07/22/2019 Author: VT-METALL

Issues discussed in the material:

- What are the main advantages and disadvantages of arc welding

- What are the advantages and disadvantages of different arc welding techniques?

- How to minimize the disadvantages of arc welding

One of the widely used methods for joining metal surfaces is arc welding. The essence of this technology is that the thermal energy required to melt the joined edges of metal surfaces using an electrode is obtained through the action of direct or high-frequency current. Let us dwell in more detail on the advantages and disadvantages of arc welding.

general information

This method has additional international names; abbreviations are widely used in the manufacture of components. You can find - MMA (Manual Metal Arc - the literal translation of our term), the Russian abbreviation RDS, or in short - RD. The method was invented by Russian engineer Nikolai Bernardos, who subsequently improved his device and created varieties. The patent for the invention was purchased and introduced into the production of metal structures around the world. The classic material is a carbon electrode, but there are new inventions, methods that use melting rods.

Stages of the procedure

All professional and amateur welders operate according to the following algorithm:

- Preparation involves thoroughly cleaning all surfaces and securing the workpiece in the workplace.

- The appearance of an arc. For it to form, you need to apply voltage and touch the metal with the tip 2-3 times with quick movements.

- Carrying out a seam - speed and angle varies depending on the physical characteristics of the material.

- Final processing - unevenness should be removed, excess scale should be removed, and the joint should be cleaned.

Sometimes additional operations are required, such as preheating the workpiece or supplying shielding gas. However, the main elements of the algorithm are reflected correctly.

What it is?

Arc welding (go to service) is the process of joining parts using an electrical discharge in a gas, called an “arc.” It is obtained between two electrodes when the voltage is increased to a certain level.

The arc mechanism consists of an anode and cathode, an arc column, and transition regions. In the working area, the temperature can reach up to 7000 °C (above the melting point of all metals used in industry), which makes the technology highly efficient and in demand.

Operating principle of equipment and technology of manual arc welding

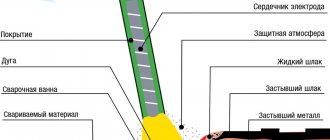

From the power source, alternating or direct current is supplied to the electric holder (both options are found). The voltage allows you to create an electric arc that heats two metal surfaces. When the handle moves behind the conductor, a weld pool is formed. In this area, diffusion joining of molten alloys occurs. After they cool, the substance crystallizes and again turns into a solid element - already monolithic. To prevent the seam from oxidizing under the influence of oxygen, the wire in the electrode is coated with a special compound, which, when melted, releases an inert gas that displaces O2.

How is RDS done?

The electric arc is maintained by the supplied current. In this case, different polarities are possible. The classic option is that a minus is applied, and a plus is supported on the workpiece, but a situation occurs with the opposite supply of voltage. Electric arc length is the distance between the weld pool and the electrode. It depends on the speed of the electrical holder. In addition to the gas from the conductor coating, slags are formed in the area of iron smelting, which contribute to:

- increasing the speed of metal processing;

- longer maintenance of high temperature;

- good, even welded joint;

- protection from oxygen and oxidation.

How to strike an arc

It is necessary to lightly touch the workpiece with the end of a vertically directed electrode 2-3 times. If you do not quickly remove your hand, sticking will occur and the surface will be damaged. The second method for manual electric arc welding is to move the end of the material along the future seam. Let's watch the training video:

How to move a weld correctly

You can cook it at an angle “back” and “forward”, that is, towards yourself and away from you. In the first case, the heating of the alloy is stronger, and in the second, less. That is, you should make a choice depending on the material. The angle of inclination is selected in accordance with the formed weld pool. The length of the electric arc should always be the same - about 2-3 mm. Depending on the required strength of the structure and the alloy used, you can choose one of the types of electric arc welding motion, the diagrams of which are presented in the article.

How does electric welding work?

To obtain the necessary heat, which allows the melting of the base metal and the electrode rod, it is customary to use the method of forming an electric arc. Melts of metals, both base and electrode, are combined in a special welding container, resulting in solidification and formation of a weld . The electrode element is made of steel and treated with a special coating, which protects the bath itself during the melting process. A layer of slag and gas cloud acts as such protection, which prevents the penetration of nitrogen and other gaseous substances in the air.

To maintain the effect of the electric arc, the electrode and the element being welded are constantly exposed to electrical energy from a special device. Under the influence of the temperature of the electric arc, the edges of the workpiece being welded (together with the metal of the electrode) begin to melt. Temperatures inside the arc reach 4000 degrees Celsius. In such a container, the metal workpiece is connected to the electrode. In turn, the molten slag floats to the surface, creating the required protection. To obtain the necessary electrical energy, a special transformer is used.

Safety in MMA

Always wear a protective suit and shoes with strong toes and thick soles. Never start working in flip-flops or with any parts of your body exposed. You should also wear special welding gloves - quite sensitive to movement, but well protective. Be careful with your eyes and always wear welding goggles or a visor. Prepare your work area thoroughly and remove flammable items. Always have a fire extinguisher and a first aid kit nearby, as the activity is associated with risks.

Consumable electrodes used in the manual arc welding process

All conductors on sale can be divided into:

- Fusible. Their core melts and is added to the molten metal of the two workpieces and remains in the weld. It is coated with flux powder that is effective for creating a gas atmosphere.

- Infusible. Made from tungsten and used exclusively to supply current. Gas for the bath is supplied by a special hose.

Another difference is the cross-section diameter. The larger it is, the higher the current strength and the wider the maximum seam. More details in the video:

Filler wire - what is it?

Another variety. In essence, this is a large coil of material (aluminum, copper), which performs the same functions as a fusible electrode, that is, it conducts current and at the same time is a material for forming a connection between structural elements. The difference is the absence of sprinkling, so gas must be supplied from the outside. The second option is to sprinkle flux powder along the seam formation.

Advantages and disadvantages

Pros:

- ease of use, it is not necessary to fix the part to the floor, you can even work in weight;

- installation does not take up much space;

- it is possible to combine different alloys;

- can be moved to another place, taken with you in the car;

- ease of use - you can easily teach the basics of electric arc welding technology.

Minuses:

- Contact with gas and bright flashes of light negatively affect the health of the welder.

- A good, even seam will only be achieved after long experience and the ability to work with various materials.

- Quite a labor-intensive and lengthy process.

Let us conclude that the RDS for welders is a device that is more suitable for work at home and in small industries.

Minuses

Now let's go from the opposite - if arc welding (MMA) was such an excellent tool, engineers would not have come up with so many varieties of welding machines. It's all about the shortcomings that this equipment, like any other, also has. Here are the most important:

- Poor performance. Perhaps this is enough for small workshops, but in serious production conditions such low activity is not perceived as anything other than a disadvantage.

- The need to remove slag and fluxes from the surface being treated. An important side effect is that the resulting seam is not ideal - some of the material is still baked into it, and such inclusions must be removed.

- Harmfulness of work. Arc welding (MMA) can cause various occupational diseases or even injuries, so its use requires, at a minimum, the mandatory presence of a protective suit and compliance with safety regulations.

Now that the reader knows everything, he will be able to make his own choice and decide whether he should buy arc welding (MMA) to solve his problems.

Methods of manual arc welding of metal: welding work in different positions

This is one of the biggest advantages of installing an RDS because the worker can be in any relationship with the surfaces being welded. You will get a good connection if you adhere to certain technical standards.

Bottom position

The most common one. The workpiece lies on the floor or a low table, the person is on top. Fasten the parts well and ensure that the bath forms smoothly and evenly.

Vertical

Due to attraction, the molten metal will tend to drain, and smudges may form. It is easier to work from top to bottom, but it is better the other way around, since drops of hot material will cover the finished, hardened seam.

Ceiling

Work must be done very slowly, making periodic intervals. This way the alloy will have time to cool and crystallize so as not to drip down. This also contributes to additional heating.

pros

The main argument, which is understandable even to a person who has absolutely no knowledge of welding, is that people still have not come up with something that has definitely pushed arc welding (MMA) out of the market. But the technology really came into being back in the century before last! Therefore, this is a really good thing, and its main advantages are:

- High practicality. Thanks to replaceable electrodes, any type of steel can be welded using arc welding (MMA), which is very profitable and convenient. For example, Telwin welding machines work with steel, cellulose, aluminum, cast iron, alkali, rutile and stainless steel electrodes. They can also work with both alternating and direct current, which makes them almost universal in welding.

- High efficiency. Such equipment is probably the cheapest to operate - it does not consume too much electricity or a significant number of consumables.

- No gas cylinders. Compared to semi-automatic welding machines, this is very convenient, because there is no need to buy and transport expensive and heavy cylinders, which, among other things, are also explosive.

- Welding in all positions. When using arc welding (MMA), there is no such problem when it is necessary to turn the parts being welded over and secure them at a special angle required by the device - this design works in any position, which means it is applicable in all situations.

- Compactness and low weight - in the case of welding inverters. You can hang the welding inverter on your shoulder and climb with it into places where it is impossible to climb with a large machine, even into remote corners of a construction site. For example, MMA BISON welding inverters weigh from 5 kg and are equipped with a comfortable handle and carrying strap.

- Availability of development. Thanks to the numerous features that manufacturers come up with, even beginners who are not experienced in this matter can easily start working with arc welding. For example, one of the problems that a novice welder encounters is igniting the arc. To solve this problem, Blue Weld welding machines have a quick start function - Hot Start. To solve the problem of arc sticking, Fubag welding machines are equipped with an anti-stick function - Antistick - when when the electrode comes into contact with metal, smart electronics stops the supply of welding current and makes sticking impossible. And to avoid even the possibility of sticking, Resanta arc welding machines are equipped with an arc force function - Arc Force, when the inverter increases the welding current for a very short period of time, which sharply reduces the likelihood of electrode sticking. In fact, many manufacturers equip their devices with similar functions; you just need to carefully study the characteristics of the device or consult the seller.

It looks great, and yet this technique is criticized for something. For what?

Electric arc

This term refers to a prolonged discharge of current that creates high temperatures. In fact, this is the combustion of gases, which under normal conditions do not transfer electrons and ions so intensively. It is triggered by electron emission - the release of a negatively charged particle at the moment of contact between the electrode and the metal.

The influence of welding arc welding on the quality of the seam

The shorter the distance, the smoother the connection - without drops or leaks. But it is very difficult to hold a few millimeters. Also, a short electric arc with the correct manual arc welding process leads to:

- uniform melting of the coating;

- an even beam of sparks;

- sufficient penetration depth;

- lack of oxidation.

The parameter can be determined by the sound - if it is uniform, without clicks or glitches, then you should strive to maintain this distance.

Electrode marking

The quality of welds and the strength of the connection are decisively influenced by the correct selection of electrodes. The manufacturer indicates the description, characteristics, and markings on the packaging. From the information posted, you can find out what metals are connected with these electrodes, the preferred spatial arrangement, the diameter of the rods, and the composition of the coating.

The marking is located after the name, brand in the form of a sequence of letters and numbers. The first letter indicates the purpose of the electrodes:

- U - for connecting parts made of medium-carbon steel with a low content of alloying additives;

- T - for welding heat-resistant alloy steel;

- N - for surfacing;

- A - for welding plastic metal compositions.

The second letter indicates the thickness of the coating: M - thin layer, C - medium layer thickness, D - thick layer, G - very thick coating. The third letter is the rod type; For consumable electrodes, use the letter E.

The numbers after the first three letters indicate the mechanical properties of the connection: tensile strength under tensile load, relative elongation. They are important for specialists performing critical connections.

The properties of the coating are indicated by the following letters:

- A - acid coating;

- B - basic (alkaline) coating (UONI-13/45);

- C—cellulose coating layer;

- R - rutile (ANO-4).

The last digits of the marking indicate the preferred spatial position of the electrodes during the welding process and the characteristics of the welding current.

Influence of the mode on the seam

When working with different surfaces, you should arrange the elements differently and weld the ends, straight cuts, sections, etc. But this should not force you to change hardware settings. The choice of mode depends solely on the width and depth of penetration you need. The table will help you choose:

| Metal thickness, mm | Current strength, A | Electrode diameter, mm |

| 3 | 175 — 185 | 3 |

| 5 | 200 — 225 | 4 |

| 7 | 250 — 270 | 5 |

| 10 | 300 — 330 | 6 |

Impact of current

The higher the indicator, the deeper the metal melts, the stronger the connection. But at the same time its breadth decreases. The type of equipment used also matters, whether it operates on alternating or direct electricity. In the first case, the connecting section will be narrower.

How to choose a welding machine

The choice of welding equipment is completely determined by the purposes and conditions of use. For household needs, the manufacture of simple structures, and the repair of agricultural machinery, an inexpensive device of medium power is quite sufficient.

Lightweight, efficient inverters have replaced bulky, heavy welding transformers.

When choosing a specific model, pay attention to the following characteristics:

- Device power; the maximum value is not of great importance, since the thickness of the workpieces does not exceed 5 mm; the lower limit should be as small as possible; it allows you to weld very thin sheet metal;

- In terms of functionality, semi-automatic devices and two-in-one devices are approximately the same;

- It is better to choose a model from a well-known brand; the product is more expensive, but it is more reliable and of better quality; well-known manufacturers provide maintenance and repairs;

- The quality of the connection depends on the experience and skill of the welder, and not on the cost of the equipment; You definitely shouldn’t buy the most expensive device.

Manual arc welding basics training

To become a professional manual arc welder, you must undergo training at a technical school. A professional worker has a rank that characterizes his ability to work with various materials and complex structures. But for home use, just read our article and watch the video:

On the site you can learn about other properties of metals, as well as find a wide range of equipment for band sawing. Go to our catalog to find out more. To clarify the information you are interested in, contact our managers by phone;; 8. They will answer all your questions.

How to learn the basics of craftsmanship

Learning the basic intricacies of manual welding is not difficult. Currently, you can find a lot of detailed material and video tutorials for this, which are freely available. True, if you intend to comprehend the deeper subtleties, you will have to stock up on serious sources of information, which are available in various manuals and additional guidance.

If you are a beginner and are just beginning to understand the intricacies of this skill, start with electrodes with a diameter of 3 mm, as they are considered the most popular. Thinner models are intended for welding thin metal, while thicker products require a powerful machine. Weak devices simply cannot cope with the task and do not provide the expected performance for successful work.

When purchasing a welding machine, be prepared to spend enough effort and time to learn all the basics of electric or manual welding. In this case, you will discover extensive possibilities for the practical use of equipment in domestic construction, repairing garden accessories, assembling and disassembling metal structures and in many other areas of everyday activity.

If you approach your training correctly, you can quickly and effectively learn a new industry, gaining theoretical and practical skills to work productively with metal workpieces.