Substance density table

A table is presented of the density of substances at temperatures of 5...30°C. The following substances were considered:

- metals and alloys;

- Construction Materials;

- plastics and rubber;

- rocks and minerals;

- food products;

- various glasses;

- wood of various species.

The table contains more than 500 substances and materials , predominantly in the solid state. The density of solids in the crystalline and amorphous states is characterized by the packing density of their molecules and atoms and is generally determined by the ratio of the mass of the substance to the volume it occupies.

The density in the table is given mainly for solid dry substances (unless otherwise indicated) in the dimension kg/m3. The density of substances in other states of aggregation can be found in the table of the density of liquids, and also study the table of the density of gases and vapors.

For ease of use, the substances in the table are arranged in alphabetical order. Moreover, in verbose names, as a rule, the noun is placed first, followed by a qualifying adjective, for example, “freshly cut oak.” Exceptions include common or compound names such as “asphalt concrete.”

For some substances, the table shows bulk density - the mass per unit volume of loosely poured material, for example - bulk hemp seeds, soil.

Bulk density depends on the size of the material grains, their shape and degree of compaction. Thus, the bulk density of crushed stone and gravel, depending on the size of the granules, can change by 5...10%, and when compacted, the density of these substances increases by 5...15%. Substance density table

| Substance (material) | Density, kg/m3 |

| Abs plastic | 1030…1060 |

| Aggloporite concrete and concrete based on fuel (boiler) slags | 1000…1800 |

| Acrylic (acrylic glass, polymethyl methacrylate, plexiglass) | 1100…1200 |

| Alfol | 20…40 |

| Alumel | 8480 |

| Aluminum | 2700 |

| Aminoplasty | 1450…1500 |

| Arbolit on Portland cement | 300…800 |

| Asbestos in backfill | 300…800 |

| Fibrous asbestos | 470 |

| Asbestos concrete | 2100 |

| Asbestos paper | 800…900 |

| Asbestos felt | 200…300 |

| Asbestos cement | 1500…1900 |

| Asbestos cement sheet | 1600 |

| Asbozurite | 400…650 |

| Asbestos cardboard | 900…1250 |

| Asbomica | 450…620 |

| Asbotekstolit G | 1500…1700 |

| Asbothermite | 500 |

| Rigid asbestos plywood | 1700…1900 |

| Soft asbestos plywood | 1400 |

| Felt asbestos cement | 144 |

| Asboshifer | 1700…2100 |

| Asboshifer with 10-50% asbestos | 1800 |

| Asphalt | 1100…2110 |

| Asphalt in floors and screeds | 1800 |

| Cast asphalt | 1500 |

| Asphalt concrete | 2000…2450 |

| Acetal (polyacetal, polyformaldehyde) POM | 1400 |

| Airgel Aspen aerogels | 110…200 |

| Basalt | 2600…3000 |

| Bakelite | 1250 |

| Balsa | 110…140 |

| Boehmite (roofing material) | 570 |

| Birch | 510…770 |

| Freshly cut birch | 880…1000 |

| Beryllium | 1840 |

| Large-porous sandless concrete | 1600…1900 |

| Large-porous sandless fire-resistant concrete | 1450…1750 |

| Lightweight concrete on expanded clay | 500…1800 |

| Lightweight concrete with coke | 1200 |

| Lightweight concrete with natural pumice | 500…1200 |

| Concrete on volcanic slag | 800…1600 |

| Concrete on gravel or crushed stone from natural stone | 2400 |

| Concrete based on granulated blast furnace slag | 1200…1800 |

| Concrete on ash gravel | 1000…1400 |

| Concrete on crushed stone | 2200…2500 |

| Concrete on boiler slag | 1400 |

| Concrete on sand | 1800…2500 |

| Concrete based on fuel slag | 1000…1800 |

| Extra heavy limonite concrete | 2800…3000 |

| Extra heavy magnetite concrete | 2800…4000 |

| X-ray protective concrete based on natural lump barite | 3000…3100 |

| X-ray protective concrete based on pulverized barite | 2500…2600 |

| Dense silicate concrete | 1800 |

| Thermal insulating concrete | 500 |

| Bitumen perlite | 300…400 |

| Petroleum bitumens for construction and roofing | 1000…1400 |

| Aerated concrete block | 400…800 |

| Lime-sand block | 1450…1600 |

| Bulk steel bolts | 1430…1670 |

| Coal briquettes | 1050 |

| Bronze | 7500…9300 |

| Rutabagas in bulk | 650…850 |

| Beech | 600…700 |

| Freshly cut beech | 970…1000 |

| Paper | 700…1150 |

| Booth | 1800…2000 |

| Vanadium | 6500…7100 |

| Light mineral wool | 50 |

| Heavy mineral wool | 100…150 |

| Glass wool | 155…200 |

| Cotton wool | 30…100 |

| Cotton wool | 50…80 |

| Slag wool | 200 |

| Vermiculite (in the form of bulk granules) | 100…200 |

| Vermiculite concrete | 250…1200 |

| Viniplast | 1350…1400 |

| Vinipor hard | 200 |

| Construction felt in bales | 300 |

| Woolen felt | 150…330 |

| Acetate fiber (cellulose acetate) | 1300…1350 |

| Viscose fiber (hydrocellulose) | 1500…1540 |

| Tungsten | 19250 |

| Beeswax | 950 |

| Freshly cut elm | 1000 |

| Structural aerated concrete | 1100…1200 |

| Thermal insulating aerated concrete | 400…700 |

| Gas gypsum | 400…600 |

| Gas silicate | 280…1000 |

| Gas glass | 200…400 |

| Pebbles | 1800…1900 |

| Getinax | 1350 |

| Dry molded gypsum | 1100…1800 |

| Gypsum concrete on granulated blast furnace slag | 1000 |

| Gypsum concrete on boiler slag | 1300 |

| Drywall | 500…900 |

| Plaster (slabs) | 1400…1600 |

| Gypsum slag | 1000…1300 |

| Clay in the form of dough | 1600…2900 |

| Fireproof clay | 1800 |

| Clay gypsum | 800…1800 |

| Alumina | 3100…3900 |

| Gneiss (facing) | 2800 |

| Freshly cut hornbeam | 995 |

| Gravel (filler) | 1850 |

| Expanded clay gravel (backfill) | 200…800 |

| Shungizite gravel (backfill) | 400…800 |

| Granite (cladding) | 2600…3000 |

| Powdered graphite | 445 |

| Soil 20% water | 1700 |

| Soil in embankments | 1600…1800 |

| The soil is silty, dry | 1600 |

| The soil is marly | 1700 |

| The soil is dry | 1500 |

| Pear (wood) | 730 |

| Tar | 950…1030 |

| Gamboge | 1200 |

| Dacryl | 1190 |

| Dinas in refractory products | 1700…1900 |

| Dense dry dolomite | 2800 |

| Birch firewood | 500 |

| Softwood firewood | 350…450 |

| Oak | 700 |

| Freshly cut oak | 1000…1030 |

| Duralumin | 2600…2900 |

| Freshly cut spruce | 800…850 |

| Iron | 7870 |

| Reinforced concrete | 2500 |

| Vibrated reinforced concrete on crushed limestone | 2450 |

| Reinforced concrete on expanded clay | 1500…1800 |

| Reinforced concrete on pumice | 1100…1500 |

| Reinforced concrete | 2400 |

| Acorns in bags | 470…520 |

| Dry pulp in bulk | 200…260 |

| Sand backfill made of hydrophobic sand | 1500 |

| Peat backfill | 150 |

| Slag backfill | 700…1000 |

| Wood ash | 780 |

| Coke ash | 750 |

| Gold | 19320 |

| Limestone (cladding) | 1400…2000 |

| Limestone is dense | 2400…2900 |

| Limestone is porous | 2000…2100 |

| Vulcanite products | 350…400 |

| Diatomite products | 500…600 |

| Products made from expanded perlite with a bitumen binder | 300…400 |

| Newelite products | 160…370 |

| Foam concrete products | 400…500 |

| Perlite phosphogel products | 200…300 |

| Sovelite products | 230…450 |

| Invar | 7900 |

| Iporka (foamed resin) | 15 |

| Cocoa beans in bags | 250…340 |

| Coal dust | 730 |

| Hard rock curb stone | 2000…2300 |

| Porous ceramic stone Braer | 810…840 |

| Building stone | 2200 |

| Gypsum concrete stones | 1100…1500 |

| Hollow-core stones made of lightweight concrete | 500…1200 |

| Solid stones made of lightweight concrete DIN 18152 | 500…2000 |

| Solid stones made from natural tuff or expanded clay | 500…2000 |

| Rosin | 1070 |

| Kaolin powder | 520 |

| Kaprolit | 1200 |

| Kaprolon | 1150 |

| Capron (polycaprolactam) | 1140 |

| Carbolite black | 1100 |

| Asbestos insulating cardboard | 720…900 |

| Corrugated paper cardboard | 150 |

| Corrugated cardboard | 700 |

| Cardboard facing | 1000 |

| Thick cardboard | 600…900 |

| Cork cardboard | 145 |

| Multilayer construction cardboard | 650 |

| Thermal insulating cardboard | 500 |

| Foamed rubber | 82 |

| Vulcanized rubber soft gray | 920 |

| Natural rubber | 910 |

| Fluorinated rubber | 180 |

| Crushed quartz | 1450…1600 |

| Red cedar | 500…570 |

| Expanded clay | 800…1000 |

| Lightweight expanded clay concrete | 500…1200 |

| Expanded clay concrete on quartz sand with porosity | 800…1200 |

| Expanded clay concrete on expanded clay sand and expanded clay foam concrete | 500…1800 |

| Expanded clay concrete on perlite sand | 800…1000 |

| Expanded clay peas | 900…1500 |

| Ceramics | 1700…2300 |

| Asbozurite brick | 900 |

| Diatomaceous brick | 500 |

| Blast-furnace brick (fire-resistant) | 1000…2000 |

| Carborundum brick | 1000…1300 |

| Clinker brick | 1800…2000 |

| Red dense brick | 1700…2100 |

| Red porous brick | 1500 |

| Facing brick | 1800 |

| Silicate brick | 1000…2200 |

| Construction brick | 800…1500 |

| Treble brick | 700…1300 |

| Slag brick | 1100…1400 |

| Masonry "Poroton" | 800 |

| Rubble masonry made of medium-density stones | 2000 |

| Gas silicate masonry | 630…820 |

| Masonry made of gas silicate thermal insulation boards | 540 |

| Masonry of ordinary clay bricks on cement-perlite mortar | 1600 |

| Masonry of ordinary clay bricks on cement-slag mortar | 1700 |

| Masonry of ceramic hollow bricks with cement-sand mortar | 1000…1400 |

| Small brick masonry | 1730 |

| Masonry made of hollow wall blocks | 1220…1460 |

| Masonry made of 11-hollow silicate bricks with cement-sand mortar | 1500 |

| Masonry made of 14-hollow silicate bricks with cement-sand mortar | 1400 |

| Sand-lime brick masonry with cement-sand mortar | 1800 |

| Triple brick masonry with cement-sand mortar | 1000…1200 |

| Slag brick masonry with cement-sand mortar | 1500 |

| Cellular brick masonry | 1300 |

| Maple | 620…750 |

| Freshly cut maple | 1000 |

| Cobalt | 8900 |

| Faux leather in rolls | 1300 |

| A natural skin | 800…1000 |

| Mine coke | 380…530 |

| Peat coke | 275…400 |

| Kopel | 8900 |

| Bonfire | 100…200 |

| Ivory | 1830…1920 |

| Raw coffee beans in bags | 440…670 |

| Oil paint (enamel) | 1030…2045 |

| Starch packed in bags | 590…750 |

| Silicon | 2000…2330 |

| Organosilicon polymer KM-9 | 1160 |

| Buckwheat | 720 |

| Pearl barley | 810…830 |

| Millet groats 1st grade | 825 |

| Rice groats | 830 |

| Barley groats | 670 |

| Xylolite (magnolite) | 1000…1800 |

| Lavsan (polyethylene terephthalate, PET) | 1380 |

| Brass | 8100…8850 |

| Ice 0°C | 917 |

| Ice -20°С | 920 |

| Ice -60°C | 924 |

| Polyvinyl chloride multilayer linoleum | 1600…1800 |

| Polyvinyl chloride linoleum on a fabric base | 1400…1800 |

| Linden (15% humidity) | 320…650 |

| Freshly cut linden | 795 |

| Larch | 670 |

| Freshly cut larch | 840 |

| Asbestos-cement flat sheets | 1600…1800 |

| Gypsum cladding sheets (dry plaster) | 800 |

| Lightweight cork sheets | 220 |

| Heavy cork sheets | 260 |

| Lithium | 530 |

| Onions in bags | 400…480 |

| Caustic magnesite | 800…900 |

| Magnesia in the form of segments for pipe insulation | 220…300 |

| Magnesium | 1740 |

| Manganin | 8400 |

| Manganese | 7400 |

| Asphalt mastic | 2000 |

| Bitumen mastic | 1350…1890 |

| Stitched glass fiber mats and strips | 150 |

| Mineral wool mats, stitched and with a synthetic binder | 50…125 |

| Basalt mats, canvases | 25…80 |

| MBOR-5, MBOR-5F, MBOR-S-5, MBOR-S2-5, MBOR-B-5 | 100…150 |

| Copper | 8940 |

| Chalk | 1800…2800 |

| Powdered chalk (ground) | 950…1200 |

| Mikanite | 2000…2200 |

| Mipora | 16…20 |

| Molybdenum | 10300 |

| Morozin | 100…400 |

| Marble (cladding) | 2800 |

| Premium wheat flour | 680…900 |

| Boiler scale (rich in lime) | 1000…2500 |

| Boiler scale (rich in silicate) | 300…1200 |

| Deck flooring | 630 |

| Sodium | 967 |

| Nylon | 1300 |

| Nickel | 8900 |

| Niplon | 1320 |

| Nichrome | 8400 |

| Tin | 7300 |

| Freshly cut alder | 800…830 |

| Wood sawdust | 200…400 |

| Tow | 120…160 |

| Gypsum wall panels according to DIN 1863 | 600…900 |

| Paraffin | 870…920 |

| Oak parquet | 1800 |

| Piece parquet | 1150 |

| Panel parquet | 700 |

| Paronite (gasket material) | 1200 |

| Pumice | 400…700 |

| Pumice concrete | 800…1600 |

| Foam concrete for construction | 600…1200 |

| Heat-insulating foam concrete | 300…500 |

| Foam gypsum | 300…600 |

| Foam ash concrete | 800…1200 |

| Foam plastic MFP-1 | 40 |

| Polystyrene foam PS-1 | 100 |

| Polyfoam PS-4 | 70 |

| Foam plastic PVC-1 and PV-1 | 65…125 |

| Foam resopen FRP-1 | 65…110 |

| Expanded polystyrene | 40…150 |

| Expanded polystyrene "Penoplex" | 35…43 |

| Polyurethane foam | 40…80 |

| Polyurethane foam sheets | 150 |

| Penosilalcite | 400…1200 |

| Foam silicate | 280…1000 |

| Foam glass | 200…400 |

| Lightweight foam glass | 100..200 |

| Penofol | 44…74 |

| Glassine | 600 |

| Reinforced ceramic ceiling with concrete filling without plaster | 1100…1300 |

| Flooring made of reinforced concrete elements with plaster | 1550 |

| Monolithic flat reinforced concrete floor | 2400 |

| Perlite | 200 |

| Expanded perlite | 100 |

| Perlite concrete | 600…1200 |

| Perlitoplast-concrete | 100…200 |

| Perlite phosphogel products | 200…300 |

| Mountain sand | 1500…1600 |

| Sand for construction work | 1600 |

| Ground quartz sand | 1450 |

| Perlite sand | 50…250 |

| Fine river sand | 1500 |

| Fine river sand (wet) | 1650 |

| Sand dry | 1500 |

| Tuff sand | 700…1000 |

| Compacted molding sand | 1650 |

| Slag sand | 800…900 |

| Sandstone | 2200…2700 |

| Burnt sandstone | 1900…2700 |

| Fir | 450…550 |

| Plastic concrete (furfural concrete) | 2000…2500 |

| Platinum | 21450 |

| Pressed paper plate | 600 |

| Fireproof heat-insulating board Avantex brand Board | 200…500 |

| Cork plate | 80…500 |

| Facing tiles, tiles | 2000 |

| Wood-fiber and particle boards | 200…1000 |

| Gypsum slabs | 1000…1200 |

| Expanded clay concrete slabs | 400…600 |

| Polystyrene concrete slabs | 200…300 |

| Resol-formaldehyde foam boards | 40…100 |

| Glass staple fiber boards with synthetic binder | 50 |

| Cellular concrete slabs | 350…400 |

| Reed slabs | 200…300 |

| Flax insulating slabs | 250 |

| Mineral wool slabs with bitumen binder grade 200 | 150…200 |

| Mineral wool slabs with synthetic bond | 170…230 |

| Mineral wool slabs with synthetic binder grade 200 | 225 |

| High-hardness mineral wool slabs | 200 |

| Semi-rigid mineral wool slabs with starch binder | 125…200 |

| Soft and hard mineral wool slabs with synthetic and bitumen binders | 50…350 |

| Foam plastic boards based on resol phenol-formaldehyde resins | 80…100 |

| Expanded polystyrene plates (extrusion) | 32 |

| Perlite-bitumen slabs | 300 |

| Perlite-fiber slabs | 150 |

| Perlite-phosphogel slabs | 250 |

| Construction slabs made of porous concrete | 500…800 |

| Thermobitumen thermal insulation slabs | 200…300 |

| Peat thermal insulation slabs | 200…300 |

| Fiberboard slabs | 300…800 |

| Carpet covering | 630 |

| Synthetic coating (PVC) | 1500 |

| Seamless gypsum floor | 750 |

| Polyamide | 1020…1130 |

| Polyvinyl chloride (PVC) | 1400…1600 |

| Polyisobutylene sheet | 1320…1430 |

| Polycarbonate (Diflon) | 1200 |

| Polypropylene | 900…910 |

| Polystyrene UPP1, PPS | 1025 |

| Polystyrene concrete | 150…600 |

| Modified polystyrene concrete | 200…500 |

| Polyurethane | 1200 |

| Polyvinyl chloride | 1290…1650 |

| High Density Polyethylene | 955 |

| Low density polyethylene | 920 |

| Linen (textile) in pieces | 600 |

| Semi-ebonite M-1751 and M1814 | 1320…1330 |

| Foam rubber | 34 |

| Gunpowder (pressed) | 1750 |

| Gunpowder (loose) | 900 |

| Pressspan | 1000…1500 |

| Granulated technical cork | 45 |

| Mineral cork based on bitumen | 270…350 |

| Cork flooring | 540 |

| Asbestos dust | 400…600 |

| Coal dust | 540…680 |

| Shell rock | 1000…1800 |

| Gypsum grout mortar | 1200 |

| Gypsum perlite solution | 600 |

| Porous gypsum perlite solution | 400…500 |

| Lime-sand mortar | 1400…1600 |

| Lime mortar | 1650 |

| Light solution LM21, LM36 | 700…1000 |

| Complex mortar (sand, lime, cement) | 1700 |

| Cement-perlite mortar | 800…1000 |

| Cement-sand mortar | 1800…2000 |

| Cement-slag mortar | 1200…1400 |

| Cement mortar, cement screed | 2000 |

| Porous rubber | 160…580 |

| Ordinary hard rubber | 900…1200 |

| Turnip | 570…650 |

| Mat | 200 |

| Ruberoid | 600 |

| Rubrax | 1050 |

| Powdered lamp soot | 1900 |

| Salo | 930 |

| Adobe | 1200…1500 |

| Boxwood (10% humidity) | 1000 |

| Granulated sugar in bags | 730…800 |

| Lead | 11370 |

| Bulk hemp seeds | 520…580 |

| Sunflower seeds in bags | 400…440 |

| Sulfur powder | 780 |

| Sulfur rhombic | 2085 |

| Silver | 10500 |

| Sitall | 2500 |

| Slate | 2600…3300 |

| Expanded clay shale | 400 |

| Roofing slate | 1500 |

| Mica along the layers | 2700…3200 |

| Expanded mica | 100 |

| Mica across layers | 2600…3200 |

| Epoxy resin | 1260…1390 |

| Stale snow at 0°C | 400…560 |

| Freshly fallen snow | 120…200 |

| Straw | 50…120 |

| Pressed straw | 250…280 |

| Solomit | 150…400 |

| Table salt | 2200 |

| Pine | 500 |

| Resinous pine 15% humidity | 600…750 |

| Stainless steel, heat-resistant and heat-resistant | 7900…8200 |

| Reinforcing rod steel | 7850 |

| Steel casting | 7800 |

| Stearin | 900 |

| Quartz glass | 2200 |

| Window glass | 2420…2590 |

| Heat-resistant glass | 2200…2400 |

| Flint glass | 3860 |

| Glass wool | 155…200 |

| Fiberglass | 1700…2000 |

| Fiberglass | 1800…2000 |

| Fiberglass | 1600…1900 |

| Pressed wood shavings | 800 |

| Anhydrite screed | 2100 |

| Cast asphalt screed | 2300 |

| Loam | 1600…1700 |

| Wet sandy loam | 1800…2000 |

| Sealing wax | 1800 |

| Talc powder | 870 |

| Textolite sheet | 1300…1400 |

| Termozit | 300…500 |

| Teflon | 2120 |

| Teak (wood 10% moisture content) | 730 |

| Tiss | 750…940 |

| Titanium | 4500 |

| Tol | 500…600 |

| Poplar | 350…500 |

| Raw peat | 550…800 |

| Peat slabs | 275…350 |

| Peat crumb | 300 |

| Tuff (facing) | 1000…2000 |

| Calcareous tuff | 1000…1500 |

| Tufobeton | 1200…1800 |

| Lump charcoal | 190 |

| Gas coal | 1420 |

| Ordinary hard coal | 1200…1350 |

| Bakelite plywood waterproof | 780…850 |

| Plywood | 600…700 |

| Molded faolite | 1500…1700 |

| Porcelain | 2300…2500 |

| Beans in bags | 500…560 |

| Faience | 1940 |

| Clinkstone | 1550 |

| Fiber red | 1450 |

| Fibrolite (gray) | 1100 |

| Gypsum fiberboard | 500…700 |

| Cement fiberboard | 250…600 |

| Phosphorus yellow (waxy mass) | 1820 |

| Phosphorus red (powder) | 2200 |

| Phosphorite | 1270…1600 |

| Fluoroplastic | 1650…1800 |

| Chromium | 7140 |

| Chromel | 8700 |

| Celluloid | 1400 |

| Aluminous loose cement | 1000…1350 |

| Compacted alumina cement | 1600…1900 |

| Hardened cement | 2600…3200 |

| Portland slag cement | 1100…1250 |

| Zinc | 7130 |

| Concrete tiles | 2100 |

| Clay tiles | 1900 |

| PVC asbestos tiles | 2000 |

| Roofing tiles | 1800…2000 |

| Anti-friction cast iron | 7400…7600 |

| White cast iron | 7600…7800 |

| Cast iron is malleable and high-strength | 7200…7400 |

| Gray cast iron | 7000…7200 |

| Fireclay powder | 1350…1500 |

| Shevelin | 100…260 |

| Silk | 100 |

| Slate | 2700…2800 |

| Granulated slag | 500 |

| Blast furnace slag | 2600…3000 |

| Coke slag | 600 |

| Boiler slag | 1000 |

| Open hearth slag | 1700…1800 |

| Peat slag | 600…1000 |

| Cinder concrete | 1120…1500 |

| Slag compacted | 400 |

| Slag pumice concrete (thermosite concrete) | 1000…1800 |

| Slag pumice gas concrete | 800…1600 |

| Gypsum plaster | 800 |

| Polystyrene mortar plaster | 300 |

| Synthetic resin plaster | 1100 |

| Lime plaster | 1600 |

| Lime plaster with stone dust | 1700 |

| Perlite plaster | 350…800 |

| Insulating plaster | 500 |

| Facade plaster with polymer additives | 1800 |

| Cement-sand plaster | 1800 |

| Shungizite concrete | 1000…1400 |

| Crushed granite | 1700…1800 |

| Crushed stone and sand from expanded perlite (backfill) | 200…600 |

| Crushed stone from blast furnace slag, slag pumice and agloporite (backfill) | 400…800 |

| Crushed brick | 1200…1500 |

| Crushed tuff stone | 700…1000 |

| Ebonite | 1140…1210 |

| Expanded ebonite | 640 |

| Ecowool | 35…60 |

| Enanth (polyenantholactam) | 1140 |

| Ensonite (pressed cardboard) | 400…500 |

| Apple tree | 670 |

| Amber | 1100 |

| Ash (humidity 10%) | 700…750 |

Sources:

- Physical quantities. Directory Babichev A.P. et al.; Ed. Grigorieva I.S. - M.: Energoatomizdat, 1991. - 1232 p.

- Enochovich A. S. Handbook of physics. M.: Education, 1978. - 415 p.

- Isachenko V. P., Osipova V. A., Sukomel A. S. Heat transfer. Textbook for universities - M.: Energy, 1975.

- Franchuk A. U. Tables of thermal technical indicators of building materials - M.: Research Institute of Construction Physics, 1969 - 142 p.

- Makarov E.V., Svetlakov N.D. Reference tables of weights of building materials, M., 1971 - 45 p.

- Construction heating engineering SNiP II-3-79. Ministry of Construction of Russia - M., 1995.

- Mikheev M. A., Mikheeva I. M. Fundamentals of heat transfer. Ed. 2nd. M.: Energy, 1977. - 344 p.

- Novichenok N. L., Shulman Z. P. Thermophysical properties of polymers. Minsk: Science and Technology, 1971. - 120 p.

Determination of product mass

All modern reference materials, GOST and technical specifications of enterprises have been adjusted in accordance with the international classification.

Using reference tables of densities of various materials, it is easy to determine their mass. This is especially true when items are heavy or appropriate scales are not available. To do this, you need to know their geometric parameters. Most often, you need to find out the mass of an object in the form of a cylinder, pipe or parallelepiped:

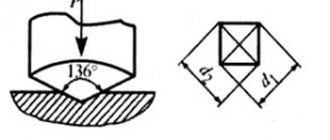

- Metal rods are cylindrical in shape. Knowing the diameter and length, it is easy to find out the mass. Mass equals density times volume. Finding the volume of an object. It is obtained by multiplying the cross-sectional area by the length. The area of a circle, knowing the diameter, is easy to determine. The squared diameter is multiplied by 3.14 (pi), divided by 4.

- We obtain the mass of the pipe in the same way. When finding the area, we take the difference between the outer and inner diameter of the section.

- To determine the mass of a sheet, bloom, slab or bar of rectangular cross-section, we determine the volume by multiplying the length, height and thickness. Multiply by the density from the reference book.

Determination of carat weight

British carats are a traditional value used to measure the purity of gold and its weight in a product. The smallest value is 8 carats (K). The specific gravity of 999 gold is 24 carats. If other elements are added to the alloy to change the characteristics of the metal, the carat value drops. The 18-karat precious metal contains 6 parts of impurities and 18 parts of pure gold.

For example, high-grade 917 gold has a mass of 22 carats. And such a popular 585 alloy is only 14 carats.

Composition and structure of iron

Iron is a typical metal, and it is chemically active. The substance reacts at normal temperature, and heating or increasing humidity significantly increases its reactivity. Iron corrodes in air, burns in an atmosphere of pure oxygen, and in the form of fine dust can ignite in air.

Pure iron is inherently malleable, but the metal is very rare in this form. In fact, iron means an alloy with small proportions of impurities - up to 0.8%, which is characterized by the softness and malleability of a pure substance. Alloys with carbon - steel, cast iron, stainless steel - are important for the national economy.

Iron is characterized by polymorphism: there are as many as 4 modifications, differing in structure and lattice parameters:

- α-Fe – exists from zero to +769 C. It has a body-centered cubic lattice and is ferromagnetic, that is, it retains magnetization in the absence of an external magnetic field. +769 C – Curie point for metal;

- from +769 to +917 C β-Fe appears. It differs from the α phase only in lattice parameters. Almost all physical properties are preserved with the exception of magnetic ones: iron becomes paramagnetic, that is, it loses the ability to magnetize and is drawn into a magnetic field. Metallurgy does not consider the β-phase as a separate modification. Since the transition does not affect significant physical characteristics;

- in the range from 917 to 1394 C there is a γ-modification, which is characterized by a face-centered cubic lattice;

- at temperatures above +1394 C, the δ phase appears, which is characterized by a body-centered cubic lattice.

At high pressure, as well as when the metal is doped with certain additives, an ε-phase with a hexagonal close-packed lattice is formed.

The temperature of phase transitions changes noticeably when doped with the same carbon. Actually, the very ability of iron to form so many modifications serves as the basis for processing steel in different temperature conditions. Without such transitions, the metal would not have become so widespread.

Now it’s time for the properties of the metal iron.

This video tells about the structure of iron: