We'll call you back in 30 seconds.

GOST R ISO 2553-2017 GOST R ISO 6947-2017 GOST R ISO 13920-2017 GOST R 55554-2013 GOST R ISO 6520-1-2012 GOST R ISO 14174-2010 GOST R ISO 14175-2010 GOST R EN 13479-201 0 GOST R EN 12074-2010 GOST R ISO 2560-2009 GOST R 53689-2009 GOST R ISO 3581-2009 GOST R ISO 3580-2009 GOST 10543-98 GOST 19249-73 GOST 21449-75 GOST 5264-80 GOST 9467- 75 GOST 21448 -75 GOST 23178-78 GOST 15164-78 GOST 14806-80 GOST 16038-80 GOST 9087-81 GOST 25445-82 GOST 26271-84 GOST 26101-84 GOST 27580-88 GOST 28915-91 GOST 2246-70 GOST 5.917-71 GOST 5.1215-72 GOST 10051-75 GOST 11533-75 GOST 10052-75 GOST 11534-75 GOST 7871-75 GOST 23518-79 GOST 14776-79 GOST 15878-79 GOST 16037-80 GOST 23949-80 GOST 26467-85 GOST 16130 -90 GOST 30430-96 GOST 30242-97 GOST 30482-97 GOST R 52222-2004 GOST 28555-90 GOST 30756-2001 GOST 14771-76 GOST 9466-75 GOST 8713-79

- gost-5264-80.pdf (873.86 KiB)

GOST 5264-80

GOST 5264–80 Group B05

INTERSTATE STANDARD

MANUAL ARC WELDING. WELDED CONNECTIONS Basic types, structural elements and dimensions Manual arc welding. Welding joints. Main types, design elements and dimensions

MKS 25.160.40 OKP 06 0200 0000

Date of introduction 1981−07−01

By Decree of the USSR State Committee for Standards dated July 24, 1980 N 3827, the introduction date was set from July 1, 1981

The validity period was lifted according to Protocol N 5−94 of the Interstate Council for Standardization, Metrology and Certification (IUS N 11−12−94)

INSTEAD GOST 5264–69

EDITION (November 2009) with Change No. 1, approved in January 1989 (IUS 4−89), Amendment (IUS 9−2009).

1. This standard establishes the main types, structural elements and dimensions of welded joints made of steels, as well as alloys on iron-nickel and nickel bases, performed by manual arc welding. The standard does not apply to welded joints of steel pipelines in accordance with GOST 16037–80.

2. The main types of welded joints must correspond to those indicated in Table 1.

3. Structural elements and their dimensions must correspond to those indicated in Table 2−54.

Table 1

| Connection type | Shape of prepared edges | Character of the weld | Cross-sectional shape | Thickness of welded parts, mm | Connection symbol | |

| prepared edges | weld | |||||

| Butt | With beaded edges | Unilateral | 1−4 | C1 | ||

| 1−12 | S28 | |||||

| With flange on one edge | 1−4 | NW | ||||

| No beveled edges | C2 | |||||

| Single-sided with removable lining | 1−4 | C4 | ||||

| Single sided with remaining lining | C5 | |||||

| Single-sided locking | 1−4 | C6 | ||||

| Bilateral | 2−5 | C7 | ||||

| No bevel of edges followed by gouging | 6−12 | S42 | ||||

| With one edge beveled | Unilateral | 3−60 | C8 | |||

| Single-sided with removable lining | C9 | |||||

| Single sided with remaining lining | C10 | |||||

| Single-sided locking | C11 | |||||

| Bilateral | C12 | |||||

| With a curved bevel of one edge | 15−100 | C13 | ||||

| With a broken bevel on one edge | C14 | |||||

| With two symmetrical bevels on one edge | 8−100 | C15 | ||||

| With two symmetrical curved bevels on one edge | 30−120 | C16 | ||||

| With two asymmetrical bevels on one edge | 12−100 | C43 | ||||

| With beveled edges | Unilateral | 3−60 | C17 | |||

| Single-sided with removable lining | C18 | |||||

| Single sided with remaining lining | 6−100 | C19 | ||||

| Single-sided locking | 3−60 | S20 | ||||

| Bilateral | S21 | |||||

| With beveled edges followed by gouging | 8−40 | S45 | ||||

| With curved edges | 15−100 | S23 | ||||

| With broken bevel edges | S24 | |||||

| With two symmetrical edge bevels | 8−120 | S25 | ||||

| With two symmetrical curved edge bevels | 30−175 | S26 | ||||

| With two symmetrical broken edges | 30−175 | S27 | ||||

| With two asymmetrical edge bevels | 12−120 | C39 | ||||

| C40 | ||||||

| Angular | With flange on one edge | Unilateral | 1−4 | U1 | ||

| 1−12 | U2 | |||||

| No beveled edges | 1−6 | U4 | ||||

| 1−30 | ||||||

| Bilateral | 2−8 | U5 | ||||

| 2−30 | ||||||

| With one edge beveled | Unilateral | 3−60 | U6 | |||

| Bilateral | U7 | |||||

| With two symmetrical bevels on one edge | 8−100 | U8 | ||||

| With beveled edges | Unilateral | 3−60 | U9 | |||

| Bilateral | U10 | |||||

| Tavrovoe | No beveled edges | Unilateral | 2−40 | T1 | ||

| Bilateral | T3 | |||||

| With one edge beveled | Unilateral | 3−60 | T6 | |||

| Bilateral | T7 | |||||

| With a curved bevel of one edge | 15−100 | T2 | ||||

| With two symmetrical bevels on one edge | 8−100 | T8 | ||||

| 12−100 | T9 | |||||

| With two symmetrical curved bevels on one edge | 30−120 | T5 | ||||

| Overlapping | No beveled edges | Unilateral | 2−60 | H1 | ||

| Bilateral | H2 | |||||

table 2

Dimensions, mm

| Symbol of welded joint | Structural elements | , no more | ||||

| prepared edges of welded parts | weld | Nom. | Prev. off | |||

| C1 | From 1 to 2 | 0 | +0,5 | From to | From to | 2+3 |

| St. 2 to 4 | +1,0 | |||||

______________ * Size for reference.

Table 3

Dimensions, mm

| Symbol of welded joint | Structural elements | , no more | |||

| prepared edges of welded parts | weld | Nom. | Prev. off | ||

| S28 | From 1 to 2 | From to | 0 | +1 | |

| St. 2 to 6 | |||||

| St. 6 to 9 | +2 | ||||

| St. 9 to 12 | +3 | ||||

Table 4

Dimensions, mm

| Symbol of welded joint | Structural elements | , no more | ||||

| prepared edges of welded parts | weld | Nom. | Prev. off | |||

| C3 | From 1 to 2 | 0 | +0,5 | From to | From to | 2+3 |

| St. 2 to 4 | +1,0 | |||||

_____________ * Size for reference.

Table 5

Dimensions, mm

| Symbol of welded joint | Structural elements | , Not more | |||||

| prepared edges of welded parts | weld | Nom. | Prev. off | Nom. | Prev. off | ||

| C2 | From 1.0 to 1.5 | 0 | +0,5 | 6 | 1,0 | ±0,5 | |

| St. 1.5 to 3.0 | 1 | ±1,0 | 7 | 1,5 | ±1,0 | ||

| St. 3.0 to 4.0 | 2 | +1,0 -0,5 | 8 | 2,0 | |||

Table 6

Dimensions, mm

| Symbol of welded joint | Structural elements | , no more | , no more | |||||

| prepared edges of welded parts | weld | Nom. | Prev. off | Nom. | Prev. off | |||

| C4 | From 1.0 to 1.5 | 0 | +0,5 | 6 | 4 | 1,0 | ±0,5 | |

| St. 1.5 to 3.0 | 1 | ±1,0 | 7 | 6 | 1,5 | ±1,0 | ||

| St. 3.0 to 4.0 | 2 | +1,0 -0,5 | 8 | 2,0 | ||||

Table 7

Dimensions, mm

| Symbol of welded joint | Structural elements | , no more | |||||

| prepared edges of welded parts | weld | Nom. | Prev. off | Nom. | Prev. off | ||

| C5 | From 1.0 to 1.5 | 0 | +0,5 | 6 | 1,0 | ±0,5 | |

| St. 1.5 to 3.0 | 1 | ±1,0 | 7 | 1,5 | ±1,0 | ||

| St. 3.0 to 4.0 | 2 | +1,0 -0,5 | 8 | 2,0 | |||

Table 8

Dimensions, mm

| Symbol of welded joint | Structural elements | , no more | |||||

| prepared edges of welded parts | weld | Nom. | Prev. off | Nom. | Prev. off | ||

| C6 | From 1.0 to 1.5 | 0 | +0,5 | 6 | 1,0 | ±0,5 | |

| St. 1.5 to 3.0 | 1 | ±1,0 | 7 | 1,5 | ±1,0 | ||

| St. 3.0 to 4.0 | 2 | +1,0 -0,5 | 8 | 2,0 | |||

Table 9

Dimensions, mm

| Symbol of welded joint | Structural elements | , no more | ± 1 | |||

| prepared edges of welded parts | weld | Nom. | Prev. off | |||

| C7 | 2 | 2 | ±1,0 | 8 | 1,5 | |

| St. 2 to 4 | 9 | |||||

| St. 4 to 5 | +1,5 -1,0 | 10 | 2,0 | |||

Table 10

Dimensions, mm

| Symbol of welded joint | Structural elements | ±1 | ±1 | , no more | , no more | |

| prepared edges of welded parts | weld | |||||

| S42 | From 6 to 8 | 4 | 7 | 10 | 12 | |

| St. 8 to 10 | 6 | 9 | 12 | 14 | ||

| St. 10 to 12 | 8 | 11 | 14 | 16 | ||

Table 11

Dimensions, mm

| Symbol of welded joint | Structural elements | |||||

| prepared edges of welded parts | weld | Nom. | Prev. off | Nom. | Prev. off | |

| C8 | From 3 to 5 | 8 | ±2 | 0,5 | +1,5 -0,5 | |

| St. 5 to 8 | 12 | |||||

| St. 8 to 11 | 16 | |||||

| St. 11 to 14 | 20 | |||||

| St. 14 to 17 | 24 | ±3 | +2,0 -0,5 | |||

| St. 17 to 20 | 28 | |||||

| St. 20 to 24 | 32 | |||||

| St. 24 to 28 | 35 | |||||

| St. 28 to 32 | 38 | |||||

| St. 32 to 36 | 41 | |||||

| St. 36 to 40 | 44 | |||||

| St. 40 to 44 | 49 | ±4 | ||||

| St. 44 to 48 | 53 | |||||

| St. 48 to 52 | 56 | |||||

| St. 52 to 56 | 60 | |||||

| St. 56 to 60 | 64 | |||||

Leg in welding joint

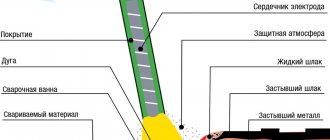

A seam is a zone of fusion between two parts. Here there is a gain formed by the electrode material. It's called surfacing.

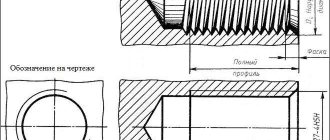

To understand what a weld leg is, it is necessary to imagine a cross section of a corner joint. The surfacing on it has the shape of an isosceles triangle with a convex or concave base.

The sides are straight and adjacent to the surfaces of the parts being welded. The length of each of them is the leg of the fillet weld.

This parameter characterizes:

- Structural strength. With an increase in the size of the reinforcement, and therefore its legs, the volume of surfacing and the area of its contact with the parts increase. Accordingly, the resistance of the connection to loads increases.

- Seam quality. If the technology is followed, both sides are equal. Failure to comply with this condition indicates a deviation of the arc to the side, as a result of which one of the workpieces is held weakly. For this reason, the strength of the structure decreases.

In mass production, it is necessary to ensure the required minimum leg in order not to weaken the product and at the same time to avoid waste of materials and energy. This will reduce the cost of production without compromising its strength characteristics.

Correct setting of the welding machine

The operating mode is determined by 3 parameters:

- tension;

- current strength;

- speed of electrode movement.

Setting up the device consists of selecting their optimal values.

The following factors influence this:

- Workpiece thickness.

- Material.

- Type of seam.

The parameters are selected experimentally, acting in the following sequence:

- Take an unnecessary fragment from the same material as the workpieces that need to be welded.

- Clean it with a grinder to a metallic shine.

- Set the voltage on the machine to 15-20 V and the welding current to 100 A.

- Light the arc and, by gradually adjusting the parameters, achieve stable combustion with good penetration depth.

- Record the optimal settings in writing or by taking photographs.

- Smoothly reduce the current until the arc goes out. Record the amperage at which this occurred.

- Return the regulator to 100 A, ignite the arc again and increase the current to the highest value. He is also recorded.

- Reduce the voltage by 0.5 V and determine the minimum and maximum current in the same way. Repeat this action several times, each time reducing the voltage.

- Return to optimal settings.

- In the same order, determine the upper and lower current limits, increasing the voltage several times in 0.5 V increments.

We recommend reading: How to calculate the strength of a weld

Points 6-10 of the instructions allow you to determine the extreme points of the range within which the device can be adjusted before working with other workpieces.

When setting up a semi-automatic machine, the feed rate of the filler rod is selected depending on the current strength: the greater the amperage, the faster the material should flow.

Types of seams and joint geometry

The connected parts are oriented relative to each other in different ways.

Depending on this, there are 3 types of seams:

- Stykova. The parts are located in the same plane, the ends of their walls abut one another.

- Overlapping. The seam is used with the same arrangement of parts, if their small thickness (less than 8 mm) does not allow the use of the butt option. The elements are placed one on top of the other with an overlap of 2 mm and welded on both sides along the edge.

- Angular. It is used in cross-shaped, L- and T-shaped joints. Parts may be positioned at a deviation from a right angle, for example, a cross-shaped connection of the form “X” instead of “+”.

We recommend reading Features of an overlap welding joint

There are frontal and flank lap joints. The first is performed by welding the applied part along the end edge, the second - along the side edges on both sides.

Weld parameters.

In addition to the leg, the geometry of the weld is characterized by a number of parameters.

The main ones are:

- Width. Maximum horizontal size.

- Height. The same goes vertically.

- Convexity or concavity. Distance from the surface of the parts to the highest point of deposition.

- Penetration depth. The vertical distance from the surface of the parts to the bottom point of the molten metal.

The deep part of the seam is called the root. It is adjacent to unmolten metal. Boiling the root is the most critical stage when joining massive pieces. Seams in such structures are made in several approaches.

First, the root is formed, trying to weld the edges evenly and without defects with an electrode with a diameter of 3 mm. Then the thicker ones are reinforced with the required volume.

Weld length.

Consequences of incorrect leg calculations

Errors lead to the following results:

- To a lesser extent. The strength of the seam does not correspond to the design. When exposed to workload, the connection fails.

- On the big side. Materials and energy are used irrationally. The cost of a product or structure increases unjustifiably. This is especially true in mass production. Annual losses can amount to hundreds of thousands of rubles.

In a one-time production of a small-sized structure that is not subject to heavy loads, deviations in one direction or another are not critical. In this case, the seam leg can be selected approximately.

A large structure, under load from a large dead weight and heavy mechanisms, requires a different approach.

Leg and other parameters of welds are calculated with great accuracy and in accordance with GOST requirements. Otherwise, the structure may collapse.

Application area

T-welds can most often be found in tall metal structures, where it is necessary to create various beams with floors, when welding barriers, creating bodies and frames of metal products, and so on. It is very widely used in professional activities. It is not always possible to find it in the domestic sphere, since due to the difficulty of creating it, people try to avoid it, although a welder even with average experience will be able to make a quite high-quality connection. Often T-joints are made to strengthen the structure with additional planks, beams and other elements, which are much simpler and easier to fasten exactly perpendicularly. This can be done both during the initial assembly of the metal structure and during subsequent repairs and additions.

Influence of welding speed and mode

There is a dependence of the weld cross-section configuration on the process parameters:

- As the current increases at a constant voltage, the temperature increases, so the penetration depth becomes greater. But with excessive amperage, metal can be burned.

- An increase in voltage at a constant current leads to an increase in the length. If there is an excess, lack of penetration is possible.

- As the speed of movement of the electrode increases, the heating temperature of the metal decreases. The seam width and penetration depth are reduced. At speeds above 50 m/h, the lack of temperature leads to the formation of defects that make the seam weak.

- The viscosity of the electrode material affects the shape of the amplification. The higher it is, the more convex the surfacing becomes.

We recommend reading How quality control of welded joints is carried out

The welding mode is selected according to the workpiece with the smallest thickness, so as not to burn through it.