Advantages of the model

- The relatively light weight of the Husqvarna 142 chainsaw and the ergonomic design, combined with the curved front handle, make the operation of the equipment as comfortable as possible.

- The anti-vibration system allows you not to feel tired for a long time.

- A guard and chain brake are provided to ensure user safety.

- The power of the Husqvarna 142 chainsaw is increased through a forged crankshaft consisting of three sections.

Engine

Engine breakdown is one of the most common and time-consuming. This problem is manifested by the following factors:

- Unstable operation at idle.

- Does not start.

- There is not enough power, or the Husqvarna 142 chainsaw starts and stalls as soon as it starts to pick up speed.

Before you begin repairing the Husqvarna 142 chainsaw, it is recommended to conduct a complete diagnosis of the equipment to accurately determine the causes of the problems.

Video on the topic

Share articles on social networks and comment. And I say goodbye to you, good luck and see you again!

When your chainsaw doesn’t start, even though you’re doing everything right, it’s puzzling.

However, do not rush to take it for repairs - the reason may not be that serious and it is possible that you can completely cope with the alleged malfunction with your own hands.

You can find a solution to why the chainsaw is difficult to start when hot, in the instructions.

If for some reason you don’t have it, then we will talk about the structure of the device and possible problems in the first part.

If you do everything correctly, according to the instructions, but the chainsaw still does not start or stalls, then the second section will help you, where you will learn about the most common solutions to this problem.

The most popular and frequently used chainsaw models by Russian users are the Ural, Husqvarna, Shtil 180 and Partner.

Although they have their own characteristics, they are generally similar, so we will describe possible causes of breakdowns and ways to eliminate them in general for all tools.

The reason why the Husqvarna 142 chainsaw does not start

If the Husqvarna 142 chainsaw does not start, there may be several reasons. The most common ones include the following:

- Damage to spark plugs - to understand whether a spark plug is working properly, you need to unscrew it and inspect it. If the porcelain insulator has cracked, you see a burnt or damaged electrode, you should immediately replace the spark plug. In addition, after working for several seasons, the Husqvarna 142 chainsaw requires inspection of spare parts. Spark plugs also wear out their lifespan, and to ensure the safety of the saw, replace them with new ones.

- Carburetor clogged - during operation, gradually, fuel vapors settle on the internal walls, forming a sticky consistency that can clog the carburetor, preventing the engine from starting. You will need to clean it with a special detergent. When repairing a Husqvarna 142 chainsaw, carburetor adjustment is always carried out with a warm engine and cleaned systems.

- Malfunction of the ignition coil - before you decide to replace this part, make sure that the spark plugs meet the required technical condition.

Actions if a malfunction is detected in various parts of the unit

Such unpleasant phenomena as loss of power, lack of connection, and idle support are common. The reasons for this behavior of the tool are malfunctions of the chainsaw carburetor. This is expressed in contamination with particles of dust and sawdust. Such a breakdown can be easily repaired on its own.

The carburetor is cleaned using:

- a small amount of gasoline;

- Phillips screwdriver;

- brushes;

- heads, size 8.

To begin repairing the carburetor, they begin by cleaning it from dirt and dust particles and small wood. A brush is used for this. When the surface is completely free of debris, the repairman removes the cover, and then the filter.

The air collector is released after unscrewing the air filter mounts. The user now has access to the accelerator and rods. The accelerator lever is removed as soon as the throttle is lowered by pressing down with your finger.

The carburetor moves away from its seat after the choke lever is removed and closed. Then the wire is removed and pulled towards itself to stop the engine. The plastic lever, which is the place where the wire is attached, is photographed.

It is raised from the left. As a result, the carburetor is freed, which makes it possible to pull it out and clean it. For these purposes, it is convenient to use a compressor. In its absence, the parts are washed in clean gasoline.

Disassembling a Stihl chainsaw – video

Important! When repairing a poorly functioning Stil MS 180, be sure to inspect the condition of the fuel filter. Remove it and blow out the fuel hose

The saw carburetor assembly process is carried out in reverse order. If, after this process, smoke appears from the muffler and the saw engine does not start well, then you need to make sure that there is a spring located under the lever needle.

The spring cuts off the fuel supply. In its absence, a spontaneous “overflow” of fuel into the spark plug occurs.

It is important to ensure that the spring is installed in its place and make sure that the spark plug is working

If a candle is filled with gasoline, it should be dried. To do this, the part is unscrewed and the excess fuel that gets inside is drained through the existing hole. The candle takes more than half an hour to dry. Then it is installed in place, and the chainsaw is brought into working condition.

Insufficient contact between the high-voltage wire and the end of the spark plug can also be one of the reasons for tool failure. Repair of stihl chainsaw parts can be done by replacing problematic parts.

For example, if a spark plug fails, it is replaced with a reliable one. Chains, sprockets, and tires are subject to rapid wear. They solve anti-vibration problems in the chainsaw device, so they are replaced urgently. It is recommended to keep such spare parts in stock.

How to adjust the carburetor of a Husqvarna 142 chainsaw

The carburetor adjustment of the Husqvarna 142 chainsaw should be done when the engine is warm. Pay attention to the condition of the air filter, which will need to be cleaned if necessary and make sure it is not clogged. Adjusting the carburetor of the Husqvarna 142 chainsaw with your own hands is done using three screws:

- L – for low engine speeds.

- H – for high engine speeds.

- T – for idle speed.

Turn the low and high speed control screws clockwise to the limit, and after the peak is reached, turn them in the opposite direction, one and a half turns. When idling, the Husqvarna 142 chainsaw chain must be stationary. Check at maximum speed.

You can avoid most malfunctions and costly repairs by following the manufacturer’s instructions and recommendations, as well as using original spare parts for the Husqvarna 142 chainsaw.

The Husqvarna 142 gasoline saw is known to many users for its reliability, ease of operation, as well as the high quality of branded components and factory assembly. Garden tools in this modification quickly and efficiently cut down any wood, regardless of its condition and structure. This allows the model to be used not only for cleaning the garden, but also for the construction of domestic and utility premises.

Deutz-Fahr tractors

The German brand Deutz-Fahr specializes in the production of agricultural machinery and tractors. The golden rule of a manufacturer is to invest in development and innovation. As a result, modern and reliable agricultural equipment comes off the assembly line, which makes work easier and increases productivity significantly. Today, about 1 million tractors of the brand are in use around the world.

Products

The brand produces a large number of agricultural equipment, the most popular being tractors, precision farming systems and combines.

Today the following series of tractors are produced:

- 6G.

- Episode 9 TTV.

- Episode 6.

- Episode 7 . . . .

- Agrotrac 130/150/170. .

- Agrofarm G410/430. . .

- Agroclimber F.

- Agroplus FVS.

Precision farming systems are used in many modern agricultural enterprises. Automated control and synchronization of operations significantly increases work efficiency. Deutz-Fahr offers reliable and highly precise automation. The precision farming system from Deutz-Fahr is:

- Reception of signals using all satellite systems, including corrective ones.

- A single interface for all processes and applications. Its diagonal can be 8 or 12 inches.

- Steering systems are represented by visual, power steering.

- High-precision sectional control that eliminates overlaps and skips.

- Possibility of complete automation of data management.

- A security system for large tractors has been introduced; the cameras have a wide viewing angle.

- .

- HTS 6060/6090/6095. .

History and demand

The history of the brand began much earlier than 1977, which appears in many sources. The main character was Nikolaus August Otto, who founded the world's first company specializing in the production of engines in 1864. Already in 1890, a thresher was invented. 4 years later, the first Deutz tractor with a 26 hp gasoline engine was released. In 1927, the first diesel tractor Deutz MTN222 was produced, which in fact became the beginning of mass production of standard and now familiar tractors.

Since 1936, small agricultural enterprises have already begun to use mechanization and its face - the Deutz F1V 414, with a power of 11 hp.

In 1937 Klöckner was acquired, which became Klöckner-Humboldt-Deutz or simply KHD. This company becomes the largest conglomerate of the Reich. At that time, KHD worked in all areas related to engine production.

Since 1949, the production of tractors with a diesel engine and air cooling Deutz F1514 and F2514 has been launched. Already in 1955, the 100 thousandth copy was produced.

1961 – start of cooperation with Fahr AG. It was made possible through the exchange of shares in KHD. In 1968, KHD bought part of the shares of Fahr AG and a brand appeared that is today recognizable in many countries - Deutz-Fahr.

In 1977, DX series engines were put into mass production, which were officially introduced a year later. These were diesel engines with 5 and 6 cylinders. Their power varied from 80 to 160 hp. A little later, in 1980, the series was also replenished with 4 cylinder models.

In 1990, production of AgroXtra tractors was launched. 1991 Topliner series combine harvester.

1995 became a landmark year, because it was during this period that the Italian group SAME joined the corporation. The full name of the company began to look like this: SAME Deutz-Fahr or SDF. The Agrotron series has also been released.

In 1996, it was decided to move production facilities from Cologne to Lauingen. In the same year, the Gigant 400 forage harvester was introduced. Further history is largely connected with the release of new equipment, namely:

- 2001 – Agrotron TTV with continuously variable transmission.

- 2004 – production of Teleskoplader loaders and rotary combine was launched

- 2009 – production of the Agrotrac series started. It is intended for countries with more flexible gas emission standards.

- 2013 – series of S9000 combines.

The last significant event in the history of the brand occurred in 2017, when the most modern tractor plant in Europe began operating. The main specialization is equipment with a power of 130 hp.

Deutz-Fahr units are in demand in agriculture in almost all countries of the world, and especially in Russia and the CIS. They were loved for their performance, modernity, powerful and economical engines. After domestic tractors and combines, many appreciated the comfortable conditions of the operator.

The device of the Husqvarna 142 chainsaw

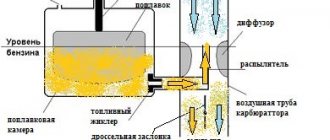

One of the main advantages of the 142nd model of the Swedish brand Husqvarna is the competent selection of its components and the high quality of the original assembly. The basis of the garden tool consists of a 2-stroke gasoline engine, the chrome-plated cylinder of which has a volume of 30 cm3. Starting a standard internal combustion engine is done by pulling the recoil starter cable. A proprietary Japanese Walbro brand carburetor with forged jets and an improved fuel injection system is responsible for preparing and enriching the fuel mixture with air in the internal combustion engine configuration. The manufacturer equipped the engine with a fuel and oil tank with a volume of 370 and 190 ml, respectively.

The Husqvarna 142 chainsaw is equipped with a durable clutch, which is responsible for the continuous connection of the engine with the saw set. All spare parts of the mechanism are made of durable steel, resistant to high temperatures and corrosion.

Model specifications

The Husqvarna brand chainsaw in the proprietary 142 modification has solid factory parameters.

These include:

- petrol engine power – 2.58 liters. s./1.9 kW;

- idle/maximum speed – 3000/13000 rpm;

- The manufacturer's recommended length of the tire used is 30–38 cm;

- weight with filled fuel and oil tanks – 4.9 kg.

Despite the impressive maximum speed parameters, the engine of the Husqvarna model is quite quiet. When operating the model under maximum loads, the sound impact level on the operator is 105 dB.

Chainsaw delivery set

When ordering the Husqvarna 142 model, the buyer receives absolutely everything necessary to start using and further maintain the garden tool. The model kit includes:

- branded tire and chain;

- plastic tire cover;

- hand tools for assembly and maintenance;

- user manual.

For an additional fee, the manufacturer supplies the chainsaw with a bag for transportation, branded oil for 2-stroke engines and additional spark plugs.

Adjusting the carburetor of the Husqvarna 142 chainsaw with your own hands

In order for the 142nd model of the Husqvarna brand to work properly, its owner must promptly adjust the chainsaw carburetor.

This should be done in the following cases:

- if the Husqvarna 142 chainsaw does not start;

- if the engine starts but runs intermittently;

- if the engine starts and stalls when you press the gas trigger;

- if fuel consumption increases sharply.

All these malfunctions threaten more serious breakdowns, which will be quite difficult to cope with on your own and without the necessary experience. To prevent this, you need to adjust the element responsible for enriching the fuel mixture with air. Setting up the carburetor of the Husqvarna 142 chainsaw should be done in the following sequence:

- First you need to set the Husqvarna chainsaw carburetor to factory settings. To do this, with a cold engine, you need to turn the adjusting screws as indicated in the model’s operating manual;

- After this, you need to start the saw motor and give it 5 minutes to warm up completely. After this, you need to slowly turn the screw “L” until the engine starts to operate at maximum idle speed. Immediately after this, screw “L” must be turned out 1/4 turn in the opposite direction;

- If the chain on the bar then rotates, the operator will need to begin turning the "T" bolt one at a time until the chain stops;

- Next you need to find the maximum engine speed. To do this, you need to hold the gas trigger and start turning the “H” bolt until the engine begins to operate stably at high speeds. After this, screw “H” must be turned out 1/4 turn in the opposite direction.

After adjusting the carburetor, you need to turn off the Husqvarna chainsaw engine and start it again. To check engine operation, the operator must press the throttle trigger sharply several times. If, when the trigger is pressed, the engine quickly gains speed and loses it when the trigger is released, then the adjustment of the standard carburetor was carried out successfully by the operator.

The lawn mower stalls when you press the gas, how to fix the problem

Reasons why a lawn mower stalls

– there can be a huge number, we offer the most common of them, and we hope that you will find yours and, of course, eliminate it. So, one of the situations is a clogged air damper, the hole behind which fuel is sprayed. If something gets into it, it can most often be quickly and easily removed. This is the simplest reason, just like a clogged filter. It needs to be washed in a solvent and then blown well with compressed air. If it cannot be repaired, then order a new one in spare parts from the KosiKosa store.

Likewise, when you press the gas, the tool stalls because the drive is clogged. The following option is also possible: fuel is not supplied in full, so you need to check or replace the fuel filter. Other possible reasons for a lawn mower stalling when you give it gas include:

- The crankshaft seals suck in air;

- The spacer that is located between the carburetor and the cylinder in a “problematic” situation;

To all these reasons why the mechanism stalls when adding gas, we will add some useful recommendations for handling the lawn mower. First of all, before starting to work with any equipment, you need to read the instructions. In this case, the consistency of gasoline and oil plays an important role, it is properly prepared by you, as well as not overheating the unit, and not leaving gasoline for the winter when you simply will not use the car.

In the full operation of any instrument, the coordinated work of all its components plays an important role. And if in one it is, then in the other it is a piston or a carburetor. Owners of brush cutters who want to use their tools to their full potential need to understand that under a load for which the machine’s capabilities are not designed, the entire mechanism or its individual parts may simply break. Therefore, only competent and moderate operation presupposes long-term effective operation of any gas-powered tool.

The trimmer stalls at idle - causes and solutions

Common situations why the trimmer stalls

or brushcutter, it is worth considering its operation at idle speed. Let's get straight to the reasons:

heating of the gearbox and a decrease in speed on the drum as a result of the fact that the gasoline solution is not prepared quite correctly. The required proportion is 1:4; carburetor contamination; the throttle valve is clogged; when the damper is opened (if such an experiment was carried out), the air flow makes the mixture “lean”; carburetor adjustment; air filter clogged;

An insufficient amount of fuel, which is needed for the operation of a gas-powered tool, will lead to a situation where at high speeds, when increasing, the trimmer works, but stalls at idle. In a situation with a carburetor, the device will stall on a cold start and on a hot start.

For any user of a lawn mower - professional or amateur - it is important to understand that any problem with the tool may depend on a minor part coming off, a fastener coming loose or clogging, as well as a global breakdown of an important part of the mechanism

A beginner and an experienced owner can encounter the problem of a stalled lawn mower; situations arise with used and completely new mowers, and we will look into which ones exactly in this article. So, the tool may stall under load, immediately after starting, that is, it starts and stalls when the entire mechanism heats up, at high speeds, or it does not even pick up speed and stalls. In all these cases, in fact, the same systems, elements, components are involved, but the breakdown or malfunction of each of them, more precisely, the nuances, cause the individual situation mentioned above. The answer to the question of every user: why does the lawn mower stall?

, you will receive only on our website in the news articles section.

To fully understand your individual situation, carefully read the signs and accompanying nuances when the scythe stalls, and then it will be easier for you to find a way out and quickly solve the problem. If you need certain ones, then you can do it wholesale and inexpensively at the best gas powered tools store in Ukraine, “Benzo Zip”.

Chainsaw malfunctions and how to fix them

Owners of the Husqvarna 142 model often encounter typical breakdowns caused by improper use of garden tools or simple wear of its parts.

These malfunctions include:

- the chainsaw does not start - the cause of this breakdown lies in the spark plug being flooded. To be able to start the saw motor, you need to remove, wash and dry the spark plug. After this, you need to blow out the cylinder by sharply pulling the starter cable several times with the spark plug turned out. After this, you need to screw in the spark plug and start the engine of the garden tool;

- increased vibration during operation of the saw - repair of this breakdown is carried out by cleaning or replacing the muffler. You will also need to inspect the springs of the anti-vibration system. If necessary, sagging parts must be replaced;

- shooting sounds - if loud popping noises are heard during operation of the Husqvarna model, then the causes of the breakdown should be sought in the carburetor or muffler. The operator will first need to adjust the carburetor. After this, you need to remove and wash the muffler;

- leakage of oil to lubricate the chain - to eliminate this breakdown, you need to check the condition of the oil pump and pipes. The faulty part will need to be replaced.

To avoid further breakdowns of the Husqvarna 142 chainsaw, you need to use high-quality gasoline and oil to refuel it. This will help prevent increased wear of parts and protect model components from overheating.

Restoring the operation of the tool

To restore the operation of the saw, no matter the Ural or Shtil brand, you need to know the location of the breakdown.

First, we check and change the unsuitable fuel mixture. If the saw still does not start, then we check further point by point.

The problem is in the candle - we pull it out and dry it. Under no circumstances should you pierce it, as this will lead to a malfunction of the part. Thirty minutes after drying, you can insert the spark plug back, first checking to see if there is any fuel left in its place.

In addition, the spark plug may simply break, so it is better to have a spare one to rule out the cause.