Chinese chainsaw. Carburetor repair. Carburetor adjustment.

Spare parts Powerful Chinese chainsaw Hunter analog Husqvarna 365

.

Carburetor repair

.

Start the chainsaw and let it run for about 10 minutes.

Place the Husqvarna 365 chainsaw on a level surface with the saw blade facing away from you and with both bar and chain in contact with the surface.

Find the maximum idle speed by slowly turning the low speed jet clockwise and counterclockwise.

When the maximum number of revolutions is found, turn the jet L counterclockwise 1/8. 1/4 turn.

Fine adjustment of idle speed using screw T

The idle speed is set using the screw marked T.

If adjustment is required, the idle screw T should be turned clockwise until the chain begins to rotate.

Then turn the screw counterclockwise until the chain stops.

The correct number of revolutions is considered to be the one at which the chain saw engine runs smoothly in all positions with a sufficient margin up to the number of revolutions at which the chain begins to rotate.

High speed jet H

The high-speed H jet regulates the power and speed of the Husqvarna 372, 365 XP chainsaw.

Headset

The cutting unit is included in the category of replaceable equipment. The standard kit consists of a proprietary 18-inch guide bar and a wear-resistant chain model H42, with a standard pitch of 3/8 inches.

The bar and chain are lubricated and cooled by the automatic supply of oil to the working area, liquid that is taken from a 420 ml oil tank located in the housing. The use of an oil pump with adjustable performance allows you to consume oil with 50% savings.

The lubrication system is designed for a certain density of chain oil. The use of substitutes can seriously affect the performance and other operating parameters of the oil pump, and the service life of the headset.

HUSQVARNA

Technical specifications Husqvarna 372 XP

Engine's type. Gasoline Cylinder displacement, cubic cm, 70.7 cm3 Maximum power, kW. 3.9 kW (9600 rpm) Rated power at operating speeds, hp 5.3 hp (9600 rpm) Idle speed. 2700 rpm Spark plug. Champion RCJ7Y 5776166-02 (61141), Husqvarna HQT-1 5774840-01 (63893), NGK BPMR7A Interelectrode gap. 0.5 mm Fuel tank capacity 0.77 l Torque, max. 4.3 Nm / 6600 rpm Chain lubrication tank capacity. 0.4 L Lubrication circuit pump type. Adjustable flow Chain pitch. 3/8 inch chain thickness. 1.5 mm / 0.058 in. Bar length included. 45 cm / 18 inches Recommended bar length, min-max 38-71cm / 15-28 inches Chain rotation speed to maximum. it turns out. 21.4 m/s Equivalent vibration level, front/rear handle. 3.5 / 4.0 m/s2 Guaranteed sound power, dB (A). 115 Weight (without cutting equipment), kg. 6.1 kg

A chainsaw is needed in construction, gardening, and landscaping - its presence greatly simplifies the performance of a number of wood processing tasks. The main component of this tool is the engine, the operation of which largely depends on the condition and settings of the carburetor. This is where the fuel mixture is prepared. This means that if the saw does not start, stalls, or does not provide the required power, it is likely that the reason for this is improper operation of the carburetor. Fortunately, in many cases you can deal with this on your own. Only for this you need to know and understand the structure and operating principle of this unit and, of course, the chainsaw itself.

Purpose of Husqvarna 365 and where it can be used

Husqvarna 365 was developed for use in difficult conditions, throughout the working day. This means that it can be used to solve any, even the most complex problems, anywhere where it is needed. The saw is well adapted for work in winter, when the temperature drops quite low, and at the same time performs well when working in the heat. Additionally, the 365 18 Husqvarna chainsaw can be equipped with a heated carburetor in order to avoid icing when using the saw in severe frosts. This is relevant for the northern regions of our country, where, due to the lack of roads, deforestation work is carried out mainly in winter.

The saw is actively used for working in the garden and for preparing large volumes of firewood, which is very important for those who live in rural areas.

Another area of application for this chainsaw model is emergency rescue work. Together with special saw chains with Pobedit tips, this saw turns into a universal tool that can cut not only wood, but also metal parts or concrete structures, for example, locks, rowlocks, awnings, fragments of concrete buildings, and at the same time the chain retains its function for a long time performance.

How does a chainsaw carburetor work?

The main purpose of a carburetor is to mix fuel with air in the required proportions. If the latter are violated, this almost instantly affects the operation of the engine.

Chainsaw carburetor Stihl MS 181 C BE

Chainsaw carburetors may differ in design. However, their basic elements and operating principle remain approximately the same.

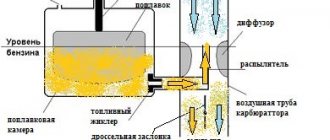

Carburetor design:

- The basis

This is a wind tunnel, across which there is an air damper - with its help the intensity of the air supply is regulated.

This part is where the base tube narrows - here the air flow speed increases, i.e. air is always supplied to the carburetor under some pressure.

In this area, the fuel comes into contact with the air flow. Fuel enters the atomizer from the float chamber through a nozzle (dispenser).

- Float chamber

This is a container that allows you to keep the fuel mixture in a stable state.

Chainsaw carburetor design diagram

A chainsaw carburetor works according to the following principle:

- when the engine starts, the main damper opens and a stream of air is supplied into the air channel at a certain speed;

- the speed of the air flow, as well as the level of the float in the chamber, are regulated by the position of the damper, namely due to the difference in pressure in the float chamber and the air channel;

- fuel from the float chamber is sucked into the nozzle, and from there into the diffuser;

- passing through the diffuser, the air captures the fuel entering there;

- the resulting mixture is fed into the cylinder cavities through the intake channels.

The principle of operation of a chainsaw carburetor

The pressure in the float chamber is approximately equal to atmospheric pressure, but a vacuum occurs in the air channels of the carburetor when the chainsaw engine starts. Opening the damper increases the air supply intensity. As a result, more fuel enters the carburetor, and the number of engine revolutions increases.

Advantages and disadvantages of the Walbro HD 6B carburetor

Undoubtedly, this carburetor has many advantages. Here are some of them:

- High-quality assembly of the carburetor and its high reliability. With proper and timely carburetor care, your chainsaw can serve you for many years. Numerous reviews on the Internet only confirm this.

- Convenient carburetor design. The membrane in the pulse chamber allows you to pump fuel when working in any position of the chainsaw, be it horizontal, vertical or side cutting. This is very convenient, unlike chainsaws with float-type carburetors, where fuel enters the carburetor by gravity and when cutting sideways the saw simply stalls.

Of the minuses, I would like to note the absence of a primer on the carburetor or a heating system for it. In Russia, it is often necessary to operate a saw in the winter season. In severe frosts, starting problems sometimes occur.

When choosing a carburetor, there is a chance of running into a fake. To avoid buying a counterfeit, before purchasing, watch the following video, which shows in detail what the factory packaging and the Zama carburetor itself for the Husqvarna 365 chainsaw look like.

Why is primary adjustment needed?

During the first hours of operation, the 2-stroke chainsaw engine requires running-in, on which the quality of its further operation depends. During the running-in process, the carburetor is initially adjusted - the optimal parameters for preparing and supplying the fuel mixture are established.

Initial running-in of the chainsaw: working with thin material

Most modern chainsaws are sold adjusted. However, it doesn’t hurt to check the quality of the factory settings - in the end, it’s you who will have to work with the tool.

When starting up for the first time, the chainsaw should operate in a gentle mode. Therefore, for several hours after start, it is recommended not to overload the engine and cut only small branches and trunks up to 10 cm thick.

Simple rules will help you insure against malfunctions of the chainsaw carburetor:

- Always mix gasoline and oil according to the manufacturer's instructions.

Proportions of the fuel mixture for a chainsaw engine

The chainsaw must start correctly, ensure a stable rotation speed of the sprocket and a smooth increase/decrease in power. There should be no extraneous knocks, pops or noises when the engine is running.

Professional hand chainsaw at work

The main thing during the initial running-in of the tool is to ensure that the fuel consumption corresponds to the power used, i.e. in practice, the saw should not go out, “sneeze”, smoke or run jerkily.

Read also: DIY suction cup for lapping valves

Detailed review of Husqvarna 365

In terms of external design features, this is a completely understandable chainsaw, which is used by thousands of workers around the world and shows unpretentiousness in repairs and a number of other advantages. Swedish engineers spend a long time on each model, so the 365 is truly a professional in its class with all the necessary components (hand guards, chain catcher, decompression valve, handle and much more).

Advantages

Of course, a chainsaw has more positive characteristics and features, which include:

- a unique heating system for the handles allows you to work in winter without discomfort;

- modern cooling system and a new system with centrifugal air purification;

- engine crankcase made of magnesium aluminum alloy;

- conveniently shaped handles for a secure, confident grip on the chainsaw;

- parts of the crank mechanism are created manually from high-grade forged steel;

- On the side of the cover there is a chain tensioning mechanism, it is conveniently located and helps to quickly make adjustments.

It is impossible not to note the new starter with a unique Smart Start system. According to the manufacturer, this system provides 2 times faster start and start of the chainsaw. A particularly relevant system for long-term use.

Additionally, we note the Air Injection air purification system, which has a centrifugal action and helps to increase the life of the chainsaw and the life of the air intake filter.

Other characteristics

Very often, the Swedish chainsaw is used far outside the city, so the 365 model is equipped with everything necessary for long-term unhindered work. For example, the fuel tank is increased to 770 grams, while the oil tank has a capacity of 420 ml. Despite the above characteristics regarding the tire used, other models can be installed; a tire up to 70 cm long is suitable. In the standard kit you can find a 45 cm long tire with a chain having a link thickness of 0.058.

The chain and bar have a long life due to cooling through lubrication in the form of self-supply of oil to the working area. Oil is also automatically supplied from the oil tank. This is possible thanks to a modern oil pump. A special feature of the tank is the ability to regulate its performance, which in turn saves the owner up to 50% of fuel and lubricants.

Where to use the Husqvarna 365 chainsaw?

Initially, the Swedish brand created characteristics for the Husqvarna 365 chainsaw that allowed it to work in difficult conditions and provide high productivity. Today it is a reliable assistant even for working all day long. You can also work with the equipment all year round; for winter, heated handles are installed; in summer, the chainsaw does not overheat and works well at high temperatures.

If you plan to operate in extreme cold, we recommend that you pay attention to an additional option - a carburetor heating system. This way it will not freeze and will supply fuel unhindered.

About Husqvarna 365, some reviews say that the model can work in temperatures as low as -40 degrees.

Husqvarna 365 is also great for other tasks:

- firewood preparation;

- gardening;

- pruning trees, branches.

How to recognize carburetor failures?

Typical carburetor malfunctions are easy to recognize. They are expressed in the fact that the chainsaw engine starts and immediately stalls or shows no signs of life at all. Well, or it consumes fuel with all its might, producing clouds of black smoke and aggressive vibrations instead of the required power.

Operation diagram of a chainsaw carburetor

Carburetor settings may be affected by:

- lack of fixation of the adjusting screws;

Chainsaw adjustment screws

New CPG chainsaw Husqvarna 365

Chainsaw air filter with nylon insert

Any problems found should be corrected immediately. But how can you determine that the problem is in the carburetor? To do this, watch how your tool works.

Typical signs that the carburetor settings are off include:

- Unstable motor operation

As a rule, the reason for this is the use of the wrong (lean) fuel mixture.

- Excessive fuel consumption

It is expressed in an increased release of exhaust exhaust, which turns black. This means that fuel is not completely consumed, i.e. the mixture is oversaturated.

The carburetor is adjusted correctly - the saw starts the first time

- Arbitrary changes in engine power

May be associated with damage to the fastening of the adjusting screws or the protective cap.

- Increased fuel consumption accompanied by vibrations and pops

This indicates critical wear of the piston group, so adjusting the carburetor will only postpone major repairs for some time.

- Sneezing and engine jerking

This picture is observed when the carburetor channels are clogged or its filters are faulty. In this case, adjustment should be carried out only after thoroughly washing the unit.

Chainsaw fuel filter

Despite the fact that the carburetor is the most complex part of the engine, you should not be upset if you detect malfunctions in its operation. Instead, you need to arm yourself with some tools, a design diagram of the unit and sound logic.

Chainsaw carburetor being repaired

Popular malfunctions of the Husqvarna 254 XP chainsaw

Even despite the high build quality of professional Husqvarna chainsaws, there are a number of typical malfunctions, most often occurring after 3-4 years of active use. The most common:

- Problems with water getting into the carburetor channels, or carburetor breakdowns caused by fuel quality. In the first case, the fuel supply system is practically impossible to adjust, and in the second, deposits form inside the system, which render the carburetor unusable.

- When applying excessive load to the saw while operating on a mixture depleted of oil, engine malfunctions occur - scuffing and jamming of the pistons.

- During active operation in dusty conditions, bearing malfunctions occur.

Do-it-yourself disassembly: nothing complicated

First of all, you need to prepare a place for disassembly. This could be a workbench or a regular table. In addition, you need a rectangular piece of fabric or cardboard - on it you will carefully fold the carburetor parts. And finally, a tool: for disassembly you will need a set of open-end wrenches and screwdrivers, a special cleaning compound and an ultrasonic cavitation bath.

Chainsaw carburetor repair tool

First, you will have to dismantle the chainsaw carburetor. This is done in this order:

- To get to the carburetor, you need to remove the top cover of the chainsaw, secured with three bolts.

Removing the carburetor cover

Removing the fuel hose and drive rod

Removing the throttle cable

After removing the gasoline hose, the carburetor is ready for disassembly

The carburetor must be disassembled in the order prescribed by the design and functional solutions of its elements. The parts of the chainsaw carburetor do not differ in size, so you need to fold them carefully and in order, trying not to lose anything.

Disassembling a chainsaw carburetor in the photo

After disassembly, it is necessary to carry out troubleshooting and replace damaged or worn parts. Next, the entire set should be washed with a special product, dried and wiped with a dry lint-free cloth. The jets and tubes of the assembly must be purged with compressed air, or, in order to more thoroughly remove formations on their internal surfaces, they must be treated with ultrasound beforehand.

Properties and features of alternative applications

The operating time of the tool in operating modes is not limited, with the exception of short breaks for refueling and routine maintenance.

In private and farm households, the capabilities of the saw are used:

- for large-scale work on the procurement of wood fuel;

- construction of wooden log houses for residential and ancillary facilities;

- landfills and sawing of old trees.

Thanks to its versatility and wide functionality, the Husqvarna 365 saw is included in the standard equipment of emergency rescue units of the Ministry of Emergency Situations. The wear resistance of carbide chains allows the tool to be used for sawing concrete and non-massive metal structures.

Carburetor tuning: main points

Reassembly of the carburetor is carried out only after complete cleaning, drying and blowing with compressed air. However, do not forget that some gaskets and seals, even if there is no damage, must be replaced.

You can begin adjusting the carburetor if it is correctly troubleshooted, of high quality assembly and flawless re-installation on the engine.

Principles of carburetor tuning:

- screws H and L adjust the ratio of air and fuel mixture, i.e. throttle position. Tightening the screws clockwise leads to a lean mixture and the engine switches to low speeds. When unscrewing (counterclockwise), the mixture becomes richer and the engine speed increases;

- screw T is responsible for adjusting the idle speed: turning it clockwise increases their number, counterclockwise - decreases it;

- The screws are adjusted in LHT order.

Chainsaw carburetor calibration

The general adjustment algorithm looks something like this:

- Initially, the highest idle speed is found by turning screw L and then returning ¼ turn counterclockwise. If the chain rotates at idle, turn screw T in the same direction until it stops completely.

- With the engine warm and running at full speed, turn screw H ¼ turn to the left, then let the engine run for 10 seconds and check the maximum speed using a tachometer. It must correspond to the number indicated in the instrument passport.

- After calibration with screws L and H, using screw T, the idle speed is adjusted. If everything is done correctly, the engine will operate evenly in all its positions.

Reminders for calibrating the carburetor on the chainsaw body

Upon completion of the adjustment, all that remains is to reinstall the chainsaw cover with the insulating gasket, after which you can begin the main work. If the settings are correct, the chainsaw engine will receive the optimal fuel mixture. This will ensure its normal efficiency, as well as overall comfort and safety of working with the tool.

Specifications

For the Husqvarna 365 chainsaw, the technical characteristics of the base model and modification are slightly different. The main ones are:

- two-stroke engine;

- cylinder volume - 65.1 cm³;

- engine power - 3.5 kW;

- the ability to set the tire length to more than 18″;

- maximum torque - 3.9 N/m;

- fuel consumption - 490 g/kWh;

- The weight of the assembled saw is 6 kg.

The company produces one modification - Husqvarna 365H. Externally, it is very different with high handles. Area of use: felling trunks in deep snow. Main features of the modified chainsaw:

- High handles that house the tank and controls. This allows you to not bend over and work while standing.

- Turning the handles during felling changes the location of the tire in space.

The technical characteristics are completely identical to the model 365 SP (9670828-18), and the cost is almost 2 times more.

On the market you can find the Husqvarna 365 XP chainsaw. This is a Chinese fake, which can be distinguished by the following features:

- fastening the fuel filter cover without latches;

- different shape and size of the fuel filter;

- There is no metal plate with the model number and designation.

User manual

The instructions come standard and contain a lot of useful information.

In it you can find:

- Basic information about the safe use of chainsaws and special protection.

- Break-in instructions.

- A section on assembling and starting a chainsaw, which is very important for those who have not previously had experience with such equipment.

- Basic information about faults and their elimination.

- Information on how to perform maintenance and cleaning.

- A detailed description of the chain sharpening process and all the tools necessary for this.

The instructions must be read and the information contained therein must be used, otherwise there is a risk of premature damage to the saw and injury to the operator.

Description

4.6 liter two-stroke power unit. With. developed using unique X-Torq technology, which allows reducing fuel consumption by up to 20%, while cleaning the chainsaw exhaust by up to 70%. Double inertial cleaning of incoming air masses helps to increase the service life of the air filter.

Husqvarna chainsaw in action

The starting system of the Husqvarna 365 chainsaw is improved by an additional inertial spring on the starting cable. Carburetor with combined damper control, contactless ignition system.

What to do if the chainsaw continues to not start?

If the initial inspection did not yield anything or the defects were eliminated during the search process, but the chainsaw still does not start, then you need to look for more serious reasons. It is best to identify and repair such breakdowns at a service center. However, if you have experience, you can find and eliminate them yourself. What to diagnose and check?

- Compression in the cylinder;

- Compression in the crankcase;

- Carburetor operation.

In the first case, checking the compression in the cylinder will allow you to find out the condition of the cylinder-piston group (CPG) of a chainsaw that does not want to start when cold. To do this you need a compression gauge. The device is screwed into place of the spark plug and the engine is started idle. Measuring the readings allows you to judge the condition of the CPG. In the absence of a compression gauge, you can determine the compression in the cylinder offhand as follows:

- Place your finger on the spark plug hole;

- Try to start the chainsaw engine.

By placing your finger on the spark plug hole and pulling the starter, you can check the compression in the cylinder

If you feel that your finger is being pulled strongly into the spark plug channel, then everything is in order with compression. The absence of vacuum in the chamber indicates a malfunction. The cylinder-piston group needs a more detailed inspection, which will give an idea of the condition of the piston and cylinder, piston rings and bearings.

A chainsaw may not start when cold due to a lack of compression in the engine crankcase. The main reason for this is damage to the gasket located between the cylinder and the crankcase. It is quite easy to detect a lack of compression:

- Disconnect the upper tube from the carburetor;

- Pour gasoline into a regular cork;

- We immerse the removed tube in the fuel;

- We pull the starter several times.