Major manufacturers of low-speed drills

The quality of the instrument depends on the reputation of the manufacturer. Experienced craftsmen identify a number of models that deserve attention.

Makita

A brand from Japan, specializing in the production of electric tools, has gained worldwide trust due to the quality of its products. Among the variety of drills from this company, the unit model 6300-4 is popular. The specimen is suitable for high-quality work by experienced craftsmen. The price is within 14.5 thousand rubles. The tool allows you to perform all popular tasks, including preparing solutions.

Appearance of the Makita 6300-4 drill Source Makita-profi.ru

Felisatti

The Italian manufacturer, whose brand produces everything needed for construction work, also produces low-speed drills. The professionals appreciated the professionalism of the Italians, choosing the DMF23/1150VSE device among popular models.

Metabo

Among countries producing power tools, Germany ranks high, distinguished by reliable and high-quality products. Metabo produces drills that any DIYer will appreciate. However, the high cost of the devices deters non-professional construction workers from purchasing them. Thus, the price of the common B32/3 drill model is 59 thousand rubles. Not everyone can afford to work with an expensive tool.

Russia

If, when choosing a manufacturer, the question is about saving money, you should pay attention to Russian brands. The efficiency of Interskol or ZUBR tools is at the level of foreign competitors. The availability of products from domestic companies forces craftsmen to make a choice in their favor.

There are several worthy models on the Russian market, for example, drill Zubr ZDM-1200R Source stroyberi.com.ua

Techniques for drilling holes in wood

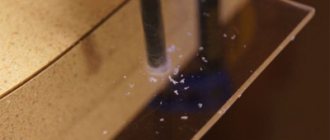

At the preliminary stage, the surface should be countersinked. The essence of the procedure is to make a small recess according to the dimensions of the head of the fastener at the site of subsequent drilling. Then the main drilling is carried out using equipment of a nominal mounting diameter. If you plan to use dowels, then drilling is carried out without preliminary countersinking. If there is no need to drill through the workpiece, then use a feather drill. It is designed to organize a tenon joint and can be equipped with a built-in drilling depth limiter.

To preserve the structure of the wood when drilling large holes, annular cutters and feather drills are used. Unlike cylindrical drills, they practically do not create chips on a wooden surface.

There are several models of ring drills for small dowels on the market, but they do not have a long service life Source Brigadir52.ru

Drilling with feather drills

Place a feather drill in the intended location and use the drill at low power. The process continues until the master sees the end of the tool from the back of the block. To eliminate chips in the hole area, drilling is then used from the opposite edge. The workpiece is turned over in the desired direction, fixed and drilled, installing the drill in the hole already made.

Homemade conductors

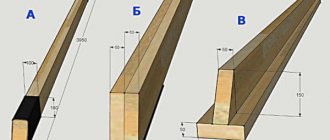

First of all, it should be noted that the simplest models of jigs are very inexpensive, so making a template for dowels with your own hands is not always advisable. In addition, you need to take into account that models for confirmations are the easiest to make. Options for dowels have a more complex design.

To independently create such a device, you need drawings that are easy to find in open sources. There are also instructions in different forms. They describe the creation of various types and variants of templates for dowels: with one and several holes, from different materials, etc. The starting materials can be represented by improvised raw materials such as wooden blocks, fragments of reinforcement and plates, etc. So, a square one will do reinforcement 10x10 mm. In addition, you will need plumbing tools and equipment such as a drill and grinder. To create more complex jigs, a welding machine is required.

Creating a template for dowels yourself involves several stages. At the first stage, the reinforcement is cut into fragments, the length of which is determined by the dimensions of the product. Next, holes are made for drilling, for which you need to know their parameters. They have a diameter of 5 mm and are 8 mm from the edge of the jig and 32 mm from each other. To increase ease of use, it is possible to equip it with a stop. It can be a plate bent at a right angle and fixed to the product. The parts are fixed using a clamp and fastened with threaded connections. In addition, sometimes homemade conductors are equipped with trays for chips in the form of fragments of plastic bottles.

Do-it-yourself dowels for timber

The construction of structures made of wood implies the mandatory use of special fastening fragments. Such elements are aimed at ensuring that the design is of high quality, reliable, monolithic, and as durable as possible.

What is a dowel?

An integral part of the structure are dowels, or dowels. It is the quality of this part that determines the reliability of the entire structure. You can easily make dowels for timber even with your own hands. The procedure is not anything particularly complicated. The main thing is to follow the chosen method.

What are wooden dowels?

First, it’s worth understanding what the dowel itself is. The part is a miniature fragment made to strengthen the walls of a log house made of timber. In this case, it is the diameter of the dowels for the timber that acts as one of the most key characteristics.

Dowel for stairs

The purpose of the dowels may be different. For example, wooden dowels are aimed at fixing log structures. The detail allows you to slow down a variety of negative consequences that invariably accompany the functioning of wooden structures. It could be:

- drying out;

- deformation;

- loosening;

- bias.

Such peculiar pins, installed correctly and correctly, will make the building stable. The beams of the structure will be placed in such a way that they will remain unchanged after a couple of months and after several decades.

Spikes for fixing timber: which ones to choose and why?

The most popular are dowels made from hard wood. The most durable options are spikes made of oak or birch. It is not possible to deform, bend, or break them. However, there is one condition. They must be properly secured. What are their shape and sizes? The optimal solution is details with rounded contours. Their length should not exceed 25 mm. Wooden dowels must be smooth and even not only at the point of installation, but over the entire surface. It is these nails that guarantee the longest possible service life.

Installing dowels in timber is a mandatory rule for timber and log structures. Birch thorns are the most common option. Such dowels cannot become an analogue of self-tapping screws or primitive nails. If they are used, it is impossible to guarantee the stability and reliability of the structure. It is also worth abandoning the use of reinforcement. Metal versions can lead to a number of negative consequences, which is explained by the direct interaction of materials with different thermal conductivity parameters. What can the use of metal dowels lead to? It could be:

- condensation formation;

- coating the surface of the spikes with rust;

- rotting of the entire layer of wood.

The nuances of creating dowels

How to make dowels for timber? It's actually a simple procedure. It's easy to do it yourself. To do this, you will need to use logs of a certain length. The blanks (ideally made from birch) must be split into many small fragments. It is advisable to make them in the form of squares. Then you will need to trim them. This is done manually. It is recommended to give the workpieces a round shape of the desired diameter.

It is very easy for lathe owners to make dowels. Using it, elements are created quickly and accurately. If there are no wooden logs, you can always use cuttings from shovels that have already gone out of use. To give them the required size and shape, you just need to cut them. Round parts can also be easily created using a circular saw.

Subtleties of fastening dowels made of wood

How is the beam fastened with dowels? You can also do it yourself, without using the services of professionals. The procedure is extremely simple. Using wood tenons will first require finding the middle of the plane being used. At this point it is necessary to make the appropriate markings. This is where the hole will be created later.

Now you need to drill a hole using a drill. It is in this that you will then need to attach the dowels. That is why it is very important to choose the drill diameter correctly. Its dimensions must be identical to the same parameters of the spike. As for the depth, it is 1.5 timber. The question of what dowels for 150x150 timber turns out to be quite simple. In the video you can see how this procedure is performed.

In this case, the task itself disappears: how to drill the timber for the dowels. Of course, the best option is a modern drill. It is much more important to ensure that the hole is processed correctly. The entry angle depends on the position of the drill. It must be strictly perpendicular to the base itself. Competency in performing this step will allow you to avoid problems with the installation of fragments in the future. It is also worth remembering that if the dowel is located extremely loosely in the timber, this will deprive the structure of all the advantages of this type of fasteners. You should also avoid excessive density. The length of the dowel should not be greater than the established dimensions. Protrusion of a part above the surface leads to problems during the inevitable shrinkage of the structure.

Some secrets of the procedure

A dowel made of wood, like the metal versions, is aimed at connecting 2 logs or beams. That is why there are several secrets on how to properly attach them. Professional assembly of timber for dowels implies:

- compliance with chess alternation, taking into account the perimeter of the structure;

- the optimal distance between them is in the range from 1000 to 1500 mm;

- proper combination of openings and bowls of approximately 300 mm;

- coincidence of the degree of humidity of the dowels with a given parameter of the base itself.

The photo shows how to install it yourself without errors. Those holes that needed to be pre-drilled with a drill are now filled with core buttons. They are the ones needed to mark the timber. If you don’t have such a special fragment at hand, you can sharpen it in pencil format. Its diameter must correspond to the prepared hole. They should be attached directly to the center of the base.

The next step is to lay a couple of boards on a perfectly flat and smooth surface. In this case, the parts need to be barely pressed against each other. However, most builders are interested in the question of how to drive dowels into timber. The tenon must be placed as tightly as possible in the groove. There should be no bevels or other defects between the timber and the dowel. In this case, you will not need to drill anything else. Nagel will do his job with ease. For this purpose, you can use a marking thicknesser. When the tenons are installed, you need to treat the fragments of the boards with glue. This will allow you to connect the workpieces that need to be firmly clamped during the process and then dried.

brusportal.ru

Advantages and disadvantages

The main advantage of conductors is that not even highly qualified specialists, but “ordinary” people at home can work with them.

And they will produce clear and precise holes (both perpendicular and inclined). You will not need to perform any calculations and markings, and this reduces how

labor intensity and work time.

The following advantages of using this type of device can be highlighted:

- The drilling jig is capable of providing perfect accuracy for both straight and inclined drilling.

- To use them, markings and preliminary scrupulous calculations are not required.

- Speeding up the assembly of furniture parts and other structures.

- The ability to drill several holes at a time without making preliminary markings.

There are much fewer disadvantages of drilling jigs; to be more specific, there is only one: the rather high price of this device. That is why some carpenters make their own jigs.