Wood splitters are very useful devices in everyday life. They should not be underestimated, since the convenience and safety of firewood collection directly depend on such devices. Much attention should be paid to the gearbox for the wood splitter, which is an important element of the system.

How to choose?

Choosing the right gear unit means guaranteeing the overall reliability of the system and its long-term operation. If you make the slightest mistake, you will have to spend money on repairs or replacement of any part at the most important moment. In the worst case, you will have to change the elements interconnected with the broken part. Therefore, it is very important to use the help of professional designers and engineers.

They pay attention to a variety of factors:

- placement of the gearbox in space;

- its mode of operation;

- general load level;

- the temperature to which the device heats up;

- the type of tasks performed and the degree of their responsibility.

There are many types of gear units. If you choose the right element, the worm gear will work for at least 7 years. The service life of cylindrical systems can be 1.5-2 times longer.

However, obtaining advice from engineers is not always possible in practice. In this case, the simplest recommendations that will be discussed below can help you out.

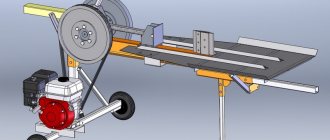

Rack splitter

It is much easier to make a rack-and-pinion wood splitter. It is based on a powerful frame, to which a wedge-shaped knife, an electric motor and a gearbox are attached. This device consists of the following components:

- Gear unit.

- The drive is petrol.

- Belt drive pulley.

- Gear with teeth.

- Rotating pulley.

- Rack with pusher.

- Handle.

- Cutting cleaver.

- Frame with gutters.

- Gearbox.

Operating principle: the log is placed in a special recess, and due to the operation of the pulley, it is pushed towards the working knife and sawed.

The main advantages of a homemade rack wood splitter:

- Has a simple assembly design.

- Quite durable.

- Can operate from a 220 V drive and higher.

- Can split any wood.

- Economical to operate, consumes little electricity.

- High performance.

- It is in no way inferior to a hydraulic wood splitter.

Among the shortcomings, one can note the non-compliance of the device with European safety standards. But with proper use, the risk of injury is minimal.

In order for your work to be done efficiently, you need to choose the right drawing. There are many options for rack-type wood splitters on the global network. You can easily choose the right one.

An important design element of a rack-and-pinion log splitter is the frame. Take its assembly seriously.

You will need the following materials:

- I-beam

- Profile pipe.

- Standard channel.

- Metal corner.

- Wheels, if there is a need to transport the wood splitter from place to place.

You need to assemble all the parts into one design. The mechanism must stand firmly on the ground and not sway during operation. A piston is provided on the device to push the log. It is necessary to correctly calculate the pushing force in order for the wood splitter to work properly. Otherwise, the logs may fly out after cutting or, on the contrary, get stuck. This piston can be purchased ready-made. A piston from a tractor, jack or any agricultural equipment will also work.

If your device uses an electric motor, ensure safety and install a protective coupling. It is advisable to use a cutting cleaver consisting of four incisors. This way the log will split into four parts at once.

It is better to equip the wood splitter with a horizontal laying method. This ensures the best movement of the block to the cutting cleaver. Alloy steel is ideal as a material for the cutting element.

About types of systems and more

When preparing to assemble a mechanical or hydraulic wood splitter, you need to start by preparing kinematic diagrams. They will show you what types of gear units should be used.

- In a horizontal cylindrical apparatus, the axes of the input and output shafts are located in a common plane, but on parallel lines.

- Vertical gearboxes are similar in structure - only the orientation of the main plane differs.

- In single-stage worm gearboxes, Two-stage worm gearboxes are designed with shaft axes placed parallel to each other. They are deliberately placed in different horizontal planes.

- Bevel-helical gearboxes are also a special type . Among the two shafts, the output has increased importance. It is its orientation in space that has a decisive influence. In worm-type devices, one type of gearbox can be installed for all orientations of the output shaft in space. The cylindrical and conical designs almost always allow the output shafts to be positioned strictly horizontally. Exceptions are rare; for the most part they are achieved through design tricks.

With the same dimensions and weight, cylindrical mechanisms are 50-100% more efficient than their worm-type counterparts. They last just as long. That is why (for reasons of economic efficiency) the choice is completely obvious.

Types of devices by method of movement

Equipment is classified according to the criterion of mobility. They can be mobile or stationary, which affects the features of their operation. When choosing the appropriate option, you need to take into account its features:

- Stationary products are characterized by massive dimensions and heavy weight, so they are intended for use in one place. It is not advisable to operate such installations in everyday life, due to the complexity of their transportation. At the same time, they have such an undeniable advantage as high power ratings, which allows them to be used for working with the hardest types of wood: walnut, oak, beech.

- Mobile or portable - in addition to their compact size and light weight, such installations are equipped with transport wheels, thanks to which the equipment can be moved to another location independently and without the help of special equipment. These types of installations are the best types for domestic use.

The choice of the appropriate option depends on various factors, for example, frequency of use, place of use, volume of work, hardness and size of wood, etc. If chopping wood is done only at home, then you can use stationary installations, which have increased technical and operational parameters.

Other nuances

The gear ratio of the gear unit is of great importance . It is determined using information about the number of turns of the electric motor and the required torsion parameters of the output shafts. The indicator established as a result of the calculation is rounded to the nearest standard value. It is important to note that the motor shaft, and therefore the output gear shaft, should not rotate faster than 1500 times per minute. Within these limits, the motor parameters are selected according to the general requirements for the device.

The required number of steps is established according to special tables. The initial indicator for determination is precisely the gear ratio. If GOST for a gearbox states that it will be used “occasionally,” this means that :

- the maximum load will be 2 hours for every 24 hours (no more);

- 3 or 4 starts per hour (no more);

- mechanical movements are carried out without striking the mechanism itself.

The so-called cantilever loads on the shafts are also determined. They must match the level specified in the accompanying documents for gear units, or even be less. It is necessary to take into account both the average level of work over an hour (in minutes) and the torque. Since all these nuances are difficult to predict in home-made designs, it is not recommended to make gearboxes from the rear axle and similar auxiliary units . The quality of their work turns out to be unsatisfactory compared to even “average” factory devices.

A geared motor is preferable if compactness of the drive is a priority. Over 95% of structures of this kind are designed for arbitrary placement of the output shaft. The step-by-step assembly instructions also note that there is no need to use couplings when connecting the motor and gear assembly. But you need to understand that such devices are expensive. In addition, an individual order with the required parameters must be sent each time.

By independently assembling an analogue that requires the use of couplings, you can easily reduce costs by 10% or even 20%.

Do-it-yourself knife wood splitter from a traction winch

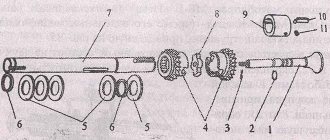

Making a knife log splitter has some difficulties. To construct such an installation at home, you will need a large number of parts, so their manufacture is not always rational, unless you have a gear unit and an electric motor at your disposal. Next, we will consider the features of manufacturing a wood splitter for splitting knife-type firewood from an old traction winch, which consists of a power unit and a gearbox.

- The drive mechanism is a 3.2 kW electric motor with a shaft rotation speed of 1500 rpm.

- The motor shaft is connected to a gearbox, which at the output of the driven shaft has a rotation speed of 10 revolutions per minute. This speed is enough to have time to install logs for splitting.

- The rod is made from a truck axle shaft, the length of which is 1 meter. Its role is as a stop, with the help of which the logs are pressed against the cutting knife.

- The thrust heel is made from a 120 mm angle.

- The stop moves along a surface made of an I-beam.

- The knife is made from tractor attachments.

If you have a gear unit, making such a design will not be difficult. At the same time, the installation is characterized by high productivity. The structural elements can be placed on a frame with wheels, which will allow the installation to be transported. How a wood splitter works in action is shown in the video below.

Based on the information described, it will not be difficult to make a wood splitter yourself, saving your finances and getting a high-performance unit for home use.

Models

- When assembling wood splitters, a single-stage gearbox RCHN-80A . Its characteristic feature is the placement of the “worm” on top. The developers assumed that their product would be used in low-capacity industrial devices. The helix is oriented to the right. There is no fan inside the continuous cast iron housing, efficiency ranges from 72 to 87%.

- Ch-100 modification works successfully under constant and changing, uniform and reverse loads. The design provides torsion of the shafts in any direction.

Pros and cons of homemade models

Let's look at several of the most successful models of mechanical wood splitters, which are easy to manufacture, easy to use, safe and can simplify the process of processing wood into firewood as much as possible. Mechanical wood splitters are divided into several types. Let's look at their positive aspects and disadvantages.

Mechanized wood splitter

A simple version of a homemade wood splitter with a simple drive, which is the easiest to make, since it does not require large financial outlays. Even if the necessary parts are not available, acquiring them will not be particularly difficult. However, such a device will bring the greatest benefit only if the need for firewood is minimal. The disadvantages of such a wood splitter are the long handle on which the cutter is attached, and considerable effort. But even such a primitive mechanical wood splitter can significantly facilitate the work of preparing firewood.

Spring pressure wood splitter

A pressure or spring wood splitter implies certain costs for materials for manufacturing, but will significantly reduce the load on the worker’s muscles. The mechanics remain the same, but a spring shelf is added to the strut. The spring should not deform during compression and have a certain elasticity (Fig. 2). The height of the frame of such a wood splitter is usually 65-80 cm. The design is simple, takes up little space, but has its drawbacks:

- such a wood splitter requires complex work with an impact tool, which increases the risk of injury;

- it makes it much easier, but does not reduce the effort when preparing firewood to a minimum.

Vertical inertia wood splitter

Another simple version of a mechanical wood splitter. The advantages of such a wood splitter are ease of manufacture and low cost of material. This wood splitter will also make working with soft wood much easier. There are few disadvantages to such a wood splitter - it is useless for working with sticky varieties of wood, since the cleaver will get stuck in the log and getting it out, given the small size of the wood splitter, will be problematic.

Electromechanical wood splitter

In order to make your work as easy as possible in the process of converting wood into solid fuel through the use of a mechanical wood splitter, it is possible to install an electric drive on it, as shown in the photo (Fig. 4). However, the manufacture of such a wood splitter requires certain costs, knowledge in electromechanics, the ability to read drawings and the use of electric welding.

Homemade mechanical wood splitter with gearbox: assembly and operation

A 1:32 gearbox + 6.5 hp walk-behind tractor was used.

*Two-stage horizontal cylindrical gearboxes for general machine-building use, types RM-250, RM-350, RM-400, RM-500, RM-650, RM-750, RM-850, RM-1000, are designed to increase torque and reduce rotation speed.

Products for this article

The cone of the screw splitter is 7.5 cm in diameter, 30 cm in length, with a two-start thrust thread. Weight 5 kg.

Many people want to make a mechanical wood splitter with their own hands. However, not everyone knows where to start. It is interesting to read about the design of a particular device. They look quite attractive in the photographs.

The retail chain offers those interested a whole arsenal of machines for splitting logs. Quite interesting videos have been made for some of them; the features of their work have been demonstrated over the years. On the stands near the proposed models there are results of chopping firewood into individual logs.

Types of mechanical cleavers for firewood: their advantages and functional features

There are many more types of mechanical wood splitters than manual ones. This is due to the wide variety of types of drives used. However, the advantage of mechanical devices lies not only in the virtual absence of physical effort, but also in the ability to split large-sized firewood. Split firewood is much easier to cut into small logs than to cut large logs.

The operating principle of mechanical wood splitters is based on the following manipulations:

- laying or installing logs in a special chute;

- the drive (there are different types) drives the supporting part or cutting blade, thereby influencing the workpiece;

- the knife digs into the wood, as a result of which the workpiece splits into two or more parts, which also depends on the design of the knife.

The undeniable advantage of such units is also their high speed of operation, as well as the ability to process large volumes of firewood. It should be noted that thanks to mechanical wood splitters, it is possible to split wood of various species, which manual devices cannot always cope with.

Like manual wood splitters, mechanical devices can also be made by yourself. Moreover, you don’t need to buy anything for this, since the devices can be made from improvised materials that are available in your garage. Actually, we will pay special attention to this, but first we will consider what types of mechanical devices are divided, and how they differ.

Why do we need firewood - improving fuel quality

There are quite a lot of energy sources in the modern world:

- Natural gas is available over large areas. It is enough to open the burner and light it, and a bluish light appears, which releases a significant heat flux.

- The liquid fuel supplied through the injectors burns with a bright red or yellowish flame. Even heat engines use different types of liquid energy carriers.

- Coal and its processed products have a long combustion cycle. The reddish flame gives off heat for a long time not only by convection; a powerful flow of thermal radiation reaches all surrounding objects.

- Firewood was the first available source of heat. They remain relevant today.

Many homes use stove heating. Baths and saunas, when advertising their services, indicate that they use wood of certain tree species as a heat source. Outdoor cooking traditionally involves the use of wood in the technology of cooking food.

Tools and materials

To make the blade you will need the following:

- Bulgarian. Preparing the blade of an old ax or spring requires sawing and shaping. This can be done with a regular hacksaw, but the labor costs will be disproportionate. The grinder will require a cutting wheel. Since you will have to work with spring steel, it is better to take a diamond-coated disk.

- Abrasives. The finishing of the metal will have to be done manually. You can use an engraver with diamond bits and stones. If you don't have it, sandpaper, needle files and files will do.

- Hacksaw. To make an ax handle, you will need a handsaw. Wedging and fitting are easier to do on machines, but regular hand tools will do.

- Welding machine.

The following are used as the basis for the chopping part:

- Old axe. You can buy them at a flea market or at a metal collection center. Old Soviet axes are made of good steel, which does not splinter if you miss a log.

- Spring. Spring steel has a high carbon content. It practically does not chip and can withstand constant shock loads. At the same time, it is easy to heat treat. A device for chopping firewood with your own hands from a spring is appropriate, since the shape of the blade can be selected to suit your own requirements.

The ax handle must be made of hard wood. Soft pine, spruce, fir and larch will not work. You can choose:

- Oak. You can take the same log that will split. Oak is hard, cheap and available.

- Beech. The wood is inexpensive, but beautiful. It has a porous structure, so it is easy to saw, but holds its shape well.

- Birch. Birch is hard, but axes for splitting firewood must be impregnated with linseed or tung oil.

- Nut.

Theoretical foundations of heat engineering - solid fuel combustion

To make it easier to set fire to wood, it needs to be split into relatively small fragments. After splitting the logs into separate logs, the surface of contact of the combustible material with the air is increased. As a result, instantaneous heat transfer inside the firebox increases in proportion to the combustion area. Therefore, the procedure of chopping wood is a technique that allows you to increase the efficiency of fuel use.

In thermal engineering, the following concepts have been introduced to characterize fuel:

- The highest calorific value, implying the total heat released during the combustion of a specific type of combustible substance.

- The lower calorific value is the actual amount of heat, which takes into account the energy costs for heating the fuel and the removal of ingredients from it during the combustion process that are not involved in the process itself.

Therefore, drying firewood is a technique that improves the performance of a fuel cell. Pre-grinding increases the efficiency of drying firewood, and subsequently burning it in a stove or other device for burning solid fuel.

Recommendations from our expert

To ensure that the wood splitter is reliable and lasts as long as possible, you should listen to the following tips:

- Do not ignore painting the structure, especially when you plan to install it outdoors.

- Make calculations with a reserve. This applies to engine power, steel thickness and other indicators.

- Start working with diagrams and drawings. Proper preparation will save time during installation and help avoid loss of materials due to errors.

- Try it on first, and then carry out welding or other fixation.

A wood splitter greatly simplifies the life of users who often have to prepare logs. Once assembled, the structure will save time and effort in the future. Making it yourself allows you to avoid unnecessary expenses.

Wood splitting process

There are different ways to chop wood. Traditionally, it is customary to strike with an ax, trying to split a sawn fragment of a log, striking the end part.

A heavy wedge (the ax is wedge-shaped) is inserted into the body of the log. If you come across wood without knots and with a loose structure, then even with relatively little physical effort, the wedge will be inserted inside. Tangential forces will push the fibers apart, causing the body to split into two components.

If the apex angle is made small, then the wedge-shaped body will penetrate deeply inside, but the magnitude of the tangential forces will be small. The destructive force will not be enough. The ax will jam in the resulting gap.

When a less acute angle is formed, the tangential forces will be more significant. They can split wood.

With slow penetration of the wedge, the kinetic energy not accumulated as a result of the swing and subsequent impact becomes decisive. The process occurs by introduction into a plastic body, where, when certain values are reached, the bonds between the fibers are broken.

How to make it yourself and what you need for it

The simple design and good performance have helped the wood splitter become popular and many people want to make it themselves. The main part is the cone for the wood splitter. You can buy it in a specialized store, depending on the size the price will vary. You can also ask for the cone to be turned in a turning shop.

The material for manufacturing is ideal tool steel, which has increased strength. It is worth knowing that the depth of the log split depends on the diameter of the cone and the bevel. Table 1.1 shows the dimensions of the cones and the possible depth of wood splitting in this case:

Table 1.1 Dependence of log splitting on the diameter of the log splitter cone

Screw, rack, and pneumatic wood splitters are tools designed for splitting logs into logs. Rural craftsmen assemble wood splitters from scrap parts, but they are low-powered and the designs require modification. A cleaver with a cone screw is easy to make yourself or buy inexpensively.

Mechanical assistants for splitting wood

A number of metalworking enterprises produce wood splitters. Based on their operating principle, they are divided into several types:

- Cleavers are installations for chopping action. The logs are placed on special supports, and then blows are applied with a weighted chisel.

- The chopping wedge is placed motionless, and the objects to be split are supported on them. The blows are applied with heavy sledgehammers, the splitting is carried out when passing through a passive working element.

- Pressers are installations with a mechanical pusher drive. The log is laid on a bed, and then it is pushed through a flat or cross-shaped knife.

- Screw destroyers are embedded inside the layered material. Penetrating deeper, they split even strong and twisted wood.

Wood splitter - what is it and what is it for?

A wood splitter is a special machine that consists of three main parts:

- Knife or blade - designed for longitudinal splitting of workpieces.

- The stop is an important structural element that is designed to hold the workpiece when a knife acts on it. The pusher is used in fixed blade installations. Serves to push the workpiece towards the cutting element.

- Drive - a mechanism that drives the knife or thrust part, reducing the distance between these two structural units for the purpose of splitting workpieces.

Often, wood splitters are also called splitting axes or wood splitting machines, which, in addition to longitudinal splitting of logs, are intended for trimming. Such machines are an alternative replacement for hand splitting axes or axes, which are equipped with the function of splitting firewood. Unlike them, the machine allows you to perform work not only faster, but also much better, and most importantly, safer. The likelihood of injury is extremely low, which is due to the absence of rapidly rotating working parts compared to a sawmill. The photo below shows a model of a rack-and-pinion device.

This is interesting! Using a wood splitter, large logs are split into small logs, which are ready for use.

Cutting wood with wedge devices

Wedges are the simplest devices for cutting wood. In them, the level of labor mechanization is minimal. The main task of the device is the oriented fixation of the block relative to the cutting edges. The blows are delivered by the user himself, swinging a heavy hammer or sledgehammer.

In cleavers, the movement of the wedge ax is performed along a constant trajectory. The processing object is placed on a stationary platform. To maximize the impact force, the mass of the actuator is increased.

To soften the operation of the device, it is equipped with powerful springs. They soften the impact at the end point, preventing the wedge from touching the supports (preventing the wedge from dulling). Along the way, the springs help the user lift the heavy knife to strike again.

In a stable position, the entire system is in a balanced state. The moment created by the weight of the load G located on the arm L₁ is balanced by the force of the spring F on the arm L₂.

It is most convenient to use springs from a car. For standard cars, the initial compression value is F = 8 kN (800 kg). Shoulder L₁ = 2.0 m. Taking arm L₂ = 0.3 m, the weight of the load G = 300 kN (30 kg) is obtained. The spring mechanism works quite softly, although the action of the wood splitter is based on striking the logs being cut.

Self-production of the machine

It is possible to make a wood splitter with your own hands even if you do not have some of the necessary parts. However, if you do not have the skills to carry out welding work, then it would be better to purchase such a machine in a store or order it from a specialist. Poorly performed welding can result in serious injury.

To make a homemade wood splitter, you will need:

- profile pipes or corner;

- sheet metal;

- electric motor with starter;

- screw cone;

- support with bearing units and shaft;

- pulleys and V-belts;

- fastener

Drawings for making a machine, if you have certain skills, can be drawn up yourself or found on a thematic forum on the Internet. Many craftsmen who have made such a unit on their own post not only them, but also videos with the sequence of actions.

Work begins with the manufacture of the frame. For this purpose, profile pipes 40x25 mm or corner 40x40 mm are used. The dimensions of the frame will depend on the dimensions of the parts used and can be approximately:

- height – 70-80 cm;

- width – 50-55 cm;

- length – 70-80 cm.

Structurally, the frame consists of 4 legs (supports), connected to each other by welding with horizontal sections of pipes or angles. In the lower part there is a place for installing an electric motor. This may be an additional frame made of the same material, or a platform made of sheet iron.

The jumpers in the upper part are welded flush with the ends of the legs. The resulting frame is sheathed with sheet metal with a thickness of at least 1 mm. A screw mechanism with a pulley is attached to one of the sides. A wedge is welded under the screw, which will fix the wooden block during splitting. An electric motor is installed on the lower platform. Both pulleys must be in the same plane. The starter is mounted on one of the supports in such a way that it is possible to conveniently and quickly turn off the unit in the event of an unusual situation.

It must be remembered that the entire load is concentrated on one side of the structure. This must be taken into account when installing it for work. To make the machine easier to move, it is equipped with wheels, which are located on an axis mounted under the electric motor. Before turning on the unit for the first time, you must ensure that all parts are securely fastened. The finished cone splitter is cleaned of rust and painted. The electric motor is connected to the network using a 4-core cable of the appropriate cross-section with mandatory grounding.

Mechanisms for feeding logs for splitting

Wood splitters, which implement the principle of pressing through fixed knives, mechanize the main technological process: splitting logs into separate fragments. Based on the type of pusher drive, it is customary to determine:

- Hydraulic, in which the pushers are connected to the rods of hydraulic cylinders. The pump creates pressure in the oil, which is transmitted inside the mechanism. These are the simplest designs, since hydraulic drive devices do not have additional energy converters.

- Inertial ones use rotating masses. The energy accumulated by the flywheels is converted into forward movement of the pusher. The devices use special clutches that are engaged by the operator after installing a piece of log on the bed.

- Rack and pinion mechanisms use a converter from rotational to translational motion using a gear and a rack with teeth. At the right moment, the gear rotates until it engages the teeth of the actuator. The pusher moves the block onto the stationary knives. It splits into smaller elements.

- The crank mechanism receives torque from the gearbox. It is converted into translational movement of the pusher. Switching on (off) is regulated by a constantly open clutch. At the right moment, the operator engages the clutch, the crank begins to rotate, causing the connecting rod to move forward. The cycle ends with the return of the crank and connecting rod to their original position.

- Split nut and lead screw. The engine turns on, the rotation of the shaft is transmitted to the lead screw. At the right moment, the split nut is connected, the rotating shaft moves it, acting on the pusher. To return, the direction of rotation of the shaft is changed (a reverse rotation gear is used).

What types of wood splitters are there according to the principle of their functioning?

Installations are classified into types depending on such parameters as the type of knife mechanism used and the method of driving it. Before purchasing a suitable equipment option or starting to manufacture it, it is necessary to determine the design differences, as well as the presence of corresponding advantages and disadvantages.

According to the type of execution of working elements on wood splitters, they are:

- knife or guillotine - they consist of a cone-shaped knife that splits logs by cutting into them. Such devices are characterized by increased safety, since they do not rotate. Their main disadvantage is that over time they require sharpening of the cutting edge. Knife devices also have an advantage - the ability to split wood in the required place and into the required number of logs;

- screw - the working body is presented in the form of a cone-shaped element - a drill, which has cutting spiral edges, through which it is screwed into the wood and splits or tears it into pieces. They are characterized by increased efficiency, but at the same time they have low safety indicators. It is important to carefully control the process, especially when the logs are fed into the rotating blade manually. It is impossible to predict how many pieces the log will be split when using such cleavers, which is sometimes a disadvantage (why sometimes, since the more logs the log is broken into the first time, the better, but sometimes it is necessary to obtain not too small pieces).

It is also important to take into account that screw cleavers practically do not require sharpening of the cutting edges, therefore they are characterized by a long service life. The choice of the appropriate option should be based on operational features. For example, if it is important to obtain logs of the same size, then preference should be given to knife-type installations.

Wood splitting machines are also divided into types based on the method of actuating the cutting part. If everything is clear with screw-type installations (their working element rotates along an axis), then with knife-type devices, not everything is so simple. They are divided into the following types:

- The knife is stationary - installations in which the compression of the log occurs due to the movement of the supporting heel. The heel acts on the workpiece, pressing it against the knife element, thereby splitting the wood. The advantage of such installations is an increased degree of safety, since the knife is always stationary. The installations are also distinguished by their simplicity of design, which has a positive effect on their cost. When the cutting edge becomes dull, the knife can be removed and sharpened or even replaced with another, which takes no more than 5 minutes.

- With movable knives - they differ from the previous version in that it is not the supporting part that is driven, but the cutting element. The advantages of such installations are that it is possible to carry out more precise actions for splitting logs. However, the installations are considered less safe, since during the movement of the knife, fingers can get under its cutting edge, which will lead to adverse consequences. In addition, since the knife is mounted on the hydraulic cylinder rod, this complicates not only the design, but also the specifics of removing it for replacement or sharpening.

It is also important to note that the installations are divided according to the method of arrangement of the workpieces. The machines come with vertical and horizontal installation of logs, which affects the ease of their operation. Most modern models have horizontal loading of workpieces, and the vertical type is often used when working with long logs.

This is interesting! The knife on knife log splitters can have different configurations. The simplest are products with one edge, which divide the workpieces in half. To work with large logs, it is rational to use cutting elements with two or more cutting edges that are shaped like a cross or a star. Cross blades cut the workpiece into 4 parts at once, and with a star-shaped blade, into a larger number of logs.

Screw splitter

Such devices do not have high performance, but they take up relatively little space. They are installed in woodsheds (rooms for storing firewood). There they also split the bars into small logs and wood chips.

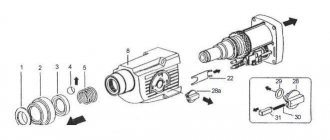

The machine includes:

- An electric motor transmits torque from it to the actuator.

- Drive and driven pulleys with a V-belt, a reduction V-belt transmission helps to increase torque and also reduce the rotation speed on the main part of the device.

- The cone is the main working body. A persistent conical thread is cut on the conical surface. When rotating inside the body being destroyed, the conical screw part cuts deeper, pulling the log towards the support.

- A wedge is an auxiliary device that helps destroy a drawn part.

Manual wood splitter

This wood splitter is the easiest to make. The principle of its operation is based on the energy of hitting the cleaver with a heavy object. The effect is almost the same as if you put an ax on a log and hit the ax head with a sledgehammer. But this crowbar is more convenient to use and the work speed is higher.

Wood splitter

Its advantage is that it is safe to use, easy to manufacture, and takes up little space. Does not require delivery of each log to him. It will be convenient to move from one log to another. While working with it, your back remains straight, which is important when chopping large volumes of firewood. You don't have to bend over each log to split it.

But it requires the use of human physical strength and makes a loud metallic sound during operation. To protect against sound, you will have to wear headphones.

The crowbar consists of only two parts. The first part is directly a splitter with a guide pipe, and the second part is a shock. The impact part can be external, that is, wrap around the guide pipe, or internal - go inside the guide pipe. For this cleaver to be effective, one rule must be followed when making it. The part of the cleaver with the guide and blade should be as light as possible, and the striking part as heavy as possible, but within reasonable limits, since the striking part will have to be lifted manually. The greater the difference in mass between these two parts, the higher the efficiency of the cleaver.

Wood splitter crowbar.

Drawing of a wood splitter.

When making a crowbar cleaver, the main thing is to observe the rule of a large difference in the masses of the parts of the cleaver and maintain a sufficient stroke length of the striking part to create a strong blow. This length should be approximately 50-60cm.

To make the first part of the cleaver as light as possible, you need to use a thin-walled pipe as a guide and make the blade of the cleaver narrow.

If vibration is transmitted to the hands during an impact, it can be significantly reduced by making the handles wooden. If the handles are made of metal, then they need to be welded onto the heaviest and most massive impact part, this will also help reduce vibration.

To ensure smooth movement of the striking part and reduce the sound of metal parts rubbing against each other, a polypropylene pipe should be used between these parts.

To avoid rapid riveting of the metal at the point of impact of the two parts of the crowbar, the contact patch between them should not be too small.

For ease of working with a crowbar, logs should be placed inside an old car wheel. This will prevent chipped pieces from flying away from the logs, and they will always be in the same position.

Video: manual wood splitter crowbar

Step-by-step guide to making a spring log splitter

To complete the work you will need the following tools:

- Angle grinder (grinder) with a set of cutting discs and cleaning flap wheels.

- Welding machines and modern inverter-type household devices for welding steel structures are relatively small in weight. The process is carried out using direct current, so the welds are neat, and the molten metal of the electrode completely fills the joints between the parts.

- Clamps will help connect the parts to be welded.

- Measuring and marking tools will help produce blanks for future designs.

- Channel No. 10...16 (the number determines the height expressed in centimeters).

- Profile pipe 40·60 mm (30·60 mm).

- Rail 300…400 mm long.

- I-beam No. 12...16.

- Corner No. 30...50.

- Bushing from the car suspension (it may have wear).

- Pipes with a diameter of 40...70 mm.

- A suspension spring for a passenger car, for example, from a VAZ.

Before starting work, a preliminary design is drawn. Some craftsmen have mastered engineering design programs, with the help of which they can work out the details of a future product. Manufacturing details are shown below.

An approximate diagram will help you navigate the process of manufacturing the installation.

The support is made from the channel. A stand is welded to it. It is best to use an I-beam for the rack. This type of rolled product has high rigidity. Under prolonged loads, it is quite difficult to bend such an element.

To ensure stability of the base, jibs are welded to it. Additionally, stops are created from the existing pipes; they will prevent a possible fall of the entire product.

A support for the spring is cut from the channel. A square hole is sawn through it. This will allow you to securely fix the element on the rack in the future.

The installation height of the support is determined by the length of the existing spring. At the same time, they focus on the height of the entire wood splitter, as well as its ease of use for humans. It is convenient to lift a load located at waist height. You will have to lift it slightly above chest level.

All these considerations will allow you to choose the height of installation of the spring support on the strut.

The corners are used to make jibs. They will hold the support. Then, when the wood splitter is dynamically loaded, there will be no displacement of the supporting surface.

To fix the lower end of the spring, you need to make a cylindrical clamp. A small piece of pipe is used to make it. It is advisable to select a pipe according to the inner diameter of the spring. Then it will not move during operation.

There is a slot in the top of the rack. A bushing is installed in it. Then it is boiled. When installing, you must maintain perpendicularity to the rack. The hub axis must be parallel to the ground. For welding, a conductor is used that will allow the specified conditions to be met.

The shaft is installed in the sleeve. A rocker arm is welded to it (a channel is used). A small piece of pipe is mounted on the lower part of the rocker. The upper part of the spring will be fixed in it.

In order for the rocker to move freely, a window is cut in it; its dimensions depend on the parameters of the rack.

A profile pipe is welded to the rocker arm. A chisel is installed at its end. These tools are made from carbon steel U9...U10. The hardness of this metal is HRC 60...63. This tool will last a long time. During operation, it is easy to sharpen it using an angle grinder and a grinding wheel.

The wood splitter becomes operational. A load (part of the rail) is welded above the chisel. For ease of use, the handle is welded. To reduce damage to your hands, wear rubber elements. They will dampen vibration upon impact.

To work, you will need to install a large piece of log. Logs will be placed on it, which will have to be cut.

The log is held with one hand. They raise the cleaver and then strike.

The cleaver goes down. The fragment located below splits. The chisel goes lower. If a complete split occurs, the point hits the wood support and does not become dull.

General points

To ensure normal storage of firewood in the woodshed, it should be properly prepared.

Wood is stored in the form of logs, which are obtained from split logs. If you purchased timber in the form of long logs, which is very profitable, then in order to be able to store the wood, they should be cleared of branches and twigs, sawn into logs, and then split into more or less uniform logs. At the same time, it is necessary to cut the logs into logs of the same length so that they not only fit in the barn, oven, but also stacked in a neat stack. In a well-assembled woodpile, the wood dries better because it is well ventilated.

During cutting, the easiest way is to prepare a wooden stick, a branch and use it to check the size of the next log, or use a chainsaw to prepare firewood to mark the entire log using a tape measure at once, and then start cutting. For the convenience of cutting logs, you should prepare trestles and stands of the original type, since sawing wood on the ground is inconvenient.

Previously, two-handed saws were used to cut logs on trestles.

After the logs of approximately the same size are prepared, you can start chopping them. Classical splitting of firewood involves the use of an ax or cleaver, but there is also an alternative, mechanical option, when firewood is split by a special machine, a wood splitter. It is worth noting that working with an ax is very labor-intensive, so using a special machine not only speeds up, but also makes the work easier.

If you live in a house that is heated exclusively with wood, if you have a bathhouse, then to simplify and facilitate the process of collecting firewood, you should definitely consider purchasing a wood splitter. This device will facilitate the annual winter wood harvesting activities for the following year. By the way, the system is so simple that you can easily do it yourself.

If there is no wood splitter, you will have to chop the wood into logs using an ax. If you also don’t have experience and skill in this matter, then this activity will be very dangerous for you, so we decided to give some recommendations for such work.

Safety precautions when chopping wood

You should adhere to the following recommendations:

- You only need to work in closed shoes so that a bounced piece of log does not injure your foot.

- Logs must be fed vertically to the cone mechanism.

- Chopping firewood should be carried out away from houses, people, animals, and recreation areas, so as not to harm the estate or others.

- The ringer's position should be stable, with feet shoulder-width apart.

- Gloves are not used when working with a screw splitter. The rotating screw can catch the glove and pull the hand along with it. The same applies to hanging parts of clothing.

- In a homemade screw unit, it is important to provide an emergency stop. To do this, it is equipped with a pedal or emergency button. Moreover, simply disconnecting it from the network is not enough, because the shaft will continue to spin for some time. A special electromagnetic brake is required in the closed state.

When choosing a product for splitting firewood for the dacha, preference should be given to mechanical types or hydraulic ones that run on gasoline. They will be inexpensive, and the performance will be high. The alternative is to make one of these types yourself.

Assembly diagram of a hand-held device

This type only makes the process of splitting logs easier, so you still have to work hard.

For production we will need:

- materials that you already have, or you will have to purchase them;

- drawings, video tutorials from practitioners, photos of finished copies and the work process - finding these materials on the Internet is not so difficult;

- tools - grinder, welding inverter;

- welder skills, the ability to draw up and calculate a diagram and ingenuity, because any ready-made diagram will need to be adapted to the parts you have on hand.

A round frame is brewed, the diameter of which is slightly larger than the diameter of the chocks (approximately 23 cm). To do this, you need to take a round, thick metal blank and weld two pipes to it, the height of which should be 35 cm. To complete the frame, you will also need to weld a ring on top. A knife is installed at the bottom with the tip facing up, and holes for fasteners are made in the base.

A log is placed on the knife and hit with a sledgehammer on top. However, it is worth remembering that such a wood splitter is only suitable for soft wood species.

How to properly chop wood with an ax: use a cleaver

You can cut a log in many ways and with different tools, but there are special devices that make the life of a woodcutter easier. The best ax for chopping wood is considered to be a simple taiga hatchet, which can be made even at home from old carpentry tools. Its feature is the presence of a gradual expansion and less weight for a comfortable and sharp swing. Many people ask why there is a sharp swing with a cleaver at all and why it is easier to split a log with an ax with a swing. This is elementary: the impact force is greater, due to which the blade immediately reaches the expansion and all the energy goes towards expanding the log. This way, the log scatters quickly and easily, and the metal does not get stuck in the wood.

Such an ax for chopping wood allows you to get the job done much faster, since it very rarely gets jammed in the wood, and its low weight reduces the load on the body, increasing the productivity of the woodcutter. With its help it is very convenient to cut down trees, so the tool can be called universal. No tricks are required when chopping: a standard block for chopping wood, a normal swing, a stronger blow and that’s it, the log is broken. If it is not broken, repeat the swing and blow until you break it.

If you need a tool specifically for splitting, then it would be better to take it with a large head extension, but keep in mind that it will be much worse for felling trees and turning logs. In general, it will be very difficult to work with it, since it is not intended for frequent blows; here you will have to take it by force. It’s better to watch a video on how to properly chop wood with a cleaver before using it, since the technique is very different from working with a taiga or carpenter’s hatchet.

When you need a little wood

In southern regions and/or for heating utility rooms, little firewood is required. A normal guy could pin them by hand effortlessly, and then let the missus just try not to serve the stopar for dinner. But there is a problem: the correct swing. Without it, swinging a cleaver is exhausting and dangerous, and developing a swing for chopping wood is no easier than skills in using edged weapons; see, for example, how a fighter chops firewood in Kurosawa’s “Seven Samurai.”

A manual mechanical wood splitter, again contrary to popular belief, saves little or no muscle effort when chopping wood, but allows you to do it quite safely without having to master the woodcutter's swing. Its additional advantage is that it can work both in gravitational-inertial and pressure modes. The latter allows you to little by little, but manage the most stubborn chumps of almost any diameter. The main thing is that their cuts are parallel and approximately perpendicular to the longitudinal axis of the log, otherwise the work will be much more dangerous.

Wood splitter device with a sliding ax

The structure of a manual mechanical wood splitter is shown in Fig. The lever arm is taken from 1.5 m; the bigger, the better. Load - depending on its strength, 10-50 kg. If the splitter is fixed motionless, this wood splitter works only as an inertial one: the lever is lifted by the handle and forcefully lowered onto the block. If the splitter can be moved along the lever, then the wood splitter can also be push-type; The lever arm is extended by a pipe placed on the handle.

There are a number of significant nuances in the design of a lever manual wood splitter (shown by arrows on the right in the figure). The first is the cleaver. A simple wedge made from a piece of rail is ineffective and gets stuck in the wood. Such a wood splitter works much better with the Strela cleaver (see above), especially since it can be inexpensively purchased ready-made. The second is the spring; it is the most traumatic element in this design. The spring force is needed such that the free lever with the cleaver in the farthest position is held approximately horizontally. The spring must be secured to the heels so that it does not come off them with the full swing of the lever; It’s better to pass a swinging guide into the spring.

Device of a manual mechanical wood splitter

And lastly, if the lever wood splitter is not rigidly attached to the supporting area, then its front legs must be made no less than the maximum length of the lever arm + double the diameter of the largest block. How to make your own lever wood splitter with improved kinematics, see next. video: