Metal chasing is a type of decorative and applied art and a type of cold metal processing. It is the process of applying a flat or three-dimensional pattern to a metal sheet using a special tool and execution techniques.

At its core, it is a process of artistic metal processing. Both varieties are used to decorate the facades and interiors of public and private houses, paintings, weapons, kitchen utensils, everyday items, and items made of precious metals.

Metal embossing is widely used by designers and builders in their work. Nowadays, this is a popular type of artistic product, which is in demand and amazes with its diversity. Requires the highest skill from the performer.

It’s not difficult to do embossing with your own hands if you know the types of craftsmanship, the nuances of manufacturing, the materials used and develop your own style.

Process Basics

The image is created by striking a hammer with a tool applied to the surface of the metal. The configuration of the impression depends on the shape of the working part of the instrument. Then it is sequentially rearranged and the operation is repeated until the entire pattern is knocked out. Complex images are minted using several tools with working parts of different shapes.

Depending on preferences, metal minting is performed in different styles:

- historical;

- Old Russian;

- eastern;

- Georgian;

- Moroccan;

- Uzbek;

- modern.

The quality of the images depends on the degree of training of the minter.

Regardless of the style, each master has his own “handwriting” of performing the work. Despite the apparent complexity, it is not difficult to master metal embossing with your own hands.

Complex images are minted using different tools

Essence of the process

The essence of the embossing technique is the impact of the hammer on the embossing tool. An imprint corresponding to its type remains on the metal.

By performing multiple blows, a relief is obtained that matches the sketch. The shape of the design is conveyed with great expressiveness and accuracy, depending on the tools used by the embosser during the work process. At the same time, the quality of work depends on his qualifications and skill.

Each master has his own style of work. Metal stamping on non-ferrous and ferrous metals differs in type and technology.

Types of coinage

Depending on the shape of the object and the complexity of the design, embossing can be:

- Openwork, similar in appearance to metal lace. The work begins with cutting out the background, then the final cutting is carried out along the prepared lines. Since the thickness of the openwork partitions is small, during annealing it is necessary to ensure that they do not melt. Openwork embossing is often applied to three-dimensional objects as a finishing touch.

- Contour, which is minted on sheet metal without a pre-applied relief. Visually, such embossing is similar to engraving, but differs from it in convex or concave shapes. This method is used for the manufacture of decorative elements of interiors and for applying ornaments to flat surfaces.

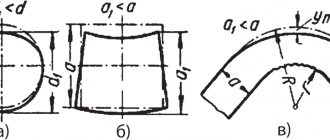

- On bulky objects. The most difficult type of embossing to perform, since the design is embossed on a curved surface. However, experienced craftsmen cope with the work without much difficulty.

- Embossed. It is also classified as a complex species. The work begins by punching out the contours of the design, then the image is made in relief. At the final stage, the image details are aligned and polished.

Coinage

The art of coinage dates back to the times of the ancient world, as an example, we can cite the gold mask from Mycenae.

Chasing - handmade

The design is minted on a sheet of metal, having previously laid it on a birch or linden ridge. In addition to them, rubber and a bag of sand are used as a substrate for execution. Some craftsmen use lead.

By the way, mints where coins were minted could not do without minting. They are made of metal more than 1 mm thick. To obtain high-quality and accurate relief, special presses are used, with a pre-installed stamp on which drawings and the necessary inscriptions are applied. The press provides the force necessary for impact, deforming the surface to the required state.

By the way, regardless of the type of embossing, it is completed by finishing.

Materials used

Embossed jewelry is traditionally made from silver and gold. Most craftsmen work with cheaper metals:

- Copper with a thickness of 0.3 to 1.5 mm. It is plastic, easy to process, depending on the brand with a light or dark shade of red. Copper and its alloys are more often used than other metals for decorating rooms.

- Red copper, sheets of which can be rolled to a thickness of 0.05 mm. Due to its softness, relief embossing can be easily performed even on voluminous products of complex shape. High resistance to corrosion allows the installation of decorative elements made of hammered copper on the facades of houses.

- Various brands of brass with golden yellow color in different shades. High (up to 50%) zinc content increases hardness and reduces flexibility. However, despite its lower ductility than copper, brass is easily minted.

- Tompak is a type of brass with a low (up to 10%) zinc content. Due to the large proportion of copper, the metal turns out to be red in color with a yellow tint. The alloy with the addition of aluminum up to 5% acquires a color indistinguishable from the color of gold. Tombac is used to make badges, medals for anniversaries, cheap jewelry, and decorative elements for interiors.

- Aluminum and its alloys. The metal is easily minted, but due to its low melting point, care must be taken during heat treatment to ensure that the design does not become deformed. Duralumin imitates silver well, but it is difficult to work with, since due to its low flexibility, the metal may crack when knocking out the relief.

- Tin plate on which beginners practice their embossing skills. However, masters also do not neglect this accessible material.

- Ferrous low-carbon metals. The blanks are pre-annealed and etched to obtain a decoper, on which images with large relief or designs with small details are minted.

- Roofing iron for embossing contour images with shallow relief without background and small details.

- Stainless steel with a thickness of 0.5 to 0.8 mm. The metal looks beautiful, but due to its high strength and dense structure it is difficult to knock out. High resistance to corrosion allows us to make embossed memorial plaques and plaques for monuments and monuments from stainless steel.

- Cupronickel and nickel silver are nickel alloys with a high copper content (81 and 65%, respectively), so they are ductile and easy to polish. Chemical treatment makes the surface golden, silver, or imitates antique bronze.

Various types of products

Embossing is widely used in the production of products for various purposes, from sheets of metal of different grades. It is widely used in the decoration of buildings inside and outside. This operation is used in the production of metal utensils, decorative manels, and jewelry.

Forging products

When creating products, craftsmen use special techniques, for example, chasing grapes. There are many secrets in this business that are often passed down from generation to generation.

Paintings and interior elements are produced in embossing workshops. In addition, some craftsmen carry out work on the production of paintings that consist of several layers, including those that consist of several metals. This combination gives the composition multicolor.

Embossing on three-dimensional products

In embossing workshops, fragments are also produced that can be installed in furniture made from solid wood and various types of panels.

A special type of coinage is frames for icons; in addition to drawings, precious stones are fixed on their surface.

For as long as coinage has existed, separate styles have developed (Caucasian, Eastern, etc.). Modern masters use all previously developed styles and at the same time develop their own.

Equipment and tools

In addition to the workbench, the embosser’s workplace is equipped with metalworking yews, an electric sharpener, a cabinet or rack for storing tools, materials, reagents, etc. The set of equipment is supplemented by:

- container and electric stove for heating bitumen;

- two 0.5x0.5 m tarpaulin bags with dry fine-grained sand;

- baths for chemical solutions;

- a box with sawdust for drying workpieces;

- blowtorch for annealing;

- rubber gloves for chemical processing;

- canvas gloves for working with hot workpieces;

- metal plate for editing.

Basic tools for metal stamping

The basic tools for metal stamping are called coins. They are made of high-carbon steel in the form of square or round rods 12 - 18 cm long of different sections. The lower part is called the battle. The middle section is thickened to make it easier to hold in the hand. Depending on the form of the battle, the coins are given names:

- tubes create rounded depressions;

- bypass lines are drawn in the form of a series of points;

- contours of the image are applied with canfares;

- with rough or smooth edges the background is leveled;

- Punchers perform a punch from the back side;

- the background is stuffed with chops with a semicircular or straight cut;

- curly ones make prints of non-standard shapes.

Hardwood coins perform the same functions as metal ones, but are larger in size. To work with them you will need a wooden hammer (mallet). Such coins are used to create large designs with deep relief. Large images are knocked out with metal hammers and blows are struck on the coinage. Therefore, one side is made spherical and the other flat.

ARTISTIC COUNTERING and METAL PRODUCTS

COINING TECHNOLOGY

- a complex and labor-intensive process in which every millimeter of the metal surface is processed.

COINING TECHNOLOGY

includes such concepts as double-sided forging with punches, hammering, firing, polishing, etching, blackening.

Our master minters

they work in easel

chasing

and use the punch

chasing technique

. For embossing work, as a rule, we use sheet materials: copper, aluminum, brass, low-carbon stainless steel with a thickness of 0.2 to 1 mm.

Using individual minting technology

Since ancient times,

minting masters

have made battle armor, dishes and various decorative ornaments from sheet metal, which had high plasticity.

Kitchen and table utensils were especially varied - cauldrons, bowls, ladles, scoops, dishes, jugs, vases, teapots and much more. The minters

not only sought to create high-quality and convenient tableware, but also tried to make it aesthetically attractive.

Among the various methods of decorative finishing of dishes, embossing

, with the help of which ornamental and narrative reliefs were created on the surface of the products.

The ancient minting masters

knew many

minting

and had their own

minting technique

, which made it possible to create both low and high relief.

When finishing the embossed relief and texture, the minters

skillfully combined smooth shiny elements of a pattern or plot image with a matte “shotted” background, engraving, niello and gold lining.

The technique of minting that came from ancient times

and

CHASING TECHNOLOGY

is widely and variably used by our

embossing masters

when creating decorative panels and tableware, artistic embossing and custom embossing, which serve as worthy interior decoration.

COINING TECHNOLOGY

passed down from generation to generation, from master to master.

CHASING TECHNOLOGY

has its own secrets, which every

master minter

carefully and reliably keeps from strangers.

Our minters

comprehensively studied the history of the embossed craft, its application,

embossing techniques

, starting from Byzantium, Iranian artistic silver, Russian embossed frames, etc., which made it possible to penetrate into the innermost secret of metal and create metal embossing ornaments unsurpassed in subtlety, beauty and strength.

I use a unique embossing technique

, our minters can

produce embossing

that combines fairly large sizes of products (from 100 sq. cm and more) with filigree finishing of parts.

The most difficult of all types of artistic embossing

—

embossing

on sheet metal, since when working on sheet metal, you need to create a pattern, a relief, and the texture of the material in the process of

making embossing

.

And when coining

by casting, only the identification and completion of a previously created form, cast from various metals, occurs.

COINING TECHNOLOGY

for metal consists of the following stages:

1. Preparation of the drawing - without detailing

To demonstrate a sample of a completed pattern for embossing

, we carry out the initial sketches for

the manufacture of coinage

either in full size or on a scale (for large products) without detailed detailing, in a decorative and generalized form.

expected in the coinage

are shaded in the drawing.

2. Making life-size sketches with detail

At this stage of coinage production

On the sheet we make a sketch (

embossing

) in full size and carefully draw the composition with texture and ornamentation.

To perform minting

the embossing

pattern on paper : entirely - for simple shapes that have one radius of curvature (cone, cylinder), on which the paper is easily applied, or in parts - for spherical and complexly profiled shapes that have several radii of curvature.

3. Selection and preparation of the workpiece

Based on the size and configuration of the coinage

,

the embosser

cuts a rectangular blank from the sheet metal with scissors in such a way that the entire design can be freely placed on it and a small free edge 30-40 mm wide remains around.

This edge is necessary to more firmly hold the workpiece on the resin during the embossing

, especially when knocking out high relief close to the edges.

According to minting technology

This stage is completed by annealing and pickling (treatment of the metal surface to remove dirt, rust, scale and oxides).

4. Roasting

Thanks to tarring, the workpiece is firmly fixed, which is necessary when working as a chaser

. In addition, the imprint from the strike is clear and defined. Volumetric forms - glasses, vases, round sculptures, as well as deep bas-relief and high relief forms are minted, filled with resin.

5. Transferring the design to a metal surface and fixing the image

At this stage our minters

remove a duplicate from the

coinage

on carbon or tissue paper, which is glued to the metal with rubber glue.

Based on a pasted duplicate of the coinage

The outline of the composition is pierced with dots using the finest canter chasing, and the design is fixed on the plate with a dotted line.

6. Execution of the drawing

Carrying out the consumption of the embossing

– drawing a contour with a solid line.

The chaser

all the turns and bends of the contour with more frequent blows and a greater inclination of the chase inside the curve. On a polished steel plate, a sheet of metal is repeatedly forged on both sides with stamped punches, revealing the filigree texture and ornamentation of the bas-relief.

The next stage of hammering is carried out by the minter

of the coinage

are already revealed , and the ornamental surface, on the contrary, is smoothed out and becomes similar to a plate processed by the finest chisels.

7. Lowering the background around the design

This work is performed with a hammer on a harder surface to level all areas of the background.

8. Annealing

If further work with the relief is planned, then the embosser

performs annealing because After tracing the outline and lowering the background, the metal plate lost its plasticity after many blows. To do this, it is heated to a dark red color and allowed to cool, after which it is picked up again. During the heating process, the metal regains its viscosity and plasticity.

9. Raising the relief and knocking out the relief

This operation of minting technology

consists in further raising the relief (if this is provided for in the drawing).

The embosser

hammers out the relief on the reverse side on rubber or sandbags.

At the same time, the master strives to raise the relief as accurately as possible, in accordance with the embossing pattern. Sometimes the rise of the embossing relief is

made a little higher than it should be, with some margin, with the expectation of subsequent refinement in resin.

After punching out the relief and leveling the background, the embosser

anneals the plate again, bleaches, washes and dries it for secondary resinization and final resin finishing.

10. Secondary tarring and final modification of the relief

The final embossing of the relief consists of a detailed elaboration of all forms, identifying their characteristic features and, at the same time, subordinating the details to the main thing, creating an overall integral impression of the entire embossing relief

.

IN COINING TECHNOLOGY

The relief and texture of embossed surfaces plays a big role in the final finishing.

The combination of smooth, forged and matte (rough) relief elements helps to achieve a great decorative effect with minor differences in relief heights.

The use of various patterned embossings, which give individual areas of the relief a striped, lattice, pitted or cellular texture, significantly enriches the coinage

Minting technique

with subtle strokes or cuts made with consumables, they emphasize this or that shape.

Our minters

pay great attention to finishing the background

of the mint

- they make it either smooth, forged, or matte, variegated and patterned.

Sometimes the background of the coinage

is canted, and sometimes it is completely cut through (for a thin sheet) or cut out with a jigsaw (for a thicker sheet of metal).

11. Embossing with perforation

If the coinage

provides for a perforated, end-to-end background, it is performed after finishing work on the relief.

In this case, the minter

uses the technology of drilling, chopping and filing metal.

12. Product finishing

After machining the metal is minted

subjected to annealing, etching with nitric acid, blackening, washing, patination, grinding with abrasives, final grinding and polishing. It is also possible to secure protective films with varnish.

13. Completion

Completes the entire minting

- production of a base subframe onto which processed sheets of metal are stuffed, and final assembly of all the details of the

embossing

.

Rice. MINTING TECHNOLOGY diagram

on resin.

In addition to the main processes and the order of their implementation in COINING TECHNOLOGY

there is great variety in the sequence of work and minting

techniques

.

Depending on the specific conditions, material and tasks, various options for embossing technology and techniques

.

of embossed work can be distinguished:

, differing in their technology and giving a different artistic effect:

- flat metal embossing, made with a consumable

- embossing of

three-dimensional forms - consumable with perforation or edging of the background

- embossing

without patterns, not figurative - stuffing the texture with a puroshnik, boboshnik or patterned embossing - consumable with background lowering

- consumable with light relief knockout from the inside

- relief embossing

with full relief processing of varying heights and degrees of detail - embossing

without grinding large generalized decorative reliefs from sheet aluminum, copper or iron - a modern technique - minting of

three-dimensional sculptural items - embossing

by casting

Metal processing - embossing

- is a truly complex process, both from a technical and artistic point of view.

Knowledge of various metal embossing techniques and mastery of embossing techniques

allows our

embossers

to create elegant artistic

embossed

works, complex decorative patterns, ornaments and inscriptions on flat

embossing

.

Our decorative works, made using a very complex and labor-intensive punch embossing technique

, are particularly strong and durable.

With this embossing technique,

the master processes every millimeter of the metal surface, beating out the texture of the background and ornament, and then embossing a relief image of figures of people, animals, and plants on resin. One of the features of our work is the filigree processing of every centimeter of relief with embossing.

Mastered minting techniques

make it possible for our

minters

to use both traditional

minting

- copper, as well as soft aluminum or hard material brass when making products.

Using a combination of embossing techniques

we can both emphasize and highlight individual elements and create the entire composition in the same style.

When making coinage

The use of techniques and unique

embossing techniques

allows us to perform very complex processes, such as blackening, shotting, patination, and skillful imitation of precious metals.

These and many other technical techniques create a complex texture and unique coloring of metal embossing - the surface of the relief shimmers with a mesh of the finest patterns, sparkles with pearl grains, glistens with golden scales. The metal can take on various shades of gold, the tone of old silver or velvety greenish bronze, darkened by time.

Our professional minters

will successfully use their experience and knowledge

of COUNTERING TECHNOLOGY

when creating beautiful works of art for you.

Order the production of coinage

from us, and you will receive the best quality and original execution.

Similar articles:

- The influence of the environment on METAL PRODUCTS The passage of time always leaves traces that appear on metals as a result of natural chemical...

">Patina and bluing on CHASING and METAL ARTWORK

- PATINATION and OXIDATION The finished embossed composition can be left in the natural metallic color of the original plaque, but it can also be “aged”...

“>Finish processing of coinage - PATINATION and OXIDATION

- Book title: Artistic processing of metals Year of release: 1988 Author: Lyamin I.V. Publisher: Mechanical Engineering Language: Russian Number of pages…

«>Artistic processing of metals

- Book title: Art Nouveau Ornament Year of release: 2007 Author: V. I. Ivanovskaya Publisher: V. Shevchuk Language: Russian Number of pages: 94 Form…

"> Art Nouveau ornament

- Book title: Twelve metalworking techniques Year of release: 2004 Author: Tim McCreight Publisher: Eksprint Language: Russian Number of pages…

">Twelve metalworking techniques

Latest articles:

- ARTISTIC CHECKING on metal One of the most ancient and beautiful ways of obtaining relief figures and metal products is ARTISTIC CHECKING...

">ARTISTIC COINING

Past articles:

- COUNTERING - GLOSSARY Abrasive powder is a grinding powder consisting of crushed glass, emery, chromium oxide and other substances of a certain...

">GLOSSARY OF TERMS on coinage

- PHOTO OF COUNTERING - our works You can evaluate the quality of minting by our works presented in this section. This section shows only some...

">PHOTO OF COINING

- COUNTERING TO ORDER - high quality and individuality Our company produces COUNTERING TO ORDER. WHEN ORDERING COUNTERING you receive copyrighted coinage...

">ORDER COINING and COINING TO ORDER

- COST OF COINING - calculation features Estimation of COST OF COINING is an individual process. THE PRICE OF COINING depends on many factors and the initial in...

“>COUNTING COST and COINING PRICE

- CHASING METAL CHASING is one of the most ancient types of decorative and applied arts and artistic metal processing. COUNTERING - technological...

">COUNTERING and COUNTERING ON METAL

Minting technology

The work is performed in the following order:

- draw a life-size image on paper;

- according to the dimensions of the sketch, a plate is cut from the metal sheet with allowances that are needed for mounting on a substrate or when framed;

- the workpiece is annealed and then leveled;

- a layer of white gouache or paint is applied to the front side;

- Using carbon paper, the image is applied to the metal, then traced with a scriber;

- On the workpiece fixed on the substrate, first the outer contour of the design and internal lines are knocked out, then the relief details.

At the final stage, decorative finishing is carried out:

- grinding to remove irregularities and roughness;

- polishing, after which the product will acquire a finished look, and the metal’s resistance to corrosion increases;

- patination (aging) - treatment with sulfur and chlorine solutions to imitate antiquity;

- painting brass and copper products with metallized paints;

- oxidation with chemical solutions to give the surface a color from green to black;

- Enameling with glass alloys of different colors is used to decorate small products or individual parts;

- tauching - driving in a thin wire of another metal to highlight the outline or details of an image.

Important!

Before decorative processing begins, the product is washed, degreased, and dried in sawdust.

Technological process

The work of embossing begins with the preparation of the drawing, which is made in full size. The drawing must be done in a contour manner, that is, objects must be depicted without shadows. It is necessary to leave on the sheet the margins necessary to fix it on the metal.

Technological process of minting

To transfer a design, the workpiece is scanned onto paper. Based on the latter, a contour is cut out of the metal. Its size should slightly, by 3 - 4 cm, exceed the area of the image printed on the paper. This strip of metal is needed to secure the metal on the work site. By the way, resin is used to enhance the fixation of the metal sheet.

DIY minting process

One begins to learn the art of embossing with simple images that are easy to find freely available on the Internet. After mastering the skills of working with different types of coins, they move on to complex compositions. For the first three-dimensional images, it is better to choose copper.

It is important to immediately learn how to mint correctly. It is held, slightly tilted back, with the fingers of the left hand, without using the little finger. In order not to limit the freedom of movement, the hand is kept suspended, without resting the elbow on the tabletop. The tool is moved forward after making an imprint of the required depth. When doing copper embossing with your own hands, it is recommended to apply a thin layer of plasticine to the surface of the workpiece so that the embossing glides better.

To improve ductility, the metal sheet is annealed. Minting begins with the application of external contour lines on the front surface. From the inside, the outline is pulled out after filling the internal lines. Then the main relief is filled and leveled. The work is completed with decorative processing.

Since finishing is performed with toxic substances, when working at home, it is necessary to follow safety rules for handling and storing aggressive liquids. The treatment is carried out inside a fume hood or ensures effective ventilation of the room. Containers with reagents are closed with well-ground stoppers.

Currently, coinage is very popular. Therefore, after mastering this type of artistic metal processing, you can organize a profitable business. Thematic drawings can be easily found on the Internet and original compositions can be created based on them.