Tubing is used to extract minerals using drilling rigs. They can also be used to create compact small artesian wells. They may differ in length, wall thickness, material, and so on. Preservation, storage and transportation of these parts must be carried out in accordance with the GOST standard. This will increase the shelf life of the products, making them more durable and reliable. But why do we need tubing? How much does a standard tubing pipe weigh according to GOST? And how to properly store these parts in a warehouse? These issues will be discussed in the article.

Operating principle of drilling rigs

To understand the purpose of tubing, you need to know the principle of operation of drilling rigs. Drilling rigs are used to extract water, gas and oil, which are located deep underground. They differ from each other in many parameters - operating principle, design, performance characteristics and others. Typically, a drilling rig consists of three elements - an aboveground platform, a drill string and a power system. The installation may also include additional elements - a controlling pneumatic drive, a drill cooling system, warning sensors, and so on.

Drilling technology

- At the preparatory stage, geologists conduct exploration and outline the proposed drilling location. Then the drilling platform is mounted and a test run of the installation is performed. During the test, the following parameters are checked: the quality of the joints of parts with each other, the level of vibration, and the level of load on the electric motor.

- If everything is fine with the platform, a well is drilled. For drilling, a drill string is used, which is connected to an electric motor. At the end of the column there is a sharp tip-chisel, which destroys hard rocks.

- During operation, the drill string rotates along its axis, which leads to the formation of a well. At the same time, the waste soil is supplied to the surface. Modern rigs are equipped with a system for supplying protective chemicals, which minimizes the risk of damage to the drill string.

- After creating a well, it is necessary to fix it. To solve this problem, two technologies can be used. In the first case, an additional pipe is installed in the well, which creates a gap between the column and the pipe itself. Soft mixtures are poured into this gap and quickly harden. In practice, this method is rarely used. In the second case, a casing pipeline is installed in the well, which has thick walls and can withstand any load.

- After strengthening the well, pipes are inserted into the casing to pump out minerals or water. Tubing can be used as such a pipe. Before they are introduced into the well, they are secured using well couplings, which turn the individual tubing pipes into a single compression string. To extract minerals, an electric motor is started, which pumps oil or gas from the well to the surface. On the drilling platform, minerals are packed into containers (barrels, tanks, vats).

Please note that tubing can be used in other scenarios. A simple example: a pipeline can be configured not to suck in liquids, but to spray them. This technology allows for the injection of liquids, which can be useful in some areas of human activity. Examples - well repair, geological exploration, local increase in pressure, creation of additional inflows to the main well.

Connection rules (installation)

All NKT with threaded connections are screwed together without adapters with couplings of strictly appropriate size (according to GOST 633-80).

Table 3. Connection rules (installation)

Deviations from these standards are fraught with emergency situations due to leaky connections.

The tightness of couplingless products is guaranteed if the operating pressure does not exceed 50 mPa. They are connected very firmly due to the fact that the ends are equipped with an outward landing. To make the connection possible, manufacturers provide conical sealing surfaces as standard. They (seals) are located directly behind the threads.

Coupling models are also guaranteed tightness if the operating pressure does not exceed 50 mPa.

GOST requirements

The tubing pipe is used to transport liquid and gaseous substances from wells to the surface. In technical terms, they are ordinary seamless pipes. According to GOST, they must have the following properties:

- High strength. During operation of the production platform, liquids and gases will flow through the pipeline under pressure. It is necessary that the pipeline installation retains its strength and does not crack. Even small leaks or cracks will lead to complete depressurization of the installation, which can lead to failure of the entire platform.

- Tensile resistance. Most modern wells are not completely straight. This is caused by various reasons: shortcomings in drilling, changes in the shape of the well due to the movement of the earth, and so on. It is important that the pipes retain their shape and do not crack when bent. In case of low tensile strength, the column may leak, which will lead to the destruction of the system.

- Density, tightness. The material from which the pipeline is made must be dense and airtight. This factor is especially critical for the ends of the installation that will be threaded. If the material is plastic, the thread will be of poor quality. Because of this, the tightness of the seams will be compromised, which can lead to depressurization of the system.

- Corrosion resistance. A large amount of liquid or steam will flow through the pipeline while the drilling rig is operating. This can cause rust to form, causing the pipe string to fail. For the manufacture of tubing, high-carbon steel is used, which contains chromium-based alloying additives. This component prevents the formation of rust and also stimulates the formation of a protective oxide film on the metal surface. Thanks to this, the installation does not crack or rust while the tower is in operation.

Operation

There are a number of rules that must be followed when operating tubing. 1. They should not be dropped to the ground during loading and unloading. You need to use a crane. 2. Pipe trucks are an essential element of their transportation. Dragging or bending in such a way that they sag or bend is prohibited. 3. Before laying the pipes on the site, you need to place wooden blocks under them. Safety rings for pipes must be screwed on if they are placed on threaded parts. 4. Before lifting via bridges, it is necessary to determine the condition of the product. To do this, a template is passed through it, having a diameter several millimeters less (two or three) than the internal diameter of the part. The length of the template is 5-10 cm. Before it comes out, the lower end of the product is held. 5. It is imperative to go over the threads of the coupling and nipple with a metal brush before starting screwing, and treat the threads with lubricant. 6. It is unacceptable to hit the coupling with a sledgehammer.

Dimensions, weights and tolerances of unset tubing couplings

Functions, features of tubing

The main functions of pumping and compression pipelines are the extraction of liquids and gases from wells, maintaining reservoir pressure, and major workover of wells. The starting material is usually steel with a medium or high carbon content. Other materials can also be used - plastic, aluminum, copper + various alloys. Such pipeline systems will have low strength, so tubing made from these materials is used only in the case of small wells (dacha plots, small artesian wells). For mining, pipes are attached to each other to form a single column.

The following technologies are used to connect individual elements to each other:

- Threaded connection. This technology is applicable only if the ends of the pipes have threads (applied at the factory). To connect two separate parts, a tubing coupling is used, which has an internal thread. To connect, the ends of the pipelines are cleaned using polishing tools. Then the tubing coupling is screwed onto one pipe (half the thread). After this, the second tubing pipe is also screwed into the coupling. If necessary, additional adjustments are made to the parts to ensure a tight connection.

- Welding or soldering. This technology is used if the ends of the pipes do not have threads (or their quality is low). To connect, the parts are placed close to each other - then they are connected using a welding machine. Any welding method can be used - automatic, semi-automatic, electric arc method and others. The main difficulty in welding is that the piping parts are usually made of steel. Therefore, the ends will have to be heated to high temperatures, which complicates the technical procedure. In practice, welding technology is rarely used due to its complexity.

Tubing pipe weight

The weight of the tubing pipe depends on three parameters - overall diameter, wall thickness and typical length. Compression tubing tubing73-5.5 and tubing tubing89-7 are popular - the numbers indicate the cross-sectional diameter and wall thickness. Long, thick-walled pipes have a lot of weight, while short, thin parts will have little weight.

| Section diameter (mm) | Wall thickness (mm) | Typical length (m) | Approximate weight (kg) |

| 73 | 5,5 | 2 | 19 |

| 73 | 5,5 | 3 | 28,5 |

| 73 | 5,5 | 4 | 38 |

| 89 | 7 | 2 | 29,5 |

| 89 | 7 | 3 | 44 |

| 89 | 7 | 4 | 58,5 |

Areas of use

Tubing pipes are used both for their intended and non-direct purposes. Initially they are intended for the oil industry:

- completion of oil and gas wells;

- bitumen extraction wells;

- injection pipelines.

The specifics of the application determined the pipe tubing material, which is distinguished by high performance indicators. Over time, the products began to be used for other purposes:

- arrangement of water pipelines in private and multi-apartment construction;

- use as supporting structures for installing foundations, fences and other vertical structures.

Screw piles of different load-bearing capacities are made from tubing by welding blades to the pipe.

Features of operation and storage

Let's consider some features of the operation and storage of tubing:

- Using lubricant. Before installing the tubing string, it is necessary to lubricate the end of the tubing with a protective lubricant. The type of lubricant depends on the nature of the well, the type of casing and the category of metal from which the pipeline is made. The lubricant must be applied carefully in accordance with the dosage rules. A lack of lubrication or its excess negatively affects the strength of the structure and also complicates its installation.

- Welding protective environment. Soldering should be carried out in a protective environment (argon). If shielding gas is not used, there is a risk that the metal edges of the part will be damaged during welding. This seriously increases the likelihood of corrosion, which will lead to deformation and cracking of the pump string.

- Removing a pipe from the system. In case of prolonged downtime of the drilling platform, it is necessary to dismantle the tubing. After all, the edges of the pipe are in constant contact with the liquid medium, which can lead to corrosion. After dismantling, it is necessary to rinse the installation and lubricate it with protective lubricant. Check for damage, cracks, and corroded areas.

Tubing pipes can be stored in any cool, dry place. It is better to pack them in special blocks made of wood, plastic and metal. It is best to store such units in a warehouse with good ventilation. In accordance with GOST rules, each spare part must be marked. It should contain all the important data about the part - markings, type, brief information about the manufacturer, information about the workers responsible for its production in the workshop. Blocks with pipes can be transported in any convenient way (using trucks or trains, planes, water transport, and so on). In the event of a sale at the request of the buyer, control procedures must be performed to prove that the parts are in proper condition.

Types and classification of pump and compressor pipes (Assortment)

The classification is based on various parameters.

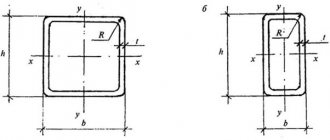

By tightness:

- couplingless;

- with threads for couplings (guarantee improved sealing).

Based on the type of medium being lifted to the surface (pumped out), nct groups are divided for operation in different wells:

- oil;

- gas producers;

- pumping;

- bituminous (in areas of the heavy oil zone).

Recycling wells (reserve) are included in a special category.

Classification according to GOST 633-80 implies the following groups:

- Tubing - with a coupling connection (standard version). The task is to ensure total tightness of the system under conditions of 50 MPa.

- NKT-V - with external (upset) thread. Required to organize the movement of gas and liquid media in the column. It provides standard functionality: lifting, debugging or lowering operations.

- NKB - with external connecting thread. NKT B is intended for the formation of a coupling-free main line.

- NCM - for the most difficult areas. Couplings with increased requirements for tightness are used as connecting elements.

Since this product plays the role of communications in the completion of individual wells and large-scale highways, it is particularly durable. To produce smooth workpieces and couplings, steel grades are used: D, E, K, L and M.

Table 2. Assortment

Production technology

Tubing pipes are made in several stages:

- Manufacturing of standard type pipes. After smelting the metal, a hollow semi-finished product is formed, which ends up in the pipe-rolling shop. Here, a full-fledged part is formed from a blank using the cold or hot rolling method. At the end, the part is hardened and cooled (if necessary). If the spare part will be stored in the workshop for some time, then intermediate marking will be applied to it in accordance with GOST rules.

- Preparatory work. Now the finished pipeline part enters the production workshop. Here the spare part is degreased and then cleaned. Grinding equipment is used for cleaning; manual processing is rarely used due to its low efficiency.

- Threading on one end. After treatment, control ultrasonic flaw detection is performed. If everything is fine with the spare part, a thread is applied to one of its edges using special tools. Immediately after applying the thread, repeated flaw detection is carried out, which makes it possible to determine the quality of the thread. If all is well, a tubing coupling is mounted on the end of the part. Then the installation is cleaned with water.

- Threading the second end. Now the worker uses tools to apply threads to the other end of the part. Then he performs control flaw detection, and the check is performed twice, since a protective coupling will not be mounted on this end. If everything is fine with the spare part, a protective casing-protector is screwed onto the thread.

At the end, final processing, packaging, and transportation are performed. Upon completion of all work, the finished spare part is washed and checked for defects, damage, and scratches. Control weighing is also carried out and GOST markings are applied. If all is well, the spare part undergoes a preservation procedure. Finally, it is packed into metal, plastic or wooden blocks for storage in a warehouse.

Characteristics

Basic requirements for tubing pipes:

- high resistance to aggressive environments that cause metal corrosion, as well as oxidation of transported media;

- resistance to low and high temperatures;

- plasticity is necessary for products to regulate the integrity of the line during heating/cooling and during internal pressure fluctuations. This parameter is ensured by the presence of plastic connections in different sections of the pipeline;

- absolute tightness;

- permeability of substances in the lumen of the pipe.

These qualities are regulated by various documents - GOST and individual specifications, which are available at each manufacturing enterprise.

The dimensions of the tubing pipe are specified in the assortment of the state standard:

- nominal diameter (external, rounded to the whole value) – 27...114 mm;

- length – 6...10 m (measured and unmeasured), can be adjusted according to customer needs.

Each product released from the conveyor has a mark from which you can find out all the defining characteristics: tubing pipe diameter, wall thickness, resistance value, grade or type of steel, name of the manufacturer.

Characteristics of tubing

Pipes for a pumping unit must be of high quality to cope with the functionality and high load. There is no damage, loss of integrity, delamination or cracks that could lead to their depressurization. There should be no ruptures or displacements inside the well itself in order to avoid major repairs of the well and equipment for as long as possible. These products can also be used to supply water from an autonomous well. Another application of the tubing pipe is the injection of air to clean the well using the blowing method.

Products of this class are subject to high quality requirements.

Since such parts often come into contact with an aggressive environment outside, there is high pressure inside, so they must be different:

- corrosion resistance;

- wear resistance;

- absolute tightness;

- excellent patency along the trunk (smooth).

The standard is within 6-10.5 m, at the customer’s request they can be 1 meter longer, that is, 11.5 m. Industrial production of tubing pipes is established in accordance with GOST, where the dimensions are specified and described in tables.

Products of this sample are produced in 2 types:

- with smooth ends;

- with external thread.

Tubing pipes treated at the connections have the greatest protection against depressurization and corrosion. The threads are additionally equipped with a special lubricant to ensure absolute tightness of installation. Visually, they differ in that the ends have coated external threads to connect the ends of two pipes with a special coupling.

Guaranteed tightness of communications under standard load - coupling pipe connection. The usual pressure in the system is within 50 MPa, and a special trapezoidal thread is used.