Repair of walk-behind tractors: do-it-yourself, MB-1, gearbox, carburetor, regulator, gearbox

Dismantling and assembling the gearbox of walk-behind tractors Oka, Neva, Cascade (MB-1)

Disassembling and assembling the gearbox MB-1

The gearbox of the MB-1 walk-behind tractor is the basis on which other components and assemblies of the walk-behind tractor are mounted. Therefore, to repair the gearbox with disassembly, it is necessary to disassemble the walk-behind tractor, for which you need to dismantle the engine, steering column, pan, brackets with forward and reverse belt pulleys, gear pulley, wheels.

Before disassembling the gearbox, clean it from dirt and drain the oil.

Remove the rotating head from the gear shift knob by knocking out the pin holding it with a thin drift.

Unscrew the locking screw 11 (Fig. 36) and remove the bushing 9 and the retaining spring 10 from the shift shaft 7.

Unscrew bolts 17 (Fig. 35) securing the body halves, then tightening bolts 7 (2 pcs.) and 10.

Place the gearbox on the left half of the housing, using a thin screwdriver or knife, carefully so as not to damage the gasket, uncouple the halves of the gearbox housing and remove the right half. Leave the spacer washers for the tie bolts on the block sprockets.

Note. It is recommended to remove only defective parts from the gearbox, without completely disassembling the gearbox.

To disassemble the gear shift mechanism, remove retaining ring b from shift shaft 7 (Fig. 36), ensuring free movement of sprockets 31. 32 (Fig. 35). Remove the cotter pin 3 (Fig. 36) from the threaded part of the shift handle 1, unscrew it (counterclockwise) from the block 8 and remove the handle and the block from the shaft.

Wash removed parts and replace defective parts. Replace the shift shaft seals after removing it from the gearbox.

Reassemble the gearbox in reverse order. Apply a thin layer of sealant to the mating surfaces of the body halves.

Start connecting the halves of the housing with the central tightening bolts 7 and 10 (Fig. 35), then the bolts for fastening the halves, starting from the middle part of the gearbox with a sequential transition of tightening the bolts to the edges.

Before final tightening of the bolts, check the smooth running of the moving parts of the gearbox.

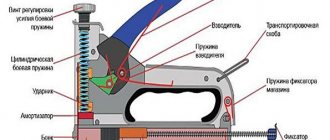

Rice. 35. Gearbox with walk-behind tractor MB-1 (longitudinal section): 1 — shift handle; 2 — right half of the body; 3 - gasket; 4 — chain (34 links); 5 - plug; 6 - finger; 7 - bolt; 8 — right square; 9 — second sprocket block; 10 - bolt; 11 - finger; 12 — chain (30 links); 13 — third block of sprockets; 14 - finger; 15 — bearing; 16 — output shaft; 17 — M6 bolt; 18 - cover; 19 — cuff; 20 — bearing; 21 — chain (28 links); 22 — half of the body, left; 23 — left square; 24 — chain (36 links); 25 — first block of sprockets; 26 — chain (46 links); 27 — shift shaft (input shaft); 28 — cuff; 29 — bearing; 30 - bearing; 31 — sprocket (first gear); 32 — sprocket (second gear).

The internal structure of the gearbox is shown in Fig. 36-40.

Rice. 36. Shift shaft: 1 — shift knob; 2 — sealing ring; 3 - cotter pin; 4 — asterisk; 5 — washer: 6 — ring; 7 — shift shaft; 8 — switching block; 9 — bushing; 10 — clamp spring; 11 — locking screw

Gear running-in

The final stage of assembling a spur gearbox is running in the gears. Using the procedure, contact spots are corrected, existing defects are corrected, and the contact area is increased. After running-in, the roughness of the meshing surface decreases, the noise level decreases, and the working life of the gears increases.

The running-in of surfaces in contact with the gear clutch includes grinding them with an abrasive paste. The grain size of the material is selected based on the accuracy of engagement and the hardness of the teeth. The recommended procedure for processing gearing is contained in technical documentation and instructions. General algorithm of actions during running-in:

- The teeth are coated with a thin layer of abrasive material.

- The mechanism is started for 5–10 minutes. The motor frequency is set to 20–30 rpm.

- Remove the paste from a pair of teeth and check the condition of the working surfaces. The procedure can be considered complete if there are traces of contact and there are no scuffs or other effects.

- The paste must be replaced and then the device must be started again, gradually increasing the braking torque on the output shaft.

- Every 30 minutes the mechanism is stopped, the working surfaces are checked, and the abrasive paste is changed.

- After removing the abrasive paste, you need to run-in the mechanism for 90–120 minutes. Industrial oil must be periodically applied to the teeth so that the surface becomes smooth and shiny, and the remaining abrasive material is completely removed.

If there is a multiple number of teeth in a pair, the gear tooth and the two meshing wheel teeth must be marked before the procedures. When assembling, they are brought into engagement to ensure that the previously run-in teeth match. If there is an odd number of teeth, all elements are run in, so there is no need to mark them.

MB-1 walk-behind tractor: operating instructions and do-it-yourself fault repair

Special equipment, such as a walk-behind tractor, is very useful in farming. Due to the fact that walk-behind tractors are maximally balanced in terms of price, cost and performance ratio, they benefit greatly from both tractors and other special equipment.

With its help, you can perform a large number of different operations that take a lot of time and require a lot of effort, using manpower and simple equipment. All areas where a walk-behind tractor can be used no longer evoke disgust and reluctance to work.

In fact, all the work comes down to management - you just need to be present as a driver.

This applies to both modern technology and older models of walk-behind tractors, because over the decades their design, in general, has changed little - weight has decreased, the variety of models has increased, and more advanced materials are used for manufacturing.

But the frame, engine placement and control method remained the same , the attachments, in fact, remained unchanged, the difference can only be external, in insignificant details.

Therefore, the good old walk-behind tractors, whose service life has already exceeded thirty years, are still in service, and do their job year after year. But every year they increasingly need repairs and replacement of parts and components.

After all, any equipment wears out and needs repair. And you should pay great attention to this if, for example, you make long trips with a loaded trailer. A seized hub won't be a big deal, but a malfunctioning part of a more complex part like the transmission will be frustrating, to say the least.

Therefore, you should familiarize yourself with all the “symptoms” of breakdowns in order to diagnose and prevent a malfunction in time.

Features of care

Servicing the Ural walk-behind tractor is not particularly difficult.

Each use must begin with a parts inspection. If any fasteners or components are not tightened sufficiently, this must be corrected manually. In addition, the wiring is inspected - the presence of exposed wiring indicates that further operation of the walk-behind tractor is unacceptable. The condition of the belts and the presence of oil or gasoline leaks are also assessed. By the way, the lubricant has to be changed every fifty hours of operation. Gasoline is changed as needed, but you will have to ensure that it is always clean.

Device

The MB 1 walk-behind tractor was very popular at one time , namely in the eighties and nineties of the last century.

At that time, the special equipment market, if it can be called such, was filled with the products of Soviet factories, among whose products the Lucha equipment was considered one of the best of its kind. The Luch MB 1 walk-behind tractor confidently competed with the similar Niva walk-behind tractor.

It regularly performed its main function - cultivating a field or garden, transporting goods: crops, firewood, building materials. It was then that the spread of homemade trailers began, and the trend towards turning these walk-behind tractors into mini tractors became established.

Although the technical characteristics of the "Luch" MB 1 are in many ways inferior to modern walk-behind tractors, during the peak of its distribution they were at their best - the mass of the assembled device is equal to one hundred kilograms, the speed is from 3.6 to 9 kilometers per hour, on a flat road, loaded , it consistently produces 8-99 kilometers per hour.

Acceleration to hundreds is, in principle, possible, but only under very specific conditions, which hardly anyone has recreated. Fuel consumption is 1.5-2 liters per hour , the fuel tank volume is 3.6 liters, so experienced drivers always have a canister of fuel in reserve.

Its big advantage is that the engine does not require constant filling of oil - timely maintenance, if necessary, is sufficient. The walk-behind tractor is quite easy to operate - this process does not require much physical effort.

The minimum space required for a turn has a radius of only 1100 millimeters. The movement of the walk-behind tractor is smooth, thanks to the chain gearbox with V-belt transmission, gear shifting occurs smoothly, without jerking.

For more information about the Luch MB1 walk-behind tractor, watch the video:

The transmission of the walk-behind tractor is quite reliable, has two forward and two reverse gears, and the engine is quite powerful for such a product - 5 horsepower, provides good traction and stable speed. High cross-country ability and soil traction are achieved due to pneumatic tires with large tread.

MB 1 is also convenient for transportation thanks to the quick-release steering wheel and wheels. As for possible problems, the occurrence of which is inevitable during the operation of any equipment, especially those manufactured during the times of the Soviet Union, repairing the Luch walk-behind tractor will not become a serious problem.

Using soil tillage equipment

The use of attachments turns the walk-behind tractor into a good assistant for summer residents. Such units include:

- Trailer. Using such a device you can transport a weight of 500 kg. This could be construction waste, grass clippings or grown crops.

- Potato planter. The tool not only digs furrows for planting, but also buries the planted tubers.

- Plow. Used when cultivating heavy areas of land.

- Lugs. When the walk-behind tractor is operating, these units improve its grip on the ground.

- Hiller. Performs the work of adding soil under the root part of plants.

- Mower. This device is used to prepare hay for the winter.

- Flat cutters. The grass between the rows is removed.

- Snow plows. Used in winter.

Repair instructions

In order to restore a faulty walk-behind tractor "Luch" MB 1, the repair instructions will definitely not be superfluous. By instruction we mean the same booklet that was supplied with all equipment produced in Russian factories.

But, as you know, without experience it’s quite difficult to figure out what’s broken, not to mention the design of the walk-behind tractor itself. But a person who is experienced in repeated repairs will be able to identify the problem without wasting time and also quickly fix it.

A good example of the level of knowledge and how well a person navigates a given walk-behind tractor is the reason why fire occurs from the exhaust pipe. The reason could be very simple - a defect associated with partitions in the muffler, which could burn out or simply fall off.

If the walk-behind tractors "Luch" MB 1, Cayman, Patriot, Texas, Foreman, Crosser, Viking, Forza do not start , then there may be more than enough reasons for the problem, starting from the presence of gasoline in the tank before it enters the carburetor, or if the belts are not in order or there are problems with their size...

In the first case, it is necessary to carry out simple manipulations: you need to fill the float chamber until the fuel begins to pour out from the hole in the lid. Or, check how gasoline flows by disconnecting the fuel hose from the carburetor.

A thin stream means that one of the filters is clogged - the fuel filter inside the tank, or the air filter in its lid. In this case, to restore operation it is enough to clean them, or, in extreme cases, replace them. But if you have any ignition problems, you should still check the spark plugs.

It needs to be unscrewed and inspected - if the spark plug is dry, it means the mixture is not getting into the cylinder. Otherwise, the problem is in the carburetor itself.

Ignition coil

The ignition coil of the Luch walk-behind tractor is an important part of the ignition system.

With its help, a low-voltage impulse, using the primary winding, is converted into a high-voltage one, which is supplied to the spark plug using a wire. Essentially, this is a sealed pulse step-up transformer, which, although manufactured using sophisticated technology, does not last forever.

there is no spark during the start , then there can only be one option - replacing the old coil with a new one, since it is not possible to repair it.

Carburetor

One of the vulnerable parts for which the Luch walk-behind tractor is known is the carburetor. It is best to repair a faulty carburetor after first familiarizing yourself with its diagram, since without disassembling the engine it will not be possible to even inspect it.

If you have already read all the necessary documentation and are ready to begin the actual repair, first you need to check whether everything is in order with it, as follows: after dismantling, you need to apply a stream of air through the fuel supply fitting when the part is in the working position.

A garden sprayer is an important and highly effective tool in the competent organization of work in the garden, allowing you to protect the plant, timely fertilize and carry out preventive maintenance. Here's how to make a sprayer with your own hands.

Snowmobiles are an indispensable form of personal transport in the northern regions. Yamaha snowmobiles - Japanese quality for harsh winters.

Those who sow lawn grass by hand know how difficult it is to achieve uniform seeding. By clicking on the link, you will become familiar with the different types of lawn seeders.

This operation must be repeated by turning the carburetor around and blowing into it from the other side. In the first case, the air should pass freely, in the second, it should not pass at all. If in both cases everything happens as described above, then the valve is working properly and fuel is flowing properly.

If air does not pass through, it means the carburetor is clogged and needs to be cleaned .

To do this, remove the cover over the fuel supply valve and pour cleaning agent into all channels. Having allowed it to cope with the contamination, the carburetor needs to be thoroughly cleared of dirt. Compressed air from a compressor is perfect for this.

Gearbox

Another cause of malfunctions is the gearbox of the Luch walk-behind tractor. Although most often it is the consumables that wear out, such as the gearbox seal of the Luch walk-behind tractor. It is replaced if a leak appears.

Running the gearbox dry, without oil, can lead to consequences in the form of rapid wear of the components - the gearbox will very quickly fail. The oil seal is replaced quite simply with a screwdriver; you just need to remove the cap and boot; there is no need to drain the oil.

Engine

The engine is the main unit of the walk-behind tractor , which most often needs repair.

It is with it that all the main difficulties associated with operation and work arise.

Repairing the engine of a walk-behind tractor Luch, Sadko, Don, Huter, Profi, Plowman, Champion with your own hands is quite possible, but it is still better not to start without prior preparation in the form of reading the instructions, especially if you have not done this before. In order to successfully repair the MB 1 “Luch” walk-behind tractor by disassembling the engine, the video will be very useful.

It will be possible to see all the nuances and details that cannot be taken into account in text format. In principle, engine repair, if the problem cannot be identified from the very beginning, can be entrusted to a specialist.

The need to replace the air filter for the MB 1 “Luch” walk-behind tractor arises if the engine does not develop power . As a result of prolonged operation, a lot of dust accumulates in it and a sufficient amount of air does not enter the carburetor.

Of course, you don't have to replace the filter every time problems like these arise. Simple cleaning is enough - if the contamination is not critical, you can simply remove the dust, but if there is a lot of dust inside, you will need to clean it with a vacuum cleaner.

The foam rubber will need to be thoroughly washed with detergent. After the filter’s service life expires, it loses its properties - then simple cleaning will no longer bring the expected effect, they will either need to be done more often or the filter must be replaced with a new one.

Milling cutters

Among all the attachments that are used on a walk-behind tractor, some may wear out faster due to the specifics of its use. These are the cutters for the Luch walk-behind tractor.

Due to the fact that they are installed instead of wheels, a lot of stress is created at the fastening points, as a result of which the fastening holes flare out over time.

As a result, play in the cutter occurs - the walk-behind tractor loses stability, which negatively affects the shaft, which can receive serious damage or become deformed.

To avoid this, it is necessary to constantly monitor the integrity of the cutter fastening device and its general condition. At the initial stages of deformation, the problem can be corrected using electric welding, gradually welding additional metal seams.

In the same case, if welding does not help and the cutters continue to become loose, the fasteners can be repaired by replacing them with similar homemade ones. Old fasteners should be cut off and new ones welded in their place.

Maintenance

What does maintenance mean? This is a series of measures that ensure proper operation and proper storage of equipment. Maintenance of the “Mole” cultivator means the following work:

- washing;

- cleaning;

- lubricant;

- control;

- gas station;

- control;

- fasteners;

- adjustment of all blocks and systems

Such work must be done as often as possible, especially if you have to work in unfavorable conditions.

Before starting the cultivator engine, it is necessary to check the presence of fuel, oil, etc. It is necessary to fill the mixture to a certain level, and if necessary, replace the fuel and oil. For cultivators, Avtol oil (M-8V) is used, which proved itself during the Soviet Union.

If it is difficult to get it, then you can use analogues:

- 10W-30 (do not use at temperatures above +27 degrees);

- SAE 30 (do not use at temperatures below +4 degrees).

Adjustment work involves adjusting the clutch, reverse gear, carburetor, spark, etc.

Cleaning work includes cleaning the filter, working surfaces, housing and all clogged parts on the surface of the Mole motor-cultivator. If malfunctions occur, or for preventive purposes (less often), it is necessary to clean the internal parts of the machine.

Before putting any part back in its original place, make sure it is in good working order.

Installation or replacement of any attachments must be carried out with the engine completely turned off. When preparing for long-term storage, the motor cultivator requires conservation. To do this, you need to prepare the engine in a certain way (see instructions), then clean (rinse) and dry all the external parts of the “Mole”, wipe them with a rag, drying them well. After this, you need to lubricate all accessible areas of the cultivator with grease. The unit is now ready for a long rest.

How to repair a walk-behind tractor gearbox yourself?

The material presented in this article is especially in demand for people who repair their equipment themselves. Next, the main “subtleties” regarding the repair of the walk-behind tractor gearbox will be touched upon. To go directly to the topic of repair, you need to understand the gearbox structure. Looking ahead, it is necessary to say: the structure of the gearboxes of modern walk-behind tractors is similar to each other, there are only minor differences in one model or another.

To avoid the question “How to disassemble a walk-behind tractor?”, you need to be familiar with all the details. We list the main parts and components of any modern walk-behind tractor: covers and pulley; bushings with bearings; lever, axle and fork for shifting; input shaft block with gear; input and output shaft of the walk-behind tractor gearbox. Accessories: washers and seals; right and left axle shaft; clutch and clutch fork; bracket and spring.

Possible malfunctions of the V-belt drive

Possible reason: the belt tension when the clutch lever is pressed is greater than normal.

Elimination method: set the normal belt tension when the clutch lever is pressed, ensuring the deflection of the upper belt branch within 8-10 mm when applying a force of 5 kgf to the middle branch, often between the pulleys.

Incomplete clutch engagement

Possible reason: the belt tension when the clutch lever is pressed is less than normal.

Remedy: The same (see point 1)

Possible cause: belt delamination.

Remedy: Replace the drive belt.

This is interesting: Bush hydrangea: description, planting, care and propagation

What kind of breakdowns happen?

In most cases, problems in the walk-behind tractor gearbox arise due to overloads. Such breakdowns include bursting of bushings on a metal chain, which leads to the so-called “slippage”. Also, owners of walk-behind tractors very often find broken gear shift bushings. To avoid such troubles, experienced owners advise changing gears only when the equipment is completely stopped, and never while moving. In addition, star breakage is considered a common phenomenon. That is, factory welding is not enough for the star to withstand overloads.

It’s very easy to “get out” of this annoying situation; you just need to return the star to its original position and secure it with much better welding. Lateral loads lead to wear of the support washer, after which the bushings fly off the chain. In addition to all of the above, it is necessary to periodically check the oil level in the gearbox and also replace it.

Design and operating principle

The engine for the Ural walk-behind tractor can be changed periodically, since the manufacturer often pleases consumers with improved new products. In addition, situations arise when the previous one fails, and a sudden replacement has to be carried out. The most popular engines are ZiD, UMZ-5V, UMZ5 and Lifan - any of them can be substituted. The engine is equipped with a carburetor, for example, “K16N”. Its ignition system is responsible for the required ignition of the mixture presented in the cylinder. The energy storage is either a coil or a capacitor.

In general, both the design and operation of the device are simple and understandable. Thanks to the disc clutch, the torque is transferred to the gearbox. The latter, by reversing, activates the functioning of the walk-behind tractor. Next, the gearbox chain is started, which is responsible for the running wheels, which are a combination of gears. In addition, belts play an important role in the device.

Spare parts for Ural are quite common, and finding and purchasing them is not a difficult task.

How to check the oil in the gearbox of a walk-behind tractor?

Monitor the amount of oil constantly. Otherwise, careless attitude to technology will lead to fatal consequences. Fresh oil is added every 50 hours. Along with this, excessive loads should be avoided, which ultimately lead to the rapid deterioration of mechanisms and components. Let's move on directly to changing the oil:

- We install the equipment on a flat area. We find a probe 70 cm long.

- The dipstick is bent and pushed into the oil fill hole until it stops, after which we remove the rod.

- We observe the oil level, which should be at least 25 cm. Add 2 liters of oil to the dry gearbox, at least 1.5 liters.

The filling oil must be GOST specific. It makes no sense to use cheap oil, because sooner or later it will cause breakdowns inside the walk-behind tractor gearbox.

Internal combustion engine

Malfunctions that arise in the operation of the engine are one of the most frequently occurring problems, since when the walk-behind tractor is operating, it is the engine that is subject to critical loads. The motor in the device is a typical internal combustion unit. Recently, four-stroke devices have been used in the design of motor cultivators. The engine consists of the following parts:

- filtration unit;

- crankshaft;

- cylinder and valves;

- bearing;

- cooling and starting system.

The operation of an engine is based on the processes occurring in its cylinders, which determine the conversion of thermal energy into mechanical work.

During the four-stroke cycle, two full revolutions of the crankshaft occur, accompanied by strokes: intake, compression, expansion and exhaust. When the engine starts, the piston moves from the top to the bottom. The camshaft cams release the intake valve. A fuel mixture mixed with air enters the cylinder through the valve. Next, the piston begins to move upward again, compressing the mixture, while its temperature increases.

The spark produced by the spark plug ignites the mixture and creates gases. The resulting gases push the piston, performing useful work. This mode is called the working stroke. As soon as the piston goes down again, the exhaust valve closes and then, when raised, begins to force gases out of the cylinder. The waste material exits through the outlet valve and, passing through filters, is thrown out.

Failures that occur due to engine malfunctions are usually divided into two states: first, the engine does not start, second, there is a start, but the operation is unsatisfactory.

No response to launch

Such an event is not necessarily associated with direct damage to the engine, so repairs begin with a general inspection of the product and its cleaning, after which the continuous supply of fuel and the functionality of the spark plug are ensured.

To do this, the candle is unscrewed and inspected. If it is dry, then this indicates that fuel is not entering the cylinder. The carbon deposits present are removed mechanically, using a knife and an awl as a tool. The spark plug is wiped off, and then after shutting off the fuel supply, the starter starts. This operation allows you to dry the combustion chamber, clearing it of any remaining diesel or gasoline fuel. If during inspection it turns out that a spark does not appear between the spark plug terminals, then it is replaced with a known working one.

It is better to follow the sequence of actions according to the instructions developed for the Zubr walk-behind tractor, but this does not mean that it cannot be applied to other device manufacturers, for example, Agros, Tarpan, Lifan, Krot, etc. The sequence of operations is as follows:

- The position of the motor is checked. If necessary, it is leveled.

- The presence of fuel in the tank is determined.

- The next step is to check the tank flap. If a blockage occurs, it is removed.

- The hole in the fuel tank cap is inspected for the possibility of obstructing the passage of air.

- If there is no fuel supply, the entire fuel supply system is cleaned.

- The condition of the generator coil - magneto - is studied. If it is suspected that it is not working, it will be replaced.

- An increase in heating of the cylinder walls indirectly indicates depressurization of the combustion chamber. Therefore, the piston ring is checked and replaced if necessary.

It is also necessary to remember the need to check the starter. Its repair, for example, as in the Centaur walk-behind tractor, consists of restoring the clamping force of the springs. Sometimes the starter cord needs to be replaced. In the case of an electric starter, you will need to check the batteries. Burnout of the windings practically does not occur, but wear of the brushes is possible.

Causes of operational problems

When the engine starts, but after a while begins to run intermittently or stall, first clean the carburetor and fuel supply system. In addition, it would not hurt to assess the condition of the crankcase cuff. It may have a lot of wear and need to be replaced. Accumulated fumes in the muffler or cylinders clog the gas path, and a dirty air filter prevents the mixture from being produced at the desired composition, resulting in the engine running intermittently.

Other Possible Problems

When operating the cultivator, problems may arise associated with the appearance of periodic exhausts, and the device begins to smoke. To get rid of smoke, you will need to drain the remaining fuel and replace it with one containing fewer impurities. You should also check for oil leaks, which could get onto the valve and ignite there. The appearance of popping noises indicates an insufficient fuel level or a malfunction in the power system.

If sounds occur in the starter area, then there is an excess amount of lubricant on the ratchet. And the device being pulled to one side during operation is most often associated with different degrees of inflation of walk-behind tires.

Thus, repairing a motor cultivator with your own hands is not so difficult. More than half of the malfunctions are eliminated by cleaning and replacing consumables with high-quality ones. And if you periodically perform maintenance and avoid overloading the work, then you won’t have to repair the device anytime soon.