Construction staples are fastening elements with which beams and logs are connected. They are quite useful and necessary when building a traditional wooden house. They are used during the construction of the roof frame.

Such products are called forged because they are made from reinforcement using the forging method. Other fasteners clearly lag behind construction staples for timber and logs in terms of reliability.

Corner connections

There are different ways to connect the beams to form an angle. Previously, they were traditionally attached “into a bowl”, making the joint not at the ends, but slightly retreating from them. The result was a cross-shaped joint with ends protruding outward. But there are many ways to avoid leaving such protrusions that interfere with the exterior finishing.

Since the beam has the correct geometry with a rectangular or square cross-section, it is much easier to connect than a log. Even rounded. This shape simplifies the marking and production of grooves and allows for tight joints.

Let's look at the main options for connecting timber at an angle to each other:

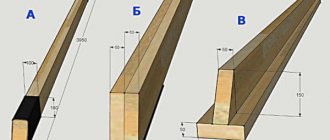

- Butt. The simplest method that does not require cutting or grooves. One beam is butted end to side of the other, in each row such joints are shifted and alternated, as in the previous photo. This connection is very fragile and requires additional fixation with perforated steel plates, staples or other fasteners. In addition, end-to-end corners, even with high-quality insulation, begin to blow out over time and let moisture in. Therefore, this method is used mainly for the construction of outbuildings and other non-residential buildings.

The joint is additionally secured with a bracket and a steel angle Source www.allremont59.ru

- Half a tree . This type of joint is very common, as it is accessible even to inexperienced carpenters. It involves removing part of the beam from the end to half its depth. The end result is steps that overlap each other. To strengthen the joints, they are drilled through and dowels are driven into the holes. They also fasten the beams along the length of the span between the corners.

Corner connection in half a tree Source 900igr.net

- In the paw. This fastener is very similar to the previous one, but the end is cut out not at a right angle, but at an angle.

- Dovetail. One of the most durable and reliable ways to fasten timber together. It consists of a tenon-groove locking device. Moreover, the spikes have the shape of a trapezoid, which increases the area of conjugation of the two elements and does not allow them to “spread apart”.

The shape and size of the tenon are selected so that it fits tightly into the groove formed by two tenons of the transverse rims Source stroyfora.ru

- Root thorn. Otherwise, such a connection is called a “frying pan” or “warm corner”, since it is windproof, without through gaps from the street to the room. In this case, the locking T-shaped connection is made secret by cutting out a rectangular or trapezoidal groove in the horizontal plane not to the entire thickness of the beam, but only to half. The tenon of the second beam repeats its shape. This joint is called a blind pan and is used to fasten the outer corners of a house. When constructing internal partitions, an open frying pan is often used, cutting a groove along the entire thickness of the beam. Additional strength is provided by driving a dowel into the lock.

Warm corner with rectangular and trapezoidal tenon Source i0.wp.com

See also: Catalog of timber house projects

- Into the bowl. The method is similar to joining a half-tree, but the grooves are cut not at the ends of the crowns, but with an indentation from them and the formation of residues protruding beyond the perimeter of the walls. The groove can only be on one side of each crown - and this is the simplest and easiest option to implement. Cutting can be done on two opposite faces, or on all four.

For reference! Four-sided grooves are quite difficult to manufacture; they are usually made in the factory when ordering a log house according to a finished project.

One of the options for connecting timber to each other using the “bowl” method with four-sided grooves Source utwood.su

These methods are used for any corner joints, not exclusively rectangular ones. Simply, the ends of the beams are first sawed off to form bevels that give the desired angle at the junction.

Fastening the crowns of the log house

A crown is one row of timber laid in a rectangle and fastened at the corners.

They make up the walls of the building, its foundation. The beams must be fastened together very carefully, both in corners and in straight sections, so that they do not rotate around their axis or shift. This is possible even if the beam is rectangular in cross-section. Iron nails cannot be used for wood - they will not withstand the load and conditions of use. Wood has a certain moisture content, which will cause the iron to oxidize and break down over time. And then the house itself will fall apart. When constructing log houses, wooden nails are used - dowels. They can be round or rectangular in cross-section, but preference is given to round ones. As the timber structure dries and shrinks, it creates less stress. The dowels must be placed strictly vertically.

On straight sections of walls, holes are drilled at regular intervals of 1.5-2 m, into which the dowels are driven. It is customary to retreat approximately 50cm from corners and openings. Then the top row is combined and installed. To make the task easier, the crowns are assembled on the ground in sections of several rows. For corners, there are several ways to attach timber.

Connections in length

The standard maximum size of timber is 6 meters in length with different sections. This is often not enough to build the walls of a large house, install rafters or lay floor beams. You have to splice 2 or even 3 elements in the longitudinal direction. And it’s one thing when it is a crown that has support under it in the form of a foundation or an underlying crown, and another thing if there is no such support. We have to decide how to splice the beam along its length in order to withstand the load not only from its own weight, but also from the structures resting on it.

Such problems are solved in ways similar to those already described. The fastening is simply done not at an angle, but along the beams.

During the construction of canopies, gazebos and other similar structures, the jointed timber may not have any support Source i.ytimg.com

See also: Catalog of companies that specialize in the construction of houses made of timber

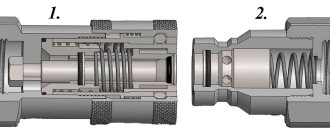

- Half a tree. A fastening unit already familiar to you, when symmetrical straight notches are cut from the ends up to half the thickness of the beam. Splicing with oblique notches will be more reliable. But in any case, additional fixation with plates, pins or dowels is required.

- Oblique castle. In this case, the connected ends are also cut obliquely, but the cuts are not flat, but stepped in shape with certain parameters for each protrusion. When combining two beams, they must exactly repeat each other. “Sliding” is prevented by an already proven method - driving dowels into the joint. Without a special tool, solving the problem of how to connect 100x100 beams together in this way is almost impossible.

- Straight patch lock. At the ends of the beams, peculiar hooks are cut along their entire width. This is the most reliable splicing method for hanging beams.

Straight and oblique lock Source i1.wp.com

- Root thorn . This is the same type of connection that was described in the previous chapter. The spike can be either rectangular or trapezoidal. The trapezoid is much more reliable, as it prevents vibrations in the horizontal direction.

- On the key. If, when installing a main tenon, a tenon is formed at the end of one beam, and a groove is selected in the other, then in this case two grooves are made, the beams are laid end-to-end, and a key is driven into the resulting hole, repeating its shape. It is pre-coated with wood glue or PVA glue to increase the strength of the joint.

Note! When building walls, it is not enough to decide how to connect the beams together along the length. It is necessary to shift the joints relative to each other so that they do not coincide along the vertical line in adjacent crowns.

The production of locking joints is noticeably simplified and accelerated if you do not mark each beam individually, but make a template from thin and dense sheet material.

How much weight does a construction bracket have?

The weight of fastening hardware is directly dependent on its dimensions and expected load. For clarity, the required values of U-shaped brackets are summarized in the table.

| № | Diameter/length/height, mm | Weight, kg |

| 1 | 6.5x150x70 | 0,075 |

| 2 | 6.5x200x70 | 0,1 |

| 3 | 8x250x60 | 0,12 |

| 4 | 8x250x70 | 0,14 |

| 5 | 10x300x70 | 0,26 |

| 6 | 10x350x70 | 0,277 |

| 7 | 10x 400x70 | 0,316 |

Connection fastener

With the advent of modern fasteners made of durable alloy and galvanized steel, many construction processes have been simplified, including the installation of reliable connecting units in timber structures. Some of them have been used for a long time and are traditionally popular. Others appeared relatively recently, so they may be unknown to people whose profession and interests are not related to construction.

Traditional fasteners

The simplest and most reliable of them are dowels or dowels made of hard wood. They blend perfectly with the base material without causing it to deform, crack or rot. In combination with adhesives, they allow for durable fastening.

Assembling a log house on steel dowels Source remontik.org

Pins are also metal. Their main advantage is their high strength and durability, which is why they are often used to fasten timber crowns vertically.

Nails and staples, which used to be almost the only types of fasteners for wood, are now trying not to be used in the construction of permanent buildings, since the ferrous metal from which they are made is incompatible with wood. It corrodes easily, damaging the wood and gradually deteriorating. For the same reason, it is not recommended to use homemade dowels cut from reinforcing bars.

Modern fasteners

A wide variety of fasteners are made from perforated rolled steel with a thickness of at least 2 mm with an anti-corrosion coating. It is made from:

- plates of different lengths and widths with holes for screws and anchors. A large assortment of standard sizes allows you to solve problems such as connecting beams together along a length of 150 by 150, fastening rafters at the ridge part, or strengthening a sagging joint without lower support;

Galvanized connecting plate Source www.sibwindows.ru

Video description

This video shows how to make a groove on the end of a beam using a template and a chainsaw:

If the structure of spliced beams does not require the formation of smooth edges, they can be overlapped, tightened with nails on both sides or metal pins at several points. This is often done when you need to lengthen the rafters. Or get powerful logs or floor beams by merging two beams not only in length, but also in thickness. In such cases, before joining the timber, the joints must be shifted relative to each other.

How to fasten beams together across widths

The lumber material is used to make bridge decks, lay floors in freight cars and industrial buildings, and make panels for laying on foundations and soil. Unlike floor laths, timber structures are joined together without the use of a tongue-and-groove lateral connection; this method of installation is called “smooth reveal”. The structures are fastened with construction staples, fixed with 30-40 mm edged boards laid around the perimeter and 100 mm nails, and a screw metal tie is used. This connection allows

disassemble and assemble structures, make temporary flooring.

Reinforced floors are used in warehouses, sports and entertainment complexes. To hold lumber together indoors, synthetic glue is used; when finishing the interior, the timber is fastened with a longitudinal dovetail key.

Cross Lap Knit

Lap knitting is a universal connection of lumber, used when laying walls made of logs and timber. The workpieces are placed at right angles into cut-out grooves; the size of this groove depends on the size of the material used. Such a lock is used in the construction of log houses and ceilings, the construction of bridges, and the construction of canopies. The main methods of cross fastening:

- Half-tree connection;

- Quarter and third wood joint;

- Notch in one row.

The most widespread cross-shaped connection in half a tree is when cutting corners into a bowl; it is used in the construction of utility structures, residential buildings and baths. The structure is reinforced with building brackets, dowels and dowels.

Length extension

The length of industrially produced timber is determined by GOST 24454-80; of the many sizes of timber, 3- and 6-meter blanks are most in demand. When splicing, the ends of the joined beams are secured in various ways:

- Half-tree connection;

- On the root thorn;

- Straight patch lock;

- Oblique patch lock;

- Oblique cut.

The choice of fastening for the connected beams depends on the tasks at hand. For decking, a straight lock is used; for vertical supports, a half-tree or tenon lock is used; for the construction of 3D structures, oblique locks are used. Locks are reinforced with building brackets, dowels and dowels; bolted fastenings are used for load-bearing supports. In order to maintain the uniformity of the surface texture of the laminated veneer lumber, the length is increased using the toothed connection method or butt joints with a key, and the joints are reinforced with waterproof glue.

The longitudinal installation of timber roof rafters has its own characteristics - it is necessary to take into account the impact of multidirectional loads. For the connection, an oblique cut is used, reinforced with bolted fastening with a diameter of 10-12 mm.

Advantages and disadvantages

Hardware has both a positive side when working with them and a negative characteristic.

Staples have the following advantages:

- Convenient transportation of products;

- Speed and ease when connecting building blocks;

- Increasing the strength of reinforced concrete material;

- Saving money when constructing a facility.

Minuses:

- Additional expenses for equipment for working with staples;

- High-quality products have an expensive price.