Torque is the main characteristic of a screwdriver. It determines the diameter of the screw and the depth of its tightening, as well as the material (wood, concrete, steel, etc.).

The torque is determined by the power of the tool, which depends on the engine and battery. The documentation for the device usually indicates the maximum possible diameter and length of the screw. In this case, the maximum possible torque reaches 60 Nm; for a home tool it is 10-12 Nm.

The efficiency of a screwdriver increases significantly if it can be used in pulse mode (chipping, like a hammer drill).

Types of screwdrivers

According to the power source used, the tool is:

Rechargeable. Cordless screwdrivers are used in everyday life and in production. The battery capacity is 1.5Ah and above, the voltage is 10-12V (household) or 18-36V for professional ones. The most common are nickel/metal/hybrid batteries. Lithium and nickel cadmium are also used. The choice of a cordless screwdriver is very suitable for new buildings where power has not yet been supplied.

Network screwdriver. It is powered by a 220V network, the disadvantage is the presence of a network cable (limited length, some inconvenience during operation).

Pneumatic is used in mass production, where there are permanent pneumatic power lines.

According to the type of work performed, screwdrivers are divided into two groups:

Household (home, amateur). They are used for a small amount of work - minor (occasional) repairs, one-time work (changing doors, assembling furniture).

Professional ones are used for large volumes of work in construction, furniture production, etc.

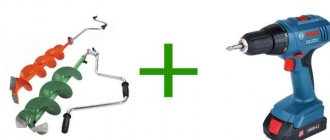

Particularly noteworthy are tools that combine 2 functions - a drill and a screwdriver.

Selecting a screwdriver

First of all, you need to determine its exact purpose:

Max. torque – 60-120 Nm;

voltage – 18-36V;

battery capacity – more than 3Ah;

such tools are more expensive and require certain skills to operate.

If necessary, you can choose a combined tool - a drill and a screwdriver, which is often very convenient.

It is also necessary to pay attention to charging the battery. If a household battery can be charged in 3-6 hours, then for a professional battery this time is 40-60 minutes. For reliable operation, it is recommended to have a set of 2 batteries.

The tool can be equipped with special gearboxes to reduce the speed of the electric motor. Gearboxes are usually of the planetary type, which are small in size and weight with a fairly high gear ratio. Such gearboxes easily switch to drilling mode (drill). Modern screwdrivers have a torque regulator, which allows you to screw in screws with the required force, which prevents stripping threads, grinding off splines and

Choosing a screwdriver (cordless screwdriver) is a completely solvable task. To do this, you need to know what characteristics you need to pay attention to when choosing. First, we decide whether a household or professional model is needed. If you are buying a screwdriver for small jobs around the house, for work in the country, etc., then your choice is a household screwdriver. If the screwdriver is expected to be used intensively for a long time, then you need a professional screwdriver. This material will tell you how to choose a screwdriver.

Let's return to the main characteristics that you need to know when choosing a cordless screwdriver:

Motor voltage

screwdriver. Modern models of screwdrivers have motor voltages from 7.2V to 24V (Volts). The higher the voltage, the less current is needed to produce the required power. Accordingly, it is easier to obtain more power in a screwdriver with an 18V motor rather than a 12V or 7.2V motor. It is worth clarifying that the most popular screwdrivers have 12V, 14V and 18V motors.

Torque

screwdriver. Torque is measured in Nm (Newton per meter). In simple words, torque is the force with which your screwdriver screws in screws. The greater the torque, the more possibilities the screwdriver has. In modern household screwdrivers, the torque is usually 10-28 Nm. This is quite enough for housework. With a torque of 28-30 Nm, the screwdriver can screw in 100 mm self-tapping screws and drill wood and metal. Speaking of drilling in wood and metal, modern household models are capable of drilling holes up to 20mm in wood and up to 13mm in metal. In professional screwdrivers, the torque reaches 70-140 Nm.

Most screwdrivers have a torque adjustment

. It is used where greater control is required when performing certain jobs. Adjustment occurs by switching the ring located on the screwdriver body, at the base of the chuck. On the ring there are numbers indicating modes in setting the torque. The “drill” icon after the maximum number on the ring indicates the drilling mode.

Using the example of tightening screws, the function is used like this:

When tightening screws of different lengths, you don’t need one torque. For smaller screws, a lower tightening force is sufficient, and for longer screws, a correspondingly higher tightening force is sufficient. Most likely, everyone who screwed a self-tapping screw into wood at least once, but buried it in the material. And where it is necessary for the surface to be flat and smooth, dents are not allowed. When the so-called “ratchet” is triggered, and this happens when the set torque is too high, the screwdriver stops tightening the screw. Thus allowing more precise control of the work process. This function also protects the motor from overload.

Accumulator battery

screwdriver. It is the battery that allows you to work mobile and not depend on the length of the cord. Screwdrivers use three types of batteries:

NiCd

(nickel-cadmium) - these batteries are the most affordable, but the characteristics are simpler than those presented below. The capacity of such batteries is from 1.2 or 1.5 A/h (Ampere hour). A screwdriver with a capacity of 2.0A/h, under the same conditions, can work longer than a screwdriver with a battery capacity of 1.2A/h. A capacity of 1.2-1.5A/h is sufficient for home use. And given the current battery charging time of 1 hour, you will always have a “fresh” battery at hand. Of the minuses: they require complete discharge.

NiMh

(nickel-metal hydride) - these batteries are more expensive, but their capacity is also higher, from 1.5 to 2.6 A/h. Suitable for both home use and more complex and long-term use. Does not require complete discharge.

Li-Ion

(lithium-ion) batteries are the most expensive and have a high capacity, which can be above 3.0A/h. Another advantage of Li-Ion batteries is their light weight. The difference in weight can reach 40%. Li-Ion batteries do not have a memory effect, which means you don’t have to wait until the battery is completely discharged.

It is worth saying that the warranty does not cover batteries, since they often fail due to the fault of the buyer. If you leave the battery at a low temperature even overnight, such batteries may no longer be usable. Store batteries in a warm place.

Speed

screwdriver. Different types of work require different speeds. For drilling, higher speeds of 1000-1300 rpm are needed. To tighten screws, 400-550 rpm is enough. Screwdrivers come in single-speed, two-speed and three-speed types. Switching speeds allows you to work with the speed you need to solve various problems.

So. If you are choosing a screwdriver for your home, then a 12-14V screwdriver with a battery capacity of 1.2-1.5A/h and a torque of 15-26Nm is suitable. This screwdriver can handle almost any job around the house. Household screwdrivers with these characteristics cost from 1300 to 3000 rubles. You should not chase a low price; as a rule, the price tag for a screwdriver below 900 rubles indicates that such a screwdriver will not work for a long time. When choosing, pay attention to the recognition of the manufacturer, warranty conditions, quantity. Well, the screwdriver itself should be held in your hand, turned, pressed, etc.

If you decide to buy a new screwdriver, or understand the functionality of the old one, we recommend that you read this article. The information is intended primarily for “dummies” who are not very well versed in power tools.

Most screwdrivers and drills are equipped with a ratchet (clutch for adjusting torque). Many ordinary users do not really understand the purpose of this mechanism, and practically do not use it in everyday work. With different speed modes, things are different: this characteristic is clear to the user, which is why tools with several gear stages are popular. Let's figure out why a ratchet is needed in a screwdriver and how to use it correctly. We remind complete “dummies” that visually the presence of a ratchet in a power tool can be determined by a kind of rotating ring, which can be installed in one of about 20 positions.

How does a ratchet work and what is it used for?

Most readers have a rough idea of the principle of operation of the clutch mechanism in a car, designed to select between engine operation in idle mode and the mode of supplying torque to the drive. The ratchet in a screwdriver works on the same principle. When the trigger is pressed, torque is transmitted from the engine to the cartridge. And with the help of a ratchet you can set the maximum force at which the engine begins to idle and the rotation of the cartridge stops.

How and why to use a ratchet?

By using a ratchet, you can control the depth of screwing in the fasteners. This is especially important during finishing work, when the surface quality of the product plays an important role. So, for example, when screwing a screw into drywall, the fastener may well go right through, since drywall is not particularly strong, and the screw head is easily recessed into the material. Therefore, in this case it is best to set the ratchet to the minimum value. The same is true with decorative and finishing elements that can be damaged under high loads. When working with small fasteners, it is also difficult to do without a ratchet, because too high a torque can destroy the fastener. A ratchet will also be useful when installing flooring, when you want the fastener heads to be slightly recessed into the surface of the board. You can first make several test runs, changing the ratchet settings, and then, having selected the optimal position, quickly complete the work, achieving the required result with each of the boards.

The ratchet will help prevent the bit from cutting off the slot when driving screws into very hard materials, such as pressure-treated wood or hardwood.

But there are also cases when the ratchet position should be at the maximum, for example when drilling holes with regular and countersink drills, as well as hole saws. For some screwdrivers, the drilling position on the coupling is indicated by a corresponding icon with a picture of a drill, while for others it is simply the last possible position, without any special marks.

How to choose the right mode

The adjustment itself is extremely simple; all you need to do is turn the coupling to the desired position. The scale will help you navigate this. If you need more torque, turn the clutch towards higher values. If you are not sure of the required power, it is better to start with low values, gradually increasing the torque until you achieve the desired result. When working with drywall and small fasteners, it is advisable to start from the minimum position. If you need to screw fasteners of large diameter or length into wood, you can start with the middle position of the coupling. If you are working with large square-head screws, you will most likely have to work at the maximum setting. During operation, you may have to change the settings up and down.

Before you begin, you should ask yourself the question: “Will the material be damaged if the screw goes too deep into it?” If the answer is yes, it is better to start work with a deliberately underestimated torque, adding more in the process. Selecting the right mode may require several trial approaches, but if you have to work for a long time with monotonous operations, in the end you will be able to save a lot of time by working almost automatically.

Is it possible to use only one ratchet mode?

Many users who do not want to understand the issue do just that, often setting the maximum torque value on the ratchet. If you don't care about damage to the material and fasteners, you can follow their example.

Some people are driven to such a strange decision by the fact that when the selected torque is exceeded, the ratchet makes frightening sounds, and it seems that the tool is about to break.

If you still decide to use the full functionality of your screwdriver, you should pay attention to the fact that the scales on the torque-regulating couplings are not standardized. That is, “6” on a ratchet from one manufacturer does not necessarily correspond to “6” on another, even if the models belong to the same class.

Every person at least once in his life has dealt with such a tool as a screwdriver. Everyone has ever twisted bolts, screws or self-tapping screws.

Sometimes, if a screw needed to be screwed into a hard surface or there were a lot of these screws, such screwing became quite difficult. To facilitate such “twisting” processes, a special device was created - a screwdriver. We'll talk about how to choose a good screwdriver for your home in this article.

Moment of power

Torque is defined as the force exerted on a rigid body during rotation. For example, you need to tighten a hex bolt. For this task, there is a key that requires force. The product of this force and the length of the key is that very torque. More leverage provides more torque. This indicator is measured in newtons per meter.

A traction torque of 10 Nm for a screwdriver can be represented as a load with a mass of 100 grams at the end of a meter-long lever, or you can reduce the length of the lever to 10 cm, increasing the weight of the load to 10 kg.

If the technical specifications of a tool indicate a maximum torque of 25 Nm, this means that the motor will transmit, through a gearbox, to the chuck a force equal to the impact of a 2.5 kg load through a meter-long lever.

The importance of increased torque when working with fasteners of large diameters and lengths is due to the high friction force that occurs at the moment of screwing. The deeper the fastener is immersed in the material, the higher this force will be.

Types of cartridges

Industrial companies have mastered several types of cartridges used for the screwdrivers they produce, some are interchangeable, others are strictly individual. Each type has a number of advantages, but none is without disadvantages. This is probably why a single universal type of product has not yet been developed that would satisfy the desires of consumers and the capabilities of manufacturers.

The quick-release chuck has a simple design: a steel sleeve with a grooved surface for easy holding by hand is installed on a steel spindle. To tighten it, you do not need a special key that requires constant attention. This is one of the most reliable and wear-resistant types of cartridge, but over time it also becomes unusable during active use. Round shank drills become increasingly difficult to tighten and begin to turn. Over time, the cams holding the drill work. It is better to simply replace the product.

The self-clamping chuck also does not require a special key. This is one of the most technically advanced cartridges. It does not require the use of muscle force to tighten it. A slight turn of the movable coupling is sufficient. Some models of screwdrivers use chucks with one clutch. On others with two rotary couplings. This type of chuck is most convenient when changing working attachments frequently, for example, when drilling alternates with tightening screws and you have to quickly rearrange the drill and bit. The main body parts of this cartridge are made of tool steel, and the external parts are plastic.

Chuck with hex shank (hexagon). As the name suggests, the shank of this product has a hexagonal shape. This cartridge also does not require a special key. This type of assembly is widely used on mini-drills and for special engraving machines used in jewelry making and bone carving. Special collet chucks are also used for mini-drills and drills. Using such microtools, holes are drilled for mounting electronic boards.

Bit cartridge is a special cartridge for bits. This product is usually used to install bits and is used only for unscrewing (screwing) threaded fasteners (bolts, nuts, screws, self-tapping screws, etc.). Its version is an angular chuck, used for working in hard-to-reach places; it transmits torque to a bit, the position of which can be adjusted with a special handle.

Converting a screwdriver to power from a 220V network

If the battery fails and it cannot be repaired, the only way out is to convert the cordless screwdriver into a mains one.

Power supplies 24 and 12 Volts

In this case, the power of the power supply must exceed the power of the engine, taking into account possible overloads at the moment of completion of tightening. It is not indicated in the device passport, but this parameter is written on the body of the electric motor, or it can be calculated by connecting the device to a constant voltage source through an ammeter. For a 70W motor, a 120W power supply is sufficient.

Important! The charger's power is insufficient to operate it. When converting a cordless screwdriver into a mains-powered one for 220 volts, you must use a different power supply

Using an external power supply

The external power supply device is larger in size than the built-in one, but in any case, if you power the screwdriver from the mains, the tool will be “tied” to the socket by a wire.

External power supply

Attachment to shaft

The attachment of the chuck to the tool shaft is also different. It is not always possible to find a mention of this important design feature of your screwdriver in the instructions. When it is inevitable to replace a cartridge, you often have to deal with this difficult issue yourself. There are several types of fastening, as well as the cartridges themselves.

Threaded fastening is quite common. To remove such a cartridge, you need to clamp a hex key of the largest possible size in it. By turning the key counterclockwise, you should unscrew the cartridge from the shaft. Sometimes quite significant force is required to remove the assembly. In some cases you will have to resort to using a hammer.

No less popular is fastening with a fixing screw. To determine this type of fastening, you need to move the chuck jaws as far apart as possible, which will open access to the head of the screw with a left-hand thread. Unscrewing will require some effort; during operation, the left screw is tightened quite strongly. Well, don’t forget that the thread is left-handed.

The old Morse taper mount is also found. This method of connecting the cartridge and shaft has been known since the end of the 19th century and still remains quite common. The shaft has a cone such that the reverse cone must be on the chuck. The angles of the cones must match. A screw with a left-hand thread is also used to secure the unit. Cartridges with this mount may be marked: B10, B14, etc., from 4 to 45.

Selecting parameters

To fully answer the question “how to choose a screwdriver”, you need to talk about the technical parameters

The parameters of the batteries and cartridge have already been discussed, there are still some technical characteristics that need to be paid attention to

Before choosing a screwdriver, carefully study its structure and characteristics

Torque

In the technical specifications there is a line “Maximum torque”. This is an indicator that shows how much force the tool can develop. Measured in Nm (Newton per meter). For a household (amateur) tool or for a “clean” screwdriver, it is enough for the maximum torque to be 10-15 Nm. For a professional and universal one (with a drilling function), it should be larger - in order to quickly and confidently do the necessary work even on hard materials or screw in powerful screws.

The greater the torque, the larger the fastener can be tightened.

Number of steps

Different materials and different screws require different torques. It is changed using a special switch, which allows you to change it from minimum (1 Nm) to maximum. The number of steps may vary. The more there are, the more accurately you can select the required force.

This is not so important for corded screwdrivers, but it is important for cordless ones - with heavier loads, the batteries discharge faster. Therefore, it is important to choose the optimal mode

Torque is set on a scale

To track when the drill has reached the specified torque, the moment this parameter is exceeded, the chuck rotates idle, making clicking noises. This mechanism protects the instrument from overheating and is popularly called a “ratchet”. A useful feature that extends the life of the screwdriver.

Torque selection

How to choose a screwdriver based on torque? If you buy a tool for a specific type of work, you can focus on the diameter of the screws that will have to be tightened. This parameter is also in the technical specifications, but there is the following dependency:

- A screw with a diameter of 6 mm is screwed into soft materials with a torque of 10 Nm, into hard materials - 25 Nm.

- For a diameter of 7 mm, the force should be 11 Nm for soft materials and 27 Nm for hard materials.

- For screws with a diameter of 8 mm, 15 nm is used when screwing into soft materials and 30 nm when working with hard ones.

These parameters will also be useful during work - you can immediately set the required values, only slightly adjusting the value for a specific case. So, when working with drywall, you will need a lower value so as not to overtighten the screws and not pierce the cardboard. You will have to select the torque depending on the type of wood - the screws go into spruce with more force than into pine.

Spindle speed or speed

The torque must be provided by a sufficient spindle speed. For working with soft materials such as wood, the normal speed is 400-500 rpm; for working with concrete or metal, a faster rotation is required - 1200-1300 rpm - this is normal.

It's really hard to choose

So when choosing a screwdriver, look not only at the torque, but also at the spindle speed. They must be agreed upon. Only then will it be convenient to work with the tool in different modes.

Number of speeds

There are screwdrivers that can operate at two speeds. These are mainly professional and semi-professional models. Speeds are switched depending on the density of the material being worked with. You can try different speeds and with screws of different sizes.

Having two speeds is useful for professional models

Selecting the speed allows you to save battery power. As a result, the tool lasts longer on a single charge. For household models, this is not the most necessary option, but it is nice to have.

What is a cartridge?

The chuck is one of the most important components of a screwdriver. He got the chuck from his predecessor - an ordinary hand drill, and she, in turn, from a stationary drilling machine. In view of the requirements placed on the new tool, this part has undergone a number of design improvements.

The usual chuck of a drilling machine, the main task of which is to reliably hold a drill operating in constant mode for a long time, turned out to be not very convenient for a hand-held mobile tool. Due to its high reliability, this type of chuck is very widespread; it can be successfully used for a wide variety of attachments, and a special key allows you to securely tighten the knot. But the key is also the weak link of the entire structure. It is impossible to quickly replace a working tool with it, and accidental loss of a key can stop work for a long time, since it will be impossible to remove or install a drill or bit.

The screwdriver chuck had to become no less mobile than the tool itself, intended for individual use. Design thought, as often happens, went in one direction, but in different ways. As a result, several types of cartridges for cordless screwdrivers appeared, the common properties of which were their functionality, speed and ease of use, i.e. replacement of working tools.

For some models, it is possible to install a classic chuck with adjustment of the clamping mechanism using a special key.

What to do when you need to work with viscous mixtures?

It is not uncommon for a screwdriver with an impact function to be used for mixing viscous mixtures. To do this, you should choose equipment with high power, since ordinary household equipment may not be able to cope with the assigned work; the effort will not be enough. The torque of this device must be high, i.e. You should buy professional equipment. It is possible to use mechanical built-in gearboxes; they make it possible to use the equipment even at 1st speed. It is necessary to provide a cooling system; it is important to prevent overheating of the motor.

If the screwdriver is used to assemble shelves or install a regular cornice, then more power is not needed, torque will not be of particular importance. If equipment is purchased for frequent use, and you will need to perform various types of work related to the preparation of mortars, then you need to choose from semi-professional and professional tools. They will provide all the required conditions for quality work.

When choosing a screwdriver for home, you need to pay attention to its many parameters. You should immediately decide whether you need a professional tool or a not too powerful household one will do. After this, you should familiarize yourself with the proposed set of functions and technical characteristics, among which torque .

Screwdriver torque

When choosing a screwdriver, you should understand several important features. You can buy a tool for household use, perform simple work from time to time, or set the goal of purchasing a tool of a professional category in order to perform commercial tasks with its help. In any case, pay attention to the torque characteristic to prevent overload and damage to the product during intensive use.

Maximum revolutions per minute

Not less important. The parameter indicates at what frequency the spindle will rotate. For most modern tools, electronics are responsible for adjusting the rotation speed. The rotational speed of the chuck, as well as the torque, affects the capabilities of the drill-driver when driving screws or drilling in a hard surface.

There is an inverse relationship between torque and speed. As the speed increases, the torque decreases and vice versa.

To give the tool the ability to change the ratio of these quantities, the design has a mechanical gearbox, and to further increase functionality, the product is equipped with multi-stage or two-speed adjustment.

It turns out that at low speed with high torque it is optimal to tighten the screws, and at the second, at high speed, drill in materials. If there is a third speed, then it is used for drilling small-diameter holes at high speeds.

Maximum torque can be achieved by fully pressing the start button. With two-speed drills/drivers, the first speed will have a higher torque rating than the second.

The adjustment ring next to the chuck, marked from 1 to 15, determines the amount of torque. Sometimes there are more divisions on the scale, and as a rule, there is a position indicating the drilling mode. By setting one of the numerical marks on the regulator, we limit the moment at which the tool stops turning and characteristic clicks begin. In drilling mode there are no such restrictions; the machine will try to tighten the fasteners to the maximum of its capabilities. It is important to remember that the numbers do not indicate the specific value of the moment, but only help to increase or decrease it.

It is generally accepted that screwdrivers with a high torque of 40-60 Nm are obviously professional, and on the contrary, those with a torque of up to 20 Nm are only suitable for amateur craftsmen.

There are production tasks in which high torque is not required, but in which special requirements are placed on the tool in terms of wear resistance and maintainability. Only a tool designed for intensive work can cope with work on a conveyor line or in a furniture assembly shop on an ongoing basis. Such machines are generally considered professional, regardless of the amount of torque.

To simplify the choice of tool, we will conditionally designate what torque is required for different types of tasks:

- For household use and occasional use, models up to 10-15 Nm are suitable; these are cordless screwdrivers and DIY-class screwdrivers - for home craftsmen.

- For use for commercial purposes: furniture assembly, frame-panel construction, finishing work, installation of metal structures - tools with the largest torque range from 10 to 35 Nm are suitable.

- Separately, it can be noted that for mixing dry mixtures, a reserve of torque is required and, at a minimum, it should be 65 Nm.

- Amateur and professional fishermen should note that a fishing screwdriver capable of drilling holes using an ice drill attachment must have a torque of at least 80 Nm.

A universal specimen must have a high enough torque to not only be limited to tightening screws, but also to drill holes of various diameters in almost all materials.

Theory

In our article on “choosing the best screwdriver,” we already touched on this topic, but now we’ll tell you in a little more detail, but so that no one gets a headache from the formulas.

The main indicator of a screwdriver's power is torque (torque), which is measured in Nm. Figuratively speaking, 10 Nm would be equivalent to the rotational force created by a one-kilogram weight mounted on a one-meter lever, the other end of which is rigidly attached to the rotating shaft.

For semi-professional models of screwdrivers, as well as those intended for home craftsmen, the typical torque value is from 10 to 60 Nm. If we take the “average temperature in a hospital,” then we can carefully assume that a certain average screwdriver has a torque characteristic of 25 Nm.

However, not everything is so simple here, since in practice the output torque value of electric motors is not constant and depends, first of all, on the speed - the higher the speed, the lower the torque on the shaft. Ideally, the graph is linear with a slight slope - the lowest torque will be at maximum speed, the highest - with a stationary shaft. But in the latter case, a situation will arise, in fact, of a short circuit of the electric motor windings. How many seconds the motor will burn out depends on what its windings are made of. But rest assured, you will be provided with smoke and a burning smell.

In order not to lead to “sin”, expensive models have an automatic shutdown system in case of overload, when the ratio of the number of revolutions per second in relation to the consumed current suddenly exceeds a dangerous threshold. However, our question here is completely different - what is the line that cannot be crossed, that is, what is the minimum engine speed, and, consequently, the torque at which it will operate without overheating and further damage to itself?

In other words, we already operate with two torque values. Which one do you think is indicated by the manufacturer in the technical specifications of the screwdriver? No, you didn't guess. Each manufacturer has its own measurement method and its own concept of this characteristic. No one reveals the details, and there is no general standard. Therefore, very often you can observe a situation where a screwdriver with weaker characteristics turns out to be noticeably more powerful than a stronger one.

The only way out of this situation can be practical tests under the same conditions.

Types of drill attachments

A drill without attachments is, in principle, an empty space. One of the varieties of such attachments is drills. They can be:

- spiral, designed for working with wooden, metal, plastic products. That is, such attachments are universal;

- with carbide tips used in the process of drilling particularly durable materials. For example, concrete, stone;

- feathers, used to create large holes. Moreover, in their appearance they resemble oars.

The attachments can also be used as mixers. With their help you can mix, for example, paints and various solutions.

The function of an electric screwdriver or screwdriver is given to the drill by other attachments - bits.

More about making the right choice

When purchasing, you should always check the diameter of the holes that the tool can make. But here you need to understand that this indicator will be different for each hole, so focus more on what you will be working with. If you want to get a hole of a diameter that the drill is not designed to work with, you risk damaging the unit. Depending on your preferences, choose the type of cartridge. Nowadays, serrated (secured with a key) and quick-release (secured by hand) chucks are produced. There are practically no fundamental differences here. Now you know what a cordless drill/driver is. We figured out how to choose a device, so let's go further and talk about the batteries used.

Tool Features

The popularity of this power tool is due to a number of its advantages, the main one of which is versatility. You can screw in (unscrew) screws, screws, self-tapping screws using a wide range of different bits. You can insert a drill and drill a hole in both wood and metal. There are other attachments that expand the range of use of a screwdriver. The next advantage of the tool is mobility. Having a removable battery, this electric device can be used where it is impossible to turn on a conventional electric drill due to the lack of an electrical network.

The device is equipped with a number of regulators. You can adjust the speed of rotation of the bit or drill and the force with which the impact on the working tool will occur, as well as the direction of rotation of the shaft. And in some models there is also a flashlight; such a tool can be used in rooms where there is no artificial electric lighting.

In specialized auto repair shops and enterprises, pneumatic screwdrivers are often used. A special feature of this option is the drive from a compressed air flow. For the tool to function properly, you need a compressed gas cylinder or a compressor that will supply air through a hose. The advantage of this product is its high productivity. If during a work shift you need to constantly tighten and unscrew many screws and nuts, a pneumatic screwdriver is indispensable.

A more common household appliance with a replaceable battery, whose performance is limited by the electrical capacity of the battery, is, of course, not intended for industrial-scale work.

Such an instrument requires periodic cooling and short but regular breaks in operation. Which completely satisfies any home craftsman, and most repair teams get by with ordinary, albeit professional, screwdrivers with a removable battery.

Possible problems

The screwdriver chuck remains its most vulnerable part, this is due to the constant manipulations necessary to change the working tool. This main drawback of the node is caused by the very logic of its existence. It is impossible to avoid periodic replacement of the chuck during intensive use of the screwdriver. During operation of the tool, the unit constantly experiences tension, which is difficult to combine with the mobility of its individual parts.

Problems with the cartridge are easy to identify. The first signal will be frequent turns of the drill, first of a small diameter, and then of increasingly larger ones. Over time, bits may begin to pop out during operation. In some cases, the alignment is disturbed and the drill actively “beats”; this phenomenon is not only unpleasant, but also quite dangerous, as it causes the drill to break. At high speeds, its fragment can cause serious injury.

An incorrectly clamped bit can cause increased material consumption due to unintentional damage and can also cause injury when tightening a screw. When choosing a new cartridge to replace a worn one, you need to pay attention to the factory markings.

After a long period of use, it is often difficult to recognize its traces; in this case, the type of cartridge and the method of its fastening will have to be determined by eye.

How to choose a chuck for a screwdriver, see the video below.

If you decide to buy a new screwdriver, or understand the functionality of the old one, we recommend that you read this article. The information is intended primarily for “dummies” who are not very well versed in power tools.

Most screwdrivers and drills are equipped with a ratchet (a clutch for adjusting torque). Many ordinary users do not really understand the purpose of this mechanism, and practically do not use it in everyday work. With different speed modes, things are different: this characteristic is clear to the user, which is why tools with several gear stages are popular. Let's figure out why a ratchet is needed in a screwdriver and how to use it correctly. We remind complete “dummies” that visually the presence of a ratchet in a power tool can be determined by a kind of rotating ring, which can be installed in one of about 20 positions.

How does a ratchet work and what is it used for?

Most readers have a rough idea of the principle of operation of the clutch mechanism in a car, designed to select between engine operation in idle mode and the mode of supplying torque to the drive. The ratchet in a screwdriver works on the same principle. When the trigger is pressed, torque is transmitted from the engine to the cartridge. And with the help of a ratchet you can set the maximum force at which the engine begins to idle and the rotation of the cartridge stops.

How and why to use a ratchet?

By using a ratchet, you can control the depth of screwing in the fasteners. This is especially important during finishing work, when the surface quality of the product plays an important role. So, for example, when screwing a screw into drywall, the fastener may well go right through, since drywall is not particularly strong, and the screw head is easily recessed into the material. Therefore, in this case it is best to set the ratchet to the minimum value. The same is true with decorative and finishing elements that can be damaged under high loads. When working with small fasteners, it is also difficult to do without a ratchet, because too high a torque can destroy the fastener. A ratchet will also be useful when installing flooring, when you want the fastener heads to be slightly recessed into the surface of the board. You can first make several test runs, changing the ratchet settings, and then, having selected the optimal position, quickly complete the work, achieving the required result with each of the boards.

The ratchet will help prevent the bit from cutting off the slot when driving screws into very hard materials, such as pressure-treated wood or hardwood.

But there are also cases when the ratchet position should be at the maximum, for example when drilling holes with regular and countersink drills, as well as hole saws. For some screwdrivers, the drilling position on the coupling is indicated by a corresponding icon with a picture of a drill, while for others it is simply the last possible position, without any special marks.

How to choose the right mode

The adjustment itself is extremely simple; all you need to do is turn the coupling to the desired position. The scale will help you navigate this. If you need more torque, turn the clutch towards higher values. If you are not sure of the required power, it is better to start with low values, gradually increasing the torque until you achieve the desired result. When working with drywall and small fasteners, it is advisable to start from the minimum position. If you need to screw fasteners of large diameter or length into wood, you can start with the middle position of the coupling. If you are working with large square-head screws, you will most likely have to work at the maximum setting. During operation, you may have to change the settings up and down.

Before you begin, you should ask yourself the question: “Will the material be damaged if the screw goes too deep into it?” If the answer is yes, it is better to start work with a deliberately underestimated torque, adding more in the process. Selecting the right mode may require several trial approaches, but if you have to work for a long time with monotonous operations, in the end you will be able to save a lot of time by working almost automatically.

Is it possible to use only one ratchet mode?

Additional functions.

Additional features that help make using a hand screwdriver more convenient and efficient include the following:

Presence of reverse. Reverse is the rotation of the cartridge

in the opposite direction. The reverse function can even be considered basic, since it is thanks to it that it is possible to unscrew something;

Spindle lock. The lock makes it easier to change screwdriver attachments in the chuck;

Backlight. With a small flashlight

The screwdriver can illuminate the work surface; such a screwdriver with a flashlight can be used in unlit rooms or in conditions of poor visibility on the street.

Some screwdriver manufacturers add a special case to the kit, in which it is very convenient to carry and store the tool, as well as a special holster. Therefore, when choosing a screwdriver, look for the presence of such a suitcase, a holster for a screwdriver

will also be an additional plus. I hope these tips will help you learn how to choose the best screwdriver.

The torque of a screwdriver is a significant parameter that you need to pay attention to when choosing. It is necessary to take into account whether the tool will be used for home or professional work. There are a variety of models on sale today that differ in their characteristics.

The construction market offers many models of screwdrivers from various manufacturers, which differ depending on the power source, parts and functions.

Dacha.news

Very often on forums people wonder what power they should choose a screwdriver in order to easily drive self-tapping screws or screws of such and such a diameter and length?

Or, in other words, what torque should a screwdriver have in Nm for certain tasks? People get different answers to these questions. Most often, there are offers from “all-knowing specialists” to buy expensive semi-professional 18-volt models. Like, they can definitely do anything. But is it worth paying twice as much if it suddenly turns out that younger 10-14 volt models are also good? And if there is a difference, what is it?

We will try to briefly talk about the theory and move on to practice.

Hand-held household screwdriver2. Rotational speed.

The rotation speed indicates the number of revolutions of the working nozzle per unit of time. This indicator helps determine how fast you can unscrew or tighten something.

It should be noted that for normal operation with screws

and with self-tapping screws, a speed of 450-550 rpm or even less is quite sufficient. If a screwdriver is used for drilling, then this requires a speed of 1000 rpm. These are relatively small rotation speeds; for example, in an angle grinder, the rotation speed can reach 11,000 rpm.

The rotation speed, as well as the torque, can be adjusted using a special screwdriver speed controller, the presence of which is also a positively necessary factor.

Battery characteristics.

If a screwdriver does not use an electrical network (corded screwdriver) for operation, but an internal battery, then it is a cordless screwdriver. From battery

The duration of operation of the tool and many of its other parameters will depend. When purchasing a screwdriver, you should pay attention to the type, capacity and voltage of the battery.

There are the following main types of screwdriver batteries: lithium-ion, nickel-cadmium and nickel-metal hydride batteries. Most household models of screwdrivers are equipped with nickel-cadmium batteries. Such batteries

They have a limited number of charging and discharging modes and the so-called “memory effect”, so they need to be fully charged and discharged too.

More expensive tools

have lithium-ion batteries that do not have a “memory effect” and can be recharged without waiting for complete discharge. Nickel-metal hydride batteries for screwdrivers are no longer considered relevant.

Screwdriver battery capacity

measured in amperes/hours. The time during which the tool can work without recharging depends on the capacity. The larger this capacity, the better. On average, for household use you can take screwdrivers with a battery capacity of 1.2 A/hour.

Screwdriver battery voltage

determines electrical power and, accordingly, work productivity. Measured voltage in Volts. A more powerful screwdriver makes the job easier.

When choosing a household screwdriver, focus on a battery voltage of 12-14 V.

When buying a cordless screwdriver, also pay attention to the presence of a charger in the kit. Charger

for a screwdriver battery it works in a similar way to chargers for mobile phones.

Good to know

How to store a screwdriver

Better separately from the battery. If you have a model with a nickel-cadmium battery, then before finishing work and disconnecting the battery, it must be completely discharged. After removing the battery, it must be charged. Remember that Ni-Cd has a high self-discharge current, therefore, during long-term storage, it needs repeated recharging.

Is it possible to drill with a screwdriver?

If you have a model that has two operating modes - drilling and screwdriver. Typically, professional models have such abilities, for example the Makita DF347DWE. It is not necessary to use a model that does not have a drilling mode; the engine may burn out, because drilling requires higher speeds to reduce the load.