Post updated: May 26, 2020

There is no such person who has not seen yellow metal in his entire life. There are several minerals found in nature that are similar in appearance to the yellow metal. But as they say: “all that glitters is not gold.” In order not to confuse the precious metal with other materials, you need to know the density of gold.

Basic information about copper

Copper is the most common non-ferrous metal. It received its name in Latin – Cuprum – in honor of the island of Cyprus. It was mined there by the ancient Greeks thousands of years ago. Historians even came up with the Copper Age , which lasted from the 4th to 5th centuries BC. e. At that time, people made from popular metal:

In the table D.I. Mendeleev, it ranks 29th. This element has unique properties - physical, chemical and mechanical. In ancient times, copper could be found in the natural environment in the form of nuggets, sometimes of very large sizes. People heated the rock over an open fire and then cooled it sharply. As a result, it cracked, which made it possible to restore the metal. This simple technology made it possible to begin the development of a popular element.

Features of the table used

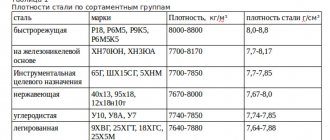

In order to calculate the weight of the future product, which will be made from cast iron, you should know its dimensions and density index. Linear dimensions are determined in order to calculate the volume. A calculation method is used to determine the weight of a product in cases where it is not possible to weigh it.

When considering methodological tables, it is worth paying attention to the following points:

- All metals are divided into several groups.

- For each material, the name and GOST are indicated.

- Depending on the melting point, the density value is indicated.

- To determine the physical value of specific gravity in kilograms or other changes, conversion of units of change is carried out. For example, if you need to convert grams to kilograms, then multiply the table value by 1000.

Determination of specific gravity is often done in special laboratories. This value is rarely used when carrying out actual calculations during the manufacture of products or the construction of structures.

Properties

Copper is a non-ferrous metal of a reddish color with a pink tint , endowed with high density. There are more than 170 types of minerals in nature that contain Cuprum. Only 17 of them undergo industrial mining of this element. The bulk of this chemical element is contained in ore metals:

- chalcocine - up to 80%;

- bronitite - up to 65%;

- Kovelin - up to 64%.

From these minerals copper is enriched and smelted. High thermal conductivity and electrical conductivity are the distinctive properties of non-ferrous metal. It begins to melt at a temperature of 1063 o C, and boils at 2600 o C. The Cuprum brand will depend on the production method. Metal happens:

Each type has its own special parametric calculations that characterize the degree of shear resistance, deformation under the influence of loads and compression, as well as the tensile elasticity of the material.

Non-ferrous metal actively oxidizes during heating. At a temperature of 385 o C, copper oxide is formed. Its content reduces the thermal conductivity and electrical conductivity of other metals. When interacting with moisture, the metal forms cuprite, and with an acidic environment - vitriol.

Copper Specific Gravity

Due to its properties, this chemical element is actively used in the production of electrical and electronic systems and many other products for other purposes. The most important property is its density of 1 kg per m 3 , since this indicator is used to determine the weight of the product being manufactured. Density shows the ratio of mass to total volume.

The most common system for measuring density units is 1 kilogram per m3. This figure for copper is 8.93 kg/m3. In liquid form, the density will be 8.0 g/cm 3 . The overall density may vary depending on the type of metal that has various impurities. For this purpose, the specific gravity of the substance is used. It is a very important characteristic when it comes to the production of materials that contain copper. Specific gravity characterizes the ratio of the mass of copper in the total volume of the alloy.

The specific gravity of copper will be 8.94 g/cm3 . The specific density and weight parameters of copper are the same, but such a coincidence is not typical for other metals. Specific gravity is very important not only in the production of products containing it, but also in the processing of scrap. There are many techniques that can be used to rationally select materials for forming products. In international SI systems, the specific gravity parameter is expressed in newtons per 1 unit of volume.

It is very important to carry out all calculations at the design stage of devices and mechanisms. Specific gravity and weight are different values, but they are necessarily used to determine the mass of blanks for various parts that contain Cuprum.

If we compare the density of copper and aluminum , we see a big difference. For aluminum, this figure is 2698.72 kg/m 3 at room temperature. However, as the temperature increases, the parameters become different. When aluminum transforms into a liquid state when heated, its density will be in the range of 2.55−2.34 g/cm 3 . The indicator always depends on the content of alloying elements in aluminum alloys.

Determination of carat weight

British carats are a traditional value used to measure the purity of gold and its weight in a product. The smallest value is 8 carats (K). The specific gravity of 999 gold is 24 carats. If other elements are added to the alloy to change the characteristics of the metal, the carat value drops. The 18-karat precious metal contains 6 parts of impurities and 18 parts of pure gold.

For example, high-grade 917 gold has a mass of 22 carats. And such a popular 585 alloy is only 14 carats.

Technical indicators of metal alloys

The most common copper-based alloys are brass and bronze . Their composition is also formed from other elements:

All alloys differ in structure. The presence of tin in the composition allows the production of bronze alloys of excellent quality. Cheaper alloys include nickel or zinc. The produced materials based on Cuprum have the following characteristics:

- high ductility and wear resistance;

- electrical conductivity;

- resistance to aggressive environments;

- low coefficient of friction.

Read also: Welding inverter Tolyana avt200

circuit diagram Copper-based alloys are widely used in industrial production. They are used to produce dishes, jewelry, electrical wires and heating systems. Materials with Cuprum are often used to decorate the façade of houses and make compositions. High stability and ductility are the main qualities for the use of the material.

Also, do not forget that the specific gravity of a metal is the force of gravity directly taken as a basis for the volume of a given substance.

The specific gravity of a metal and its density are in the same relationship to each other as the weight and mass of a body, and therefore the specific gravity can be determined by the formula:

The unit of specific gravity of a metal (stainless steel, brass, cast iron, copper, bronze, etc.) is:

– in the SGS system - 1 dyne/cm 3,

– in the SI system - 1 n/m 3,

– in the MKSS system—1 kg/m3.

All these unit values are related to each other by the relation

0.1 dyne/cm3 = 1 n/m3 = 0.102 kg/m3.

When determining the specific gravity of a metal, it is also possible to use a non-systemic unit of 1 G/cm 3 .

Since the mass of a substance, expressed in g, is equal to its weight value, expressed in G, the specific gravity of the metal, expressed in these units, is equal in number to the density of this metal, which will be expressed in the CGS system. A similar numerical equality can be traced between the specific gravity in the MKSS system and the density in the SI system.

Thus, the specific gravity of a metal is the weight per unit volume of an unconditionally dense (non-porous) material. To indicate the specific gravity, the mass of the dry material should be divided by its volume in a fully dense state - in fact, this is the formula for determining the weight of the metal. In order to achieve such a result, the metal must be brought into such a state that there are no pores in its particles, and the structure is completely homogeneous.

All metals known and used in industry have certain physical and mechanical properties, which, in fact, determine their specific gravity. There are several fundamental criteria that uniquely identify a particular metal or alloy.

Features of metals and their quality and weight characteristics

In order to have a more accurate understanding of the specifications of each type of metal, it is necessary to determine what is meant by this group of substances.

Metals are substances that have characteristic properties, including high strength, thermal and electrical conductivity, ductility, and a special metallic luster characteristic of each group. Metallic elements make up almost 3/4 of all elements known in nature, but not all of them can be widely used in industry. Some of them are quite rare in their true condition and specific gravity. Of the most important and valuable metals for technological processes and production, only a small part is contained in the earth’s crust. These are iron, aluminum, magnesium, titanium, etc.

Specific gravity of cast iron

Ferrous metals (black steel, cast iron) are the technical name for iron alloys and iron itself. For thousands of years they have been fundamental in the making of tools. Despite the stable growth in production of the chemical industry, non-ferrous metallurgy, and heavy industry, ferrous metals are still considered the main structural material in many sectors of human activity. In terms of production volumes of most of the most important types of ferrous metallurgy products (iron ore, cast iron, steel, steel pipes, coke, refractories), Russia occupies a worthy place as a leader throughout the world. Ferrous metals are divided into cast iron and steel depending on their carbon content and their specific gravity.

Cast iron is an alloy of carbon and iron with a carbon content of more than 2.13%. Cast iron is endowed with a low capacity for plastic deformation and excellent casting properties. It contains graphite inclusions - the shape and size of which determine the type of cast iron and its scope of application. Gray cast iron is a material in which carbon is contained in a free state in the form of flake graphite. High-strength cast iron contains carbon in the form of spheroidal graphite, and is used for the manufacture of parts that are subject to significant mechanical loads during operation. Malleable cast iron may have increased ductility characteristics when compared to the above cast iron. It is used in the production of parts where higher levels of mechanical properties are required.

The specific gravity of cast iron and its alloys is determined by the weight of one cubic centimeter, which is expressed in grams . The higher the specific gravity of the metal, the heavier the finished product can be. The table below illustrates the typical physical properties and specific gravity associated with certain types of cast iron.

| Specific gravity of steel Specific gravity of stainless steel Specific gravity of copper and copper alloys Specific gravity of aluminum Specific gravity of brass Specific gravity of bronze To calculate the weight or length of rolled metal based on the specific gravity of the desired grade, there is a special metal calculator. See also tables: Specific gravity of titanium, nickel, zinc Determination of the specific gravity of metals. Modern science has long stepped forward compared to the technologies that were used at the dawn of the development of heavy industry, and can offer various variations of metal alloys that differ from each other not only in their qualitative characteristics, but also in their physical and chemical properties. In order to determine how suitable a particular alloy of black or stainless steel is for production, its specific gravity is calculated. All bodies that have the same volume, but are made from different substances, for example, from iron, brass or aluminum, have different mass, which is directly dependent on its volume. In other words, the ratio of the volume of the alloy to its mass is a constant value that will be characteristic of a given substance. The density of a substance is calculated using a special formula and is directly related to the calculation of the specific gravity of the metal. The specific gravity of a metal is the ratio of the weight P of a homogeneous body of this substance to the volume of the metal. It is denoted by γ. Then, according to the formula, the specific gravity of metals is calculated as: |

Read also: Accessory for a sharpening machine for sharpening knives

| Table 1. Typical physical properties and specific gravity of cast iron | |||||

| Cast iron type | Specific gravity G/cm3 | Coefficient of thermal linear expansion a·10 -v 1/ о С, at temperatures 20-100 о С | Heat capacity in cal/G o C | Residual magnetism in gs | Note, with increasing temperature: “+” – increases; “-” – decreases |

| White | 7,5±0,2 | 8±2 | 0,13±0,02 | 5000±1000 | «-» |

| Grey | 7,1±0,2 | 10±2 | 0,12±0,02 | 5000±1000 | «+» |

| Malleable | 7,3±0,1 | 11±1 | 0,12±0,02 | 5000±1000 | «-» |

In addition to the non-bulk group of light metals, such as aluminum, magnesium, which have a specific gravity of no more than 3, most metals can have a significant specific gravity individually. For example, due to the large specific gravity of platinum (21.45) and gold (19.32), found in natural form, they can be mined using the method of washing from relatively light particles of sand and clay that accompany them in different layers of the soil.

The low specific gravity of some metals is very important in the construction and design of aircraft, and therefore, at the moment, light alloys and their characteristics are being especially carefully studied.

To calculate any rolled metal product by specific gravity, there is a special metal calculator for this.

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Each metal has certain physical and chemical properties. They determine their specific gravity and density. Thus, pure gold is a metal with increased heaviness and no less high density - 19.32 g/cm3. This figure puts gold in seventh place among all metals.

Different systems use different units of measurement: SI = N/M3, MCSS = 1 kg/m3, CGS = 1 dyne/cm3. In addition, the specific gravity of gold is expressed in grams per cubic centimeter. This is a non-system unit of measurement.

How to distinguish real yellow metal from a fake

At the moment, there is a very large percentage of counterfeit gold on both the Russian and foreign markets. There is a huge risk of purchasing gold jewelry containing up to 5% of the precious metal or without it at all. Basic rules when buying gold will help you avoid feeling deceived.

First, you should take a good look at the product. There must be a sample on it. Moreover, it should not consist of crooked numbers or blurry marks. Otherwise, this is the first sign of a counterfeit.

A sample of a unified state hallmark for gold products.

The next sign of a fake is the reverse side of the precious metal jewelry. It must be as well made as the front side, otherwise it is a low-quality product. It is also possible to determine the quality of a product using a characteristic such as gold density, but it is impossible to conduct such an experiment in a store.

There is also a way to determine it, called a strength test. True, it is not always possible to scratch a gold item in front of the seller, so this method cannot be implemented.

Iodine test.

The following chemical methods can serve as good ways to determine the quality of a product. You can drop a little iodine on the yellow metal jewelry. If the speck is dark in color, then we can speak with confidence about the quality of the product being offered. Table vinegar can also help. If, after three minutes spent in it, the precious metal has darkened, then you can safely take the product to a landfill.

Gold chloride can be a great help in determining quality. From the chemistry course, it became known not only the density of gold, but also the fact that it cannot enter into any chemical reactions. Therefore, if after applying gold chloride to a precious metal it begins to deteriorate, then this is a real fake and should belong in the trash.

One of the best ways to protect yourself from purchasing counterfeit goods is to purchase precious metal products in well-known specialized stores.

In this case, there is a high probability of purchasing a truly high-quality product. Even though their price is a little higher than in various shops and markets, the quality is worth it. Otherwise, you can purchase a counterfeit product and very much regret the money saved.

Physical properties

Noble metal has the following physical characteristics:

- increased strength;

- thermal and electrical conductivity;

- plasticity;

- bright characteristic shine.

The main feature of gold is its inertness. Thanks to her, metal received a noble calling. Inertness prevents oxidation, so gold jewelry retains its original appearance for centuries.

Perhaps the only drawback of gold is its softness. It is compensated by adding various impurities to the alloys. Due to it, gold becomes harder, but at the same time its main characteristics change: melting point and density.

In addition to softness, gold has increased heaviness. To calculate the weight of one cube of gold, special formulas and tables have been developed, which present the same indicators for different metals.

Due to its heavy specific gravity, gold mining is greatly facilitated due to the ability to wash grains of metal from smaller grains of sand and clay contained in water.

How to determine the density of gold

Real gold can be distinguished from fake gold using a simple but time-tested method. In ancient Greece, it was used by the scientist Archimedes, who was able to detect a fake and convict the jeweler who made the crown for the Syracusan king Hiero from low-grade gold.

Today, massive jewelry is well suited for determining the purity of a precious metal: bracelets, rings, chains, earrings. In order to accurately measure the volume of jewelry, it should not have any separate inserts of other metals or stones.

In order to determine the density of gold jewelry, you must have accurate scales with division values up to a hundredth of a gram and a beaker with volume graduations. The photo below shows step by step a simple method - how to determine the density of gold of any standard.

Among all the chemical elements, gold does not have the highest density; it is significantly ahead of iridium, which has the highest specific gravity among all metals known to people - 22650 kg/m3 or 22.65 g/cm3. Gold is also lighter than three other metals: osmium, platinum and rhenium.

As can be seen from the table above, among the chemical elements there is a metal that is not classified as noble, but has a density very close to gold - this is tungsten . Since tungsten and gold have almost the same density, it is often used by scammers these days. Especially today, counterfeit bars weighing 100 grams or more have become effective. The density of a 999.9 gold ingot is almost identical to the specific gravity of a tungsten ingot. A bank bar with a density of 999 gold is absolutely equivalent in weight to a pure tungsten bar of the same volume and shape.

Another metal that is much rarer, but also still used to make fake gold, is lead . Since the density of gold and lead differs significantly, it will be very difficult for scammers to deceive an attentive buyer of the precious metal. If the gold product is 375 standard, then the specific gravity of gold and lead is almost the same. With high-quality gold plating, lead can easily pass for 375 gold.

Source

Indicators of the specific gravity of other metals

Specific gravity is an indicator that is an integral characteristic of other metals.

The specific gravity of silver is affected by the fineness of the alloy. When other metals (copper, nickel) are added to it, the specific gravity and density are lost. Thus, the density of copper is 8.93 g/cm3, nickel – 8.91 g/cm3. All values are calculated using formulas.

Silver is the same noble metal as gold. Its specific gravity is 10.5 g/cm3. It melts at a temperature of 960 degrees. The main physical characteristics of silver are:

- corrosion resistance;

- low resistance;

- increased light reflectivity.

Despite its natural softness, silver has a high density and specific gravity.

Titanium is a non-ferrous metal of a white-silver hue. It has high strength, although it is light in weight. So, it is 12 times stronger than aluminum and 4 times stronger than copper and iron. In terms of the degree of presence in the earth's crust, titanium is given fourth place among the rest.

The low specific gravity of titanium - 4.505 g/cm3 is more consistent with alkali metals. An oxide film forms on its surface, which prevents the formation of corrosion.

Zinc is also a non-ferrous metal with a white-bluish tint. It has medium hardness and an initial melting point of 419 degrees. Under the influence of a temperature of 913 degrees, this metal acquires a vaporous state. Zinc has a specific gravity of 7.13 g/cm3.

Normal temperature makes zinc brittle, but increasing it to 100 degrees makes the metal flexible and ductile. When interacting with air, an oxide film forms on the surface of zinc.

The color of lead is dirty gray, but this does not affect the natural shine of the metal. However, the glow stops quite quickly due to the formation of an oxide film on the surface of the lead. The lead alloy has a high specific gravity - 11.337 g/cm3. In this indicator, it exceeds zinc, aluminum, iron and some other metals. Despite its high density, lead is a very soft metal.

The table shows the specific gravity and melting points of other metals.

Read also: Remote microphone and earpiece for listening

| Name of metal | Melting point, °C | Specific gravity, g/cc |

| Zinc | 419.5 | 7.13 |

| Aluminum | 659 | 2.69808 |

| Lead | 327.4 | 11.337 |

| Tin | 231.9 | 7.29 |

| Copper | 1083 | 8.96 |

| Titanium | 1668 | 4.505 |

| Nickel | 1455 | 8.91 |

| Magnesium | 650 | 1.74 |

| Vanadium | 1900 | 6.11 |

| Tungsten | 3422 | 19.3 |

| Chromium | 1765 | 7.19 |

| Molybdenum | 2622 | 10.22 |

| Silver | 1000 | 10.5 |

| Tantalum | 3269 | 16.65 |

| Iron | 1535 | 7.85 |

| Gold | 1095 | 19.32 |

| Platinum | 1760 | 21.45 |

Lead Density

The purer the gold, the less hard it is, so in the past the yellow metal was bitten to test. This method is unreliable. The jewelry can be made of lead, covered with a very thin layer of gold. Lead also has a soft structure. You can try to scratch the jewelry from the wrong side, and underneath a very thin layer of precious metal you may find base metal.

The density of the element of the periodic table - lead and its brother - gold is different. The density of lead is much less than gold and is 11.34 grams per cubic centimeter. Thus, if we take the yellow metal and lead of the same volume, then the mass of gold will be much greater than that of lead.

White gold is an alloy of yellow precious metal with platinum or other metals that give it a white, or rather matte silver, color. There is an opinion in everyday life that “white gold” is one of the names for platinum, but this is not so. This type of gold costs a little more than usual. In appearance, the white metal is similar to silver, which is much cheaper. The density of such elements of the periodic table as gold and silver is different. How to distinguish white gold from silver? These precious metals have different densities.

Silver is the least dense material of all those discussed in the article.

The density of gold is greater than that of silver. Its density is 10.49 grams per cubic centimeter. Silver is much softer than white metal. Therefore, if you run a silver item across a white sheet, a mark will remain. If you do the same with white precious metal, there will be no trace.

Mechanical Features

Tensile strength

The compressive strength of cast iron depends on the structure of the material itself. The components of the structure gain their strength along with an increase in the level of dispersion. The tensile strength is strongly influenced by the number, size, distribution and formagraphite inclusions. The tensile strength decreases by a noticeable amount if the graphite inclusions are arranged in the form of a chain. This arrangement reduces the cohesion of the metal mass.

The tensile strength reaches its maximum value when the graphite takes on a spheroidal shape. This form is obtained without the influence of temperature, but when cerium and magnesium are included in the cast iron mass.

- When the melting temperature increases to 400ºС, the tensile strength does not change.

- If the temperature rises above this value, the tensile strength decreases.

- Note that at temperatures from 100 to 200ºС, the tensile strength can decrease by 10-15%.

Plastic

The ductility of cast iron largely depends on the shape of the graphite, and also depends on the structure of the metal mass. If graphite inclusions have a spheroidal shape, then the percentage of elongation can reach 30.

- In ordinary gray cast iron, the elongation reaches only a tenth.

- In annealed gray cast iron, the elongation is 1.5%.

Elasticity depends on the shape of the graphite. If the graphite inclusions did not change, and the temperature increased, then the elasticity remains at the same value.

The elastic modulus is considered a conditional value, since it has a relative value and directly depends on the presence of graphite inclusions. The elastic modulus decreases if the number of graphite inclusions increases. Also, the elastic modulus increases if the shape of the inclusions is distant from the globular shape.

Impact strength

This indicator reflects the dynamic properties of the material. The impact strength of cast iron increases:

- when the shape of graphite inclusions is close to spherical;

- when the ferrite content increases;

- when the graphite content decreases.

Endurance limit

The endurance limit of cast iron becomes greater when the frequency of loading increases and the tensile strength becomes greater.

Features of the table used

In order to calculate the weight of the future product, which will be made from cast iron, you should know its dimensions and density index. Linear dimensions are determined in order to calculate the volume. A calculation method is used to determine the weight of a product in cases where it is not possible to weigh it.

When considering methodological tables, it is worth paying attention to the following points:

- All metals are divided into several groups.

- For each material, the name and GOST are indicated.

- Depending on the melting point, the density value is indicated.

- To determine the physical value of specific gravity in kilograms or other changes, conversion of units of change is carried out. For example, if you need to convert grams to kilograms, then multiply the table value by 1000.

Determination of specific gravity is often done in special laboratories. This value is rarely used when carrying out actual calculations during the manufacture of products or the construction of structures.

The physical properties of cast iron (density, thermophysical and electromagnetic properties) depend on the composition and structure, and therefore on the type and grade of cast iron.

Cast iron material: basic properties and important characteristics

Cast iron consists of carbon, iron and some impurities. It is one of the main materials of ferrous metallurgy. Cast iron is used in the manufacture of household and utility items, machine parts and in other industries. It is used in production, focusing and taking into account its properties and characteristics.

This article is precisely intended to tell you about the density of high-strength, liquid, white and gray cast iron, its melting points and specific heat capacity will also be considered separately.

The influence of impurities on the characteristics of the metal

Industrial cast iron contains impurities. These impurities greatly affect the properties, characteristics and structure of cast iron.

- Thus, manganese inhibits the graphitization process. The release of graphite is stopped, as a result, cast iron acquires the ability to bleach.

- Sulfur degrades casting and mechanical properties.

- Sulfides are mainly formed in gray cast iron.

- Phosphorus improves casting properties, increases wear resistance and increases hardness. However, against this background, cast iron still remains fragile.

- Silicon has the greatest influence on the structure of the material. Depending on the amount of flint, white and ferritic cast iron are obtained.

To obtain certain characteristics, special impurities are often introduced into cast iron during its manufacture. Such materials are called alloy cast iron. Depending on the added element, cast iron can be called aluminum, chromium, or sulfur. Basically, elements are introduced with the aim of obtaining a wear-resistant, heat-resistant, non-magnetic and corrosion-resistant material.

This video will compare the properties of cast iron and steel: