Regularly using a brush cutter, its owner may notice an increase in the temperature of the gearbox or the appearance of new uncharacteristic sounds in it that were not heard before. These signs indicate that the mechanism requires lubrication. If you ignore them, after a while new, more significant problems will appear. Thus, without lubrication, gears wear out much faster and soon require replacement. In some cases, the part jams during operation. It is worth understanding that a damaged transmission mechanism can cause damage to other structural parts. It is quite possible to repair the trimmer gearbox and lubricate the part yourself if you know how to carry out such procedures correctly and also have the necessary tools and materials.

Trimmers and chainsaws

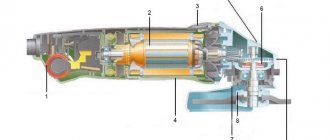

A trimmer gearbox (petrol trimmer gearbox, brush cutter gearbox) is a mechanical device located in the lower part of the trimmer (petrol trimmer or brush cutter) and is designed to transmit torque from the engine to the cutting equipment at an angle of 30°, ensuring that the cutting equipment operates in a horizontal plane (parallel to the surface ground), as well as reducing the angular speed and increasing the torque of the output shaft in a ratio of 1:1.40 (for example, if the engine runs at 12 thousand rpm, the knife will rotate at a speed of 8.6 thousand rpm ).

Lower gearbox

Rice. Lower gearbox (bevel) On mowers with a drive to a trimmer with working attachments, an adapter bevel gearbox is provided. Torque transmission occurs through bevel gears. This type of gearbox is produced in two types: serviced and maintenance-free. The name serviceable - the gearbox gets its name from the ability to add lubricant to the working cavity to lubricate the gears. If the gearbox is not maintained, then lubricant is supplied by the manufacturer for the entire service life, and the gearbox itself has a sealed housing. According to the developers of the manufacturer, such measures increase the service life of the gearbox, since contamination does not get inside through leaks in the lubrication hole. The gearbox of a lawn mower is the most loaded part, transmitting force with a change in direction, so proper care and proper lubrication are very important for the unit. What kind of lubricant is needed for the gearbox and repair of the bevel gear with replacement of bearings can be seen in the video below.

Stihl lawn mowers are deservedly popular

Rice. Popular Shtil brushcutter Shtil brushcutters vary in class, engine type and purpose. Designed for caring for small areas to clearing large areas of weeds, shrubs and young trees. In this regard, they are usually divided into classes. The first class includes amateur devices of low power up to 1.2 hp. By design, “Shtil” amateur scythes are produced with a curved rod, which eliminates the lower bevel gearbox from the design, which significantly reduces the cost and maintenance. Brush cutters with a curved bar are designed to work with cutting tools made of fishing line or polymer knives. They are convenient to use in garden plots with small areas.

The second class refers to universal units of average power up to 2.2 hp, intended for field and landscape work. In such designs, a straight rigid shaft is used, which makes it possible to equip this class with steel saw knives for attachments with which you can cut down bushes and small trees. The design provides for a serviceable bevel gearbox. What lubricant to use for the lawnmower gearbox. A special brand name “Shtil” or regular Russian lubricant Litol is used.

Engines from 6.3 to 8 hp are intended for professional use in forestry or gardening. Their name is brush cutters, these are the most powerful brush cutters for working over large areas, cutting down small bushes and trees. The arsenal of working tools includes saw blades for cleaning bushes with a diameter of up to 7 cm. Brush cutters are equipped with an anti-vibration system, which makes working with such a tool more comfortable. What kind of lubricant to lubricate the gearbox of lawn mowers with powerful drive mechanisms? The gearbox of the Shtil lawn mower is lubricated with a special branded or Shtil lubricant or Russian-made Litol 24.

Possible malfunctions of the trimmer gearbox, lawn mower gearbox, and lawn mower gearbox

- Malfunction - the trimmer gearbox gets very hot. The malfunction of the lawn mower gearbox and the lawn mower gearbox is the same as that of the trimmer. The causes of the malfunction are the lack of lubrication in the gearbox, unsuitable lubrication, or the new gearbox not being run in (when the parts have not yet been ground in). Do-it-yourself trimmer repair PrivatBank in Kremenchug.

- malfunction - knocking, play and jamming when rotating the trimmer gearbox shaft, brushcutter gearbox or lawn mower gearbox. The cause of the malfunction is the destruction of one of the bearings in the trimmer gearbox due to lack of lubrication in the gearbox, inappropriate lubrication, harsh operating conditions of the trimmer, damage to the boots on the bearings during their installation. repair - order bearings from the dealer and replace them (there are two or three sealed bearings) - for more details, see below “How to disassemble a trimmer gearbox / lawn mower gearbox / brush cutter gearbox.”

- malfunction - the gearbox wobbles or falls off the trimmer pipe. The cause of the malfunction is mechanical damage to the gearbox housing - for example, if a piece of the housing breaks off due to a strong blow with a knife on heavy metal or stone (or if the gearbox housing is damaged, for example, with a hammer during repairs). repair - replace the gearbox housing. Or, if a small piece breaks off, make a metal clamp to tighten the fracture site. Repairing a lawn mower yourself is similar to repairing a trimmer.

- malfunction - the reducer on the pipe does not clamp. As practice shows, the gearbox does not fly off the pipe at all, but theoretically, it can fly off the pipe along with the rotating knife. The malfunction of a lawn mower is similar to a trimmer. The reason for the trimmer malfunction is wear of the gearbox seat on the pipe (the aluminum of the pipe under the gearbox is worn out). repair - wrap fabric tape around the pipe under the gearbox or replace the pipe.

- malfunction - the trimmer blade has stopped rotating completely (with a characteristic metallic sound) or stops rotating under high loads (with a hard gnawing sound). The cause of the malfunction is wear of the teeth on the bevel gear in the trimmer gearbox. repair - replace the pairs of bevel gears (a pair is replaced) in the gearbox - for more details, see below “How to disassemble the trimmer gearbox / lawn mower gearbox / brush cutter gearbox.”

Is it possible to make a coil for a trimmer with your own hands?

There are a large number of trimmer heads (not automatic) on sale, which are low priced and of good quality. But sometimes situations arise, for example, at the dacha, when the trimmer reel is broken and repair is impossible, the store is far away, and you need to mow. In this case, you can quickly, literally in a few minutes, make a simple trimmer attachment for securing a fishing line from ordinary plywood 10-12 mm thick.

- Take a piece of plywood or PCB and draw a circle on it with a diameter of about 14 cm.

- Cut out the disc using a jigsaw or hacksaw.

- Drill a hole in the center of the disk that matches the diameter of the gearbox shaft. Do not forget to put a washer on it before installing the disk on the shaft.

- You can screw small corners along the edges of the disk or make 1-2 holes on opposite sides. They will serve to thread fishing line into them.

- To secure the fishing line, you can screw several screws into the plywood.

This homemade mowing attachment is secured to the shaft with a nut. It is impossible to tighten or unscrew the nut without fixing the shaft. To replace the cord, it will be enough to loosen the screws, insert a piece of fishing line of the required length and press it again.

Also, the mowing attachment for attaching the fishing line to it can be made from a metal sheet. You can understand how to do this from the following video.

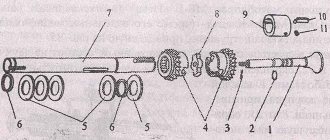

How to disassemble the trimmer gearbox

In order to disassemble the trimmer gearbox, it is necessary.

- Remove the gearbox from the pipe by loosening the two coupling bolts under the gearbox.

- Wash the gearbox with a brush, for example, in gasoline without oil and dry.

- Using round-nose pliers, bring the ends of the retaining ring together and remove it.

- Remove the second retaining ring in the same way.

- Then you need to strongly heat the housing of the trimmer gearbox, brush cutter gearbox or lawn mower gearbox with an industrial (technical) hairdryer at an outlet air temperature of 600°C.

- Then, with strong blows of a wooden block on the upper part of the gearbox housing, knock out the driven shaft with the bearing and gear (first you should try to knock out the bearings without heating). You only need to hit with a wooden block, since a metal hammer, for example, can break the body.

- In the same way, we remove the drive shaft with the bearing and gear (we strongly heat the place where the bearings sit and hit the housing coaxially with the shaft with a wooden block, knocking out the shaft with two bearings and the gear). How to disassemble a trimmer gearbox, a lawn mower gearbox and a brush cutter gearbox. To avoid heating, you can try using a shooter.

The trimmer gearbox is assembled in the reverse order of disassembly (assembly after purchase and replacement of failed spare parts). Assembling the gearbox is much easier than disassembling it - everything is assembled, literally, with your fingers. Sometimes you need to lightly tap something, install circlips and check whether the driven shaft rotates by hand.

If you decide to replace the trimmer gearbox with a non-original one, then in the new gearbox you should pay attention to the diameter of the pipe for which the gearbox is intended (usually 25.4 mm or 26 mm), the diameter of the drive shaft (usually 8 mm), the square size of the drive shaft (usually 5 mm or 9-tooth star) and mounting the protection on the gearbox, as well as on the nut (with a left-hand thread, usually M10x1.25).

Prevention of breakdowns

To avoid breakdowns and subsequent expensive repairs, it is recommended to follow a number of simple rules for operating the trimmer and servicing the gearbox.

- This garden tool should be lubricated immediately after purchase - before use. Usually or Huter) applies only a small amount of lubricant, which is only enough for break-in.

- At the end of the season or before long-term storage of the trimmer, you should disassemble the gearbox, check the condition of the bearings and gears, and lubricate the unit.

- It is necessary to add lubricant after the tool has been in use for twenty to forty hours. With intense loads, this time is reduced to twenty hours.

- It is necessary to change the lubricant to a new one when repairing the structure or before the start of the season.

- When the gearbox overheats or makes a lot of noise, you need to check for lubrication. If it is present in sufficient quantities, it is recommended to replace it completely with another one.

So, you can repair and lubricate the brush cutter gearbox yourself at home. Adding a lubricant is not difficult; a detailed description of this process and recommendations for choosing a suitable substance can be found in the operating instructions for the tool or in videos, of which there are many on the Internet. Most gearbox failures are typical for trimmers of different brands; they are quite easy to fix if you know the correct procedure. And to avoid their occurrence, it is enough to follow simple operating rules and carry out timely maintenance of the trimmer gearbox.

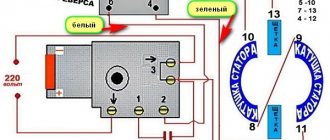

How to lubricate a trimmer gearbox / brush cutter gearbox / brush cutter gearbox

The trimmer gearbox should be lubricated at least once a year, but it is better to check the lubrication after every 20-25 hours of operation or when gear noise appears in the brush cutter gearbox. How to lubricate the gearbox of a lawn mower. To lubricate, you first need to clear the plug itself and the area around the plug from soil and grass residues so that they do not get inside the gearbox when filling it with lubricant. Then you need to unscrew the plug to lubricate the gearbox (for example, for an ECHO lawn trimmer it is a key set to “17”, for a Husqvarna it is a hexagonal key set to “5”, for a Chinese lawn mower it is a key set to “12”). It is better to use lubricant from the same manufacturer as your trimmer or simply from world-famous brands such as Oleo-Mac, STIHL, Husqvarna, Oregon, LiquiMoly, Litol-24, Azmol 158, etc., as long as it is not a fake ! The tube, if new, is unsealed by removing the cork with your fingers or using the back of the cap to break through the jumper in the nose of the tube. Then we place the trimmer on its left side, and rotating the knife with one hand (so that the gears spread the lubricant and the entire volume is filled), with the other hand we slowly squeeze the lubricant out of the tube through the hole into the gear housing until it is completely filled. Then we twist and clamp the plug of the trimmer gearbox and the plug of the tube with lubricant. If the lubricant is not in a tube (but, for example, in a jar), take a medical syringe without a needle, remove the piston, fill the syringe with lubricant (you can use your finger), and then fill the trimmer gearbox with lubricant from the syringe.

Features of different types of gearboxes

Manufacturers of electric and petrol mowers install various models of gearboxes on their equipment. They usually differ from each other in the shape and dimensions of the seat, which is made in the form of a circle (popular diameters are 24, 25.5 and 26 mm), square or asterisk.

Another difference between gearboxes of Russian, Chinese and European brands is the types of gears. They are conical, worm, spiroid, combined, wave, planetary, cylindrical . Typically, worm gearboxes are used on lawn mowers.

Petrol mower repair: overview of faults and effective methods for solving them. Photo instructions from the pros!

Modern technologies and equipment make it possible to produce the best and optimal technical solutions, which become effective assistants in arranging a summer cottage or personal plot. A green lawn and other plantings can grow quickly; to tidy up the local area and mow lawns, a gas mower is used, which is also called a brush cutter, trimmer, or gas mower.

Traditional scythes are inconvenient and unsafe to use; they require a significant investment of time and effort, which will help save money with gas-powered scythes that combine functionality and practicality in their design. In the photo of lawn mowers you can see various high-tech devices, which are characterized by a set of performance characteristics, including such parameters as increased productivity and long service life.

A convenient and reliable trimmer is a technical device consisting of individual mechanisms, parts and elements that can wear out, become unusable and be damaged during intensive use.

Even with regular technical inspection, maintenance procedures and careful storage, such devices and their individual parts require repair and even replacement; all repair procedures can be carried out independently.

Brief contents of the article:

Electric trimmer Viking device. Viking trimmers: overview of popular models

Viking is a brand with a history that produces a wide range of garden tools. The first models were created in 1981, and today this brand has merged with the Stihl concern. Together they create the best technology.

Viking trimmers are high-quality tools that are designed for work in private areas and public utilities. They are characterized by high performance and sophisticated design.

Features of Viking brush cutters

- Equipped with powerful motors.

- Well-developed security system.

- Low noise level due to noise reduction technology.

- All spare parts are freely available.

Consider popular models from Viking.

Trimmer Viking TE 600

The Viking compact electric brush cutter is used in small summer cottages. It only works when connected to electricity, so you can use it to cut grass in the immediate vicinity of your home. The Viking model is suitable for decorating lawns, edging, working near foundations, under benches. A limiter is provided to adjust the cable length.

Specifications:

- motor performance is at 0.54 kW;

- covers up to 35 cm;

- weight – 4 kg.

The automatic shutdown system at high electrical loads makes working with the trimmer safer.

Trimmer Viking TE 1000

An electric brush cutter with increased power is designed for mowing grass over large areas. When using extension cords, the tool can be used on lawns and near yards. Can process up to 500 sq. m.

Main characteristics:

- performance is at the level of 1000 W;

- covers up to 35 cm;

- works with fishing line;

- weight – 5 kg.

The Viking trimmer produces virtually no vibrations and has a reduced noise level. There is a thermal protection system, thanks to which the model is not afraid of overheating.

Trimmer Viking TE 700

The powerful Viking brush cutter works on large areas and even processes land overgrown with large weeds. It copes with overgrown bushes and young trees. Withstands the heaviest loads.

Specifications:

- productivity is at the level of 0.54 kW;

- processing occurs at a width of 35 cm;

- cutting tool – double line;

- weight – 4 kg.

The Viking trimmer is equipped with a comfortable handle, which is covered with soft material and is height adjustable. There is a system for quickly replacing the rod and stabilizing the work during a sudden stop.

The structure of a lawn mower and common malfunctions

The easiest way is to have your lawn mower repaired by allocating a certain amount of money from the family budget; prompt and high-quality repairs with your own hands are no less simple and convenient if you want to understand the design of the lawn mower and fix all the problems.

Mass and piece production of trimmers is based on the use of generally accepted technology; a typical design diagram consists of certain elements and parts, it is important to know them when carrying out independent repair work:

- top part. The basis of the entire structure, where all the important elements are assembled, such as the starter, carburetor and lawnmower engine;

- middle part. A hollow rod, inside it there is a cable connecting the motor and the gearbox, which drives the cutting line. This part contains fastenings for distributing the weight of the entire structure and a belt for fixing the trimmer on the belt of the person using the trimmer for its intended purpose;

- Bottom part. It houses the gearbox and cutting elements, which are hidden under a practical cover that protects the user. The casing provides an increased level of safety, preventing large fractions of debris, stones and glass from entering a person while working with a lawn mower.

Electric trimmer rod structure. Design Features

It should be noted that the cutting head for the trimmer contains special arrows. They allow you to perform rotational movements of the coil in different directions. An electric trimmer consists of a rod; a good electric trimmer will last. If there is a need to wind the fishing line in the direction of rotation of the shaft, it rotates to a specific position. A large amount of wound cord can cause equipment failure. Two arrows are found only on imported models. Single pointer heads are now available on the market.

If, after hitting the semi-automatic head, the cord is not wound, then its previous winding was performed incorrectly. That is, after the trimmer head was installed, the user did not pull the ends of the fishing line out of the grooves. Another unpleasant moment when mowing grass can be sintering of the coil turns.

Why is this happening? This happens when the cord meets a solid object. At the same time, it sharply brakes and with the subsequent movement the fishing line begins to go inside the device. Thus, it falls on the spool and sticks together. Because of this, the employee has to take a break and correct the situation. However, this can be avoided. Before installing the reel, it is necessary to treat the fishing line with a special silicone substance.

For various models of trimmers, a semi-automatic head is used, consisting of two parts - a body and a spool. Both elements contain springs. The second part can be performed in several ways:

- single-section - both parts of the fishing line are wound together;

- two-section - each end is wound on a certain part; this type is the most effective, since the line does not get tangled or baked.

There is a simple and cheap way to turn a single-section spool into a two-section one. To do this you will need a strong plate. From it you need to cut a circle, the diameter of which should be equal to the thickness of the spool. In this case, the thickness is taken near the place where the fishing line is wound. This circle moves freely. Next, a cut is made on the ring, put on the spool and connected with glue or tape.

As a result, you can wind the fishing line onto the required section. The head for a universal trimmer can have from two to four holes, which are located opposite each other. Mowing ends come out of them. In addition to the presented reels, there are heads into which a certain size of fishing line is inserted. In this case, the number of mustaches increases to twelve. Many users find this device quite convenient. However, not all people share this opinion.

They believe that in this situation more fishing line will have to be used. In addition, to replace it, it is necessary to stop the work process. Electric trimmer. An electric trimmer consists of an electric motor and a handle. The trimmer head, which can be of various calibers, is suitable for cutting grass, shrubs and trees. Before purchasing a trimmer, you need to study the area, as well as the features of the equipment. So, we found out what the universal trimmer head is for and how to refill it correctly.

Determining the causes of the malfunction

If the trimmer engine does not start or stalls immediately after starting, if the gearbox overheats or during operation of the device, extraneous noise is heard and vibration is clearly felt, it is important to carry out a visual inspection and identify the non-working unit.

To optimize preparatory measures before repair, you should carry out simple diagnostics and check step by step:

- presence of fuel in the tank and lubricant in the main components;

- the serviceability of the spark plug and its performance;

- cleanliness of the brush cutter's fuel and air filters;

- clogging of the exhaust channel and breather of the device;

- quality of the fuels and lubricants used.

To determine the functional performance of the ignition of a lawn mower, you should determine whether the spark plug works by testing the appearance of a spark when it comes into contact with the body of the functional device.

The spark plug itself can be replaced with a new one by first drying the spark plug channel; if necessary, the old element is also dried, cleaned with special devices and returned to its place.

Garden Trimmer

A lightweight and convenient trimmer for removing grass, and without smelly fuel or an annoying electrical cord that clings to everything it can. You can mow vegetation even in the most difficult to reach places, such as near a fence, border or around trees, without much effort and waste of time.

Benefits of a trimmer

Durable ABS plastic housing

will withstand shocks and falls

Powerful electric motor

copes with dry grass and large weeds

Telescopic handle

allows you to reach the most inconvenient places

Protective shield

protects your face and eyes from flying debris

Trimmer equipment

Trimmer:

1 PC.

Material:

ABS plastic

Telescopic handle:

1 PC.

Line:

24 pcs.

Shield:

1 PC.

Nutrition:

6 AA batteries (not included)

Garden Trimmer efficient and economical

Compare the Garden Trimmer to more expensive and cumbersome gas trimmers

Garden Trimmer

- Price: 1590 rub.

- Compact and lightweight

- Does not require handling skills

- Low noise

- Safe

- Runs on cheap AA batteries

Petrol trimmer

- Price: from 8000 rub.

- Heavy and uncomfortable

- Requires handling skills

- Very noisy

- Traumatic

- Additional expenses for gasoline and oil

Customer Reviews

“Great thing for mowing grass”

Powerful enough for its light weight. What is important to me is the motor in a very durable housing; You can work on wet grass and not be afraid that the trimmer will burn out. An excellent thing for mowing grass along the fence on the site and between trees. Mows dry grass and dandelions quickly and efficiently. You can safely work with fishing line in a vertical plane.

Ivan Kochetov, Moscow

“For two seasons of operation there were no breakdowns”

Powerful trimmer. I've been using it in the village for 2 years now, and it hasn't let me down yet. The grass can be overgrown, but the trimmer does a great job and the grass doesn’t get wrapped around the fishing line. There were no breakdowns during two seasons of operation. The trimmer is perfect where you need to mow the grass not only in the country house, small areas, but also in the surrounding areas.

Vasily Minaev, Kazan

“For keeping in neat condition, 6-7 acres is just right”

This trimmer is not the first, before this there was another manufacturer, after working with which my hands shook from vibration for another hour. With the Garden Trimmer there are no problems with vibration - it’s comfortable to work with. There is also no backlash observed yet. The set includes a fishing line and a shield. For my site I use fishing line, its consumption is small. For keeping it in neat condition, 6-7 acres is just right.

Carburetor repair

When inspecting the carburetor, you should pay attention to the possible leakage of the fuel used; to identify carburetor problems, the following measures must be taken:

- purging the fuel hose to eliminate possible clogging of the element;

- checking and replacing the gasket located between the engine and carburetor;

- determination of tightness and maintaining constant pressure in the unit.

If necessary, you can disassemble and thoroughly clean the unit yourself, using gasoline; cleaning the nozzle and channels is carried out using compressed air.

Checking the correct application of lubricant to the angle grinder gearbox

The last step when servicing an angle grinder is to ensure that the lubricant is properly applied and distributed inside the gearbox. To do this, after the gear unit has been assembled, turn on the power tool without load for several minutes, while ensuring that there are no extraneous sounds, smells, etc. If they occur, you must immediately disconnect the angle grinder from the network. The heating of the gear unit is also checked. The lubricant must distribute heat evenly and the temperature of the gear unit should not be very high.

After some work, unscrew the 4 screws, then remove the cover from the gearbox. The helical gears should be visually inspected for the presence of lubricant. If it is missing, it means that too little lubricant was used and should be reported. If during work it is squeezed out of the cracks, then it means that there is too much of it and the excess should be removed. After making any changes, check the operation of the angle grinder again without load.

Breakdown of the starter and gearbox

The gearbox transmits torque from the motor shaft to the cutting tool; during operation, its gears must be absolutely clean and always lubricated with a special lubricant.

Carrying out a technical inspection on your own once a season will eliminate the need to repair the gearbox or replace it, with the purchase of an expensive new unit.

A starter is necessary to bring the trimmer into working condition; its diagnosis consists of checking the tension of the cord engaged with the teeth of the starter coil, which are often destroyed during a sudden start.

A non-working starter in a lawn mower cannot be repaired; it must be replaced with a working unit as part of a mandatory technical inspection or a set of repair measures.

The cutting elements require special attention and care; they must always be cleaned of dirt and mown grass after use. Regular inspection and thorough preparation of the device for operation will help you avoid expensive and time-consuming repairs, and always be confident in the functionality of the lawn mower.

Rod and drive of the working element

The rod has two very important functions: the first - it forms a rigid frame of the entire structure, the second - a shaft passes inside the hollow metal rod, which connects the working element with the engine. By the appearance of the rod, you can determine the class of the tool; if the rod is curved, this is convenient for work, but in this case the drive is a flexible shaft, which cannot transmit large torque. If the rod is straight, there is a rigid metal rod inside, it is much more reliable and it can transmit more torque. Therefore, professional tools always have straight shafts.

Disassembly and repair of the upper gearbox of a trimmer brushcutter

Published May 24, 2018

Disassembly and repair of the upper gearbox of a brush cutter (trimmer)

Online store of spare parts for garden equipment - https://benzozapchasti.com.ua Rental of garden equipment - https://tehprokat.com.ua

Watch our new videos on the new generation blockchain video service Viuly, an analogue of yuotube https://viuly.io/r/K5852255a74cd13b

If you have questions about repairing the upper gearbox of a brush cutter, ask, I will answer.

Where is the promised link under the video?