In the modern world, an important aspect of a private home is its energy efficiency. That is, the ability to spend a minimum amount of energy to maintain a comfortable climate in the house. To spend less energy, you need to take care of reducing energy losses.

Thermal conductivity of materials is the ability of a material to retain heat in cold weather and keep cool in summer.

Heat capacity is the amount of heat absorbed (released) by a body in the process of heating (cooling) per 1 kelvin.

Density is the ratio of the mass of a body to the volume occupied by this body.

General concept of thermal conductivity and its nature

If we answer in simple words the question of what thermal conductivity is in physics, then it should be said that the transfer of heat between two bodies or different regions of the same body is the process of exchange of internal energy between the particles that make up the body (molecules, atoms, electrons and ions). Internal energy itself consists of two important parts: kinetic and potential energy.

What is thermal conductivity in physics in terms of the nature of this quantity? At the microscopic level, the ability of materials to conduct heat depends on their microstructure. For example, for liquids and gases, this physical process occurs due to chaotic collisions between molecules; in solids, the main share of the transferred heat is due to the exchange of energy between free electrons (in metallic systems) or phonons (non-metallic substances), which are mechanical vibrations of the crystal lattice .

Notes

- [dic.academic.ru/dic.nsf/natural_science/14229/FOURIER Natural history. Encyclopedic Dictionary. Fourier's law.]

- D.V.

Sivukhin. General physics course: thermodynamics and molecular physics. - M.: Fizmatlit, 2006. - P. 345. - [ustu.ru/fileadmin/user_upload/kafedra_fiziki/pdf/3b.pdf Study of thermal conductivity of gases.] // Methodological instructions.

- J. C. Maxwell, Philos. Trans. Roy. Soc. London 157

(1867) 49. - C. Cattaneo, Atti Seminario Univ. Modena 3

(1948) 33.

Methods of transferring thermal energy

When considering the question of what the thermal conductivity of materials is, it is worth mentioning possible methods of heat transfer. Thermal energy can be transferred between different bodies through the following processes:

- conductivity - this process occurs without the transfer of matter;

- convection - heat transfer is directly related to the movement of matter itself;

- radiation - heat transfer is carried out due to electromagnetic radiation, that is, with the help of photons.

For heat to be transferred through the processes of conduction or convection, direct contact between different bodies is necessary, with the difference that in the process of conduction there is no macroscopic movement of matter, but in the process of convection this movement is present. Note that microscopic motion occurs in all heat transfer processes.

For ordinary temperatures of a few tens of degrees Celsius, it can be said that convection and conduction account for the bulk of the heat transferred, and the amount of energy transferred by radiation is negligible. However, radiation begins to play a major role in the process of heat transfer at temperatures of several hundred and thousand Kelvin, since the amount of energy Q transferred in this way increases in proportion to the 4th power of absolute temperature, that is, ∼ T4. For example, our sun loses most of its energy through radiation.

Generalizations of Fourier's law

It should be noted that Fourier’s law does not take into account the inertia of the thermal conduction process, that is, in this model, a change in temperature at some point instantly spreads to the entire body. Fourier's law is not applicable to describe high-frequency processes (and, accordingly, processes whose Fourier series expansion has significant high-frequency harmonics). Examples of such processes are the propagation of ultrasound, shock waves, etc. Maxwell was the first to introduce inertia into the transport equations [4], and in 1948 Cattaneo proposed a version of Fourier’s law with a relaxation term: [5]

\tau\frac{\partial\mathbf{q}}{\partial t}=-\left(\mathbf{q}+\varkappa\,\nabla T\right).

If the relaxation time \tau is negligible, then this equation becomes Fourier's law.

Thermal conductivity coefficient for solids

The coefficient of thermal conductivity for solids k has the following physical meaning: it indicates the amount of heat that passes per unit time through a unit surface area in a body of unit thickness and infinite length and width with a temperature difference at its ends equal to one degree. In the international system of SI units, the coefficient k is measured in J/(s*m*K).

This coefficient in solids depends on temperature, so it is usually determined at a temperature of 300 K in order to compare the ability to conduct heat of different materials.

House that captures heat

A properly planned and oriented house is partially capable of accumulating solar heat itself and providing comfortable living, subject to the following conditions:

- Limiting the number or reducing the size of windows facing north;

- The house should be located from east to west;

- It is necessary to plant coniferous trees on the side of the predominant winter winds;

- Make the facade from the south more open; the busiest and most visited rooms should be located there;

- Deciduous trees on the site should not block the winter sun;

- On the south side it is advisable to arrange a canopy from the hot summer sun.

Thermal conductivity coefficient for metals and non-metallic solids

All metals, without exception, are good conductors of heat, the transfer of which into them is carried out by electron gas. In turn, ionic and covalent materials, as well as materials with a fibrous structure, are good thermal insulators, that is, they conduct heat poorly. To fully explain the question of what thermal conductivity is, it should be noted that this process requires the presence of a substance if it is carried out through convection or conduction, therefore, in a vacuum, heat can only be transferred due to electromagnetic radiation.

The list below shows the values of thermal conductivity coefficients for some metals and non-metals in J/(s*m*K):

- steel - 47-58 depending on the steel grade;

- aluminum - 209.3;

- bronze - 116-186;

- zinc - 106-140 depending on purity;

- copper - 372.1-385.2;

- brass - 81-116;

- gold - 308.2;

- silver - 406.1-418.7;

- rubber - 0.04-0.30;

- fiberglass - 0.03-0.07;

- brick - 0.80;

- wood - 0.13;

- glass - 0.6-1.0.

Thus, the thermal conductivity of metals is 2-3 orders of magnitude higher than the thermal conductivity values for insulators, which are a clear example of the answer to the question of what low thermal conductivity is.

Thermal conductivity plays an important role in many industrial processes. In some processes, they try to increase it by using good thermal conductors and increasing the contact area, while in others they try to reduce thermal conductivity by reducing the contact area and using heat-insulating materials.

Concrete materials with the addition of porous aggregates

The thermal conductivity coefficient of the material allows it to be used for the construction of garages, sheds, summer houses, bathhouses and other structures. This group includes:

- Foam concrete. It is produced with the addition of foaming substances, due to which it is characterized by a porous structure with a density of 500-1000 kg/m3. In this case, the ability to transfer heat is determined by the value 0.1-0.37 W/m*K.

- Expanded clay concrete, the performance of which depends on its type. Solid blocks do not have voids or holes. Hollow blocks are made with voids inside, which are less durable than the first option. In the second case, the thermal conductivity will be lower. If we consider general figures, the density of expanded clay concrete is 500-1800 kg/m3. Its indicator is in the range of 0.14-0.65 W/m*K.

- Aerated concrete, inside of which pores measuring 1-3 millimeters are formed. This structure determines the density of the material (300-800kg/m3). Due to this, the coefficient reaches 0.1-0.3 W/m*K.

Convection in liquids and gases

Heat transfer in fluids occurs through the process of convection. This process involves the movement of molecules of a substance between zones with different temperatures, that is, during convection, mixing of a liquid or gas occurs. When fluid matter gives off heat, its molecules lose some of their kinetic energy, and the matter becomes denser. On the contrary, when fluid matter heats up, its molecules increase their kinetic energy, their movement becomes more intense, accordingly, the volume of matter increases and density decreases. That is why cold layers of matter tend to fall down under the influence of gravity, and hot layers try to rise up. This process causes the matter to mix, facilitating the transfer of heat between its layers.

We recommend: Thermocouple for a gas boiler: detailed instructions on the design and principle of operation, checking the serviceability of the thermoelectric sensor with a multimeter, restoration and replacement

Types, properties and applications

According to their purpose, brick is divided into construction, special and facing. The construction type is used for masonry walls, the facing type is used for facade and interior design, and the special type is used for foundations, road surfaces, and the laying of stoves and fireplaces.

Narrower specialization is due to the different structure of products.

Solid brick

It is a solid block with random voids amounting to less than 13%.

Solid bricks are:

Silicate, ceramic - used for the construction of self-supporting walls, partitions, columns, pillars and so on. Solid brick structures are reliable, frost-resistant, and capable of bearing additional loads. The partitions provide good sound insulation with a small thickness and retain a large amount of heat.

In addition, the material is quite decorative and popular with many modern designers. But the high coefficient of thermal conductivity and water absorption forces the construction of external walls of great thickness or making them three-layer, combining them with insulating materials and other types of bricks.

Fireclay - made from special refractory crushed clay and fireclay powder by firing at elevated temperatures. It is used for laying out fireplaces, stoves and other structures where fire resistance is required. The specifics of the application determined a wide variety of product forms:

- wedge-shaped and straight;

- large medium and small sizes;

- shaped with profiles of varying complexity;

- special, laboratory and industrial crucibles, tubes and other equipment.

Clinker - made from refractory clays with various additives. Fired at very high temperatures until completely baked. Various components and variability in the firing regime give the bricks increased strength, water resistance and a wide range of shades from greenish, when fired with peat, to burgundy with charcoal marks. Previously widely used for paving sidewalks, it is now used in masonry and cladding foundations. The thermal conductivity of ceramic bricks is quite high.

Hollow brick

The material allows 45% of voids from the total volume, and also differs in shape, structure and location of voids in the bar. The thermal conductivity of a hollow brick directly depends on the amount of air in its body - the more air, the better the thermal insulation.

A brick with voids is a block with two or three large through holes, which serve rather to make it lighter and cheaper than to improve thermal insulation. It is used on a par with a solid analogue, with the exception of foundations and other structures that require increased strength.

Slotted brick - the entire body of the block is pierced with holes of various shapes and sizes.

- rectangular;

- triangular;

- diamond-shaped;

- through and closed on one side;

- vertical and horizontal.

Quite good strength and low thermal conductivity determine its demand for the construction of external walls of residential buildings.

Porous brick - available in several sizes. In addition to a large number of holes, it has a porous structure of the material, which is formed when special small fractions added to the clay burn out. It has the best set of qualities for the construction of external walls. Strength, low thermal conductivity and large dimensions reduce construction time significantly, while complying with the latest SNiP requirements. Warm ceramics are characterized by the lowest thermal conductivity, but due to their fragility, they still have limited use.

The facing brick is also hollow, successfully combining artistic and insulating properties.

Table of thermal conductivity indicators of building materials

| Name of material | Thermal conductivity coefficient, W/(m*K) |

| Ceramic block | 0,17- 0,21 |

| Porous brick | 0,22 |

| Ceramic slotted brick | 0,34–0,43 |

| Sand-lime brick | 0,4 |

| Ceramic brick with voids | 0,57 |

| Ceramic solid brick | 0,5-0,8 |

| Sand-lime brick with voids | 0,66 |

| Solid sand-lime brick | 0,7–0,8 |

| Clinker brick | 0,8–0,9 |

Almost always, in the construction of a house, several types of bricks with corresponding characteristics are used for different structural elements.

Factors affecting thermal conductivity

The thermal conductivity coefficient of a material depends on several factors:

- As this indicator increases, the interaction between material particles becomes stronger. Accordingly, they will transmit temperature faster. This means that as the density of the material increases, heat transfer improves.

- Porosity of a substance. Porous materials are heterogeneous in their structure. There is a large amount of air inside them. This means that it will be difficult for molecules and other particles to move thermal energy. Accordingly, the thermal conductivity coefficient increases.

- Humidity also affects thermal conductivity. Wet surfaces of the material transmit more heat. Some tables even indicate the calculated thermal conductivity coefficient of the material in three states: dry, medium (normal) and wet.

When choosing a material for insulating rooms, it is also important to take into account the conditions in which it will be used.

Material temperature

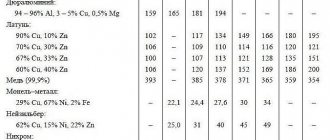

The effect of temperature on the ability to conduct heat differs for metals and nonmetals.

In metals, conductivity is mainly due to free electrons. According to the Wiedemann-Franz law, the thermal conductivity of a metal is proportional to the product of the absolute temperature, expressed in Kelvin, and its electrical conductivity. In pure metals, electrical conductivity decreases with increasing temperature, so thermal conductivity remains approximately constant. In the case of alloys, electrical conductivity changes little with increasing temperature, so the thermal conductivity of alloys increases in proportion to temperature. On the other hand, heat transfer in nonmetals is mainly associated with lattice vibrations and the exchange of lattice phonons. With the exception of high-quality crystals and low temperatures, the path of phonons in the lattice does not decrease significantly at high temperatures, and therefore the thermal conductivity remains constant over the entire temperature range, that is, it is insignificant. At temperatures below the Debye temperature, the ability of nonmetals to conduct heat, along with their heat capacity, decreases significantly.

Phase transitions and structure

When a material undergoes a first-order phase transition, for example from a solid to a liquid or from a liquid to a gas, its thermal conductivity may change. A striking example of such a change is the difference between this physical quantity for ice (2.18 W/(m*K) and water (0.90 W/(m*K).

Changes in the crystal structure of materials also affect thermal conductivity, which is explained by the anisotropic properties of various allotropic modifications of a substance of the same composition. Anisotropy affects different scattering intensities of lattice phonons, the main heat carriers in nonmetals, and in different directions in the crystal. A striking example here is sapphire, whose conductivity varies from 32 to 35 W/(m*K) depending on the direction.

Electrical conductivity

Thermal conductivity in metals changes along with electrical conductivity according to the Wiedemann-Franz law. This is due to the fact that valence electrons, moving freely throughout the crystal lattice of the metal, transfer not only electrical, but also thermal energy. For other materials, the correlation between these types of conductivity is not pronounced, due to the insignificant contribution of the electronic component to thermal conductivity (in nonmetals, lattice phonons play the main role in the mechanism of heat transfer).

Convection process

Air and other gases are, as a rule, good heat insulators in the absence of convection. This principle is the basis for the operation of many heat-insulating materials containing a large number of small voids and pores. This structure does not allow convection to spread over long distances. Examples of such man-made materials are polystyrene and silicide airgel. In nature, heat insulators such as animal skin and bird plumage work on the same principle.

Light gases such as hydrogen and gel have high thermal conductivities, while heavy gases such as argon, xenon and radon are poor conductors of heat. For example, argon, an inert gas that is heavier than air, is often used as an insulating gas filler in double-glazed windows and light bulbs. An exception is sulfur hexafluoride (SF6 gas), which is a heavy gas and has a relatively high thermal conductivity due to its high heat capacity.

Necessity of calculations

Why is it necessary to carry out these calculations, is there any benefit from them in practice? Let's take a closer look.

INTERESTING: Plastic rings for wells: types, sizes and installation

Assessing the effectiveness of thermal insulation

Different climatic regions of Russia have different temperature conditions, so each of them has its own standard indicators of heat transfer resistance. These calculations are carried out for all elements of the structure in contact with the external environment. If the structural resistance is within normal limits, then you don’t have to worry about insulation.

If thermal insulation of the structure is not provided, then you need to make the right choice of insulating material with suitable thermal characteristics.

Heat loss

Heat losses at home

An equally important task is to predict heat losses, without which it is impossible to properly plan a heating system and create ideal thermal insulation. Such calculations may be necessary when choosing the optimal boiler model, the number of radiators required and their correct placement.

To determine heat losses through any structure, you need to know the resistance, which is calculated using the temperature difference and the amount of heat lost from one square meter of the enclosing structure. And so, if we know the area of the structure and its thermal resistance, and also know for what climatic conditions the calculation is being made, then we can accurately determine the heat losses. There is a good calculator for calculating heat loss at home (it can even calculate how much money will be spent on heating, approximately of course).

Such calculations in a building are carried out for all building envelopes interacting with cold air flows, and then summed up to determine the total heat loss. Based on the obtained value, a heating system is designed that should fully compensate for these losses. If the heat losses are too large, they entail additional financial costs, and not everyone can afford this. In this situation, you need to think about improving the thermal insulation system.

Separately, we need to talk about windows, for which the heat transfer resistance is determined by regulatory documents. There is no need to do the calculations yourself. There are ready-made tables in which resistance values are entered for all types of window and balcony door structures. Thermal losses of windows are calculated based on the area, as well as the temperature difference on different sides of the structure.

The calculations above are suitable for beginners who are taking their first steps in designing energy-efficient homes. If a professional gets down to business, then his calculations are more complex, since many correction factors are additionally taken into account - insolation, light absorption, reflection of sunlight, heterogeneity of structures, location of the house on the site, and others.

Table of thermal conductivity of thermal insulation materials

To make it easier to keep your house warm in winter and cool in summer, the thermal conductivity of walls, floors and roofs must be at least a certain figure, which is calculated for each region. The composition of the “pie” of walls, floor and ceiling, the thickness of the materials are taken into account so that the total figure is no less (or better yet, at least a little more) recommended for your region.

Heat transfer coefficient of modern building materials for enclosing structures

When choosing materials, it is necessary to take into account that some of them (not all) conduct heat much better in conditions of high humidity. If such a situation may occur for a long period of time during operation, the thermal conductivity for this condition is used in the calculations. The thermal conductivity coefficients of the main materials used for insulation are given in the table.

Name of material /Thermal conductivity coefficient W/(m °C)

| Dry | At normal humidity | At high humidity | |

| Woolen felt | 0,036-0,041 | 0,038-0,044 | 0,044-0,050 |

| Stone mineral wool 25-50 kg/m3 | 0,036 | 0,042 | 0,,045 |

| Stone mineral wool 40-60 kg/m3 | 0,035 | 0,041 | 0,044 |

| Stone mineral wool 80-125 kg/m3 | 0,036 | 0,042 | 0,045 |

| Stone mineral wool 140-175 kg/m3 | 0,037 | 0,043 | 0,0456 |

| Stone mineral wool 180 kg/m3 | 0,038 | 0,045 | 0,048 |

| Glass wool 15 kg/m3 | 0,046 | 0,049 | 0,055 |

| Glass wool 17 kg/m3 | 0,044 | 0,047 | 0,053 |

| Glass wool 20 kg/m3 | 0,04 | 0,043 | 0,048 |

| Glass wool 30 kg/m3 | 0,04 | 0,042 | 0,046 |

| Glass wool 35 kg/m3 | 0,039 | 0,041 | 0,046 |

| Glass wool 45 kg/m3 | 0,039 | 0,041 | 0,045 |

| Glass wool 60 kg/m3 | 0,038 | 0,040 | 0,045 |

| Glass wool 75 kg/m3 | 0,04 | 0,042 | 0,047 |

| Glass wool 85 kg/m3 | 0,044 | 0,046 | 0,050 |

| Expanded polystyrene (foam plastic, EPS) | 0,036-0,041 | 0,038-0,044 | 0,044-0,050 |

| Extruded polystyrene foam (EPS, XPS) | 0,029 | 0,030 | 0,031 |

| Foam concrete, aerated concrete with cement mortar, 600 kg/m3 | 0,14 | 0,22 | 0,26 |

| Foam concrete, aerated concrete with cement mortar, 400 kg/m3 | 0,11 | 0,14 | 0,15 |

| Foam concrete, aerated concrete with lime mortar, 600 kg/m3 | 0,15 | 0,28 | 0,34 |

| Foam concrete, aerated concrete with lime mortar, 400 kg/m3 | 0,13 | 0,22 | 0,28 |

| Foam glass, crumbs, 100 - 150 kg/m3 | 0,043-0,06 | ||

| Foam glass, crumbs, 151 - 200 kg/m3 | 0,06-0,063 | ||

| Foam glass, crumbs, 201 - 250 kg/m3 | 0,066-0,073 | ||

| Foam glass, crumbs, 251 - 400 kg/m3 | 0,085-0,1 | ||

| Foam block 100 - 120 kg/m3 | 0,043-0,045 | ||

| Foam block 121-170 kg/m3 | 0,05-0,062 | ||

| Foam block 171 - 220 kg/m3 | 0,057-0,063 | ||

| Foam block 221 - 270 kg/m3 | 0,073 | ||

| Ecowool | 0,037-0,042 | ||

| Polyurethane foam (PPU) 40 kg/m3 | 0,029 | 0,031 | 0,05 |

| Polyurethane foam (PPU) 60 kg/m3 | 0,035 | 0,036 | 0,041 |

| Polyurethane foam (PPU) 80 kg/m3 | 0,041 | 0,042 | 0,04 |

| Cross-linked polyethylene foam | 0,031-0,038 | ||

| Vacuum | |||

| Air +27°C. 1 atm | 0,026 | ||

| Xenon | 0,0057 | ||

| Argon | 0,0177 | ||

| Airgel (Aspen aerogels) | 0,014-0,021 | ||

| Slag | 0,05 | ||

| Vermiculite | 0,064-0,074 | ||

| Foam rubber | 0,033 | ||

| Cork sheets 220 kg/m3 | 0,035 | ||

| Cork sheets 260 kg/m3 | 0,05 | ||

| Basalt mats, canvases | 0,03-0,04 | ||

| Tow | 0,05 | ||

| Perlite, 200 kg/m3 | 0,05 | ||

| Expanded perlite, 100 kg/m3 | 0,06 | ||

| Linen insulating boards, 250 kg/m3 | 0,054 | ||

| Polystyrene concrete, 150-500 kg/m3 | 0,052-0,145 | ||

| Granulated cork, 45 kg/m3 | 0,038 | ||

| Mineral cork on a bitumen basis, 270-350 kg/m3 | 0,076-0,096 | ||

| Cork flooring, 540 kg/m3 | 0,078 | ||

| Technical cork, 50 kg/m3 | 0,037 |

We recommend: Electric heat guns - operating principle, how to choose, best models, prices and reviews, where to buy

Some of the information is taken from standards that prescribe the characteristics of certain materials (SNiP, SP, SNiP II-3-79* (Appendix 2)). Those materials that are not specified in the standards are found on the manufacturers' websites. Since there are no standards, they can differ significantly from different manufacturers, so when purchasing, pay attention to the characteristics of each material you purchase.

How to choose materials for thermal insulation at home

Note that there is no universal best insulation. For each individual case, you need to select the appropriate material.

To figure out how to choose thermal insulation for your home, consider its types:

Mineral wool. Easy to install and insulates well. But it cannot withstand pressure and is not suitable for wet areas. Depending on the type of raw material from which it is produced, there are stone (basalt), glass and slag. Basalt-based home insulation is completely non-flammable and does not chip. Glass wool has two main advantages: it is non-flammable and very cheap. But working with it is not at all comfortable, since the material is itchy and causes allergies. Slag wool is only suitable for attics and non-residential buildings as it is not environmentally friendly.

- Foam glass

. Available in blocks, durable. This is a new and expensive material. - Styrofoam

. Its popularity is determined by its low price. Does not absorb moisture, is partially vapor permeable, does not rot, does not mold. Durable. But it has low strength. Rodents love to build nests in polystyrene foam. The optimal density is 25 kg/m2. - Expanded polystyrene

. This insulation is made from the same material as foam, but it is modern and more durable. Used for walls, foundations, flat roofs. At the same time it provides moisture insulation. Currently, polystyrene foam is the leader in the thermal insulation rating. - Sheet polyurethane foam

. Its properties are similar to expanded polystyrene, but it is breathable and easily absorbs water. - Foam

. It is made on the basis of polyurethane foam or penoizol. Good for insulating walls outside. Covers the surface completely, without cold bridges, due to which the walls after treatment have minimal thermal conductivity. But insulation in this way is expensive - the technology requires the use of special equipment and qualified personnel. - Foamed polyethylene foam

. There is PPE or NPE. Take only PPE - it is more durable. It is used for insulating pipes, internal walls, and floors. There are options with reflective foil film.

Important characteristics:

- Thermal conductivity

. Shows how much heat in watts the material will lose. The lower the coefficient, the better. The average value is 0.038–0.046 W/mK. - Vapor permeability

. The ability of the material to breathe, allowing moisture vapor to pass through. Quality required for timber structures. - Shrinkage

. It is desirable that it be minimal or absent. Otherwise, over time, under the influence of its own mass, the thermal insulation will decrease in volume and deteriorate its properties. - Hygroscopicity

. Determines the ability of a material to absorb water vapor. Materials with high hygroscopicity are less effective because liquid increases thermal conductivity. Also, such insulation cannot be used in damp places.

- Operating temperature

. Correctly selected insulation for this parameter will serve with high quality and for a long time. For example, in the northern regions frosts can reach -40 and -50 °C. In summer, metal roofs heat up to 80–90 °C. - Flammability

. Insulation materials are flammable and non-flammable. Indoors it is better to use non-flammable or low-flammable ones. Also, non-combustible insulation materials should be used in fire hazardous areas. - Environmental friendliness

. Important for use in residential areas. Environmentally friendly materials do not emit harmful substances. - Firms

. There are a lot of manufacturers of high-quality thermal insulation. Among the brands that have proven their effectiveness are the following: Rockwool, Isoroc, Energoflex, Penoplex, Akterm Nord, TechnoNIKOL, URSA, Hotrock, KNAUF, Isover, Ecostroy.

Application of thermal conductivity in practice

In construction, all materials are conventionally divided into thermal insulation and structural. Structural raw materials have the highest thermal conductivity, but it is precisely this material that is used for the construction of walls, ceilings, and other fences. According to the table of thermal conductivity of building materials, when constructing walls made of reinforced concrete, for low heat exchange with the environment, the thickness of the structure should be about 6 meters. In this case, the structure will turn out to be huge, cumbersome and will require considerable costs.

A clear example is at what thickness of different materials their thermal conductivity coefficient will be the same

Therefore, when constructing a building, special attention should be paid to additional heat-insulating materials. A layer of thermal insulation may not be needed only for buildings made of wood or foam concrete, but even when using such low-conductivity raw materials, the thickness of the structure must be at least 50 cm.

Need to know! Thermal insulation materials have minimal thermal conductivity values.

Indicator table

For ease of work, the thermal conductivity coefficient of the material is usually entered into the table. In addition to the coefficient itself, it can reflect such indicators as the degree of humidity, density and others. Materials with high thermal conductivity are combined in the table with indicators of low thermal conductivity. A sample of this table is shown below:

Using the thermal conductivity coefficient of the material will allow you to build the desired building. The main thing: choose a product that meets all the necessary requirements. Then the building will be comfortable for living; it will maintain a favorable microclimate.

Properly selected insulating material will reduce heat loss, due to which there will no longer be a need to “heat the street.” Thanks to this, financial heating costs will be significantly reduced. Such savings will allow you to soon return all the money that will be spent on purchasing a heat insulator.

When is the thermal conductivity coefficient taken into account?

Thermal conductivity parameters must be taken into account when choosing materials for enclosing structures - walls, ceilings, etc. In rooms where the walls are made of materials with high thermal conductivity, it will be quite cool in the cold season. Decorating the room won't help either. In order to avoid this, the walls must be made quite thick. This will certainly lead to increased costs for materials and labor.

Insulation scheme for a wooden house

That is why the construction of the walls requires the use of materials with low thermal conductivity (mineral wool, polystyrene foam, etc.).

Comparison of the characteristics of popular insulation materials

Foam plastic (expanded polystyrene)

This insulation is the most popular due to its ease of installation and low cost.

Polystyrene foam is made by foaming polystyrene, has very low thermal conductivity, is resistant to moisture, is easy to cut with a knife and is convenient during installation. Due to its low cost, it is in great demand for insulating various rooms. However, the material is quite fragile and also supports combustion, releasing toxic substances into the atmosphere. It is preferable to use polystyrene foam in non-residential premises.

Penoplex (extruded polystyrene foam)

The insulation is not subject to rotting or moisture, is very durable and easy to use - it can be easily cut with a knife. Low water absorption ensures minor changes in the thermal conductivity of the material in conditions of high humidity; the slabs have high compression resistance and do not decompose. Thanks to this, extruded polystyrene foam can be used to insulate strip foundations and blind areas. Penoplex is fireproof, durable and easy to use.

Basalt wool

The material is made from basalt rocks by melting and blowing with the addition of components to obtain a fibrous structure of the material with water-repellent properties. During operation, basalt wool is not compacted, which means its properties do not change over time. The material is fireproof and environmentally friendly, has good sound insulation and thermal insulation. Used for internal and external insulation. In damp rooms requires additional vapor barrier.

Mineral wool

Mineral wool is produced from natural materials - rocks, slag, dolomite using special technology. Mineral has low thermal conductivity, is fireproof and absolutely safe. One of the disadvantages of insulation is its low moisture resistance, which requires the installation of additional moisture and vapor barrier when using it. The material is not recommended for insulation of basements and foundations, as well as in wet rooms - steam rooms, baths, dressing rooms.

Thermal conductivity coefficient of building materials: how it is used in practice and table

The practical value of the coefficient is a correctly carried out calculation of the thickness of the supporting structures, taking into account the insulation materials used. It should be noted that the building under construction consists of several enclosing structures through which heat leaks. And each of them has its own percentage of heat loss.

- Up to 30% of the total thermal energy goes through the walls.

- Through floors – 10%.

- Through windows and doors – 20%.

- Through the roof - 30%.

Heat loss at home

That is, it turns out that if the thermal conductivity of all fences is incorrectly calculated, then people living in such a house will have to be content with only 10% of the thermal energy that the heating system emits. 90% is, as they say, money thrown away.

“The ideal house should be built from thermal insulation materials, in which 100% of the heat will remain inside. But according to the table of thermal conductivity of materials and insulation materials, you will not find the ideal building material from which such a structure could be erected. Because the porous structure means low load-bearing capacity of the structure. Wood may be an exception, but it is not ideal either.”

A log wall is one of the most insulated

Therefore, when building houses, they try to use different building materials that complement each other in thermal conductivity. In this case, it is very important to correlate the thickness of each element in the overall building structure. In this regard, frame houses https://doma-rsu.ru/ can be considered ideal. It has a wooden base, we can already talk about a warm house, and insulation that is laid between the elements of the frame building. Of course, taking into account the average temperature of the region, it will be necessary to accurately calculate the thickness of the walls and other enclosing elements.

But, as practice shows, the changes being made are not so significant that we can talk about large capital investments.

Construction of a frame house in terms of its insulation

Let's look at several commonly used building materials and compare their thermal conductivity by thickness.

Thermal conductivity of brick: table by variety

PhotoType of brickThermal conductivity, W/m*K

| Ceramic solid | 0,5-0,8 |

| Ceramic slotted | 0,34-0,43 |

| Porous | 0,22 |

| Silicate solid | 0,7-0,8 |

| Silicate slotted | 0,4 |

| Clinker | 0,8-0,9 |

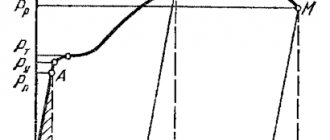

Thermal conductivity of brickwork at a temperature difference of 10°C

Thermal conductivity of wood: table by species

Wood speciesBirchOak across the grainOak along the grainSpruceCedarMapleLarch

| Thermal conductivity, W/m C | 0,15 | 0,2 | 0,4 | 0,11 | 0,095 | 0,19 | 0,13 |

Wood species Linden Fir Cork Pine across the grain Pine along the grain Poplar

| Thermal conductivity, W/m C | 0,15 | 0,15 | 0,045 | 0,15 | 0,4 | 0,17 |

We recommend: Electric heaters for heating with minimal energy consumption

The thermal conductivity coefficient of balsa wood is the lowest of all wood species. It is cork that is often used as a heat-insulating material when carrying out insulation measures.

Wood has a lower thermal conductivity than concrete and brick

Table of thermal conductivity of concrete

Concrete in its various variations is the most common building material today, although it is not the “warmest”. In construction, a distinction is made between structural and thermal insulating concrete. The former are used to build foundations and critical components of buildings with subsequent insulation, while the latter are used to build walls. Depending on the region, either additional insulation is applied to them or not.

Comparative table of thermal insulation concrete and thermal conductivity of various wall materials

Aerated concrete is considered the most “warm” and durable. Although this is not entirely true. If you compare the structure of foam blocks and aerated concrete, you can see significant differences. In the first, the pores are closed, while in gas silicates, most of them are open, as if “torn.” This is why in windy weather an uninsulated house made of aerated blocks is very cold. The same reason makes such lightweight concrete more susceptible to moisture.

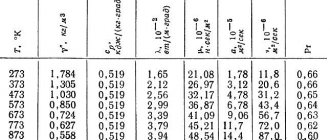

Thermal conductivity of metals: table

This indicator for metals changes with the temperature at which they are used. And here the relationship is this: the higher the temperature, the lower the coefficient. The table shows the metals that are used in the construction industry.

Type of metalSteelCast ironAluminumCopper

| Thermal conductivity, W/m C | 47 | 62 | 236 | 328 |

Now, as for the relationship with temperature.

- Aluminum at a temperature of -100°C has a thermal conductivity of 245 W/m*K. And at a temperature of 0°C – 238. At +100°C – 230, at +700°C – 0.9.

- For copper: at -100°C –405, at 0°C – 385, at +100°C – 380, and at +700°C – 350.

The thermal conductivity of copper is almost seven times higher than that of steel

Thermal conductivity table for other materials

We will be mainly interested in the table of thermal conductivity of insulating materials. It should be noted that if for metals this parameter depends on temperature, then for insulation it depends on their density. Therefore, the table will display indicators taking into account the density of the material.

Thermal insulation material Density, kg/m³ Thermal conductivity, W/m*K

| Mineral wool (basalt) | 50 | 0,048 |

| 100 | 0,056 | |

| 200 | 0,07 | |

| Glass wool | 155 | 0,041 |

| 200 | 0,044 | |

| Expanded polystyrene | 40 | 0,038 |

| 100 | 0,041 | |

| 150 | 0,05 | |

| Extruded polystyrene foam | 33 | 0,031 |

| Polyurethane foam | 32 | 0,023 |

| 40 | 0,029 | |

| 60 | 0,035 | |

| 80 | 0,041 |

And a table of thermal insulation properties of building materials. The main ones have already been discussed; let us designate those that are not included in the tables and that belong to the category of frequently used ones.

Building material Density, kg/m³ Thermal conductivity, W/m*K

| Concrete | 2400 | 1,51 |

| Reinforced concrete | 2500 | 1,69 |

| Expanded clay concrete | 500 | 0,14 |

| Expanded clay concrete | 1800 | 0,66 |

| Foam concrete | 300 | 0,08 |

| Foam glass | 400 | 0,11 |

What is the thermal conductivity coefficient of the air gap?

In construction, windproof air layers are often used, which only increase the heat conductivity of the entire building. Also, such vents are necessary to remove moisture outside. Particular attention is paid to the design of such layers in foam concrete buildings for various purposes. Such layers also have their own thermal conductivity coefficient depending on their thickness.

Table of heat conductivity of air layers

An excerpt characterizing Thermal Conductivity

“La balance y est... [The balance is established...] A German is threshing a loaf of bread on the butt, comme dit le proverbe, [as the proverb says],” Shinshin said, shifting the amber to the other side of his mouth and winked at the count. The Count burst out laughing. Other guests, seeing that Shinshin was talking, came up to listen. Berg, not noticing either ridicule or indifference, continued to talk about how by transferring to the guard he had already won a rank in front of his comrades in the corps, how in wartime a company commander can be killed, and he, remaining senior in the company, can very easily be company commander, and how everyone in the regiment loves him, and how his daddy is pleased with him. Berg apparently enjoyed telling all this, and did not seem to suspect that other people might also have their own interests. But everything he told was so sweetly sedate, the naivety of his young egoism was so obvious that he disarmed his listeners. - Well, father, you will be in action in both the infantry and the cavalry; “This is what I predict for you,” said Shinshin, patting him on the shoulder and lowering his legs from the ottoman. Berg smiled happily. The Count, followed by the guests, went into the living room. There was that time before a dinner party when the assembled guests do not begin a long conversation in anticipation of the call for appetizers, but at the same time consider it necessary to move and not remain silent in order to show that they are not at all impatient to sit down at the table. The owners glance at the door and occasionally glance at each other. From these glances, guests try to guess who or what else they are waiting for: an important relative who is late, or food that is not yet ripe. Pierre arrived just before dinner and sat awkwardly in the middle of the living room on the first available chair, blocking everyone's path. The Countess wanted to force him to speak, but he naively looked through his glasses around him, as if looking for someone, and answered all the Countess’s questions in monosyllables. He was shy and alone did not notice it. Most of the guests, who knew his story with the bear, looked curiously at this big, fat and humble man, wondering how such a bumpkin and modest man could do such a thing to a policeman. -Have you arrived recently? - the countess asked him. “Oui, madame,” he answered, looking around. -Have you seen my husband? - Non, madame. [No, madam.] - He smiled completely inappropriately. – You, it seems, were recently in Paris? I think it's very interesting. – Very interesting.. The Countess exchanged glances with Anna Mikhailovna. Anna Mikhailovna realized that she was being asked to occupy this young man, and, sitting down next to him, began to talk about her father; but just like the countess, he answered her only in monosyllables. The guests were all busy with each other. Les Razoumovsky... ca a ete charmant... Vous etes bien bonne... La comtesse Apraksine... [The Razoumovskys... It was amazing... You are very kind... Countess Apraksina...] was heard from all sides. The Countess got up and went into the hall. - Marya Dmitrievna? – her voice was heard from the hall. “She’s the one,” a rough female voice was heard in response, and after that Marya Dmitrievna entered the room. All the young ladies and even the ladies, with the exception of the oldest ones, stood up. Marya Dmitrievna stopped at the door and, from the height of her corpulent body, holding high her fifty-year-old head with gray curls, looked around at the guests and, as if rolling up, slowly straightened the wide sleeves of her dress. Marya Dmitrievna always spoke Russian. “Dear birthday girl with the children,” she said in her loud, thick voice, suppressing all other sounds. “What, you old sinner,” she turned to the count, who was kissing her hand, “tea, are you bored in Moscow?” Is there anywhere to run the dogs? What should we do, father, this is how these birds will grow up...” She pointed to the girls. - Whether you want it or not, you have to look for suitors. - Well, what, my Cossack? (Marya Dmitrievna called Natasha a Cossack) - she said, caressing Natasha with her hand, who approached her hand without fear and cheerfully. – I know that the potion is a girl, but I love her. She took out pear-shaped yakhon earrings from her huge reticule and, giving them to Natasha, who was beaming and blushing for her birthday, immediately turned away from her and turned to Pierre. - Eh, eh! kind! “Come here,” she said in a feignedly quiet and thin voice. - Come on, my dear... And she menacingly rolled up her sleeves even higher. Pierre approached, naively looking at her through his glasses. - Come, come, my dear! I was the only one who told your father the truth when he had a chance, but God commands it to you. She paused. Everyone was silent, waiting for what would happen, and feeling that there was only a preface. - Good, nothing to say! good boy!... The father is lying on his bed, and he is amusing himself, putting the policeman on a bear. It's a shame, father, it's a shame! It would be better to go to war. She turned away and offered her hand to the count, who could hardly restrain himself from laughing. - Well, come to the table, I have tea, is it time? - said Marya Dmitrievna. The count walked ahead with Marya Dmitrievna; then the countess, who was led by a hussar colonel, the right person with whom Nikolai was supposed to catch up with the regiment. Anna Mikhailovna - with Shinshin. Berg shook hands with Vera. A smiling Julie Karagina went with Nikolai to the table. Behind them came other couples, stretching across the entire hall, and behind them, one by one, were children, tutors and governesses. The waiters began to stir, the chairs rattled, music began to play in the choir, and the guests took their seats. The sounds of the count's home music were replaced by the sounds of knives and forks, the chatter of guests, and the quiet steps of waiters. At one end of the table the countess sat at the head. On the right is Marya Dmitrievna, on the left is Anna Mikhailovna and other guests. At the other end sat the count, on the left the hussar colonel, on the right Shinshin and other male guests. On one side of the long table are older young people: Vera next to Berg, Pierre next to Boris; on the other hand - children, tutors and governesses. From behind the crystal, bottles and vases of fruit, the Count looked at his wife and her tall cap with blue ribbons and diligently poured wine for his neighbors, not forgetting himself. The countess also, from behind the pineapples, not forgetting her duties as a housewife, cast significant glances at her husband, whose bald head and face, it seemed to her, were more sharply different from his gray hair in their redness. There was a steady babble on the ladies' end; in the men's room, voices were heard louder and louder, especially the hussar colonel, who ate and drank so much, blushing more and more, that the count was already setting him up as an example to the other guests. Berg, with a gentle smile, spoke to Vera that love is not an earthly, but a heavenly feeling. Boris named his new friend Pierre the guests at the table and exchanged glances with Natasha, who was sitting opposite him. Pierre spoke little, looked at new faces and ate a lot. Starting from two soups, from which he chose a la tortue, [turtle,] and kulebyaki and to hazel grouse, he did not miss a single dish and not a single wine, which the butler mysteriously stuck out in a bottle wrapped in a napkin from behind his neighbor’s shoulder, saying or “drey Madeira", or "Hungarian", or "Rhine wine". He placed the first of the four crystal glasses with the count's monogram that stood in front of each device, and drank with pleasure, looking at the guests with an increasingly pleasant expression. Natasha, sitting opposite him, looked at Boris the way thirteen-year-old girls look at a boy with whom they had just kissed for the first time and with whom they are in love. This same look of hers sometimes turned to Pierre, and under the gaze of this funny, lively girl he wanted to laugh himself, not knowing why. Nikolai sat far from Sonya, next to Julie Karagina, and again with the same involuntary smile he spoke to her. Sonya smiled grandly, but apparently was tormented by jealousy: she turned pale, then blushed and listened with all her might to what Nikolai and Julie were saying to each other. The governess looked around restlessly, as if preparing to fight back if anyone decided to offend the children. The German tutor tried to memorize all kinds of dishes, desserts and wines in order to describe everything in detail in a letter to his family in Germany, and was very offended by the fact that the butler, with a bottle wrapped in a napkin, carried him around. The German frowned, tried to show that he did not want to receive this wine, but was offended because no one wanted to understand that he needed the wine not to quench his thirst, not out of greed, but out of conscientious curiosity. At the male end of the table the conversation became more and more animated. The colonel said that the manifesto declaring war had already been published in St. Petersburg and that the copy that he himself had seen had now been delivered by courier to the commander-in-chief.

Disadvantages of the high thermal conductivity of copper and its alloys

Copper has a much higher value than aluminum or brass. But meanwhile, this material has a number of disadvantages that are associated with its positive aspects. The high thermal conductivity of this metal forces the creation of special conditions for its processing. That is, copper billets must be heated more accurately than steel. In addition, there is often pre- or auxiliary heating before starting treatment. We must not forget that pipes made of copper imply that careful thermal insulation will be carried out. This is especially true for those cases when the heating supply system is assembled from these pipes. This significantly increases the cost of installation work. Certain difficulties arise when using gas welding. To get the job done, a more powerful tool is required. Sometimes, to process copper with a thickness of 8 - 10 mm, it may be necessary to use two or even three torches. In this case, one of them welds the copper pipe, and the rest are busy heating it. In addition, working with copper requires more consumables.

Working with copper requires the use of specialized tools. For example, when cutting parts made of bronze or brass with a thickness of 150 mm, you will need a cutter that can work with steel with a large amount of chrome. If it is used for processing copper, then the maximum thickness will not exceed 50 mm.

Efficiency of multilayer structures

Density and thermal conductivity

Currently, there is no building material whose high load-bearing capacity would be combined with low thermal conductivity. The construction of buildings based on the principle of multilayer structures allows:

- comply with design standards for construction and energy conservation;

- keep the dimensions of enclosing structures within reason;

- reduce material costs for the construction of the facility and its maintenance;

- achieve durability and maintainability (for example, when replacing one sheet of mineral wool).

The combination of structural and thermal insulation materials ensures strength and reduces thermal energy loss to an optimal level. Therefore, when designing walls, calculations take into account each layer of the future enclosing structure.

It is also important to take into account the density when building a house and when insulating it. The density of a substance is a factor that affects its thermal conductivity and ability to retain the main heat insulator - air. The density of a substance is a factor influencing its thermal conductivity and ability to retain the main heat insulator - air

The density of a substance is a factor that affects its thermal conductivity and ability to retain the main heat insulator - air.

Calculation of wall thickness and insulation

Calculation of wall thickness depends on the following indicators:

- density;

- calculated thermal conductivity;

- heat transfer resistance coefficient.

According to established standards, the value of the heat transfer resistance index of external walls must be at least 3.2λ W/m •°C.

Calculation of the thickness of walls made of reinforced concrete and other structural materials is presented in Table 2. Such building materials have high load-bearing characteristics, they are durable, but they are ineffective as thermal protection and require an irrational wall thickness.

table 2

| Index | Concrete, mortar-concrete mixtures | |||

| Reinforced concrete | Cement-sand mortar | Complex mortar (cement-lime-sand) | Lime-sand mortar | |

| density, kg/cub.m | 2500 | 1800 | 1700 | 1600 |

| thermal conductivity coefficient, W/(m•°С) | 2,04 | 0,93 | 0,87 | 0,81 |

| wall thickness, m | 6,53 | 2,98 | 2,78 | 2,59 |

Structural and thermal insulation materials are capable of being subjected to fairly high loads, while significantly increasing the thermal and acoustic properties of buildings in wall enclosing structures (Table 3.1, 3.2).

Table 3.1

| Index | Structural and thermal insulation materials | |||||

| Pumice concrete | Expanded clay concrete | Polystyrene concrete | Foam and aerated concrete (foam and gas silicate) | Clay brick | Sand-lime brick | |

| density, kg/cub.m | 800 | 800 | 600 | 400 | 1800 | 1800 |

| thermal conductivity coefficient, W/(m•°С) | 0,68 | 0,326 | 0,2 | 0,11 | 0,81 | 0,87 |

| wall thickness, m | 2,176 | 1,04 | 0,64 | 0,35 | 2,59 | 2,78 |

Table 3.2

| Index | Structural and thermal insulation materials | |||||

| Slag brick | Sand-lime brick 11-hollow | 14-hollow silicate brick | Pine (cross grain) | Pine (longitudinal grain) | Plywood | |

| density, kg/cub.m | 1500 | 1500 | 1400 | 500 | 500 | 600 |

| thermal conductivity coefficient, W/(m•°С) | 0,7 | 0,81 | 0,76 | 0,18 | 0,35 | 0,18 |

| wall thickness, m | 2,24 | 2,59 | 2,43 | 0,58 | 1,12 | 0,58 |

Thermal insulation building materials can significantly increase the thermal protection of buildings and structures. The data in Table 4 shows that the lowest values of the thermal conductivity coefficient are found in polymers, mineral wool, and slabs made from natural organic and inorganic materials.

Table 4

| Index | Thermal insulation materials | ||||||

| PPT | PT polystyrene concrete | Mineral wool mats | Thermal insulation boards (PT) made of mineral wool | Fibreboard (chipboard) | Tow | Gypsum sheets (dry plaster) | |

| density, kg/cub.m | 35 | 300 | 1000 | 190 | 200 | 150 | 1050 |

| thermal conductivity coefficient, W/(m•°С) | 0,39 | 0,1 | 0,29 | 0,045 | 0,07 | 0,192 | 1,088 |

| wall thickness, m | 0,12 | 0,32 | 0,928 | 0,14 | 0,224 | 0,224 | 1,152 |

The values of the tables of thermal conductivity of building materials are used in calculations:

- thermal insulation of facades;

- general building insulation;

- insulating materials for roofing;

- technical insulation.

The task of choosing optimal materials for construction, of course, implies a more comprehensive approach. However, even such simple calculations already at the first stages of design make it possible to determine the most suitable materials and their quantities.

Definition

Thermal conductivity of a material is the transfer of internal energy from more heated parts to less heated parts. The mechanism of heat transfer differs depending on the state of aggregation of the substance, as well as the temperature distribution over the surface of the material. In other words, the ability of a body to conduct heat is thermal conductivity. It is determined by the amount of heat that is capable of passing through a certain thickness of material in a certain area for a specified time (naturally, for the convenience of calculations, all indicators are equal to one). But plasters differ in the layer of application, which means the indicator will be different

Types of insulation

Among insulation materials, polystyrene foam and extruded polyurethane foam have lower thermal conductivity. These are hard, brittle materials, produced in slabs, and having a cellular structure. But it must be taken into account that as the density of the material structure increases, its ability to transmit heat also increases.

Mineral insulation, in addition to good heat retention, has excellent soundproofing properties: they dampen sounds, preventing them from penetrating into the room.

Mineral wool is produced in the form of slabs or rolls. The walls, roof, and floor are covered with slabs. Rolled insulation is suitable for covering water supply and heating pipes.

- Table of thermal conductivity of insulation

- Basvul insulation

- Ceramic brick - Thermal conductivity