Husqvarna chainsaws are indispensable assistants in the household. With the help of gasoline motorized equipment, you can perform various works related to construction, logging and simple trimming of branches. If the tool is handled correctly, it will serve for a long time, but during operation, various malfunctions occur as a result of intense loads.

When minor breakdowns are detected, they do not contact service centers and workshops; routine repairs of Husqvarna chainsaws are carried out independently, and it is necessary to investigate and analyze the probable causes of defects and ways to eliminate them.

Why it won’t start and what to do

Among the malfunctions of the Husqvarna chainsaw are poor engine starting. The engine either cannot be started at all, or it starts poorly.

There is no clear answer to the question why the chainsaw won’t start. The main assembly unit of the tool is the engine. The following conditions affect the stability of operation:

- fuel mixing;

- air;

- presence of a spark;

- lubricant

Each factor is responsible for its own working unit:

- for the fuel mixture - carburetor;

- for air - a cleaning system, in particular an air filter;

- for the spark - the ignition mechanism and spark plug;

- lubrication - lubrication system and gasoline.

A common reason why chainsaws do not start is failure to follow the starting algorithm. The engine unit should only be started after all parts have been completely assembled:

- tires;

- saw chain;

- caps

The chain brake is always on. To avoid losing control of the instrument, you must not start in the air.

Starting the engine in a cold state is done as follows:

- Place the tool on the ground, step on the back handle with your right foot, and place your left hand on the front handle.

- The saw is in a stable state, the chain does not touch the ground.

- With your right hand, take the starter handle and pull the cord, but do not twist it around your hand.

- As soon as the first flash occurs, return the choke lever to its initial position, opening it, and repeat the start.

- They gas it and let it go. The blocking is disabled.

- The engine is switched to idle speed by quickly turning off the gas limiter.

Starting a warm engine is carried out in the same sequence, but without opening the damper.

If the start is made correctly, but the engine does not work, a possible reason is the lack of fuel in the tank, or the carburetor fuel chamber is not filled. Check the tank and chamber, fill them with the mixture.

If the ignition system malfunctions, inspect the spark plug and check for the presence of a spark at the electrodes. If it is wet (gasoline floods the spark plug) and a spark is not detected, the part is turned out, dried or replaced. If it is dry and there is a spark, then there is a problem in the fuel equipment - clogging, depressurization of the gas intake.

See » Review of semi-professional chainsaw Stihl MS 260-16

Magneto malfunctions are also confirmed by a weak spark. Despite the ignition operation, there may be no flash in the cylinder, while the spark plug removed from the cylinder is wet. The solution is to purge the cylinder with the carburetor flaps open.

The electrodes of the system are covered with soot or oily. This can be removed with a wire brush. The spark plug is washed and cleaned by allowing the gasoline to evaporate.

Violation of the gap between the side and central electrodes leads to a poor start. The normal interval is 0.6-0.7 mm. It is adjusted by hemming.

If the ceramic insulator surrounding the central spark plug or the current-carrying core of the wire is damaged, replace it.

If it starts and stalls

The Husqvarna chainsaw starts and stalls when you press the gas. This is caused by a clogged carburetor jet and a dirty fuel tank filter. The defect is eliminated as follows:

- disconnect the fuel hose from the carburetor;

- inspect the fluid leakage - the breather is clean if a full stream comes out.

The next reason why a chainsaw stalls is contamination of the muffler with exhaust resins. The issue can be resolved by cleaning.

Wear of piston rings affects the operation of the cylinder-piston group. If there is play during inspection, parts are replaced.

When starting the engine, the unit may also stall:

- as a result of water entering the mixture;

- due to poor chain lubrication;

- oil wire leakage;

- clogged channels.

Pay attention to the chain:

- if dryness increases, clean the oil supply channels, inspect the elements connecting the fittings to the tubes;

- If there is an oil leak at the connecting points or there are cracks in the tubes, they are sealed with sealant.

The engine does not develop speed:

- if the piston rings burn in the grooves;

- when the crankcase rubber seals wear out and lose elasticity;

- leaks in the connection between the cylinder and the crankcase;

- due to incorrect setting of the ignition timing;

- as a result of contamination of the cylinder fins and fan grille;

- under heavy load immediately after purchasing a new engine.

This is interesting: Ural chainsaw - technical characteristics and adjustment

How does a chainsaw carburetor work?

The main purpose of a carburetor is to mix fuel with air in the required proportions.

If the latter are violated, this almost instantly affects the operation of the engine. Chainsaw carburetor STIHL MS 181 C BE

Chainsaw carburetors may differ in design. However, their basic elements and operating principle remain approximately the same.

This is a wind tunnel, across which there is an air damper - with its help the intensity of the air supply is regulated.

This part is where the base tube narrows - here the air flow speed increases, i.e. air is always supplied to the carburetor under some pressure.

In this area, the fuel comes into contact with the air flow. Fuel enters the atomizer from the float chamber through a nozzle (dispenser).

Float chamber

This is a container that allows you to keep the fuel mixture in a stable state.

Chainsaw carburetor design diagram

A chainsaw carburetor works according to the following principle:

- when the engine starts, the main damper opens and a stream of air is supplied into the air channel at a certain speed;

- the speed of the air flow, as well as the level of the float in the chamber, are regulated by the position of the damper, namely due to the difference in pressure in the float chamber and the air channel;

- fuel from the float chamber is sucked into the nozzle, and from there into the diffuser;

- passing through the diffuser, the air captures the fuel entering there;

- the resulting mixture is fed into the cylinder cavities through the intake channels.

The pressure in the float chamber is approximately equal to atmospheric pressure, but a vacuum occurs in the air channels of the carburetor when the chainsaw engine starts. Opening the damper increases the air supply intensity. As a result, more fuel enters the carburetor, and the number of engine revolutions increases.

Model specifications

The Husqvarna brand chainsaw in the proprietary 142 modification has solid factory parameters.

These include:

- petrol engine power – 2.58 liters. s./1.9 kW;

- idle/maximum speed – 3000/13000 rpm;

- The manufacturer's recommended length of the tire used is 30–38 cm;

- weight with filled fuel and oil tanks – 4.9 kg.

Despite the impressive maximum speed parameters, the engine of the Husqvarna model is quite quiet. When operating the model under maximum loads, the sound impact level on the operator is 105 dB.

An indispensable assistant for each of us

This model has a significant advantage, namely low weight, which makes it more convenient to use, and it is also quite economical, since the manufacturer equipped it with a small-volume two-stroke engine. But, despite this kind of functionality, the Husqvarna chainsaw is quite powerful. One of the most successful models is the Husqvarna 137 saw.

As for the characteristics of the chainsaw, its weight is about 4.6 kilograms, although this is the “clean” weight of the tool, without oil, fuel and tires with a chain. Of course, when fully equipped, the chainsaw will weigh significantly more, but an undeniable advantage can be considered that thanks to the long tire, which has 38 centimeters, operation becomes easier. It is this feature that makes it possible to make deeper cuts.

The chainsaw from this manufacturer has a very respectable power, which is about 1.6 kW, which contributes to a significant increase in the level of vibration waves, and this is a significant disadvantage when working with this tool. Of course, when creating their products, the manufacturer thought about how to reduce this kind of vibration and supplemented the equipment with a so-called anti-vibration mechanism.

If we talk about revolutions, then in operating mode their number is 13,000, and in running mode – 3,000.

The tool is controlled using a double-lever design with a built-in starter, which, to be honest, is quite inconvenient, since its location makes it difficult to reach certain parts during maintenance. Choosing an inexpensive chainsaw for your home is not an easy task. If you decide to opt for this model, then you will have to pay a considerable amount for such a chainsaw, since it is one of the most expensive in the range of products produced by this manufacturer. You can find out the prices for chainsaws made in Russia here.

Chainsaw delivery set

When ordering the Husqvarna 142 model, the buyer receives absolutely everything necessary to start using and further maintain the garden tool. The model kit includes:

- branded tire and chain;

- plastic tire cover;

- hand tools for assembly and maintenance;

- user manual.

For an additional fee, the manufacturer supplies the chainsaw with a bag for transportation, branded oil for 2-stroke engines and additional spark plugs.

User manual

Why do you need instructions? This is a kind of petrol tool passport, which briefly contains complete information about the chainsaw of a given model. It would be a good idea for a new owner of a Husqvarna 142 chainsaw to read the instructions before using the tool; this will protect him from mistakes, injuries and tool breakdowns.

All information is divided into sections:

- Device, assembly steps, photos and descriptions.

- Characteristics of the Husqvarna saw 142.

- Safety.

- Husqvarna 142 saw kit.

- Rules and methods of sawing.

- Preparation, launch, running-in.

- Maintenance of “Husqvarna” 142.

- Typical faults.

We suggest you study the full version of the operating instructions: Your browser does not support frames Download the Husqvarna 142 chainsaw operating manual

Safety requirements when working with the Husqvarna 142 chainsaw:

- refuel the tool away from the sawing site;

- work using safety glasses, gloves, headphones, and protective clothing;

- do not smoke near the instrument;

- do not work with a faulty chainsaw;

- do not disassemble a running saw;

- When sawing, cut with the entire tire, and not with its end; this is dangerous and leads to rebound.

Preparation of fuel mixture for two-stroke engines

Read:

The video shows how to make a fuel mixture for two-stroke engines. Calm chainsaw oil). How much oil to add to chainsaw gasoline? Refueling mowers and chainsaws

And

The use of a catalytic afterburner of exhaust gases, E-TECH technology, reduces their toxicity, is approved for use in all countries and allows us to talk about a qualitative improvement in working conditions. Gasoline for a chainsaw - what kind to pour? How to dilute gasoline for a chainsaw? (Husqvarna). We must pay tribute to the fact that Husgvarna always prioritizes improving the working conditions of its tools. 1959 saw had the lowest noise level compared to other saws, and since 1973, all saws have had an automatic chain brake to protect the saw operator from kickback. Modern chainsaws use a combined chain brake, which stops both manually - by resting your hand on the guard - and automatically, by the force of inertia of the saw's recoil. What oil to use for what oil to pour into gasoline for and husqvarna - for. Many manufacturers, to prevent kickback, eliminate the possibility of working with the toe of the saw and install a limiting shield. But Husqvarna saws do not have it, since Swedish safety standards allow working with the end of the bar. The ratio of gasoline and oil for a chainsaw: how and how to dilute gasoline for a chainsaw? In Russia, only first-class fellers are allowed to work in this way.

In 1969, Husgvarna released a chainsaw with reduced vibration levels and since then its saws have been equipped with anti-vibration systems, the quality of which is gradually improving with the release of each new model. Today, the company installs the LowVib vibration damping system on saws, the principle of which is to balance one mass with another, the inertial interaction of two masses. The chainsaw parts are isolated from the handles by steel springs, and the total mass of the handles is the counterweight. But keep in mind that the quality of vibration damping on household saws is lower, since their operating time is much less than professional saws. It is impossible not to note the double air filtration, which allows you to increase the productivity of the logger and the engine, by reducing the time for servicing the chainsaw. How to properly refuel a chainsaw, prepare what fuel to use. How to dilute gasoline for a chainsaw? The narrow body, high center of gravity and flat bottom make the operation of Husgvarna chainsaws convenient and comfortable.

And the last piece of advice is suitable for all chainsaws, without exception. Don’t forget that according to statistics, approximately 90% of all saw breakdowns are the result of careless handling of the saw set and chain. If the chain is sharpened, then it works, and if not, then it is a person. You put more effort into sawing, increasing the load on the chainsaw, reducing the service life and the entire service life of the unit.

Husqvarna petrol saws are in great demand both among novice gardeners and experienced forest fellers. Models of the Swedish brand have a number of important advantages such as reliability, balance and high working life. Moreover, each Husqvarna chainsaw has a simple design, which makes it easy to maintain and quickly fix any breakdowns that occur.

Operating instructions for Husqvarna chainsaws

In order to extend the life of the chainsaw and reduce wear of its main parts, you must carefully study and adhere to all the tips specified by the manufacturer in the instructions for use. Below we list a number of the most common questions related to the operation of Chinese and Swedish chainsaws manufactured by Husqvarna, and give detailed answers to them.

What kind of gasoline should I put in my Husqvarna chainsaw?

To prepare the filling mixture for Husqvarna chainsaws, you should use AI-92 fuel. It is extremely rare that the operating instructions for newer models of this brand indicate that 95 gasoline can be used to prepare the mixture.

As practice shows, it is better not to do this, since the country producing Huskvarna garden tools is Sweden, where gasoline is of much better quality than in the post-Soviet countries.

Which oil is suitable for a Husqvarna chainsaw?

Spare parts for Husqvarna chainsaws can last quite a long time, provided that the owner of the tool does not skimp on engine oil.

To dilute the filling mixture, you can use mineral-based or synthetic oil. The second option will always cost more, but the effect of its use will be many times better.

The ratio of gasoline and oil for a Husqvarna chainsaw

The ratio of gasoline and oil used is affected by the power of the chainsaw available. If the power of the tool is less than 2 hp. pp., then the proportion of gasoline and oil will be 1:40. In other words, 25 ml of motor oil must be diluted in 1 liter of fuel. If the power of the Husqvarna chainsaw is more than 2 hp. pp., then you will need to dilute gasoline for the Husqvarna chainsaw in a ratio of 1:50, that is, dilute 20 ml of oil in 1 liter of fuel.

Proper running-in of a Husqvarna chainsaw

- Start the chainsaw and let it run for 2-3 minutes. At the same time, sawing branches or logs is strictly prohibited;

- After this, proceed to cutting down small branches;

- After another half hour, you can begin sawing large logs.

Read also: Pork shank baked in the oven recipe

Be sure to follow these instructions - this will help you extend the life of the engine and carburetor.

How and when to adjust the ignition on a Husqvarna saw

Users of Husqvarna chainsaws often have a question: how and when to adjust the ignition. The answer is simple. Husqvarna chainsaws have an electronic ignition coil and flywheel, which do not provide for adjustment. The only thing that can be adjusted is the gap between the coil and the flywheel.

To adjust the gap at home, you need to cut a feeler gauge out of a plastic bottle, and then loosen the screws securing the coil. Next, the probe is installed between the coil contacts and the flywheel. The screws are tightened.

It is necessary to adjust the gap during maintenance or when scoring is detected on the surface of the flywheel. Such scuffs indicate that there is no gap at all.

If, after adjusting the gap between the coil and the flywheel, the parts continue to touch, then it is necessary to check the crankshaft bearings for wear. They may be very worn and require replacement.

This is interesting: Russian-made concrete mixers are popular models

Separately about the breakdown of the most common model

Let's look at the problems of Shtil 180 in more detail:

- Clogged carburetor or fuel filter. These are the most common problems that can be easily resolved after cleaning. Sometimes the filter has to be changed;

- Replacing the spark plug;

- Sometimes the cylinder or seals need to be replaced.

The Shtil saw is quite strong and durable, so you can often fix a breakdown yourself. In fact, the same applies to the Partner, Ural, Makita and Husqvarna models.

When we discover a malfunction in our chainsaw, we look for the cause in small ways, gradually checking and eliminating the problems. Such problems are easy to fix yourself. But if the breakdown is serious, and you do not have enough experience, then this should be done by a specialist.

Troubleshooting and DIY repairs

Repairing a Husqvarna chainsaw is complicated by the fact that it requires specific tools that are usually not included in the arsenal of a home craftsman. But all of them can either be bought at an auto parts store or made by yourself.

Chainsaw Husqvarna 142 - technical specifications

In addition to the usual sets of screwdrivers and a hammer, you will need:

- Piston stopper. Can be replaced with a synthetic cord from a starter with knots tied every 2–3 cm.

- Screwdriver for bolt heads on a chainsaw. They can be specific - in the form of semicircles or stars.

- Clutch adjustment key.

- Combination spark plug wrench.

- Compressor for cleaning internal volumes from sawdust, dust and dirt.

If you plan to clean and troubleshoot the cylinder-piston group, you will need a compression measuring device and an adhesive-sealant.

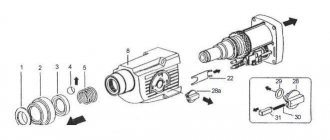

The procedure for disassembling a Husqvarna chainsaw is as follows:

Diagram of a device for checking the ignition of a chainsaw

- the top cover is removed;

- the emergency brake and saw bar with chain are disconnected;

- the starter is removed;

- the candle is unscrewed;

- a piston stopper is installed through the spark plug hole and the flywheel is removed (considerable effort will be required).

After this, the front handle is disconnected, followed by the carburetor, oil pump and lastly the engine.

Troubleshooting the ignition system comes down to replacing failed spark plugs with new ones. Only Champion RCJ7Y spark plugs are used. The ignition coil in Husqvarna chainsaws is electronic, maintenance-free, and if it fails, it is completely replaced, like the starter.

Spark plug Champion RCJ7Y

There is no need to adjust the ignition system. The only problem that can be solved by adjustment is setting the gap between the flywheel and the coil. The gap is set using plumbing gauges. The standard value is 0.2 mm.

Setting up the fuel system

The fuel system of Husqvarna chainsaws is complex. At home, it is better not to repair it, as well as service the cylinder-piston group. The maximum malfunction that can be fixed at home is cleaning the breather, eliminating kinks in the hose and replacing the filter. The same applies to the oil system - troubleshooting comes down to cleaning the hole in the breather with a needle or compressed air. It is recommended to do this preventively every 2–6 months, depending on the intensity of saw work.

Chainsaw Husqvarna 142

Carburetor adjustment

The Husqvarna 142 carburetor has 3 adjusting screws, marked H, L and T. The first is designed to set the injection at maximum speed, the second at low speed, the third determines the fuel injection parameters at idle.

Adjusting the carburetor of the Husqvarna 142 chainsaw

First, the idle injection of the fuel mixture is adjusted by turning screw L ¼ turn counterclockwise. If the saw chain moves, the movement is stopped by clamping the screw T. The adjustment is made with visual and auditory control - the motor should not squeal and white smoke should not come out of it. The correct position of the screw is determined empirically.

After this, the chainsaw accelerator is clamped and the injection at high speeds is adjusted using screw H in exactly the same way.

The leakage of excess air into the carburetor is eliminated by replacing the torn hose - the black tube going to the carburetor, or by fitting it more tightly.

Saw tension

The saw chain tension regulator is on the right side. To access it you will have to remove the side cover. The tension is adjusted by turning the bolt to the required degree.

Video on the topic: Disassembly and assembly of the HUSQVARNA 142 chainsaw

Separately about the breakdown of the most common model

Let's look at the problems of Shtil 180 in more detail:

- Clogged carburetor or fuel filter. These are the most common problems that can be easily resolved after cleaning. Sometimes the filter has to be changed;

- Replacing the spark plug;

- Sometimes the cylinder or seals need to be replaced.

The Shtil saw is quite strong and durable, so you can often fix a breakdown yourself. In fact, the same applies to the Partner, Ural, Makita and Husqvarna models.

When we discover a malfunction in our chainsaw, we look for the cause in small ways, gradually checking and eliminating the problems. Such problems are easy to fix yourself. But if the breakdown is serious, and you do not have enough experience, then this should be done by a specialist.

How to set up a chainsaw

In the process of repairing Husqvarna chainsaws with their own hands, they identify some malfunctions that appeared as a result of incorrect ignition adjustments and carburetor settings.

The mechanism is responsible for engine speed and is adjusted for operation taking into account the necessary conditions:

- climate:

- height above sea level;

- petrol;

- loads;

- oil used.

By default, for productive work, the factory settings of the carburetor of the Husqvarna chainsaw are set during testing.

The device has 3 customizable areas:

- “L” - low speed jet;

- “X” - high speed jet;

- “T” - idle speed adjustment screw (XX).

The standard settings are:

- "X" = 11/4 turns;

- "L" = 11/4 turns.

To set up the chainsaw, after break-in, adjust the carburetor: first work with the “L” jet, then with the XX “T” and “X” screws. When “L” and “X” are rotated clockwise, the quality of the working air-fuel mixture deteriorates; when rotated counter-clockwise, it becomes richer. Rotating the screw “T” clockwise increases the idle speed.

See » Advantages and disadvantages of the popular household chainsaw Partner 350

Carburetor repairs are performed by a specialist.

Carburetor adjustment

A separate section covers the carburetor adjustment sequence. Correct tuning of the fuel system contributes to stable traction characteristics and economical fuel consumption.

The work is carried out provided that the air filter is completely cleaned and the power unit is warmed up to operating temperature. By rotating the screws, quantity and quality, the engine is brought to optimal operating mode with good throttle response and stable idle speed.

Additional adjustment may be required when switching to fuel with a different octane number, or when switching the tool to winter or summer operating modes.

Break-in rules

Running in a chainsaw does not last long at XX. Therefore, after starting the engine, you need to idle for about 5 minutes, then start sawing trees with a diameter of no more than 10 cm at medium speed.

The technological process is carried out according to a cyclic scheme:

- 1.5 minutes with minimum load;

- 20 seconds on XX without it.

After operating for the first 25 hours, the unit can reach full power; all rubbing parts are worn in.

During this period, be sure to adhere to the following recommendations:

- do not overheat the power plant;

- do not work for a long time at XX;

- do not load as much as possible;

- suppress long-term slipping of the clutch.

After final running-in, the following work is carried out:

- inspection of the crank mechanism;

- cleaning carbon deposits on all parts;

- checking fasteners;

- assembly;

- preparation of a flammable mixture;

- adjusting the carburetor to maximum power under load.

The saw chain also needs running-in. Attention is paid to its lubrication and tension. The part is tensioned so that it can be rotated freely by hand. Lubrication is carried out by immersion in oil. Then the chain is run at idle for 3-5 minutes. The engine is stopped, the chain cools down and only then the tension is checked.

How to dilute gasoline for a chainsaw

Why does the Shtil 180 chainsaw not start?

How to sharpen a chainsaw chain at home

Which gasoline and oil is better to choose for refueling a Shtil chainsaw: table of ratios, how to dilute, proportions

TOP 2 reliable Hopper chainsaws and owner reviews about modification 4518

TOP 2 high-quality chain saws Tatra Garden (Tatra Garden)

What should I do

It is important that sparks on the chainsaw cannot be caused by a malfunction of the fuel system. In order not to look for problems with proper ignition, this problem must be solved immediately

The carburetor of a chainsaw can “overflow,” that is, throw too much fuel into the combustion chamber. Inside the candle there is a porcelain insulator from which a metal core emerges. On it, under the plate, they come into contact with the “ground” (minus) and a spark occurs.

But if the space inside the spark plug between the bead and ground is filled with excess fuel, especially along with conductive contamination, the circuit (spark) can slip inside the spark plug. There will be no sparks where needed.

However, if there is no spark at the chainsaw, the fuel will not burn and the spark plug must simply be wetted with fuel while the carburetor is running. It is almost impossible to visually determine whether the spark plug is overfilled and therefore not sparking or not sparking excessively. Therefore, in order to accurately diagnose this “key point” (the carburetor or inflammation is faulty), you need to have 2-3 guaranteed serviceable spark plugs on hand.

- Let's put a working candle.

- Spark checked.

If a spark occurs, this means:

- The old spark plug was faulty;

- The old spark plug worked but was filled with fuel.

The working spark plug is screwed into place and they are trying to start the engine. If it starts working correctly, the problem is solved. If not, turn the spark plug back on and watch for a spark. There are no sparks - another dry working spark plug is placed on them.

The spark burns, the candle burns, they try to start. If it does not start again, the spark plug is turned off, causing a spark. If the spark on your chainsaw disappears again and the spark plug fills up, there is an almost 100% chance that the cause is an overfill.

Chainsaw malfunctions and how to fix them

Owners of the Husqvarna 142 model often encounter typical breakdowns caused by improper use of garden tools or simple wear of its parts.

These malfunctions include:

- the chainsaw does not start - the cause of this breakdown lies in the spark plug being flooded. To be able to start the saw motor, you need to remove, wash and dry the spark plug. After this, you need to blow out the cylinder by sharply pulling the starter cable several times with the spark plug turned out. After this, you need to screw in the spark plug and start the engine of the garden tool;

- increased vibration during operation of the saw - repair of this breakdown is carried out by cleaning or replacing the muffler. You will also need to inspect the springs of the anti-vibration system. If necessary, sagging parts must be replaced;

- shooting sounds - if loud popping noises are heard during operation of the Husqvarna model, then the causes of the breakdown should be sought in the carburetor or muffler. The operator will first need to adjust the carburetor. After this, you need to remove and wash the muffler;

- leakage of oil to lubricate the chain - to eliminate this breakdown, you need to check the condition of the oil pump and pipes. The faulty part will need to be replaced.

To avoid further breakdowns of the Husqvarna 142 chainsaw, you need to use high-quality gasoline and oil to refuel it. This will help prevent increased wear of parts and protect model components from overheating.

How to remove and replace the drive sprocket

The chain moves along the bus by a drive sprocket, which is connected to the gearbox. It is an assembly unit that rotates due to a bearing. At the end of the tire there is a driven sprocket with the same pitch relative to the drive one. Therefore, when carrying out repair work, all factors are taken into account: the alignment of the splines, the presence of bearings, and the kinematics of the tool.

When the spline wears out, the drive sprocket is replaced, otherwise traction with the chain will not occur.

In order to change a part, you must perform the following steps:

- unscrew the nuts of the tire cover and remove the headset using working tools;

- remove the air filter;

- unscrew the saw spark plug;

- remove the clutch on the chainsaw;

- inspect the drum and check the crown;

- remove the chainsaw sprocket;

- if necessary, replace the broken part with a new one;

- Reassemble all parts in reverse order.

If the process of replacing a sprocket on a Husqvarna chainsaw is difficult, use the services of a specialist.

Operational Features

When operating the Husqvarna 142 chainsaw, you need to take into account its features. This is a simplified semi-professional model, not intended for everyday long-term use. The main area of application of the Husqvarna chainsaw is gardening and housing and communal services - pruning large branches, felling dried trees, etc.

The device of the Husqvarna 142 chainsaw

Powerplant - two-stroke carburetor engine with a displacement of 40 cm3

3

and a power of 2.58 liters. s., air-cooled. It runs on a gasoline-oil mixture in a gasoline to oil ratio of 50:1.

During operation, Husqvarna branded oil is required, but if this is not available, the manufacturer allows the use of any high-quality engine oil, but in a different ratio - 33:1.

The Husqvarna chainsaw has a minimum of controls - there is only a switch, a choke position lever and a combined throttle control lever. This model does not have a primer, i.e. a fuel suction button, which makes starting difficult, but makes troubleshooting easier.

Performance qualities allow you to saw dry and wet wood of various species, including hard ones such as oak and beech. In general, the Husqvarna 142 chainsaw is characterized by high build quality, unpretentiousness and reliability. Malfunctions occur rarely and are mainly associated with incorrect carburetor adjustment or failure of consumables.

Advantages of Husqvarna chainsaws

Cleaning and adjusting the carburetor

If all of the above does not help, then, most likely, the carburetor needs to be adjusted or cleaned. It is not recommended to do these procedures yourself, since most often such attempts still end in a trip to the service center. So it’s better to go there right away and not disassemble anything yourself. But if you still want to dig deeper yourself, then it’s best to watch a video that shows how experts do it:

Using a chainsaw makes difficult work easier. But sometimes the chainsaw starts and stalls, the reason for this could be any. What to do? You have to choose: take it to a specialist workshop or try to repair it yourself. We will try to help the reader understand the reasons for the failure, how to eliminate breakdowns, and give advice on operating chainsaws. In turn, it will be useful for the owner to familiarize himself with the factory operating instructions and design features of his chainsaw. This information will help him competently use and professionally repair the tool.

Circuit diagram of a chainsaw.

Classic layout

The classic Husqvarna layout makes it easy to repair your chainsaw yourself. The set with the saw chain is located on the right and side of the saw, and the emergency brake is also located there. The engine housing is covered from left to right by an auxiliary handle. The on/off button is located at the back and is oriented under the thumb, while the accelerator key is pressed on the handle.

The drum and starter handle are located on the left, above the cooling grille. Bottom left is the fuel tank cap.

All elements of the mechanism are hidden under the case cover.

Layout of Husqvarna 142

Most common problems

The most common problems with Husqvarna chainsaws include:

Chainsaw ignition system

- incorrectly adjusted carburetor;

- malfunction of the ignition unit;

- fuel unit malfunctions;

- unadjusted clutch mechanism;

- oil system malfunctions;

- Incorrect starter operation.

These problems lead to malfunctions of the chainsaw.

The saw does not start or stalls after pressing the accelerator. Possible causes are a breakdown of the starter (in this case it is not repaired, but replaced with a new one), contamination or breakdown of ignition system elements, faulty spark plugs or coil. The most common faults are spark plugs. Another option is difficulties in supplying fuel; the most likely is a clogged fuel filter or a pinched fuel hose from the tank to the carburetor. The gas tank breather may be clogged.

Difficulty starting, white smoke appears. The cause of these malfunctions is an incorrectly adjusted carburetor, supplying too little or too much fuel mixture, or preparing it in the wrong proportion. A sign of this is white smoke from the engine compartment.

Chainsaw startup sequence

Chain spinning when idling. Causes of the malfunction: unadjusted or failed clutch mechanism, unadjusted idle speed, air leaks into the carburetor or crankcase.

Chainsaw chain device

Saw chain lubrication problems. They are expressed in the absence of lubrication or the chain coming out in a dirty state. The causes of this malfunction are various - a breakdown of the oil pump, blockages in the breather (hole in the oil tank cap), oil channel or filter, or a malfunction of the oil drive gear.

Husqvarna chainsaw chain lubrication system

In what cases is Husqvarna chainsaw repair needed?

You should consider visiting our Authorized Husqvarna Service Center if:

- the saw stalls during operation, the engine turns off when the gas is released or at idle;

- the engine is difficult to start or does not start at all;

- after startup, extraneous noises are heard and smoke is observed;

- oil or fuel mixture is leaking;

- the motor runs, but the chain does not spin;

- power is lost;

- the equipment overheats greatly, etc.

The above problems arise due to:

- clogged air and fuel filters;

- carburetor malfunction;

- carburetor membrane wear;

- jamming of the throttle trigger, damage to the return spring;

- wear of the throttle valve, lever arm in the control system, needle (needle tip), etc.

Starter repair

The starter is responsible for starting the unit. Malfunctions indicate the presence of the following malfunctions:

- the spring burst;

- the pulley is damaged;

- The starting cable is damaged.

Sequence of actions for replacing a worn starter cord:

- the starter is disassembled, the mechanism is removed, having first unscrewed the screws securing the housing to the engine crankcase;

- the cord is pulled out at a distance of 30 cm through the hole in the pulley;

- the return spring is set to the neutral position;

- the central screw is unscrewed and the pulley itself is removed;

- a new cord is inserted, tensioned, while 3 turns are wound around the mechanism and secured with a screw;

- the cord is then pulled through a groove in the starter housing and handle.

The return spring is tensioned by rotating 2 turns clockwise, taking into account that it is compressed. When replacing a broken part, the spring should pop out after pulling the inner part down.