Modern furniture uses a variety of fasteners that require pre-drilling holes. To improve this process, you can buy a furniture jig. A small device allows you to speed up and simplify the process of manufacturing and assembling furniture products. Its use ensures consistently high quality of work: the holes are accurate and even, and errors are reduced to a minimum.

You can buy furniture jigs for drilling from our company. We are a manufacturer of this type of devices intended for professional use. They are actively used in the manufacture of furniture, and are also used by assemblers. Armed with our accessories, you will increase the speed and quality of your own work.

Features of application in the furniture industry

Conductors and templates are needed when assembling furniture. These things will prevent you from having a common problem that occurs during drilling—the drill hitting the part at the wrong angle. Correcting such an error will take an extremely long time, in some cases it will even be impossible.

A jig for making holes will not only allow you to correctly orient the working tool, but will also prevent it from straying from the desired trajectory.

In the furniture industry, jigs and templates are used in the following cases:

- in mass production;

- when assembling structures, when it is necessary to make holes for fasteners in the parts being connected. In this case, a jig for drilling holes for dowels or confirmat is suitable;

- a jig for drilling holes at an angle is used both in such cases and when working with thin boards, for example, MDF or chipboard.

When using such a device, the assembly process will be much easier and faster; you will be able to make the necessary holes regardless of how far they should be located from the edge of the part and how wide it is.

When assembling furniture yourself, you often have to connect parts end-to-end using dowels. Holes for dowels are best made using a special jig. The peculiarity of dowels is that despite the fact that such fasteners, although outdated, are still relevant in furniture production.

The difficulty in their use lies in the fact that the axes of the holes that are made in the parts when connecting must have a right angle with each other. Accordingly, they must be placed strictly perpendicular to each other. It is difficult to do this without a special device. Therefore, if you want to achieve high quality performance, it is recommended to buy a dowel jig.

Application

These products have been used for a long time and are widely used in metalworking. Thus, many machines are equipped with conductors. The need for templates for dowels in the woodworking industry is due to the prevalence of closed furniture joints. In this industry, the devices in question are used both in mass production and during assembly. In the latter case, furniture jigs are used to drill holes for dowels.

In addition to the above-mentioned areas, such devices are in demand in construction, mechanical engineering, and household work.

The scope of application is determined by the type of conductor. Thus, overhead devices are used for processing flat parts, chipboard and MDF boards. Corner ones are applicable both for furniture and for chipboard and MDF boards. Rotary products are designed for making holes in cylindrical parts. Universal models are suitable for small-scale furniture production. Tilting options are designed for simultaneous processing in several planes. Clip-on and sliding jigs are most suitable for home use. In addition, the latter are incompatible with single-spindle machines.

Rigid models are designed for making holes in objects with an uneven surface, such as pipes. In this case, they are secured using a clamp, but this method is not suitable for furniture, since deformation of the surface is possible.

The use of conductors simplifies and speeds up the work due to the fact that it eliminates the need for manual measurements and calculations.

Other uses

Hole jigs are used not only in furniture production. Quite often they are used when you need to make a hole in a pipe or other cylindrical part. Thanks to them, you can make a high-quality hole even in a pipe with a small diameter.

Such devices are universal and easy to use, so they are also used in the following industries:

- mechanical engineering - drilling holes in different-sized workpieces based on different materials;

- construction - drilling holes in building structures;

- home communications - as already mentioned, pipe drilling and more.

Modern drilling jigs can be of different sizes and have different operating principles. Some of them are complex, so they are easier to buy. And some modifications can be made independently, especially since some serial furniture models, especially those with universal purposes, are expensive.

Plugs and heels for chair legs using improvised materials

In order to avoid damage to the floor in the kitchen or in another room, when using wooden chairs, you should insulate those parts that can do this, that is, the legs. To do this, you can go to the store and buy special heels, or you can save money and make them yourself. The following materials are suitable for making heels for table legs:

- an old carpet, parts of it can be cut out to the desired size and glued to the legs;

- rubber, also cut out to the required size and secured with nails or glue;

- felt insoles;

- linoleum;

- leather.

You can also make plugs for the legs; the most common material for their manufacture is wine corks.

When working with wood, most craftsmen have long been making various tools on their own; for their manufacture it is possible to use improvised means. Thus, you can save a lot of money on your family budget.

Read also: How to make kurai from a plastic pipe

Benefits of use

Essentially, such a jig acts as a template for making holes so that they are made as accurately as possible. They can be used for those holes whose axis is perpendicular to the surface of the workpiece, as well as for working at an angle.

This tool is an excellent alternative to sketches and manual measurements. You can place the drill strictly at the desired angle in relation to the workpiece and will not allow any deviation. The result will be especially noticeable when it comes to making deep holes.

If you use such a high-quality device for working with chipboard, then it should have the following characteristics:

- facilitate quick assembly of furniture without the need to use complex tools;

- make it possible to make several holes simultaneously without manual marking;

- significantly improve the quality of work with the drill.

Conductors are made from different materials; there are models based on plastic or organic glass. However, the best option is considered to be made of steel , which has such advantages as:

- minimal likelihood of deformation;

- the drill is directed as clearly as possible;

- no heating during operation.

Very often, overhead models based on lightweight materials that are easy to manipulate are used as furniture jigs. Many people use factory or homemade tools.

And the most qualified and experienced craftsmen no longer use a jig, since they can easily make a hole in structures on their own as accurately as possible. But not everyone can do this.

The key advantage of such a device is that the work can be performed as accurately and efficiently as possible, even by a person who does not have the proper experience. You don't have to do markings and complex preliminary calculations. You will save a lot of time and produce furniture much faster.

Builder mistakes: typical and gross

As Alexey Markin notes, the most common mistake when making a log house from chopped logs is the small areas of contact between log and log (small width of the inter-crown groove). The thermal characteristics of such a house will be low. The head of the Domostroy-SK enterprise, Oleg Valuev, adds that in some cases the crowns may not be adjacent to each other at all (photo 1). Huge cracks will have to be caulked regularly, which will require considerable additional costs. However, the appearance and thermal characteristics of the house cannot be radically improved.

Photo No. 2

– The log house cannot sit properly due to incorrectly placed racks.

It happens that builders build a house in such a way that it simply cannot sit down.

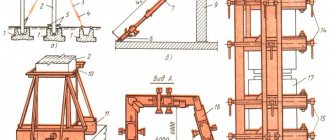

As Oleg Valuev explains, if you plan to make a veranda under the roof, then between the upper end of the post and the upper crown you need to install a special jack for shrinkage (photo 3). This will allow the log to sit evenly. Instead of a jack, you can put several planks that will need to be knocked out periodically. By the way, shrinkage jacks are clearly visible in the first illustration (Fig. 1) to ours.

Photo No. 3

– Jack for shrinkage (photo by Domostroy-SK).

Another mistake that prevents the shrinkage of a log house is an attempt to fasten adjacent crowns with nails. The log lies unevenly on the nail head, and an inter-crown gap appears. Due to a loose fit, the log may begin to “spin” during the drying process.

The problem of poor-quality waterproofing of the lower crown of a log house has somewhat lost its relevance. As a rule, the installation team performs this operation efficiently

However, the customer should pay attention to how the foundation and wooden walls are connected. If the foundation is strip or grillage, then the surface of the strip should be leveled, and between the foundation and the lower crown there should be 2-3 layers of roofing material, or a waterproofing layer of similar effectiveness

However, excess moisture can enter the wood not only through the foundation. If you lay floors and hang ceilings in a house before the frame has settled and dried, this will impede air circulation and lead to “steaming” of the house - mold or mildew may appear on the internal walls.

The head of the Domostroy-SK enterprise, Oleg Valuev, notes that in the washing room there is also no need to make baseboards on the floor. Moisture collects under them and the process of rotting also begins.

Photo No. 4

– Mold on unventilated wooden structures.

Classification of tools

Before you buy a ready-made conductor or make it yourself, you need to decide what problems you will solve with its help and only then you need to select the appropriate option in terms of design and functions.

There are a number of categories of devices that differ in their design and functional features. Here are some of them:

- overhead - such devices are applied to a part that can be processed, then it is attached to it or simply fixed manually. With their help, holes are made in various flat parts, MDF boards or chipboard;

- rotary - these templates are used when processing cylindrical parts. They are equipped with horizontal and vertical axes of rotation, so holes can be made at different angles;

- universal - such devices are suitable for small serial furniture manufacturers, where sometimes quick readjustment of the equipment used is required, they have all the functions necessary for this;

- tiltable - used when the technological procedure is carried out in several planes at once;

- sliding - such conductors do not need to be attached. Simply attach them to the surface area of the workpiece where you want to make a hole;

- fixed - they are more convenient to use, but they limit freedom of action, which is very critical when working with machines where there is only one spindle.