Every man should have such things as a grinder and a drill in his assortment of tools. A grinder can clean metal from old paint and corrosion. In everyday life, a drill can greatly facilitate repair work if you need to stir any mixture or tighten screws.

But each of these tools has a common goal - cleaning the surface from rust and corrosion. For this, metal brushes are used. You can find photos of metal brushes on the Internet so you don’t make a mistake in choosing. In this article we will look at the types of brushes.

Brushes for drills and grinders

Tools such as drills and grinders can clean any surface from rust and corrosion. Let's look at the main types of brushes.

Folk remedies

You can quickly and safely deal with rust using available tools. The most unexpected and inexpensive compounds come to the rescue, including acetic acid, hydrogen peroxide and even carbonated drinks like Coca-Cola, but for these products to work, they must be used according to the instructions.

How to remove with acetic acid?

For cleaning, it is recommended to use an essence with a concentration of 70%.

Mode of application:

- Place the instrument that needs cleaning into a suitable container.

- Fill it completely with acetic acid.

- Cover the container with a lid and leave for several days. The more rust, the longer it will take.

- After cleaning, rinse the tool in a baking soda solution. It neutralizes acid.

After this treatment, you can continue to use the devices. The effectiveness of cleaning with essence is very high. It allows you to cope even with a thick layer of rust. If it is small, then you can use table vinegar or lemon juice.

It is not recommended to use vinegar to clean aluminum tools as it will dissolve the epoxy layer and damage the metal structure.

If rust has stuck to the tool in pieces, then the areas can be cleaned with ordinary food foil. It is used as a scraper.

Citric acid and hydrogen peroxide

You can get rid of rust using citric acid and pharmacy hydrogen peroxide. To prepare the solution you will need:

- citric acid – 20 g;

- peroxide – 15 ml;

- water – 100 ml.

Instructions for use:

- All components are mixed with each other.

- Place the instrument in a suitable container and fill it with solution.

- Leave them for a day under a closed lid.

- After the specified time, the solution is drained. The instrument is washed with clean water, dried and used for its intended purpose.

During the cleaning process, the solution will become dark in color. This is normal and indicates the effectiveness of the composition. With its help you can cope with a small layer of rust.

If the instrument is severely damaged, the concentration of the solution must be increased. In advanced cases, they refuse to add water altogether, dissolving citric acid in peroxide .

The video will tell you how to remove rust using citric acid and peroxide:

How to remove Coca-Cola?

Coca-Cola is a popular carbonated drink that can be used to remove rust. The effect is achieved due to the content of orthophosphoric acid, which corrodes oxides.

Mode of application:

- pour Coca-Cola into a suitable container;

- place rusted objects in it;

- cover the container with a lid;

- leave for a day.

The next day, the part is removed, rinsed with clean water and dried.

Coca-Cola is one of the budget and effective rust removers. Sprite and Fanta have a similar effect.

Soda

You can deal with rust using baking soda. An alkaline solution will help get rid of a small layer of corrosion without harming the metal. The effectiveness of the method is explained by the active action of sodium.

Mode of application:

Prepare the required amount of soda slurry by mixing the powder with water. It should be moderately thick, reminiscent of a paste in consistency.- Using a sponge, apply the paste to the instrument.

- Leave the mixture to act for an hour.

- Rinse the product and wipe it with a dry soft cloth.

- If necessary, the procedure can be repeated.

Baking soda is not a highly effective way to combat rust, but a small layer can be removed this way.

Zinc chloride

You can use zinc chloride to remove rust. Apply it as follows:

- 20 g of zinc chloride are dissolved in 200 ml of water, the product is prepared in the quantity required;

- pour the solution into a suitable container, lower the tool into it;

- leave to act for an hour;

- Rinse the instrument with clean water and wipe with a dry cloth.

Zinc chloride contains free hydrochloric acid, which has the ability to dissolve rust. The main thing is not to overexpose the composition so that the metal itself does not turn black.

The method is quite effective; zinc chloride can cope with even large areas of corrosion.

Cup brush

The brush is capable of cleaning the surface from traces of concrete and corrosion. This kind of metal brush for grinders and drills is often used for processing flat steel products.

If you need to treat a wooden surface, you should use a nylon brush.

Exploitation

The hand tool is easy to use. You don't need to follow any rules. After each use, it is enough to clean the lint and metal surfaces from chips, rust, and dirt.

To effectively use accessories for power tools, you need to learn how to properly clamp them in an angle grinder or drill. It is important to check how firmly the fastenings are held. It is recommended to carry out a trial run of the power tool. When cleaning metal surfaces with equipment for an angle grinder or drill, you need to set the number of revolutions correctly. Metal lint cannot be used to clean the front sides. It will leave a lot of scratches that will need to be corrected and polished. You can remove scratches with polish or fine sandpaper.

Before using the equipment or hand brush, you should carefully inspect it. If the pile is bent to one side, you need to straighten it. To do this, you need to focus and lightly tap the bends with a hammer. If there is not enough lint, it is recommended to replace the brush with a new one.

To clean a metal surface from dirt, plaque, scale, and rust, you can use various tools. The simplest, most affordable option is a brush. If you have a power tool (grinder, drill, screwdriver), you can buy special equipment. Learning to use a brush is easy. You don't need any additional skills to do this.

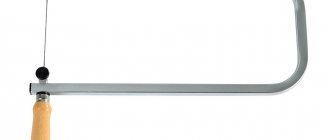

Disc brush

If you need to clean a large area of the surface, then use a disc brush. It has high rigidity and strength, so you can use it for a long time.

The brush for stripping metal is manufactured using the latest technologies. This brush is usually called a brush brush and is used in industry.

Painting materials

Before applying paint to a cleaned surface, it is better to prime it, but many modern compositions make it possible to do without a primer. The following paints are used for painting metal:

- epoxy, based on silicone resins with a hardener. High toxicity requires external use only;

- oil - a traditional composition, before using which steel products are pre-coated with primer. The presence of a pungent odor requires painting to be carried out in a well-ventilated area;

- alkyd – has good stability, does not require preliminary priming, can be applied in any conditions;

- acrylic - a modern type created on the basis of polymers. Non-toxic, easy to use, requires careful preparation;

- rubber – perfectly protects roofs and external elements exposed to precipitation.

These are classic paints and varnishes that are found everywhere and are popular. However, there are other, more specialized mixtures:

- primer-enamel applied specifically to rust, which prevents its development;

- anti-corrosion, preventing the entry of moisture and oxygen;

- forging, giving wear resistance;

- toxic nitro paints.

All of them can provide additional protection, as well as improve performance and reliability. All these actions are an important part of preparing products for further painting and increasing their service life.

Tags: Enamels and paints

Corbrush

Brushes are used to clean parts from rust and flux deposits. Also, if it is necessary to give the product a marketable appearance, this type of brush is used.

In industry, a good and correct brush is used in the production of aluminum radiators for various brands of cars.

Types of hardness

The work performed depends on the pile. The following wires are distinguished:

- Corrugated. This brush reduces machine vibration and applies gentle pressure to the surface. This happens due to the fact that the brush has springing properties;

- Twisted. The bristles curl and give a harsh action on the plane. The brush has great strength;

- Smooth. The brush quickly loses its shape and over time is unable to do its job.

All brushes differ in their cup diameter.

Mechanical rust removal

The problem of rust is constantly encountered in metal structures factories.

Storage of rolled metal at bases takes place in the open air. The raw materials are exposed to moisture and air, and a rusty mark forms quite quickly.

Hand Brushes for Rust Removal

For small production volumes, the simplest brushes with metal bristles are used. They differ in the stiffness of the bristles (wire), as well as in the method of attachment to the handle.

Some wire brushes have a brass coating on the surface of the bristles. During processing, the effect of transfer of the copper-zinc alloy to the workpiece occurs. The forming film further protects the part from oxidation.

The duration of the process depends on the complexity of the part being processed, the presence of internal cavities and dimensions. Relatively simple products are processed within a few seconds. Others require a significant investment of time.

To perform the work safely, parts are fixed on workbenches in special devices or in a vice. Be sure to wear safety glasses or masks. Gloves are put on your hands.

Mechanical brushes for processing steel products

If you have power tools or pneumatically driven devices, use mechanical brushes. They are manufactured in radial and end versions.

For installation in the chuck of an electric drill or screwdriver, the brushes are equipped with a cylindrical shank. When using an angle grinder (angle grinder), an M14 thread is created on the tool. It is screwed onto the drive shaft.

Despite their apparent simplicity, working with mechanical brushes is quite difficult. The instrument tries to escape from your hands. Therefore, special mandrels and guides are used; they help the worker hold a complex technical device in his hands.

If it is necessary to process a workpiece from all sides, it must be positioned in different positions. Special clamps allow you to firmly secure the part to the workbench. The tool is brought to the surface of the part in different ways, which helps to remove fragments of the rusty film outside the processing area. The impact speed can reach several meters per second.

Attention! Mechanical rust removal produces a large amount of metal dust. Therefore, it is necessary to protect the respiratory system from its entry. It is assumed that the worker's face and hands are protected.

Sandblasting units for removing dirt and rust

In large-scale and mass production, sandblasting machines are used to process a large number of products and semi-finished products. Sand is used as the working fluid. It is directed to the surface of the parts at high speed by a powerful air flow.

Sand grains hit the surface. Any rust that is present flies off in small fragments. Since the impact speed is quite high, the process occurs quite quickly. Large areas are cleaned within a few seconds. After such processing, the part acquires a metallic shine.

Waste sand is collected in a container. It contains knocked down rust particles; they are also used in subsequent processes for cleaning steel parts.

Processing in screens for cleaning workpieces from rust

At many enterprises, products and workpieces are cleaned of rust using screens. These are special machines (most often of the rotary type), in which parts come into contact with abrasive (sand). As a result, rust is scrubbed off the surface.

The workpieces are located inside mesh rotating cylinders. When rotating, the parts roll along the surface. The height of the fall depends on the diameter and angular speed of rotation.

Mechanical impacts between each other and with an abrasive allow you to scrub off existing coatings from the surface. It's not just the rust that gets cleaned off. In such installations, they achieve the removal of paints that form a fairly strong adhesion to the surface.

The productivity of screens is measured in tens of tons of workpieces per hour. Vibrating tables are made at home. On them, parts and abrasive interact with each other. Productivity is lower, but sufficient for home production conditions.