A little history

A device for fastening sheet materials is called a stationery stapler . Stitching occurs using a thin wire that pierces several pieces at once. The owner of the first such device was the French king Louis 15 in the 18th century. It was rarely used as a tool; it was more used as a toy.

A century later, when the rapid development of science and industry began, and with it the office, through the efforts of John McGill, who improved this mechanism, the stapler came into use among all bureaucrats in the world.

Types of staplers

Devices that perform the functions of fastening sheet materials are usually divided into construction, furniture and office. However, the difference between the first two is only symbolic. Therefore, the classification can be taken as follows:

- Device for office needs.

- Construction stapler (tacker).

- Special device for baguettes, corrugated cardboard boxes, etc.

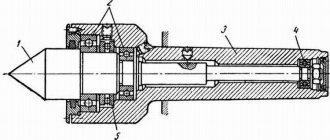

A stationery stapler not only pierces sheets, but also bends staples from the inside. This is the only difference in the operating principle. Therefore, it makes sense to get acquainted with the device using a construction sample as an example.

Fastening tools for construction

The principle of operation of a construction stapler is similar to the process of driving nails. With its help, the staple passes through the top layer or more than one (the total thickness should not be greater than the length of the staple leg). In the extreme material, the ends of the wires remain sticking out on the reverse side, like the point of a nail that has come out. Using friction, the sheets stick to the last layer.

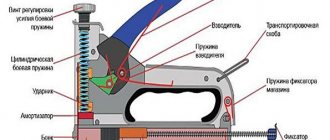

A richer classification among methods of driving a device. In this category they are:

- Mechanical hammer and lever.

- Pneumatic.

- Network electrical.

- Rechargeable.

The most popular devices are mechanical lever ones. Hammers have not become so widespread because of their operating principle - with a blow. Therefore, with their help it is not always possible to accurately drive the bracket into place. And it needs a lot of space to spread out.

Tips for choosing

Which construction bracket to choose? Every beginner may ask this question when constructing any premises.

So, what properties should a quality product have? Firstly, the brackets must be made in accordance with GOST and have a stiffener. Under no circumstances should you purchase low-quality products from dubious manufacturers. This can significantly reduce the lifespan of a construction project.

Important! The reinforcing brackets do not have a stiffening rib applied by hot forging. Since they are not used for impact work.

Secondly, when purchasing hardware, you should give preference to trusted companies that have proven themselves over many years in the construction market. You can also buy staples in the online store. There they will cost much less than in the construction departments of stores.

And the most important thing is the availability of a quality certificate for the staples. It is not recommended to purchase these products from fly-by-night companies. Where the quality of staples may be significantly lower than that of their proven counterparts.

Types of staples

All kinds of staples are used to fasten various materials. The most popular are staples in the shape of the letter P. There are also staples in the shape of a T and inverted semicircular U-shaped ones. For fastening pipeline cables, semicircular types are used, the sizes of staplers are for staplers. They come in two types of markings:

- In the form of a semicircle with a diameter of 4.5 millimeters, a stem height of 9-11 millimeters and a standard thickness of 1.25 mm. This is a type S or number 28 paperclip.

- Fasteners type L or number 36 have a slightly larger diameter (6 mm). Legs with a height of 9-10 millimeters of standard height

The most commonly used devices are staplers using U-shaped staples. They are distinguished by the following indicators:

- Diameter.

- Leg length.

- Length and thickness of the back.

The length of the leg determines how reliable the connection will be and the overall thickness of the fastened part. For thick connections you need a more powerful tool; a weak one may not penetrate the entire foot and the fastening will fall apart.

Thin back paper clips are needed for invisible fastening. Most often they are used in professional instruments.

The stronger the material, the less thickness of the leg is needed: 0.75-0.8 mm. For thin paper, choose thicker paper clips: 1.25 or 1.65 mm.

Raw materials for paper clips

The different purposes of the staples also determine the different materials for the production of these consumables. They must meet various requirements: rigidity, corrosion resistance, etc. Therefore, all brackets are metal.

Aluminum fasteners

These are the cheapest, but at the same time acceptable quality, paper clips. That is why tools using such fasteners are the best-selling. In addition, they do not rust. But other qualities make their use limited in comparison with analogues from other materials.

What metals are they made from?

Staples for staplers are made from different metals:

- Aluminum ones are the cheapest, but it is better not to use them with hard materials or in places of heavy loads: they bend when driven with great force, and can also burst under load. But they don’t rust, which can be important.

- Copper ones attach well to non-rigid materials and certainly don’t rust. But their price limits their distribution. These staples are good under wallpaper or plaster: no drips or rust stains.

- Steel staples for staplers can be hardened or not. Hardened ones are a little more expensive, but much stronger. The disadvantage of both is that they rust.

- Galvanized and stainless steel. This is the most durable and reliable type of fastener. Almost all branded staples from stapler manufacturers fall into this category.

If the legs are sharpened, it’s easier to work and you can set less power

Since the humidity in the bathhouse (steam room and washing room) is very high, you need to use stainless, aluminum or copper staples for the stapler. In those places where the load on the material will be small - when attaching a vapor barrier, for example - you can install aluminum ones, and if you decide to staple the lining with a stapler, then use stainless steel ones. Aluminum ones are not suitable because they have insufficient strength and can be torn out when the wood swells.

With all that, in each group there are options with sharpened legs, and others with unsharpened ones. Working with sharpened ones is faster and easier: they penetrate better and require less impact force. If you are working with a manual staple gun, then sharpened staples will make the job easier. In order for the unsharpened ones to penetrate completely into dense material, you have to apply good pressure on the stapler. If you need to hammer several thousand pieces, this is a significant load.

If you use steel staples, take hardened ones - they are much stronger

As the experts say, buying cheap staples means saving pennies and losing rubles. And all because during driving they bend and break. The result is that you waste time and, accordingly, money - both on finishing off or removing unsuccessfully installed fasteners, and on installing another bracket, which can also bend or break.

Popular consumables for stitchers

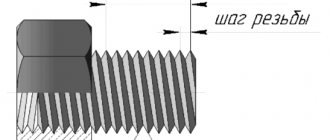

The most popular types and sizes of staples for construction staplers are 53 and 140 numbers. The first has the following values:

- The height of the leg is 4-14 millimeters.

- The back is 0.7 mm thick.

- Width 11.3 mm.

For 140 paper clips, respectively, the height is 6-14 mm, the width is 10.6 mm, and the thickness is 1.25 mm. There are staples for office staplers, the types and sizes of which are determined by the number of sheets punched in one cycle. The most common type of paper clip is 10. For other series, this will be a fractional number, where the first digit is its number, the second is the height of the leg. Therefore, when purchasing these products, you need to know which products are suitable for this particular stapler model.

How they are sold and prices

Staples for construction staplers are sold in small boxes that can contain 500, 1000, 2000, 3000, 5000 pieces. They are fastened with adhesive film into small blocks. Depending on the magazine capacity, a whole block and/or part of it is inserted - break off a piece of the required length.

Prices vary greatly. From 30 rubles for 1000 pieces of 53 types of the Saturn campaign, up to 212 rubles for the same volume from Bosh. But, as mentioned above, the difference is in the metal from which the staples are made. It feels very good while working.

Staples for a construction stapler - main characteristics and designations from different manufacturers