Main consumers of quenching oils

OJSC "AVTOVAZ" CJSC "Chelyabprommash" Kama Automobile Plant - KAMAZ Likhachev Plant - ZiL Cheboksary Tractor Plant - ChZPT Chelyabinsk Tractor Plant - ChTZ Vladimir Tractor Plant - VTZ Volgograd Tractor Plant - VgTZ Lipetsk Tractor Plant - LTZ Rostselmash Ural Heavy Engineering Plant Izh Orsky plants Novokramatorsky machine-building plant Krasnoyarsk Heavy Engineering Plant OJSC "PO SEVMASH" OJSC "East-Siberian Machine-Building Plant"

What is metal hardening oil?

To obtain metal of maximum hardness, strength and wear resistance, a process of heating to a certain temperature occurs, then cooling in a liquid. The cooling material for hardening metal is quenching oils. Thanks to the use of quenching oil, it is possible to produce steel products with a given plane accuracy, required strength and a certain structure.

Quenching oils – evrosmazki.ua

Heat treatment of metals and quenching oils

There are the following methods of heat treatment of metals:

- Annealing

- Normalization

- Hardening

- Vacation

| Way | Task | Process description |

| Annealing | Reducing the hardness of steel for better processing, improving the structure of the metal, achieving greater homogeneity, relieving internal stresses | Slow heating of the metal to +740…+850 °C*, holding, slow cooling |

| Normalization | Increased strength, hardness and toughness of steel, lower ductility of steel compared to annealed steel | Heating to a temperature above critical (temperature of change in the type of crystal lattice), holding, cooling in still air |

| Hardening | Achieving high hardness, strength, and therefore wear resistance of steel. When using this method, a nonequilibrium structure is formed, requiring subsequent tempering | Heating to a temperature above critical, holding at a given temperature, rapid cooling in a liquid medium (water or oil) |

| Vacation | Obtaining higher ductility and reducing the fragility of the martensitic structure while maintaining the level of strength, stress relief | Heating from +150...+260 °C to +370...650 °C, holding, slow cooling in air |

Note : * Temperature depends on the type of metal being processed.

The following types of hardening are distinguished:

- Cold hardening (+30…+80 °C): for thermal improvement of open-die forging and die-forging parts, hardening of hand tools, leaf and screw springs, high-strength bolts, nuts, washers, etc.

- Hot hardening (+165…+220 °C): for hardening high-precision parts (for example, parts of the drive mechanism of cars), where it is necessary to eliminate the risk of surface curvature

- Vacuum hardening: for tool, bearing, heat-resistant, high-speed steel

When heat treating metals and alloys using the hardening method, it is very important to take into account the temperature and duration of heating, as well as the cooling rate.

Water or special oil is used as a working medium in the metal hardening process.

When quenching using oil, significantly fewer thermal cracks form on the product than when quenching in water.

The production of domestic hardening oils began to actively develop in the late 90s. Currently, there is a whole range of these products on the Russian market: from simpler and proven ones to expensive imported ones, which can affect the cooling rate.

Quenching oils make it possible to obtain steel products with specified values of hardness, required structure and surface cleanliness.

When choosing an oil, it is necessary to take into account its flash point in an open crucible. It is determined by the quality of the base oil and should be 30 below the overall process temperature. Additives are added to the quenching oil in order to increase its efficiency or speed up the heat removal process.

Quenching oils must have the following properties:

- High thermal and chemical stability (preservation of properties throughout the entire service life)

- Good cleaning properties (precipitates and scale from the surface of parts accumulate in the oil)

- High resistance to evaporation (use in open quench tanks)

- Good anti-foam properties (strong swirl of hot oil in quench tanks)

- A certain level of viscosity (depends on the quenching temperature and affects oil loss when removing parts from tanks)

- Lack of water (affects oil foaming)

Physical properties of cooling oils

Quenching oils must meet the requirements of GOST in terms of physical and chemical parameters. The liquid is characterized by a long cooling time for the metal. The oil must have the following physical properties:

- high resistance to evaporation;

- absence of impurities, water and other chemicals;

- high chemical resistance (maintaining properties throughout the entire period of use);

- have excellent cleaning properties;

- high ignition temperature when heated.

have a certain level of viscosity;

Types of quenching oils

The domestic chemical industry began producing high-quality oils for metal hardening at the end of the last century. Additives are added to the quenching oil to increase oxidation resistance, reduce foaming, and have excellent cleaning properties.

Industrial oils have different applications and are accordingly used in the processing of metals with high physical requirements:

- For grinding high-alloy, high-strength steel grades, oil is used to increase the cold hardening rate.

- To create small mechanical parts from low-strength steels, low volatility oil is used.

- Hardening of volumetric parts made of alloy steels occurs using oil with excellent oxidative stability and viscosity, maximum ignition temperature.

Quenching oils – evrosmazki.ua

Types of Heat Treatment

Heat treatment, which is what this process is also called, comes in several types: processing with and without polymorphic circulation. The first type of heat treatment is used primarily for some alloys and non-ferrous metals, and the second is used for steel products.

During heat treatment, a metal product acquires improved hardness, and its initial ductility is significantly reduced. The viscosity of the material also decreases. The decrease will be even greater if the cycle is repeated repeatedly. The process of so-called “tempering” allows you to reduce brittleness and slightly improve viscosity. It affects the reduction of acquired strength, but the reduction rates will be insignificant. When tempering metals without polymorphic treatment (alloys and non-ferrous metals), a process called “aging” is used.

Introduction

There is a characteristic of steel - hereditary and acquired grain size. The grain size can be smaller or larger, and it also changes under the influence of high temperatures. How quickly depends on the amount of impurities. It is impossible to say unambiguously which crystal lattice and which compounds are better. In some cases, strength depends on this, in others ductility. This indicator must be changed depending on what kind of processing is to be done. If sheet steel or a profile is planned to be cut, then a procedure should be carried out that leads to grain coarsening. And if the work is to be done with high-carbon steel, then workpieces with a fine-grained structure are better processed.

Changing the grain size is quite difficult. In this case, hereditary propensity must be taken into account. This does not mean that the alloy will in any case have large grains, but with the same heating of two bars with different heredity, one will produce growth of compounds faster than the other. Therefore, the factor is very important when selecting heating. So not everyone can only selectively harden metal at home; you should know the chemical composition.

The alloy has many impurities. Among them:

- Ferrite. This is the fundamental element that is most abundant. It carries the basic properties, other substances only increase or decrease them.

- Cementite. Chemical formula – iron with carbon. And although element “C” increases the strength characteristics, if you use pure FeC, you may be surprised at its fragility.

- Graphite. High-carbon Damascus steels are obtained by saturation with this impurity at the time of processing by forging.

- Austenite. Formed at a moment of very high heat. At the same time, plasticity increases, and magnetic properties disappear.

Perlite. Increases hardness and tensile and compressive strength.

Types of hardening

Hardening can be either complete or incomplete. With complete hardening, significant changes occur in the structure of the material and the crystal lattice. Partial hardening is often applied to various types of tool steel products.

There are also products that require only partial hardening. That is, when it is necessary to harden not the entire metal, but a small part, for example, a cutting edge (this is how swords, various cutters for machine tools, drills and much more are hardened). On such a metal the boundary is clearly visible.

Hardening technology

Thermal hardening technology involves rapid cooling that can reduce the temperature of the product to 600 – 410°C. The time required for sufficient heating of a metal product directly depends on the heating device used. When heating the material in a powerful electric furnace, it takes 1–2 minutes to heat treat 1 mm. With the same process in an oven with an open flame, one minute is enough, and when heated in a bath with a salt solution, about half a minute. The minimum time required for hardening is using a bath with a lead solution, in which 6 seconds is enough.

When hot metal is immersed in a quenching liquid, film vapor is formed, which leads to a significant reduction in the cooling rate. The temperature in the film vapor increases significantly, and when it breaks, the liquid begins to boil on the surface of the hot metal and cools it sharply. This process is called bubble boiling.

When the metal cools, the liquid stops boiling, and therefore the cooling process itself slows down significantly. At this time, a process of convective heat exchange occurs in the metal product.

Hardening

Steel hardening is a heat treatment process, the essence of which is to heat the steel to a temperature above the critical temperature, followed by rapid cooling. As a result of this operation, the hardness and strength of steel increase, and ductility decreases.

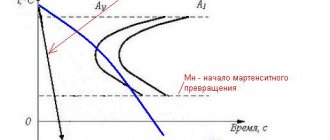

When steels are heated and cooled, the atomic lattice is rearranged. The critical temperature values for different grades of steel are not the same: they depend on the content of carbon and alloying impurities, as well as on the rate of heating and cooling.

After hardening, the steel becomes brittle and hard. When heated in thermal furnaces, the surface layer of products becomes covered with scale and is decarbonized the more, the higher the heating temperature and the holding time in the furnace. If the parts have a small allowance for further processing, then this defect is irreparable. Hardening modes for hardening steel depend on its composition and technical requirements for the product.

Hardening methods

The essence of any hardening is the transformation of austenite into martensite (iron-carbon diagram). Depending on the temperature regime, hardening can be complete or incomplete. The first method is to harden tool steel, and the second is to harden non-ferrous steel.

During hardening, one or more coolants can be used. The method of heat treatment also depends on this. Depending on the cooling medium, heat treatment of the metal can be:

- using one cooler;

- with cooling;

- intermittent;

- stepped;

- isothermal.

Quenching in one cooler

This method is used for heat treatment of simple parts made of alloy and carbon steel. The part is heated to the required temperature and then cooled in liquid. Carbon steel with a diameter of 2 to 5 mm is cooled in water, parts of smaller diameter and all alloy steel are cooled in oil.

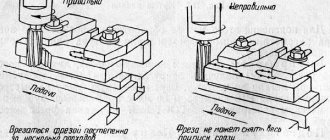

Hardening with cooling

When heat treating with a single coolant, thermal and structural internal stress conditions often occur. They develop when the temperature difference reaches a minimum. Tensile stress is formed on the surface of the metal, and compressive stress is formed in the center. To reduce these stresses, before lowering the heated part into the liquid, it is kept in the open air for a short time. The temperature of the part in this case should not be below the 0.8 K line on the iron-carbon diagram.

Intermittent

This hardening is carried out in two environments - water and oil or water and air. A part heated to a critical point is first quickly cooled in water, and then slowly in oil or in the open air. This heat treatment method is used for high-carbon steel. This method is complex, since the cooling time in the first environment is very short and only a highly qualified specialist can determine it.

Stepped

With intermittent heat treatment, the part cools unevenly—thinner surfaces cool faster than others. In addition, it is very difficult to adjust the time the part is in the first medium (water). Therefore, it is better to use step hardening. This method allows the part to be cooled in an environment at a temperature above the martensitic point. The first stage is cooling and holding the part in a given environment until all sections of the part reach the same temperature. The second stage is the final slow cooling (transformation of austenite into martensite).

Isothermal

In isothermal heat treatment, the part is heated to a critical point and then lowered into an oil or salt bath at a temperature of 250 degrees. Leave for half an hour and then cool in the open air. This hardening provides high structural strength and is used for alloy and structural steels in which the decomposition of austenite in the intermediate region does not completely occur. Subsequently, it turns not into martensite, but into bainite + 20% retained austenite, enriched in carbon. With this hardening, high strength and good toughness can be achieved.

Technological nuances of hardening

Hardening, which is a type of heat treatment of metals, is performed in two stages. First, the metal is heated to a high temperature and then cooled. Different metals and even steels belonging to different categories differ from each other in their structure, therefore their heat treatment modes do not coincide.

Heat treatment modes for some non-ferrous alloys

Heat treatment of metal (hardening, tempering, etc.) may be required for:

- its strengthening and increasing hardness;

- improving its ductility, which is necessary when processing by plastic deformation.

Many specialized companies harden steel, but the cost of these services is quite high and depends on the weight of the part that needs to be heat treated. That is why it is advisable to do this yourself, especially since you can do it even at home.

If you decide to harden the metal on your own, it is very important to correctly carry out such a procedure as heating. This process should not be accompanied by the appearance of black or blue spots on the surface of the product. The bright red color of the metal indicates that heating is occurring correctly. This video demonstrates this process well, which will help you get an idea of the degree to which to heat the metal subjected to heat treatment.

As a heat source for heating the metal product that needs to be hardened to the required temperature, you can use:

- a special oven powered by electricity;

- blowtorch;

- an open fire that you can make in the yard of your house or in your country house.

Hardening a knife on open coals

The choice of heat source depends on the temperature to which the metal to be heat treated must be heated.

The choice of cooling method depends not only on the material, but also on the results to be achieved. If, for example, it is not necessary to harden the entire product, but only a separate section of it, then cooling is also carried out pointwise, for which a stream of cold water can be used.

The technological scheme by which metal is hardened may include instant, gradual or multi-stage cooling.

Rapid cooling, which uses one type of coolant, is optimal for hardening steels classified as carbon or alloy. To perform such cooling, you need one container, which can be a bucket, barrel, or even an ordinary bathtub (it all depends on the size of the item being processed).

Cooling the knife blank in oil

In the event that steels of other categories need to be hardened or if, in addition to hardening, tempering is required, a two-stage cooling scheme is used. With this scheme, a product heated to the required temperature is first cooled with water and then placed in mineral or synthetic oil, in which further cooling occurs. Under no circumstances should an oil-based cooling medium be used directly, as the oil may ignite.

In order to correctly select the hardening modes of various steel grades, you should focus on special tables.

Heat treatment modes for high-speed steels

Heat treatment modes for alloy tool steels

Heat treatment modes for carbon tool steels

Temperature

Hardening is the transformation of austenite into martensite. In production, when choosing heat treatment temperatures, the iron-carbon diagram is used. The hardening temperature of carbon steels is very easy to determine. Heating of structural steel with a carbon content of less than 0.8% is brought to temperatures located above the GS line and above the Ac3 point by 30-50 degrees. Heating of steels containing more than 0.8% carbon is carried out at temperatures 30-50 degrees higher than those located above the PSK line. The hardening temperature of alloy steel is also selected based on the critical points, but this process is much more complicated, since in addition to carbon, such steels also contain other components.

Coolant selection

The quality of the part depends on the choice:

- clean water is used to cool simple parts and products made from carbon steel;

- For products of complex shapes, caustic soda mixed with water in a 1:1 ratio is used as a coolant. The prepared solution is heated to 50-60 degrees;

- Hardening of metal in oil is applicable to thin-walled parts made of alloy or carbon steels.

Carbon steel, which has a complex composition, is cooled in two coolers - first quickly in clean water, and then slowly in a bath filled with oil. You need to move parts from water to oil very quickly.

Principles of metal hardening at home

During manufacturing, metal products are subjected to additional heat treatment.

After heating, the characteristics of the material change and the structure improves. To do this, you don’t need to buy expensive equipment; you can harden metal at home. To avoid mistakes, you need to know the nuances of the procedure and understand the technological process. Hardening metal at home

What is metal hardening and its types?

Tempering is a popular way to improve the characteristics of a material. Heat treatment allows you to change the structure of the metal. The result of exposure to high temperature is an increase in hardness. After heating, the part quickly cools. To do this, it is immersed in a container filled with oil or water.

Most often, stainless steel, wire from different types of steel and knives are hardened at home. But after structural changes, the steel becomes brittle.

If we are talking about non-ferrous metals, then the structure does not change. For example, after hardening copper it is impossible to achieve a good hardness index.

However, in the absence of structural changes, the material does not become excessively brittle

To reduce the brittleness of steel after heat treatment, the workpiece is tempered. This is an additional heat treatment. The product is first heated and then slowly cooled.

Features of steel hardening

The main material that is subjected to heating and rapid cooling is stainless steel and alloys based on it. To improve the performance of the product, it is necessary to perform additional heating and then slow cooling. This will relieve internal tension. Processing features for different types of steel:

- Hardening of steel 45. After heating and rapid cooling, the strength increases 3 times.

- Carrying out the procedure with 40X steel. Heats up to a temperature of 860 degrees Celsius.

There are special reference books that contain information about the correct temperature conditions for processing various types of steel.

Advantages

Advantages of metal heat treatment:

- Changing the structure of the material. The grains become uniform.

- No deformation.

- Simplicity of the procedure.

- Increased hardness, increased strength.

Equipment and features of the process

To carry out the technological process of processing the material, it is necessary to use certain equipment. Special ovens are used for heating. They can run on electricity, gas or solid fuel. In addition to the heating structure, you need to prepare a container filled with water or oil. It is needed for rapid cooling of the workpiece.

Metal hardening forge

How to make a chamber for hardening metal?

In order to harden metal at home, you need to assemble a muffle furnace. Assembly steps:

- Draw a drawing of the heating chamber. You can take a ready-made drawing with dimensions and designation of the main elements.

- Lay out the main structure from fireclay bricks.

- Coat the outside of the chamber with fireproof clay.

- Bring the wires to the homemade structure and fasten the nichrome threads to the inner surface. These are heating elements.

- Cut recesses to accommodate the nichrome wire, make a hole for connecting it.

The chamber is reinforced with corners, which are secured to the contour using a welding machine. Before working with a homemade structure, a preparatory firing is carried out. To do this, it is heated to 900 degrees Celsius. A gas burner is used for heating.

Hardening steel at home

In order to harden metal at home, you can use a homemade furnace, forge, or open flame. You need to place a metal piece on the heated surface. Then it is heated to a certain temperature and immersed in coolant using forge tongs.

To carry out a technological operation correctly, you need to strictly observe the temperature regime. A pyrometer is used for this. Blacksmiths advise checking the temperature using a magnet. If it does not stick to the material, the part is heated to 760 degrees. Then the workpiece needs to be cooled.

Metal hardening can be done at home. This allows anyone to improve the characteristics of the material. You can assemble the heating chamber according to ready-made drawings.

Support the channel, just read our articles, and we will post useful information about metals for you! Also visit our website, where you will find a lot of information about metals, alloys and their processing.

What are the defects when hardening metal?

If the hardening conditions are not followed, the following defects may appear:

- cracks or warping. The reason is internal tension. If the warping can be straightened and straightened, then the cracks cannot be corrected in any way. This is the final marriage;

- burnout, which is oxides along the grain boundaries, resulting from the penetration of oxygen into metal products. Burnout is possible when the metal is heated to a temperature close to the melting point. Such metal cannot be repaired;

- overheat. When a metal is heated above the incandescent temperature, it overheats, resulting in the formation of a large structure. This metal is highly brittle. Corrected by annealing and new hardening;

- low hardness. Insufficient hardness is obtained at low heating temperatures, insufficient holding at the required temperature and low cooling rates. This defect can be easily corrected by annealing and further hardening;

- oxidation and decarbonization, which occurs when the metal is exposed to air and furnace gases. The oxidized layer, scale, causes irreparable harm to production, because such a defect cannot be corrected. To avoid this problem, it is necessary to use ovens with a protective atmosphere.

Hardening steel at home or cottage

Sometimes it happens that heat treatment of metal at home or in the country is necessary. This happens if the purchased tool turns out to be under-hardened or not hardened at all. Often there is a need to harden a knife, ax or drill. Of course, good hardening can only be done under production conditions, but male craftsmen are excellent at doing this over an ordinary fire. Sequence of home hardening:

- prepare two containers. Pour mineral oil into one, water into the other;

- We also need to prepare a tool with which we will put the metal to be hardened into the fire and remove it from it. Pincers are suitable for this procedure;

- Next, we make a fire and wait for the coals to form. We place a metal object on them that needs to be hardened;

- We monitor the color of the coals and the color of the flame. Hot coals are white. And the flame should not be white. The crimson color of the flame is optimal for the hardening process at home. A white flame indicates that the temperature inside the fire is too high, and our part may simply burn out;

- It is also necessary to ensure that black or blue spots do not appear on the metal product, which indicate deformation of the metal as a result of excessive softening. And if the metal has turned white, then such a part can be safely thrown away.

- As soon as the metal object heats up to the temperature we need, we take it out and first lower it into the oil. We do this three times, the first time for three seconds. Each time we increase the time by the same amount. We lower and take out sharply;

- Next, lower the metal tool into a container of water and leave it there until it cools completely.

Parts or objects that have an elongated shape are placed vertically in the water. To estimate the hardening temperature in a fire, we use a color table. Instead of a fire, you can use any stove.

How to harden steel over an open fire

As mentioned above, you can harden steel at home, using an open fire for heating. Naturally, such a process should begin by starting a fire, in which a lot of hot coals should form. You will also need two containers. You need to pour mineral or synthetic oil into one of them, and ordinary cold water into the other.

In order to remove hot iron from a fire, you will need blacksmith tongs, which can be replaced with any other tool of a similar purpose. After all the preparatory work has been completed, and a sufficient number of hot coals have formed in the fire, objects that need to be hardened can be placed on them.

Read also: Voltage regulator for DC motor

The color of the formed coals can be used to judge the temperature of their heating. Thus, coals whose surface has a bright white color are hotter. It is also important to monitor the color of the fire’s flame, which indicates the temperature regime in its interior. It is best if the fire flame is colored crimson rather than white. In the latter case, indicating that the flame temperature is too high, there is a risk of not only overheating, but even burning the metal that needs to be hardened.

Heated steel colors

The color of the heated metal must also be carefully monitored. In particular, black spots must not be allowed to appear on the cutting edges of the tool being processed. Blue discoloration of the metal indicates that it has softened greatly and become too flexible. It cannot be brought to such a state.

After the product has been calcined to the required degree, you can proceed to the next stage - cooling. First of all, it is lowered into a container with oil, and this is done often (every 3 seconds) and as sharply as possible. Gradually the intervals between these dives increase. As soon as the hot steel loses its brightness, you can begin to cool it in water.

Steel tarnish colors

When cooling metal with water on the surface of which droplets of hot oil remain, care should be taken, as they may burst into flames. After each dive, the water must be agitated to ensure it remains cool at all times. A training video will help you get a clearer idea of the rules for performing such an operation.

There are certain subtleties when cooling hardenable drills. So, they cannot be lowered flat into a container with coolant. If you do this, then the lower part of the drill or any other metal object that has an elongated shape will cool sharply first, which will lead to its compression. That is why it is necessary to immerse such products in coolant from the wider end.

For heat treatment of special grades of steel and smelting non-ferrous metals, the capabilities of an open fire are not enough, since it will not be able to heat the metal to a temperature of 700–9000. For such purposes, it is necessary to use special furnaces, which can be muffle or electric. If it is quite difficult and expensive to make an electric furnace at home, then with muffle-type heating equipment this is quite feasible.

Checking metal for heat treatment

Before we start heating, we need to make sure that the material of the tool we purchased is not heat-treated. We do the test using an ordinary soldering iron. We heat the tool and run it over the metal surface of interest to us. If the soldering iron sticks to the metal, then there can be no talk of any heat treatment. Smooth passage of the soldering iron over the surface of the steel or bouncing off it indicates that the item we are testing is either well heat-treated or processed too much. If there is no heat treatment, we do it ourselves.

Hardening a knife with graphite

Heat treatment of metal with graphite is good when you need to harden not the entire object, but only part of it. For a knife, this is the edge. The sequence of the knife heat treatment process at home:

- We check the tip of the knife for hardness using a needle file. If the metal grinds off easily, and the needle file makes a dull sound, then the knife is not heat-treated;

- for this process you will need graphite, which can be obtained from round batteries, take the leads of a simple pencil, or use the graphite brushes of a generator;

- we turn the mined graphite into powder;

- We use a DC welding machine as a power source. Set to minimum;

- We make the substrate from galvanized sheet. Pour graphite powder onto it;

- We connect the “plus” of the welding device to the substrate, and the “minus” to the knife handle;

- then carefully move the knife blade along the graphite so that it does not touch the substrate. We also make sure that the graphite does not ignite, otherwise our knife will be damaged;

- when the blade moves across the graphite, the latter will produce sparks. As soon as we see that the tip of the knife has heated up, we stop the process. Approximate hardening time: no more than 5 minutes;

- let the knife cool naturally, then take a file and check the hardness. If the sound made by the file upon contact with the knife is loud, and the tip cannot be sharpened, then the hardness of the blade is high.

The hardening process in production is much easier than at home. If necessary, you can try to harden the desired object or tool using “clumsy” methods using improvised means.

Literature and sources used:

- Surface phenomena in metals and alloys / V.K. Semenchenko. - M.: Gostekhizdat

- Ultra-fast hardening of liquid alloys. — Moscow: Mechanical Engineering

- Wikipedia article

Hardening metal in oil - Metalworker's Handbook

Heat treatment of metals is one of the main ways to improve their mechanical and physical-chemical characteristics: hardness, strength and others.

One type of heat treatment is hardening. It has been successfully used by man in a handicraft way since ancient times. In the Middle Ages, this method of heat treatment was used to improve the strength and hardness of metal household items: axes, sickles, saws, knives, as well as military weapons in the form of spears, sabers and others.

And now they use this method of improving the characteristics of metal, not only on an industrial scale, but also at home, mainly for hardening metal household items.