Description

Motoblocks "Cascade" have proven themselves as reliable farmer's assistants.

These are productive, durable machines capable of working with a full range of mounted implements, performing the functions of a cultivator, plowing machine, mower, snow blower and many others. In order for the walk-behind tractor to work without failures for many years, you must follow the instructions during its operation.

Timely maintenance of the walk-behind tractor is also important. For the Cascade, the maintenance schedule is the same as for any other household walk-behind tractor:

- scheduled maintenance: once a season, at the end of seasonal work and before it begins (at the beginning and end of spring, at the beginning and end of summer, etc.);

- regular mini-inspection - every day upon completion of work and turning off the walk-behind tractor, as well as an external inspection in order to identify damage, chipped paint, etc.;

- winter storage - is allocated to a separate maintenance category, since it involves draining all fuels and lubricants and storing the walk-behind tractor in a room with a positive temperature; upon completion of the winter “preservation” the unit is refilled with fuel and lubricants;

- annual engine prevention (detecting faults, eliminating them, maximizing the service life of the motor and other key components of the unit).

Next, we will look at the basic rules and requirements for fuels and lubricants, the process of starting and running in the Cascade walk-behind tractor, as well as the most common malfunctions of these devices.

What kind of gasoline goes into the walk-behind tractor? Is it necessary to add oil to gasoline for a walk-behind tractor?

Today, almost every owner of a summer house, farm or just a plot of land has such mini-agricultural equipment as a walk-behind tractor. And no wonder. These machines have long established themselves as reliable units that come to the rescue almost all year round. In order to maximize the functionality of the walk-behind tractor, it is necessary to use attachments. But this is a separate topic.

In this article we will look at a question that interests many, namely: is it necessary to add oil to gasoline when refueling a walk-behind tractor. This point is relative and depends on the model and design of the unit. All information about proper operation and the fuel that should preferably be used can be found in the instructions for the walk-behind tractor.

To dilute the fuel or not

In order to understand whether to dilute gasoline with oil, you need to thoroughly study the design principle of the walk-behind tractor. First, pay attention to what engine the unit is equipped with. They are divided into two- and four-stroke. If the engine is two-stroke, then oil must be added to gasoline. Provided that the proportions are strictly observed. As for the four-stroke engine, only pure gasoline is used here, without any additives.

It is important to know! If your walk-behind tractor is equipped with a diesel engine, then you do not need to add oil to the fuel. All diesel engines are four-stroke. Do not experiment with equipment, as this can lead to serious problems and costly repairs. Therefore, if you still decide to dilute fuel, check for sure what type of engine your walk-behind tractor has.

What types of oils are there for walk-behind tractors?

The proportions in which oil and gasoline are diluted are different, and to avoid mistakes, it is better to study the instructions. But, most often, a ratio of 1:4 is used - 4 parts of gasoline are taken for one part of oil. Don’t forget that the gearbox (if your model has one) also needs to be periodically replaced with oil changes.

So what oil should you use? Oil is an important component for the correct operation of almost all components and systems. Its main task is to get rid of unnecessary friction. When choosing oil for a walk-behind tractor engine, pay attention to the viscosity level and seasonality. Oil comes in the following varieties:

1. Summer oil. It is used in the hot season and has fairly high viscosity;

2. Winter oil. On the packaging you can see a conventional letter symbol: W, which means Winter. The viscosity of such oil will be significantly lower, for comfort in the cold season;

3. All-season oil. The most popular option among users and can be used at almost any temperature. However, it still has a difference in viscosity. The colder the winter, the lower the viscosity should be.

Using a walk-behind tractor involves not only changing the oil, but also timely maintenance. In most models of walk-behind tractors, replacement of worn-out spare parts and minor repairs must be carried out every 2000 hours of operation. If you don’t know where to buy all the necessary components or how to select a part, contact the Agro-Moto-Tata online store - here you will find a wide range of spare parts for popular models of motorcycles, and qualified personnel will help you make the right choice.

Instructions and recommendations for use

The reliability and long service life of the walk-behind tractor depend on the operating conditions, maintenance, care of the unit, and proper running-in after its purchase. To do this, you must follow all recommendations for operating the equipment.

They boil down to the following:

- Assemble the walk-behind tractor. The assembly diagram can be found in the instructions that came with the unit upon purchase.

- Fill the tank with clean gasoline.

- Check the oil level in the engine crankcase.

- Inspect the wheel mountings.

- Check engine valve clearances. The valves are adjusted using feeler gauges of 0.10-0.25 mm.

- Run-in as follows:

- do not start work with a cold engine;

- the engine must first idle;

- do not load the engine during operation;

- running-in should last at least 30 hours;

- work only in first gear;

- After break-in, change the engine oil and check the bolt connections.

- Adjust the tension of the forward and reverse belts of the V-belt drive by changing the length of the chains.

- Check the operation of the controls.

- Lubricate the starter regularly.

- Fill the gearbox with oil in a timely manner.

- Do not allow it to get into the filters.

Many farmers are wondering what kind of oil should be poured into the walk-behind tractor. In particular, they are interested in the MB 6841 walk-behind tractor with M-12GI or M-10GI filling. These are old brands of oils and are not so easy to find.

The following fuels and lubricants are suitable for Cascade walk-behind tractors:

- in the fuel tank - motor gasoline Normal-80, GOST R 51105-97;

- in the engine crankcase - motor oil M-5z/10G1, M-6z/10V, M-6z/12G1, GOST 10541-78;

- for the gearbox - transmission oil in accordance with GOST 23652-79 or aviation oil MS-20, GOST 21743-76.

Synthetic and mineral materials cannot be mixed.

The operating instructions also contain safety information, which is aimed at protecting the operator, as well as protecting the equipment from damage during operation. It is strictly forbidden to warm up the engine using an open flame, such as a torch.

To set the walk-behind tractor in motion, you must select a gear using the handle and using the markings on the body, and then press the forward or reverse lever. It is prohibited to change gears with the forward or reverse lever cocked into the working position.

Is it necessary to add oil to gasoline for a Neva walk-behind tractor? Changing the engine oil

The best option for good engine operation is to use a lubricant recommended by the manufacturer. The initial replacement is made after the first break-in, which lasts about 30 hours as a standard. Some models require a longer process of setting up and grinding in parts, in particular when replacing elements.

It is also necessary to set the time of seasonal use if only summer or winter oils are used, and not all-season.

Important! If the walk-behind tractor has been idle, the fillers will still need to be changed before starting the work process. This is because the cleanliness can be compromised by water and other foreign elements.

The oil change procedure is needed in several cases:

- simple;

- running-in, including secondary run-in after changing parts;

- heavy load at high intensity of use.

In this case, the lubricant replacement process is standard. Procedure:

- warming up the engine;

- draining the oil through a hole located on the side or bottom of the mechanism using a funnel and container for lubricant;

- The drain hole cannot be closed until the container is completely empty;

- if there is no side or bottom drain, then you will need to tilt the walk-behind tractor and drain through the filler hole;

- after completing the procedure, you need to wipe everything with a dry cloth and check the level after filling;

- The oil level in the walk-behind tractor must correspond to the previous one before draining or be filled to the control level, if available. Most often, they simply fill almost to the filler hole;

- After all the steps, the filler hole is checked and also cleaned with a rag.

Important! After the change, it is recommended to check the spark plugs, and in the best case, they are replaced.

Some engines are very sensitive. Example: for Honda, Subaru and some types from American manufacturers, the minimum lubricant class is SG, and the recommended class is SE.

Repair instructions for walk-behind tractor "cascade"

Malfunctions in the Cascade walk-behind tractor can appear in different parts of it. They can be divided into two types: breakdowns in the engine of the unit itself and in its other constituent elements. Before you begin repairing engines or carburetors, read the instructions carefully. In it you can find answers to a variety of questions.

Motor.

You may even need to rebuild the engine, that is, overhaul it. If your car has been serving you for many years, then perhaps the engine is simply worn out and needs to be thoroughly repaired and cleaned. Frequent faults:

- the engine does not start. There may be too much gasoline, which can be determined by the spark plug being wet. You need to dry the cylinder, remove the spark plug and accelerate the engine using a manual starter. If you have an electric starter, the battery may be discharged, which will also cause the unit to not start;

- insufficient engine power. Check the carburetor filter. If you use low quality gasoline, it may cause your car to perform poorly. A clogged spark plug or a violation of the gap between the electrodes will lead to a malfunction in the ignition system. Clean the muffler as well.

Carburetor.

If you notice that your walk-behind tractor is somehow not working properly or there are some changes in its operation, first check the carburetor and study the instructions.

Fuel may not reach the carburetor. To check this, you need to unscrew the spark plug. If it is completely dry, then gasoline simply does not reach here. You need to clean the carburetor filter or jet.

To conduct a complete examination of the carburetor, it must be removed and disassembled, and the fuel must be poured out. Then blowing is done through the fitting. Nothing should obstruct the flow of air, and keep the unit as it is during operation. But if you turn it 180 degrees, the air should no longer pass through.

To adjust the flow of fuel, you need to bend or bend the tongue on the float in the chamber. After this, you can blow out the jet. All parts must be cleaned with fuel and left to dry without wiping them.

The last step is adjustment, but before that you need to warm up the engine. You need to set the idle speed to the lowest setting. You need to tighten and then gradually unscrew the gas screw, monitoring the operation of the machine.

Breakdowns in other components.

So, for example, if your unit has become too noisy, then you may need to repair the gearbox of the Cascade walk-behind tractor. First, try adding or completely replacing the oil in it. If this does not help, you need to contact a technician who will replace the faulty part.

Why is break-in so necessary?

Engine break-in, as mentioned above, is extremely important and is necessary in order to extend the life of the equipment.

This is preparing the machine for further work and loads. It must be carried out not only after purchasing a new unit, but also after you have carried out major repairs. Before the main work, you need to prepare the equipment. First, you need to inspect each element, check all fastenings, any damage or breakage. All malfunctions are eliminated immediately, otherwise unforeseen situations or even failure of the unit may occur during the run-in.

https://youtube.com/watch?v=HL4GY-KOCl0

Preparation process for running in:

- check all bolts and all fastenings. They must be strong and securely screwed;

- Fill the walk-behind tractor with gasoline and also pour oil into it;

- the brake and steering systems must be checked before work, as well as several times during the break-in itself;

- the steering wheel must be in the correct position;

- check the condition of axles, bearings, seals, drives;

- According to the owner's manual, you must lubricate all parts that require it. Moreover, this stage is carried out with complete cleanliness so that no dust, dirt or small particles of anything that could negatively affect the operation of the machine get into the oil.

Which engine is better to put on a cascade walk-behind tractor?

It is necessary to take into account the fact that the domestically produced engines that were produced for this walk-behind tractor no longer exist. So you will need to choose among the imported assortment. But it’s almost impossible to find a part that meets all the parameters.

The following engines are most often installed on the Cascade:

- DM 68 is a good quality engine, which is recommended as one of the best options for installation on such equipment. Its main advantage is a reinforced transmission and high-quality assembly. Technical characteristics: power - 6 hp;

- fuel tank: 3.3 l;

- processing depth – 26 cm;

- processing width – 45/60/95 cm;

- number of gears: 2 forward, 2 reverse.

- B&S I/C is a modern engine model that is very popular among walk-behind tractor owners. This is due to its main features:

- reinforced transmission;

- increased power of 6.5 liters. With.;

- fuel tank with a volume of 3.6 liters;

- minimum noise level;

- efficient operation even at low temperatures.

- Vanguard OHV is a powerful engine that will help you get the job done quickly and efficiently. This high level of performance is achieved thanks to its power of 7.5 horsepower and fuel tank capacity of 4.5 liters.

When purchasing an engine, pay attention to its build quality. It must meet all modern requirements, this will ensure the unit a long service life and operational efficiency.

Read also: Motoblock Aurora Gardener 750

Delivery

Several delivery methods are available to you:

1. Delivery by Russian Post . It is convenient because delivery is carried out to any corner of the Russian Federation. Possibility of paying for goods upon receipt (cash on delivery).

2. Delivery by SDEK. A large number of order pick-up points. Courier service.

3. Delivery by transport companies. We deliver TK KIT, Energy, Business Lines, PEK and some others. Typically this method is suitable for large cargo. Delivery by this option is only possible with PRE-PAYMENT.

Carburetor K-60

The carburetor should be adjusted strictly according to the manufacturer's instructions for a specific model. Otherwise, you can simply break the equipment.

The K-60 carburetor is used in the M-3 model. He will require that the throttle valve be installed so that the gap between its base and the air duct is 2-2.5 mm wide. It can be seen through the pipe of such a unit as the Cascade walk-behind tractor. Adjusting the carburetor will require tightening the adjustment screw and turning it out 0.5-1 turn.

Then the engine 5 min. warm up and, turning off the adjusting screw, wait for the engine speed to decrease. This is the optimal position. To determine it at minimum speed, the rotation speed is reduced and, by smoothly turning the screw, its optimal position is found.

Knowing the principle of operation and the main characteristics of the unit, you can effectively and safely use equipment such as the Cascade walk-behind tractor. Carburetor adjustments should be made as necessary in accordance with the manufacturer's instructions.

Adjusting the operation of this component of the equipment will ensure stability of the engine speed after prolonged loads or inactivity. The presented walk-behind tractor is guaranteed to last a long time, and the actions performed with its help will not require much physical strength. Proper care and adjustment of the unit will allow you to avoid emergency situations during the processing of land plots.

Oil for a diesel walk-behind tractor - features of choice

When choosing engine oil for a diesel walk-behind tractor, you should follow the instructions in the operating instructions. However, if the instructions for use have been lost, then you will have to study the compositions available on the market more carefully. Motor oils for diesel engines are classified into the following categories. The special markings indicated on the container with lubricant will help determine the type and compliance of the composition for a particular walk-behind tractor:

- API CJ-4 - compounds with this marking are designed specifically for walk-behind tractors with a capacity of 10 hp or more. With. and more. The composition of these lubricants has increased viscosity, which guarantees the proper operation of all elements of the unit’s motor;

- API CI-4 - these oils should be used for engines equipped with different types of injection and supercharging. Such oils have good dispersing characteristics and high resistance to thermal oxidation;

- API CH-4 - lubricants with this marking fully comply with all modern requirements and quality standards. Among the advantages of these compositions, one should highlight the ability to fill them into diesel engines running on fuel in which the sulfur percentage exceeds 0.5%;

- API CA - compositions of this type are optimally suited in cases where diesel fuel contains a small amount of sulfur. Oils with this marking protect the walk-behind tractor engine from the formation of harmful deposits on its walls;

- API CB - the use of oils of this oil reduces the risk of corrosion of walk-behind tractor bearings;

- API CC - such oils will be the best option for an engine equipped with a turbocharger, but without a supercharger. These compounds help walk-behind tractors withstand long-term loads and work properly in difficult conditions;

- API CF-2 - oils of this group perform well when used in walk-behind tractors that are subject to heavy loads.

Brief overview of modifications. how to decipher factory indexes

Over the years of production, Reductor-PM OJSC has brought to the market so many modifications of the Cascade walk-behind tractor that, at first glance, it seems that there are too many of them and one can get confused in them. However, it is not. In fact, it's simple. You just need to “read” the alphabetic and digital designations in the factory indices of these walk-behind tractors.

MB6 is a model with a domestic engine (“DM66” or “DM68”). MB61 is a model with a foreign-made engine (“Briggs&Stratton” or “Honda”).

01 – steering rod. 02 – rotating steering column, which allows you to adjust the position of the steering wheel in the vertical and horizontal planes.

In the 04 series gearbox, the gearbox output shaft is mounted on needle bearings. In gearboxes of the 05, 06, 07 series, the gearbox output shaft is mounted on ball bearings.

Also, the gearboxes of the 05 and 06 series provide a reduced speed in first gear, which provides a number of advantages, for example, when working with a mower and snow blower, it allows you to mow grass and remove snow more efficiently.

The gearboxes of the 06, 07 series also use a mechanism for disconnecting the output shafts, which makes it easier to control the walk-behind tractor when turning, increases its maneuverability when used as a vehicle and when cultivating the soil.

Basic options on the basis of which all modifications of the Cascade walk-behind tractors are made:

Each modification of the Cascade walk-behind tractor provides a standard tillage depth of up to 26 centimeters. The processing width while the walk-behind tractor is moving is 45, 60 or 95 centimeters.

How to refuel a motor cultivator. How and what to fill the cultivator with?

Before using the equipment, be sure to read the instructions. As a rule, cultivators have gasoline engines. Most models are equipped with 4-stroke engines, but there are also units with 2-stroke engines. We will not go into the differences, but will try to figure out how to properly fill each of them. Many people know that for a 2-stroke engine it is necessary to use not pure gasoline, but a fuel mixture, the production of which falls on the shoulders of the user. It is necessary to mix gasoline and oil in the correct proportions. The most commonly used ratio is 1 part oil to 40 parts gasoline or 1 part oil to 50 parts oil. The mixture is first made in an empty canister.

To prepare the fuel mixture, you must not mix gasoline with oil directly in the cultivator’s fuel tank. The mixture cannot be used for 4-stroke engines.

An example of preparing a fuel mixture in a ratio of 1:50:

- Take an empty canister, a 5 liter canister of gasoline. and 0.1 l. 2-stroke oil

- Pour 2.5 liters into an empty canister. gasoline

- Pour oil into the canister

- Mix the mixture thoroughly

- Add remaining gasoline

- Stir again, fuel is ready

Further, all the rules are general for 4-stroke and 2-stroke engines. Preparing fuel and refueling should be done outdoors or in a well-ventilated area. Follow all safety precautions when working with flammable products. Since fuel expands during operation, do not fill the tank completely, leave approximately 25 mm to the top.

Do not refuel the cultivator while the engine is running.

The use of clean gasoline without oil for 2-stroke engines, dirty fuel, gasoline that does not meet the octane rating and other violations can lead to engine damage and are not subject to warranty service.

Oil and fuel

Every owner should know what oil and fuel his Cascade walk-behind tractor works with.

Regardless of what kind of engine you have (Russian-made or Chinese Lifan), you must use only high-quality clean fuel AI-92 or AI-95. Do not use old or dirty gasoline. It can clog the fuel system.

Fuel is taken from the gas tank not from the bottom of the tank, but a little higher. This prevents dirt and dust from entering further into the carburetor, but it simply settles to the bottom.

Changing the oil in the engine of the Cascade walk-behind tractor:

According to the instructions for use, it is recommended to use Soviet oils in accordance with GOST. However, the time of the USSR has already passed, and now you can find higher quality imported motor oils with improved characteristics. In summer, you can use 15W-40 series, and in winter, semi-synthetic 10W-40.

The oil should be changed every 20 hours of operation of the Cascade walk-behind tractor.

The situation is similar with the transmission. The manufacturing plant recommends using Soviet TAP-15v or TAD-17i. However, 75W-90 or 80W-90 can be used instead.

To change the transmission oil, tilt the walk-behind tractor back and pull out the plug. Before doing this, place the container for drainage. Excavation causes great harm to the soil, so you should not pour it there.

Control levers are lubricated with Litol or Solidol.

Related Posts

and what kind of oil should be poured into the gearbox of the motor unit? | Topic author: Mikhail)))

Edward is a miracle)) she has no instructions))))

Transmission oil Tap15, Tsp-10, TSP-15K, Otvod-15V, Tsp-14, TAD-17i

as well as their modern analogues to the GL4 class | 5 80 | 90

The brand of Sasha Oil is indicated in the instructions. Not a sunflower at all!

Roman Any conveys high viscosity. I fill up with nigrol or tap-17

Stepan Act about the “DIM MOTOR UNITS User Manual” or you can search the sites.

Tags: how much, filling, oil, gearbox, engine block, cascade

Motoblock Cascade, purchased in 1996. The 2011 walk-behind tractor is currently in operation and is in constant use. Obviously not.

Checking the oil level in the MB-1 gearbox, approx.

Many people ask how much oil is needed in the gearbox of a motor unit? What kind of oil should I pour into the gearbox of the motor unit? Checking the oil level in MB-1 class gearboxes, such as Oka, Neva, Cascade, Ray, etc.

Reducer MB-1, Oka, Neva, Cascade, Ray

The gear is installed on the Oka, Neva and Cascade motor unit. How to check the level and how much oil to pour into the gearbox of the motor unit is described in.

The lineup

The model range of the Cascade walk-behind tractor consists of various modifications, differing in the type of engine and, accordingly, the technical characteristics of the device. For example, the “Cascade MB 1” walk-behind tractor has 8 horsepower, only one speed in reverse, and is capable of plowing a strip of land up to 1050 mm to a depth of 150-300 mm.

In the last few years the following modifications have been developed:

- MB6-06 – the “Cascade MB 6” walk-behind tractor has a powerful gearbox with an additional set of speeds and wheel unlocking, but has a standard steering column.

- MB6-08 – has an increased speed of up to 10 km/h. The model is the most popular in its niche.

- MB61-12 - the speed of this model is even higher than its predecessor - up to 12 km/h, while the model is 11 kg lighter than the standard one. Such monoblocks cost up to 40,000 rubles.

- MB61-21 – this model is equipped with a Robin-Subaru EX-21 engine with a cylinder capacity of 211 cm3. Fuel consumption does not exceed the standard - 1.6 and 1.8 l/hour.

- MB61-22 - the model is equipped with a Honda GX-200 engine with technical characteristics standard for these walk-behind tractors.

The model range of the “Cascade” walk-behind tractor consists of various modifications

Advantages of the NMB-1N17 model

- massive weight improves the passage of virgin soils;

- the equipment has two power take-off shafts;

- 4 working speeds (including reverse gear);

- gear reducer;

- steel gear housing;

- no belts (no need to replace);

- easy silent start;

- high stability during operation;

- minimal damage to plants in the adjacent row to the one being treated;

- the walk-behind tractor operates taking into account the connection of a wide range of attachments (including equipment from others);

- The clutch material is cermet discs;

- high traction force;

- ability to transport loads weighing up to 500 kg when using a trailer;

- comfortable, non-slip handle, adjustable to the operator's height.

Ugra NMB-1N17 with the appropriate additional equipment can easily cope with the role of a snow remover, lawn mower, segment cultivator, and feed crusher.

The width of the cultivated strip of land reaches 90 cm. The reverse allows the walk-behind tractor to make turning movements, thereby increasing the maneuverability and mobility of the machine. In third gear, the unit reaches speeds of up to 9 km/h. In first gear, used for deep soil cultivation, such as cultivation, the speed is 1 km/h.

Motoblock Ugra NMB-1 N1 in action:

Engine system malfunctions during startup

If, when checking the spark plugs, they turn out to be wet, i.e. fuel flows normally, but the engine does not start, the problem may be the following:

- Ignition system failure:

- Air leaks through carburetor seals, spark plugs, plug and cylinder heads, as well as carburetor and engine cylinder connections.

If depressurization of connections is detected, it is necessary to tighten the mounting bolts, tighten the spark plugs and check the integrity of the gaskets between the spark plug heads and the cylinders.

- Incomplete closing of the carburetor air damper.

To eliminate this problem, it is necessary to ensure free movement of the damper by monitoring the quality of the drive. If jams are detected, they must be eliminated.

Compression failure and carburetor problems

It happens that the launch is carried out, but the process is significantly difficult. At the same time, the engine of the walk-behind tractor is extremely unstable and cannot develop sufficient power for normal operation.

The reason for this may be loss of compression, which can be identified by:

- carbon deposits on the working surfaces of valves, as well as cylinder block seats;

- intake valve deformation;

- wear of piston rings.

In order to restore compression, you must:

- Check the technical condition of the engine gas distribution mechanism, clean the parts contaminated with carbon deposits, and if there are defects, replace them.

- Check the condition of the piston rings and replace faulty components.

If during engine operation black smoke comes out of the muffler, and excess oil is detected on the electrodes of the spark plugs or they themselves are covered with soot, this means that:

- a supersaturated fuel mixture is supplied to the carburetor;

- the sealing of the carburetor fuel valve is broken;

- the piston oil ring is worn out;

- The air filter is clogged.

Malfunctions and ways to eliminate them

If the equipment stops working, the first thing you need to do is check the ignition coil installed on the walk-behind tractor. There may be several reasons for such malfunctions:

- wiring problems;

- breakdown in the ignition coil;

- faulty spark plugs;

- lack of spark from spark plugs installed on the walk-behind tractor (this is one of the most common causes of problems).

To check the spark plug, unscrew it and carefully inspect the side and central electrodes. If carbon deposits are found here, you can easily get rid of it using a gas burner.

When inspecting these parts, you need to pay attention to whether there is moisture on them. If the spark plug is dry, this will indicate that fuel is not getting into the cultivator engine.

If this part is wet, this may indicate that the cylinder is filled with engine oil. To get out of this situation, you need to find the cause of the breakdown, and then dry the cylinder and wipe the spark plug well. To dry the cylinder, you will need to pull the starter cable several times.

https://youtube.com/watch?v=yhRyhkA12EY

After this, it is recommended to check the coil, taking into account the recommendations of agricultural machinery repair specialists. This can be done in the same way as with a candle. You need to put a tip on it, and move the lower plane towards the magneto body. If there is no spark when the flywheel rotates, then the problem lies in the coil.

Step-by-step instructions for setting up a carburetor

- Warm up the engine.

- Screw in the maximum and minimum throttle screws until they stop.

- We unscrew the same screws back only 1.5 turns.

- Set the gear lever to the minimum travel position. However, the engine continues to run.

- Normal operation of the engine should be silent and continuous.

This operation should be carried out by Cascade units at each beginning of the season or at its end. Due to the fact that the screws are screwed in all the way, the fuel is enriched. But their slight weakening increases the air in the mixture.

In order to check whether you did everything correctly when adjusting, you just need to pay attention to the spark plugs. After prolonged hard work on the walk-behind tractor, after a short time, neither soot nor traces of fuel should form on the spark plugs.

Carburetor of the Cascade walk-behind tractor: 1 - air pipe; 2 - body; 3 - drowner; 4 — idle jet; 5 — throttle stop screw; 6 — throttle lever; 7 — carburetor mounting flange; 8 — screw for adjusting the composition of the idle fuel mixture;

Owner reviews

Dmitry, Novgorod:

“The car, of course, is not easy. It took time to adapt to work. The weight of the walk-behind tractor is felt very well, but this is an absolute plus: it handles dry soils perfectly, I have never used weights. It consumes little gasoline, especially in comparison with the neighboring "Cascade", I specifically compared and asked. I was pleased with the functionality, in general, I don’t regret buying this walk-behind tractor.”

Ilya, Kaluga region:

“I received this walk-behind tractor as a gift from my father. I worked for several months, or rather all spring and summer. Now stored in the garage. I was choosing between Ugra and Neva, I chose Ugra because of the reviews plus the seller’s advice. According to my father, and he is an experienced farmer, the walk-behind tractor has a lot of advantages: first, there are no belts, no need to change; The engine, although Chinese, consumes moderately and is not noisy. There are no complaints about working on the ground at all - he rushes like a tank. I recommend purchasing!”

Rules for operating and maintaining the unit

During the first hours of operation, you need to put a gentle load on the Cascade walk-behind tractor. The owner's manual recommends a 35-hour break-in cycle. During this time, the following conditions must be observed:

- within 5 min. the engine warms up at medium speed;

- work is carried out in first gear and medium speed;

- after 5 hours of operation, the oil must be replaced;

- the next portion of oil is changed after 5-7 hours;

- then the oil is changed after 35 hours;

- All connections are inspected and bolts are tightened.

In the future, for 1-2 months you should not give the maximum load to the unit. It is necessary that all parts get used to each other.

Maintenance should be carried out during operation. It comes down to these points:

- daily removal of dust and oil from surfaces;

- monitoring and pulling fastenings if necessary;

- belt inspection. Replacement in case of delamination;

- checking the fastening of attachments;

- The oil in the gearbox is changed every 50 hours.

When replacing a belt, you need to pay attention to the indices stamped on them. They come in A1180 and A1400.

During the work, the steering wheel is set at the required height, which is kept parallel to the ground. Skew is not allowed. Otherwise, the unit will bury itself in black soil. The depth of soil cultivation is 200 mm, and in difficult areas 100-150. If the ground is rocky, then work is carried out in first gear.

Storage is carried out in a dry room or outdoors under a tarpaulin. In case of preservation, all unpainted parts are coated with K1 lubricant. Storage time - 1 year. If longer storage is necessary, the lubricant is changed.

Attachments

The additional functions of the walk-behind tractor are very diverse and help a person to carry out a variety of work in the field and in the yard throughout the year.

Suspended equipment for walk-behind tractor:

- plow;

- hillers;

- potato planter;

- potato digger;

- mower.

Special equipment includes:

- a milling cutter that allows deeper plowing of dry, steppe soil;

- creeper;

- hitch;

- adapter.

In winter, you can attach a snowblower and a blade to the walk-behind tractor. For work in winter, the wheels are replaced with tracked modules. They reduce the slip coefficient and give the walk-behind tractor stability.

Very diverse additional functions of the walk-behind tractor

Problems with recoil starter

Sometimes it becomes necessary to replace the starter spring or even the entire device as a whole. The spring itself is placed around the axis of the drum. The task of this spring is to return the drums to their original position. If the mechanism is taken care of and is not pulled too vigorously, the device will work quietly for years. If a breakdown occurs, you must first remove the washer located in the middle of the drum body.

Then remove the cover and carefully inspect all the parts. Attention: it is better to prepare a box in which the parts to be removed will be laid out. There are a lot of them, and they are also small. After the repair, you will need to install everything back, otherwise the starter will stop working altogether. In most cases, it is necessary to replace the spring or cord, but a conclusion about this can only be made by visual inspection.

Although Cascade walk-behind tractors are equipped with strong cords, rupture cannot be ruled out. But if it is relatively easy to change the cord, then when replacing the spring you need to make sure that the connecting hooks are not damaged. When replacing the entire starter, first remove the filter covering the flywheel. This allows access to the internal parts of the device. Having removed the casing, unscrew the screws holding the basket.

The next steps are:

- unscrewing the nut and removing the flywheel (sometimes you have to use a wrench);

- unscrewing the key;

- installing a generator with inserting wires into holes on the motor wall;

- placement of magnets in the middle of the flywheel;

- connecting parts with fastening bolts;

- installation of the crown (if necessary, using a torch);

- returning the unit to the motor, screwing in the key and nut;

- installation of the mechanism basket;

- securing the insulating casing and filter;

- setting the starter;

- connecting wires and terminals to the battery;

- test run to check system functionality.

Motoblock gearbox "cascade"

The gearbox is mechanical, chain. The clutch and manual transmission are the basic components of a transmission and are often housed in a special unit.

Most models have multiple forward and reverse speeds for excellent maneuverability.

The output shaft of the reinforced gearbox is located on bearings with a significant diameter, which are resistant to mechanical damage and the negative influence of various types of vibrations.

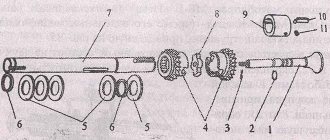

Figure 3. Diagram of the “Cascade” gearbox

1— Retaining ring, 2 — Adjusting ring, 3 — Bevel gear, 4 — Adjusting rings, 5 — Bearing, 6 — Intermediate gear shaft, 7 — Upper housing, 8 — Output shaft, 9 — Adjusting rings, 10 — Bearing, 11 — Bevel gear, 12 — Lock ring, 13 — Boot cup, 14 — Boot, 15 — Cuff, 16 — Adjusting rings, 17 — Lower housing, 18 — Adjusting spacer, 19 — Bearing, 21 — Cover, 22 — Gear, 23 - Gear, 24 - Shaft.

Repairing a walk-behind tractor engine with your own hands: common faults, photos and videos

Like any equipment, the walk-behind tractor requires timely maintenance and repair. And it is advisable to entrust their implementation to specialists who have the necessary tools and equipment and know their job well.

However, if you are also familiar with the structure of internal combustion engines and understand the topic of mechanical engineering, then you can do a lot of what may be required to restore the machine’s performance on your own.

Diesel and gasoline engines have different motor resources. For the former, the normal figure is 4000 m/h, but the latter are capable of providing only 1500 m/h. Despite this, diesel models of walk-behind tractors are not in high demand. After all, both when purchased and during operation they are much more expensive.

Therefore, most likely, you are working with a walk-behind tractor equipped with a gasoline (carburetor) engine.

All breakdowns that may occur during the operation of agricultural mini-equipment can be divided into two categories:

- startup problems;

- malfunctions.

- Malfunctions of other components and mechanisms:

- improper clutch operation;

- breakdowns in the gearbox;

- problems with the chassis;

- control and automation malfunctions;

- malfunctions of walk-behind tractor systems (cooling, lubrication, etc.).

In many ways, the success of repairing a suddenly broken machine depends on the correctness of the diagnosis. As for maintenance, it is carried out precisely in order to identify small faults that will later lead to serious ones.

If you do not have the necessary knowledge, premises, tools and materials necessary to service and repair the motor, entrust the work to a specialist!

Features and functions of belts

While it will be easy to find a replacement for a worn-out link on a Chinese walk-behind tractor, the maintenance of Perm Cascade mini-tractors is associated with certain difficulties. There are not many walk-behind tractors of this brand on the market, but each model requires its own components. If you ignore the specifics of the model, the purchased belts will quickly break and the device itself will break. Therefore, when choosing a new part, be sure to look at the instructions and look at the marking number on the worn-out element.

Interesting! The drive V-belt for the Cascade is made of polyurethane or rubber.

This component affects the quality of land cultivation. Its main function is to transmit movement. If the length of the rubber ring increases due to stretching, the tension becomes insufficient and the shafts begin to slip. As a result, the equipment fails. In this case, the correct choice of new components will determine the service life of the entire motor cultivator.

Table of engine malfunctions of the "cascade" walk-behind tractor

| Malfunction: The Cascade engine stalls during operation and does not start. Reason: no fuel in the tank; the fuel system is clogged; carburetor is out of adjustment; The carburetor is clogged. Repair: gas station; cleaning the fuel filter and hoses; it is necessary to adjust the “Cascade” carburetor; cleaning the carburetor. |

| Fault: black exhaust smoke. Reason: too much oil in the crankcase; the fuel mixture is enriched; The air filter is clogged. Repair: reduce oil level; change the type of fuel; Clean the air filter. |

| Malfunction: poor oil return to the engine. Reason: the ignition timing is incorrect. Repair: the key needs to be replaced with a whole one. |

| Malfunction: the engine does not produce the declared power. Reason: carburetor clogged, carburetor misadjustment; Carbon deposits have accumulated in the fuel combustion chamber. Repair: carburetor cleaning; adjusting the “Cascade” carburetor; you need to remove the cylinder head and clean their cavity from carbon deposits. |

The design of the Cascade walk-behind tractor is simple and classic. Like any similar unit, the “Cascade” consists of a steering rod, a two-wheel chassis, an engine and a power transmission.

Behind the engine there is a transmission, gearbox (gearbox), clutch, main gear, differential, final drive and PTO.

The main causes of breakdowns - why doesn’t the walk-behind tractor start?

The "Cascade" walk-behind tractor, like any gasoline walk-behind tractor, sometimes may not start or may not start on the first try. Possible causes of this problem could be:

- too low temperature (excessive cooling of engine, fuel);

- small amount of fuel, insufficient to turn on and operate;

- low or no oil level;

- incorrect assembly;

- clogged carburetor jets;

- oxidation of contacts in the electric starter;

- The spark plug is faulty or the spark plug needs to be cleaned;

- wire insulation is broken;

- low fuel quality

do not violate the recommendations for fuels and lubricants! This will accelerate wear on the piston group and the engine as a whole.

Specifications

The technical characteristics of the Cascade MB-6 walk-behind tractor are as follows:

- Engine type: 1-cylinder, 4-stroke carburetor, air-cooled.

- Power - 6 hp

- Working volume - 317.4 cm³.

- Cylinder diameter - 76 mm.

- The volume of oil in the engine is 0.9 l.

- Crankshaft rotation speed - 2750-3250 1 rpm.

- The type of running system is wheeled in a 2x2 pattern.

- The clutch is a V-belt drive.

- Belt size for walk-behind tractor Cascade:

- forward belt - A-1180 internal IV GOST 1284.1-89;

- reverse belt - A-1400 IV GOST 1284.1-89.

- Gearbox - 2-speed.

- Gearbox seals:

- 941/20 GOST 4060-78 - 7 pcs.;

- 942/30 GOST 4060-78 - 2 pcs.;

- 306K GOST 8338-75 - 2 pcs.;

- 942/15 GOST 4060-78.

- Number of gears:

- forward travel - 2;

- reverse gear - 2.

- The working width with the KMB 1.002.000 cultivator is 930 mm.

- Processing depth - 100-200 mm.

- Operating temperature - -5... 35°C.

- Overall dimensions - 1500x600x1150 mm.

- Machine weight - 103 kg.

The Cascade MB-61 walk-behind tractor has the following design features:

- The MB61-102, 104 units are equipped with Vanguard 7.5 HP type 0035A1 engines from Briggs & Stratton (USA), designed for operation in extreme and difficult conditions. This engine has a displacement of 205 cm³.

- MB61-122, 124 units are equipped with Intek I/C 6.5 HP (Briggs&Stratton) general-purpose motors with high performance, reliability and endurance.

- MB61-142, 144 have Intek Pro 6.5 HP engines with dual Dura-Bore barrels for long lasting performance and a float carburetor for consistent easy starting.

- MB61-152 and 154 with Vanguard 7.5 HP engines type 0127E1.

The features of the Cascade MB61 distinguish it from the agricultural equipment Cascade MB6. Motorized vehicles are efficient, reliable and well-built, but the cost of units with American and Japanese engines is much more expensive. Therefore, walk-behind tractors with domestic engines are more popular among farmers.