. It has excellent anti-corrosion properties and is often used as a raw material for the production of various structures and parts operating in difficult operating conditions. On its basis, woven meshes and filters are created for purifying water, as well as various aggressive environments with temperatures up to 790 o C.

The main area of application for 0.3 mm wire is welding structures made of alloy 12 X 18N10T and other stainless steels in cases where the use of conventional carbon steel electrodes is impossible. In addition, it is well suited for the production of moving parts of machines and mechanisms, which during operation are subject to high mechanical, thermal loads or exposure to aggressive substances.

According to the manufacturing method, 0.3 mm wire can be cold-drawn or heat-treated, according to the degree of accuracy - normal or increased accuracy, and according to ductility - classes 1, 2, 2A, 3. At all stages of production, from the preparation of raw materials to the shipment of finished products, careful quality control is carried out. Thanks to this, the material exactly complies with state standards both in terms of chemical composition and physical and mechanical properties.

Heat treatment of stainless steel is a special thermal effect on a metal base with the aim of subsequently changing certain properties or structure of the metal.

General characteristics of steel 12x18n10t

When considering 12x18n10t (GOST defines all standards), it should be taken into account that the high concentration of the main alloying elements determines the special properties of the metal. Most of the brand contains chromium and nickel.

Download GOST 5632-72

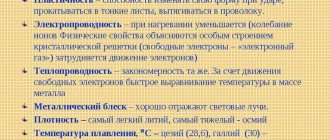

Technical features of stainless steel 12x18n10t can be characterized as follows:

- The density indicator is 7920 kg/m3.

- Hardening is carried out at temperatures of about 1100 degrees Celsius. Special equipment is required to heat the medium to this temperature.

- An analogue of steel 12x18n10t should have a hardness index of 179 MPa.

- An important parameter is the degree of weldability. Stainless steel grade 12x18n10t has no restrictions on weldability; various methods can be used. After welding, it is recommended to carry out heat treatment, which increases the strength and reliability of the connection.

- The application temperature is 650 degrees Celsius. High temperatures can lead to increased ductility and reduced protection from chemical attack.

- It is possible to process the material by cutting in a hardened state. That is why the workpiece is used for cutting when using turning or milling equipment.

Cold-worked blanks are also available for sale, which can be used to produce a wide variety of products.

An analogue of aisi is produced by many foreign manufacturers. In this case, labeling is carried out in accordance with the rules established in the country.

Annealing, hardening and heat treatment of stainless steel

Are you interested in heat treatment, annealing, hardening of stainless steel? .. Supplier Avec Global offers to buy stainless steel of domestic and foreign production at an affordable price in a wide range. We will ensure delivery of products to any point on the continent. The price is optimal.

Relevance

Stainless steel is usually heat treated to relieve stress, strengthen it, or increase ductility. Heat treatment is carried out under controlled conditions to avoid carburization and decarburization.

Annealing

Annealing is used to recrystallize the structure of austenitic stainless steels and stimulate the formation of chromium carbides. In addition, this treatment eliminates stresses generated during previous processing and homogenizes welds. Temperatures for short-term annealing of stainless steels are above 1040 °C to prevent grain growth in the structure. The controlled annealing temperature of some alloys may be lower based on grain size.

Stabilizing annealing

It is usually carried out after normal annealing. Stabilization consists of the precipitation of carbon in the form of carbides (usually niobium and titanium) in the temperature range from 870 to 900°C) for 2-4 hours, followed by rapid cooling. All ferritic and martensitic stainless steels can be annealed in the ferrite formation temperature range, or by heating above the critical temperature in the austenite range.

Subcritical annealing

Subcritical annealing temperature from 760 to 830 °C. The soft structure of spheroidized and ferrite carbides can be obtained by cooling the material (to 25°C) for an hour, or by holding the material for an hour at a subcritical annealing temperature. Annealed cold worked parts can be annealed at subcritical temperatures.

Recrystallization annealing

Ferritic steel grades across the entire operating temperature range require short recrystallization annealing (temperatures from 760 to 955°C). The supplier Avec Global offers to buy stainless steel of domestic and foreign production at an affordable price in a wide range. We will ensure delivery of products to any point on the continent. The price is optimal.

Heat treatment in controlled atmosphere

Controlled annealing conditions reduce shape distortion. This treatment can be carried out in a salt bath, but annealing carried out in a reducing environment is generally preferred.

Hardening

Like low-alloy steels, martensitic stainless steels are hardened with simultaneous austenitization. The austenitization temperature ranges from 980 to 1010 °C. At an austenitization temperature of 980 °C, the hardness first increases and then decreases. The process is also carried out to eliminate possible corrosion cracking of steel.

Vacation

Martensitic stainless steels have a high alloy content and therefore high hardenability. Full hardness can be achieved by air cooling at the austenitizing temperature, but oil quenching may be necessary to harden large areas. Hardened components must be tempered immediately after cooling in air. In some cases, components are cooled at -75°C before processing. Martensitic steels are hardened at temperatures above 510°C and then rapidly cooled at temperatures below 400°C to avoid embrittlement.

Buy. Supplier, price

Are you interested in heat treatment, hardening of stainless steel? .. Supplier Avec Global offers to buy stainless steel of domestic and foreign production at an affordable price in a wide range. We will ensure delivery of products to any point on the continent. The price is optimal. We invite you to partner cooperation.

Chemical composition and structure of the alloy

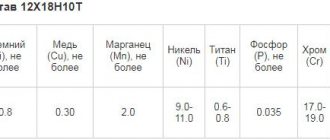

The material in question, 12x18n10t, belongs to the class of structural cryogenics. The structure can be characterized by high resistance to aggressive environments. The chemical composition of steel 12x18n10t is represented by a combination of the following elements:

- Almost any metal in its composition has a high concentration of iron. The second most important chemical element is carbon, which has a concentration of 0.12%.

- The second most concentrated element is chromium. Its concentration ranges from 17% to 19%.

- The composition included a high concentration of nickel: from 9% to 11%.

- Recently, titanium has been included in the composition of modern alloys, the concentration of which is about 0.8%.

Chemical composition of steel 12x18n10t

The remaining chemical substances have concentrations within the normal range in accordance with GOST. It is practically impossible to avoid the presence of harmful impurities in the composition, but it is possible to maintain a low concentration: phosphorus about 0.035% and sulfur no more than 0.02%.

Structural cryogenic steel 12Х18Н10Т

Brand 12Х18Н10Т – purpose

Structural cryogenic steel 12Х18Н10Т of austenitic class is used for the manufacture of vessels/apparatuses operating in solutions of acids (phosphoric, acetic, nitric), salts, alkalis at temperatures up to 3500C; parts operating under pressure at t –196 + 6000C.

As a rule, hot-rolled stainless steel sheets, circles, strips, etc. are made from steel grade 12Х18Н10Т. It should be noted that mostly Russian-made stainless steel pipes are made from steel 12Х18Н10Т. Steel grade 12Х18Н10Т is one of the most practical and reliable steels in stainless steel. Sheets made of steel 12Х18Н10Т have a wide range of thicknesses and a wide range of surface treatments, which in turn allows the end user to reduce the cost of surface treatment of stainless steel sheets.

Steel 12Х18Н10Т – domestic analogues

| Rolled metal grade | Substitute |

| 12Х18Н10Т | 08Х17Т |

| 08Х18Г8Н2Т | |

| 08Х22Н6Т | |

| 10Х14Г14Н4Т | |

| 12X17G9AN4 | |

| 12Х18Н9Т | |

| 15Х25Т |

Characteristics

| Brand | GOST | Foreign analogues | Classification |

| 12Х18Н10Т | 9940–81 | There is | Structural cryogenic steel |

| 9941–81 | |||

| 5949–75 | |||

| 18143–72 | |||

| 25054–81 | |||

| 7350–77 | |||

| 5582–75 |

Material 12Х18Н10Т – technological properties

| Flock sensitivity | Weldability | Welding methods |

| not sensitive | no limits | ESH, RDS, KTS |

Brand 12Х18Н10Т – chemical composition

Mass fraction of elements no more than, %:

| Silicon | Manganese | Copper | Nickel | Sulfur | Titanium | Carbon | Phosphorus | Chromium |

| 0,8 | 2 | 0,3 | 9–11 | 0,02 | 5C–0.8 | 0,12 | 0,035 | 17–19 |

Steel 12Х18Н10Т – mechanical properties

| Assortment | GOST | Dimensions – thickness, diameter | Heat treatment | KCU | y | d5 | sT | sв |

| mm | kJ/m2 | % | % | MPa | MPa | |||

| Hot deformed pipes | 9940–81 | 40 | 529 | |||||

| cold deformed | 9941–81 | 35 | 549 | |||||

| Bar | 5949–75 | up to 60 | Hardening 1020–11000С. Cooling (air). | 55 | 40 | 196 | 510 | |

| Wire | 18143–72 | 20–25 | 540–830 | |||||

| Forgings | 25054–81 | up to 1000 | Hardening 1050–11000С. Cooling (water) | 40–52 | 35–38 | 196 | 510 | |

| The leaf is thick | 7350–77 | Hardening 1000–10800С. Cooling (water) | 40 | 205 | 530 | |||

| thin | 5582–75 | Hardening 1050–10800С. Cooling (water) | 40 | 205 | 530 | |||

| thin hard-worked | 10 | 880–1080 | ||||||

| thin semi-hardened. |

Material 12Х18Н10Т – hardness, MPa

| Assortment | GOST | HB 10-1 |

| Forgings | 25054–81 | 179 |

Grade 12Х18Н10Т – impact strength, J/cm2

| Assortment | Dimensions – thickness, diameter, mm | Heat treatment | KCU at temperatures | ||

| -750WITH | -400WITH | +200WITH | |||

| Band | 8x40 | Delivery status | 319 | 303 | 286 |

Steel 12Х18Н10Т – heat resistance

| Temperature | Wednesday | Score or endurance group |

| 0C | ||

| 650 | Air | 2–3 |

| 750 | Air | 4–5 |

Material 12Х18Н10Т – physical properties

| T | R 109 | E 10-5 | l | a 106 | r | C |

| hail | Ohm m | MPa | W/(m deg) | 1/Grad | kg/m3 | J/ (kg deg) |

| 20 | 725 | 1.98 | 15 | 7920 | ||

| 100 | 792 | 1.94 | 16 | 16.6 | 462 | |

| 200 | 861 | 1.89 | 18 | 17 | 496 | |

| 300 | 920 | 1.81 | 19 | 17.2 | 517 | |

| 400 | 976 | 1.74 | 21 | 17.5 | 538 | |

| 500 | 1028 | 1.66 | 23 | 17.9 | 550 | |

| 600 | 1075 | 1.57 | 25 | 18.2 | 563 | |

| 700 | 1115 | 1.47 | 27 | 18.6 | 575 | |

| 800 | 26 | 18.9 | 596 | |||

| 900 | 19.3 |

Brand 12Х18Н10Т – exact and closest foreign analogues

| Australia | Austria | England | Bulgaria | Hungary | Germany | European Union | Spain | Italy |

| AS | ONORM | B.S. | BDS | MSZ | DIN, WNR | EN | UNE | UNI |

| 321 | X6CrNiTi18-10KKW | |||||||

| X6CrNiTi18-10S |

| 321S51 |

| 321S59 |

| LW18 |

| LW24 |

| X6CrNiTi18-10 |

| Ch18N12T |

| Ch18N9T |

| X6CrNiTi18-10 |

| KO36Ti |

| KO37Ti |

| X6CrNiTi18-10 |

| 1.4878 |

| X10CrNiTi18-10 |

| X12CrNiTi18-9 |

| X6CrNiTi18-10 |

| 1.4878 |

| X10CrNiTi18-10 |

| X6CrNiTi18-10KT |

| X6CrNiTi18-10 |

| X6CrNiTi18-11KG |

| X6CrNiTi18-11KT |

| China | Poland | Romania | USA | France | Czech | Sweden | South Korea | Japan |

| G.B. | PN | STAS | – | AFNOR | CSN | SS | KS | JIS |

| 0Cr18Ni10Ti | ||||||||

| 0Cr18Ni11Ti | ||||||||

| 0Cr18Ni9Ti | ||||||||

| 1Cr18Ni11Ti | ||||||||

| H0Cr20Ni10Ti |

| 1H18N10T |

| 1H18N12T |

| 1H18N9T |

| 12TiNiCr180 |

| 321H |

| S32100 |

| S32109 |

| Z10CNT18-11 |

| Z6CNT18-10 |

| Z6CNT18-12 |

| 17247 |

| 17248 |

| STS321TKA |

| STSF321 |

Alloying elements of steel 12x18n10t

The main alloying elements are chromium and nickel. They have the following effects:

- Almost all common stainless steels are obtained by including chromium in the composition, which determines corrosion resistance. In addition, the structure's ability to passivate increases.

- Nickel is added to the composition in order to improve the performance of the structure. An example is that the brand in question rolls well in cold and hot conditions.

Other alloying elements only slightly change the performance characteristics of the metal in question. An example is ferritic properties, as well as intercrystalline corrosion resistance associated with high titanium concentrations.

Physical properties

When choosing a metal, you should pay attention to its physical properties. They largely determine the scope of application and its main performance qualities. In the case under consideration, the density of stainless steel is 7920 kg/m3. The fairly high density of 12x18n10t determines that the manufactured parts are durable.

Other physical properties include the following:

- The melting point of stainless steel is more than 1000 degrees Celsius. It is almost impossible to carry out such processing in a home workshop.

- Corrosion resistance is the main reason for the demand for common stainless steels. It can be used if operating conditions include exposure to high humidity and chemical environments.

- Low magnetic properties make it possible to use it in the manufacture of various products. They are achieved by adding titanium.

The coefficient of linear expansion and the coefficient of thermal conductivity determine the possibility of using the material in the manufacture of products that can be used when exposed to high temperatures.

The specific gravity of stainless steel largely depends on the chemical composition and the processing method used.

Technological properties

Steel 12Х18Н10Т can be heat treated, which improves its performance characteristics. Depending on the purpose of processing, hardening, annealing (stabilizing or stress relief), and step processing can be used. Heat treatment helps reduce the tendency to:

- general corrosion;

- intergranular corrosion;

- knife corrosion;

- tension;

- loss of plasticity.

Steel 12Х18Н10Т is insensitive to flakes. It is recommended to carry out cutting processing after hardening. The temperature of the beginning of forging is 1200C, the end temperature is 850C.

Mechanical properties

When considering the metal, the mechanical properties of steel 12x18n10t are also taken into account. they are characterized as follows:

- Brinell hardness corresponds to 179 MPa. This point determines that the surface of the material can withstand impacts of various types.

- The tensile strength varies in a different range, usually 279 MPa.

Mechanical characteristics of steel 12x18n10t

When choosing 12x18n10t, the yield strength is also taken into account, which determines the possibility of its use when casting various products.

Other features of the metal in question include the following points:

- When doped, silicon is included in the composition. It increases density and flow rate. The concentration of this chemical element in the composition adversely affects plasticity.

- Sufficiently high ductility and impact strength are attractive performance qualities of the metal.

- As the ambient temperature decreases, the mechanical properties of the metal begin to decrease significantly.

The disadvantage is that the metal does not withstand the effects of substances that contain chlorine ions. In addition, corrosion resistance is low in relation to hydrochloric or sulfuric acid. Therefore, the scope of application is somewhat limited.

Scope of application

The use of steel 12x18n10t is very extensive:

- Food industry. It is worth considering that there are quite a lot of requirements for products used in the food industry. The metal should not interact with food and drinks.

- Chemical and oil industries. These industries also often create various containers and elements that come into contact with petroleum products and various chemicals.

- Mechanical engineering. In the mechanical engineering industry, various products are manufactured by cutting. If they will be used in high humidity and exposure to chemicals, then the material in question is often selected.

- In the fuel industry and energy sector. The metal can withstand high temperatures.

Application of steel 12x18n10t in the production of building materials

Sheet steel 12x18n10t

Tank made of steel 12x18n10t

Application of steel 12x18n10t in automotive production

Metal can be processed using automatic and manual welding. A high thermal conductivity coefficient determines the use of steel in the manufacture of heat exchange equipment. Sheet metal is also used in the manufacture of collector elements for the transmission and distribution of exhaust gases.

Seamless stainless steel pipes, which are operated under high pressure, have become widespread. In addition, the chemical composition contains titanium, which determines low magnetic qualities. A sufficiently high concentration of carbon determines a high level of strength.

Type of delivery

The main type of supply of steel grade 12Х18Н10Т is stainless steel sheet. Sheet steel of this class is the most popular on the market, in demand in all industries, and always sells well. Flat metal can be hot-rolled or cold-rolled; some characteristics of the product depend on this, including the quality of the sheet surface. The sheet can be smooth or textured, matte or polished mirror, heat-treated or etched. Rolled sheets are used to produce long products (including shaped ones), which include strip, rod, and wire.

- Steel rod is widely used in everyday life for the manufacture of fences and various decorative elements. In industry, it is used to make fasteners, bolts, springs, studs and many other parts. Steel rods are also used as reinforcement for reinforced concrete structures in construction.

- Steel strip is steel up to 4 mm thick in rolls. It is convenient to transport, it is also widely used in construction, mechanical engineering, and furniture production. It is used to produce parts and structures intended for use in aggressive environments.

- Stainless steel wire is heat-resistant, insensitive to moisture, and is used in welding equipment as electrodes for welding stainless steels. Widely used in the chemical, food, oil refining industries, mechanical engineering, architecture and construction.