When we were children, we built with sand or cubes, but now we are big guys and the profile pipe has become our construction set. Amazing thing! We paid attention to this element of construction metal when we needed material for the construction of a greenhouse and fence posts made from chain-link mesh.

In the process of choosing professional pipes of the required quantity and quality, we consulted with specialists, familiarized ourselves with the price lists of companies, looked into specialized literature and summarized the information received in this article. Everything turned out to be quite simple - now you will see everything for yourself.

- Profile rolled products are distinguished by profile type

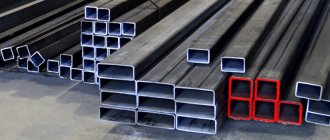

- Profile steel pipes of rectangular section (GOST 8645-68)

- Square profile pipes (GOST 8639-82)

- Steel pipes of oval cross-section (GOST 8642-68)

Marking - symbols. GOST

b - width, h - height, t - wall thickness, R - radius of external curvature.

The symbol for a bent welded rectangular profile with a height of 180mm , a width of 100mm , a wall thickness of 5mm made of steel for building structures C245 according to GOST 27772 will look like this:

Profile 180x100x5 GOST 30245 - 2003/C245 GOST27772-88

But suppliers usually use simplified markings, which include: name, cross-sectional size and wall thickness. Thus, if you see on Petrovich’s website the position: profile pipe 60x40x2 , this will mean that the construction network offers a rectangular pipe with a profile width of 60x40mm and a wall thickness of 2mm .

The profile is made in lengths from 6 to 12 m and sometimes you can find its length at the end of the marking:

Profile pipe 60x40x2 6m

The thicker the wall, the better. Here you decide based on your budget. A guide can be the information that in the open air, corrosion eats away steel by approximately 0.1 mm per year.

Do you know?

What if you pour quality concrete (without voids) into the cavity of a profile pipe, then you will get a so-called composite pipe-concrete element. Its vertical load-bearing capacity will be several times higher!

Products according to GOST 13663-86 and GOST 30245-2012: differences

It is not so easy to distinguish products manufactured according to these regulatory documents by appearance. We will indicate the main differences between them in the following table:

| Indicators | Products according to GOST 13663-86 | Products according to GOST 30245-2012 |

| Production technology | Cold and hot deformation (rolling) of solid workpieces. | Bending of strip blanks of measured width (strip) with subsequent welding of the seam. |

| Types of pipes | Seamless and welded. | Welded only. Weld breaks are allowed. |

| Purpose | General. This means that, if necessary, the pipes can be used in pipelines supplying liquids and gases. Therefore, products undergo mandatory hydraulic tests. | Structural material in construction and for the manufacture of industrial products. Finished products are not subjected to hydraulic tests. |

Different production technologies also explain differences in product range. We will show the dimensions of the profile pipe by type separately.

Profile pipe. Dimensions. Weight 1 meter. Tables

Square section GOST 8639-82

| Dimensions bxh , mm | Wall thickness, t , mm | Weight 1m, kg | Meters in 1 ton |

| Square pipe 10x10 | 1,0 | 0,269 | 3717,5 |

| Square pipe 15x15 | 1,0 | 0,426 | 2347,4 |

| 1,5 | 0,605 | 1652,9 | |

| Square pipe 20x20 | 1,0 | 0,583 | 1715,3 |

| 1,5 | 0,841 | 1189,1 | |

| 2,0 | 1,075 | 930,2 | |

| Square pipe 25x25 | 1,0 | 0,740 | 1351,4 |

| 1,5 | 1,070 | 934,6 | |

| 2,0 | 1,390 | 719,4 | |

| 2,5 | 1,680 | 595,2 | |

| 3,0 | 1,950 | 512,8 | |

| Square pipe 30x30 | 2,0 | 1,700 | 588,2 |

| 2,5 | 2,070 | 483,1 | |

| 3,0 | 2,420 | 413,2 | |

| 3,5 | 2,750 | 363,6 | |

| 4,0 | 3,040 | 328,9 | |

| Square pipe 35x35 | 2,0 | 2,020 | 495.0 |

| 2,5 | 2,460 | 406,5 | |

| 3,0 | 2,890 | 346,0 | |

| 3,5 | 3,300 | 303,0 | |

| 4,0 | 3,670 | 272,5 | |

| 5,0 | 4,370 | 228,8 | |

| Square pipe 40x40 | 2,0 | 2,330 | 429.2 |

| 2,5 | 2,850 | 350,9 | |

| 3,0 | 3,360 | 297,6 | |

| 3,5 | 3,850 | 259,7 | |

| 4,0 | 4,300 | 232,6 | |

| 5,0 | 5,160 | 193,8 | |

| 6,0 | 5,920 | 168,9 | |

| Square pipe 42x42 | 3,0 | 3,550 | 281,7 |

| 3,5 | 4,070 | 245,7 | |

| 4,0 | 4,560 | 219,3 | |

| 5,0 | 5,470 | 182,8 | |

| 6,0 | 6,300 | 158,7 | |

| Square pipe 45x45 | 3,0 | 3,830 | 261,1 |

| 3,5 | 4,400 | 227,3 | |

| 4,0 | 4,930 | 202,8 | |

| 5,0 | 5,940 | 168,4 | |

| 6,0 | 6,860 | 145,8 | |

| 7,0 | 7,690 | 130,0 | |

| 8,0 | 8,430 | 118,6 | |

| Square pipe 50x50 | 3,0 | 4,310 | 232,0 |

| 3,5 | 4,940 | 202,4 | |

| 4,0 | 5,560 | 179,9 | |

| 5,0 | 6,730 | 148,6 | |

| 6,0 | 7,800 | 128,2 | |

| 7,0 | 8,790 | 113,8 | |

| 8,0 | 9,690 | 103,2 | |

| Square pipe 60x60 | 3,5 | 6,040 | 165,6 |

| 4,0 | 6,820 | 146,6 | |

| 5,0 | 8,300 | 120,5 | |

| 6,0 | 9,690 | 103,2 | |

| 7,0 | 11,000 | 90,9 | |

| 8,0 | 12,200 | 82,0 | |

| Square pipe 70x70 | 4,0 | 8,070 | 123,9 |

| 5,0 | 9,870 | 101,3 | |

| 6,0 | 11,570 | 86,4 | |

| 7,0 | 13,190 | 75,8 | |

| 8,0 | 14,710 | 68,0 | |

| Square pipe 80x80 | 4,0 | 9,330 | 107,2 |

| 5,0 | 11,440 | 87,4 | |

| 6,0 | 13,460 | 74,3 | |

| 7,0 | 15,380 | 65,0 | |

| 8,0 | 17,220 | 58,1 | |

| Square pipe 90x90 | 5,0 | 13,000 | 76,9 |

| 6,0 | 15,340 | 65,2 | |

| 7,0 | 17,580 | 56,9 | |

| 8,0 | 19,730 | 50,7 | |

| Square pipe 100x100 | 6,0 | 17,220 | 58,1 |

| 7,0 | 19,780 | 50,6 | |

| 8,0 | 22,250 | 44,9 | |

| 9,0 | 24,620 | 40,6 | |

| Square pipe 110x110 | 6,0 | 19,110 | 52,3 |

| 7,0 | 21,980 | 45,5 | |

| 8,0 | 24,760 | 40,4 | |

| 9,0 | 27,450 | 36,4 | |

| Square pipe 120x120 | 6,0 | 20,990 | 47,6 |

| 7,0 | 24,180 | 41,4 | |

| 8,0 | 27,270 | 36,7 | |

| 9,0 | 30,280 | 33,0 | |

| Square pipe 140x140 | 6,0 | 24,760 | 40,4 |

| 7,0 | 28,570 | 35,0 | |

| 8,0 | 32,290 | 31,0 | |

| 9,0 | 35,930 | 27,8 | |

| Square pipe 150x150 | 7,0 | 30,770 | 32,5 |

| 8,0 | 34,810 | 28,7 | |

| 9,0 | 38,750 | 25,8 | |

| 10,0 | 42,610 | 23,5 | |

| Square pipe 180x180 | 8,0 | 42,340 | 23,6 |

| 9,0 | 47,230 | 21,2 | |

| 10,0 | 52,030 | 19,2 | |

| 12,0 | 61,360 | 16,3 | |

| 14,0 | 70,330 | 14,2 |

Rectangular section (GOST 8645-68)

| Dimensions bxh , mm | Wall thickness, S, mm | Weight 1m, kg | Meters in 1 ton |

| Rectangular pipe 15x10 | 1,0 | 0,348 | 2873,6 |

| 1,5 | 0,488 | 2049,2 | |

| 2,0 | 0,605 | 1652,9 | |

| Rectangular pipe 20x10 | 1,0 | 0,426 | 2347,4 |

| 1,5 | 0,605 | 1652,9 | |

| 2,0 | 0,762 | 1312,3 | |

| Rectangular pipe 20x15 | 1,0 | 0,505 | 1980,2 |

| 1,5 | 0,723 | 1383,1 | |

| 2,0 | 0,919 | 1088,1 | |

| 2,5 | 1,090 | 917,4 | |

| Rectangular pipe 25x10 | 1,0 | 0,505 | 1980,2 |

| 1,5 | 0,723 | 1383,1 | |

| 2,0 | 0,919 | 1088,1 | |

| 2,5 | 1,090 | 917,4 | |

| Rectangular pipe 25x15 | 1,0 | 0,583 | 1715,3 |

| 1,5 | 0,841 | 1189,1 | |

| 2,0 | 1,080 | 925,9 | |

| 2,5 | 1,290 | 775,2 | |

| Rectangular pipe 30x10 | 1,0 | 0,583 | 1715,3 |

| 1,5 | 0,841 | 1189,1 | |

| 2,0 | 1,080 | 925,9 | |

| 2,5 | 1,290 | 775,2 | |

| 3,0 | 1,480 | 675,7 | |

| Rectangular pipe 30x15 | 1,0 | 0,661 | 1512,9 |

| 1,5 | 0,959 | 1042,8 | |

| 2,0 | 1,230 | 813,0 | |

| 2,5 | 1,480 | 675,7 | |

| 3,0 | 1,710 | 584,8 | |

| Rectangular pipe 30x20 | 1,0 | 0,740 | 1351,4 |

| 1,5 | 1,080 | 925,9 | |

| 2,0 | 1,390 | 719,4 | |

| 2,5 | 1,680 | 595,2 | |

| 3,0 | 1,950 | 512,8 | |

| Rectangular pipe 35x15 | 1,5 | 1,080 | 925,9 |

| 2,0 | 1,390 | 719,4 | |

| 2,5 | 1,680 | 595,2 | |

| 3,0 | 1,950 | 572,8 | |

| 3,5 | 2,200 | 454,5 | |

| Rectangular pipe 35x20 | 1,5 | 1,190 | 840,3 |

| 2,0 | 1,550 | 645,2 | |

| 2,5 | 1,880 | 531,9 | |

| 3,0 | 2,190 | 456,6 | |

| 3,5 | 2,470 | 404,9 | |

| Rectangular pipe 35x25 | 1,5 | 1,310 | 763,4 |

| 2,0 | 1,700 | 588,2 | |

| 2,5 | 2,070 | 483,1 | |

| 3,0 | 2,420 | 413,2 | |

| 3,5 | 2,750 | 363,6 | |

| Rectangular pipe 40x15 | 2,0 | 1,550 | 645,2 |

| 2,5 | 1,880 | 531,9 | |

| 3,0 | 2,190 | 456,6 | |

| 3,5 | 2,470 | 404,9 | |

| 4,0 | 2,730 | 336,3 | |

| Rectangular pipe 40x20 | 2,0 | 1,700 | 588,2 |

| 2,5 | 2,070 | 483,1 | |

| 3,0 | 2,420 | 413,2 | |

| 3,5 | 2,750 | 363,6 | |

| 4,0 | 3,050 | 327,9 | |

| Rectangular pipe 40x25 | 2,0 | 1,860 | 537,6 |

| 2,5 | 2,270 | 440,5 | |

| 3,0 | 2,660 | 375,9 | |

| 3,5 | 3,020 | 331,1 | |

| 4,0 | 3,360 | 297,6 | |

| Rectangular pipe 40x30 | 2,0 | 2,020 | 495,0 |

| 2,5 | 2,470 | 404,9 | |

| 3,0 | 2,890 | 346,0 | |

| 3,5 | 3,300 | 303,0 | |

| 4,0 | 3,680 | 271,7 | |

| Rectangular pipe (42)x20 | 2,0 | 1,770 | 565,0 |

| 2,5 | 2,150 | 465,1 | |

| 3,0 | 2,520 | 396,8 | |

| 3,5 | 2,860 | 349,6 | |

| 4,0 | 3,170 | 315,4 | |

| Rectangular pipe 45x20 | 2,0 | 1,860 | 537,6 |

| 2,5 | 2,270 | 440,5 | |

| 3,0 | 2,660 | 375,9 | |

| 3,5 | 3,020 | 331,1 | |

| 4,0 | 3,360 | 297,6 | |

| Rectangular pipe 45x30 | 2,0 | 2,170 | 460,8 |

| 2,5 | 2,660 | 375,9 | |

| 3,0 | 3,130 | 319,5 | |

| 3,5 | 3,570 | 280,1 | |

| 4,0 | 3,990 | 250,6 | |

| Rectangular pipe 50x25 | 2,0 | 2,170 | 460,8 |

| 2,5 | 2,660 | 375,9 | |

| 3,0 | 3,130 | 319,5 | |

| 3,5 | 3,570 | 280,1 | |

| 4,0 | 3,990 | 250,6 | |

| Rectangular pipe 50x30 | 2,0 | 2,320 | 431,0 |

| 2,5 | 2,860 | 349,6 | |

| 3,0 | 3,360 | 297,6 | |

| 3,5 | 3,850 | 259,7 | |

| 4,0 | 4,300 | 232,5 | |

| Rectangular pipe 50x35 | 2,0 | 2,490 | 401,6 |

| 2,5 | 3,090 | 323,6 | |

| 3,0 | 3,600 | 277,8 | |

| 3,5 | 4,120 | 242,7 | |

| 4,0 | 4,620 | 216,4 | |

| Rectangular pipe 50x40 | 2,0 | 2,650 | 377,3 |

| 2,5 | 3,250 | 307,7 | |

| 3,0 | 3,830 | 261,0 | |

| 3,5 | 4,390 | 227,8 | |

| 4,0 | 4,930 | 202,8 | |

| Rectangular pipe 60x25 | 2,5 | 3,050 | 327,9 |

| 3,0 | 3,600 | 277,8 | |

| 3,5 | 4,120 | 242,7 | |

| 4,0 | 4,620 | 216,4 | |

| 5,0 | 5,550 | 180,1 | |

| Rectangular pipe 60x30 | 2,5 | 3,250 | 307,7 |

| 3,0 | 3,830 | 261,0 | |

| 3,5 | 4,390 | 227,8 | |

| 4,0 | 4,930 | 202,8 | |

| 5,0 | 5,940 | 168,3 | |

| Rectangular pipe 60x40 | 3,0 | 4,300 | 232,5 |

| 3,5 | 4,940 | 202,4 | |

| 4,0 | 5,560 | 179,9 | |

| 5,0 | 6,730 | 148,6 | |

| Rectangular pipe 70x30 | 3,0 | 4,300 | 232,5 |

| 3,5 | 4,940 | 202,4 | |

| 4,0 | 5,560 | 179,9 | |

| 5,0 | 6,730 | 148,6 | |

| 6,0 | 7,800 | 128,2 | |

| Rectangular pipe 70x40 | 3,0 | 4,780 | 209,2 |

| 3,5 | 5,490 | 182,1 | |

| 4,0 | 6,190 | 161,6 | |

| 5,0 | 7,510 | 133,1 | |

| 6,0 | 8,750 | 114,2 | |

| Rectangular pipe 70x50 | 3,0 | 5,250 | 190,5 |

| 3,5 | 6,040 | 165,6 | |

| 4,0 | 6,820 | 146,6 | |

| 5,0 | 8,300 | 120,5 | |

| 6,0 | 9,690 | 103,2 | |

| Rectangular pipe 80x40 | 3,0 | 5,250 | 190,5 |

| 3,5 | 6,040 | 165,6 | |

| 4,0 | 6,820 | 146,6 | |

| 5,0 | 8,300 | 120,5 | |

| 6,0 | 9,690 | 103,1 | |

| 7,0 | 10,990 | 91,0 | |

| Rectangular pipe 80x50 | 3,0 | 5,720 | 174,8 |

| 3,5 | 6,590 | 151,7 | |

| 4,0 | 7,440 | 134,4 | |

| Rectangular pipe 80x60 | 3,5 | 7,140 | 140,0 |

| 4,0 | 8,070 | 123,9 | |

| 5,0 | 9,870 | 101,3 | |

| 6,0 | 11,570 | 86,4 | |

| 7,0 | 13,190 | 75,8 | |

| Rectangular pipe 90x40 | 3,5 | 6,590 | 151,7 |

| 4,0 | 7,440 | 134,4 | |

| 5,0 | 9,080 | 110,1 | |

| 6,0 | 10,630 | 94,1 | |

| 7,0 | 12,090 | 82,7 | |

| Rectangular pipe 90x60 | 4,0 | 8,700 | 114,9 |

| 5,0 | 10,650 | 93,9 | |

| 6,0 | 12,510 | 79,9 | |

| 7,0 | 14,290 | 70,0 | |

| Rectangular pipe 100x40 | 4,0 | 8,070 | 123,9 |

| 5,0 | 9,870 | 101,3 | |

| 6,0 | 11,570 | 86,4 | |

| 7,0 | 13,190 | 75,8 | |

| Rectangular pipe 100x50 | 4,0 | 8,700 | 114,9 |

| 5,0 | 10,650 | 93,9 | |

| 6,0 | 12,510 | 79,9 | |

| 7,0 | 14,290 | 70,0 | |

| Rectangular pipe 100x70 | 4,0 | 9,960 | 100,4 |

| 5,0 | 12,220 | 81,8 | |

| 6,0 | 14,400 | 69,4 | |

| 7,0 | 16,480 | 60,7 | |

| Rectangular pipe 110x40 | 4,0 | 8,700 | 114,9 |

| 5,0 | 10,650 | 93,9 | |

| 6,0 | 12,510 | 79,9 | |

| 7,0 | 14,290 | 70,0 | |

| Rectangular pipe 110x50 | 4,0 | 9,330 | 107,1 |

| 5,0 | 11,440 | 87,4 | |

| 6,0 | 13,460 | 74,3 | |

| 7,0 | 15,380 | 65,0 | |

| Rectangular pipe 110x60 | 4,0 | 9,960 | 100,4 |

| 5,0 | 12,220 | 81,8 | |

| 6,0 | 14,400 | 69,4 | |

| 7,0 | 16,480 | 60,7 | |

| Rectangular pipe 120x40 | 5,0 | 11,440 | 87,4 |

| 6,0 | 13,460 | 74,3 | |

| 7,0 | 15,380 | 65,0 | |

| 8,0 | 17,220 | 58,1 | |

| Rectangular pipe 120x60 | 5,0 | 13,000 | 76,9 |

| 6,0 | 15,340 | 65,2 | |

| 7,0 | 17,580 | 56,9 | |

| 8,0 | 19,730 | 50,7 | |

| Rectangular pipe 120x80 | 5,0 | 14,580 | 68,6 |

| 6,0 | 17,220 | 58,0 | |

| 7,0 | 19,780 | 50,5 | |

| 8,0 | 22,250 | 45,0 | |

| Rectangular pipe 140x60 | 5,0 | 14,580 | 68,6 |

| 6,0 | 17,220 | 58,0 | |

| 7,0 | 19,780 | 50,5 | |

| 8,0 | 22,250 | 44,9 | |

| Rectangular pipe 140x80 | 5,0 | 16,150 | 61,9 |

| 6,0 | 19,110 | 52,3 | |

| 7,0 | 21,980 | 45,5 | |

| 8,0 | 24,760 | 40,3 | |

| Rectangular pipe 140x120 | 6,0 | 22,880 | 43,7 |

| 7,0 | 26,370 | 37,9 | |

| 8,0 | 29,780 | 33,6 | |

| 9,0 | 33,100 | 30,2 | |

| Rectangular pipe 150x80 | 6,0 | 20,050 | 49,9 |

| 7,0 | 23,080 | 43,3 | |

| 8,0 | 26,010 | 38,4 | |

| 9,0 | 28,860 | 34,6 | |

| 10,0 | 31,620 | 31,6 | |

| Rectangular pipe 150x100 | 6,0 | 21,930 | 45,6 |

| 7,0 | 25,280 | 39,6 | |

| 8,0 | 28,530 | 35,0 | |

| 9,0 | 31,690 | 31,6 | |

| 10,0 | 34,760 | 28,8 | |

| Rectangular pipe 180x80 | 7,0 | 26,370 | 37,9 |

| 8,0 | 29,780 | 33,6 | |

| 9,0 | 33,100 | 30,2 | |

| 10,0 | 36,330 | 27,5 | |

| 12,0 | 42,520 | 23,5 | |

| Rectangular pipe 180x100 | 8,0 | 32,290 | 31,0 |

| 9,0 | 35,930 | 27,8 | |

| 10,0 | 39,470 | 25,3 | |

| 12,0 | 46,290 | 21,6 | |

| Rectangular pipe 180x150 | 8,0 | 38,570 | 25,9 |

| 9,0 | 42,990 | 23,3 | |

| 10,0 | 47,320 | 21,1 | |

| 12,0 | 55,710 | 17,9 |

Specifications

Let's consider the main technical characteristics of a profile steel pipe:

- Profile view. Its main types are: square, rectangular and oval. This criterion determines the division of pipe profiles in the general assortment.

- Geometric dimensions. For rectangular views, this is the width and height. And also the length of each segment.

- Wall thickness. Quite a significant detail, because it determines the scope of further use.

- Weight. An equally significant assessment that determines the quality level of goods. Using weight and geometric dimensions, you can find out the thickness of the walls. This becomes very useful in situations where there is no access to measurements.

When describing steel corrugated pipes, it should be noted that their range is determined by GOST 8639-82. In this document, three main types of profile are distinguished:

- Cold-formed.

- Hot rolled.

- Electric welded.

The first two are seamless, and the third is made from sheet material using welded technologies.

It should be noted that any characteristic of a pipe depends on a number of its other indicators. For these reasons, we can conclude that the presence of a table of the corresponding calculated GOST values makes it possible to easily find out how high the level of quality is from a particular manufacturer.

Limit deviations and tolerances

The maximum deviations in the wall thickness of the profiles must correspond to the maximum deviations in the thickness of the initial workpiece with a width of 1250 mm of normal rolling accuracy B according to GOST 19903 . Maximum thickness deviations do not apply to bending areas.

- Maximum deviations in height and width of the profile must correspond to:

- with profile height (width) up to 100 mm ... ±1.0, but not less

- with a profile height (width) over 100 mm ... ± 0.8.

- Tolerances for external rounding radii must comply with:

- at t ≤ 6.0 mm…………….from 1.6t to 2.4t

- at 6.0 < t ≤ 10.0 mm……..from 2.0t to 3.0t

- at t ≥ 10.0 mm……………from 2.4t to 3.6t.

In the cross section of the profile, deviations from the angle of 90° should not exceed ± 1°30′.

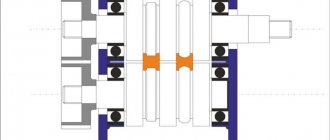

Features of the production of profile metal pipes

According to the production method, profile pipes are either hot- or cold-formed. Due to the plasticity of metals, profiling of any steel workpiece is possible under the influence of high temperatures. On a cut (section) the pipes have the following shape:

- square;

- rectangle;

- oval

Flat-oval arched profiles (or oval pipes) are no less in demand, and their production is growing. The technology for forming them is practically no different from rolling standard professional pipes. This is like an intermediate option between round and rectangular structures, and their quality and endurance indicators are an order of magnitude higher than those of these products. The technology for producing standard pipe sizes involves:

The cross-section of the pipes has the shape of an oval, square or rectangle

- method of cold molding of rounded products using a press;

- welding rectangular steel sheets.

Important! The cost of rolled steel with a welded seam is lower than the price of solid pipes. There is no need to doubt their quality: the joint is checked with a flaw detector before receiving a certificate and an acceptance certificate.

In accordance with GOST, pipes of any size (in inches and mm) are formed using two technologies that differ significantly from each other:

- By welding a sheet or strip profile (the seam can reduce the quality of the product only under significant loads, and the product has a lower price).

- Rounded rods are pressed into blanks of the same shape at a rolling mill (the technology is more expensive; seamless products bear the maximum load in vertical frames).

Pipes are produced by cold forming rounded products using a press and welding rectangular sheets

What is the best way to transport corrugated pipe from the metal depot to your site?

So, rolled products are produced in lengths from 6 to 12 meters.

8-12 meters

Only cargo or special transport. It will cost a pretty penny.

6 meters (the most common option)

Delivery of such a long length is possible using the so-called Katyusha gazelle (one end is placed on a horizontal crossbar, the other diagonally into the body). Renting a Gazelle will cost approximately 2 times less than a truck.

Any organization that trades in rolled metal has a base of private traders - shabashniks. Ask the manager to contact them or pick up the phone and chat yourself.

In our case, there was no personal presence during loading. The driver independently loaded himself at the base, controlled the amount of material and delivered the cargo within 1 hour. Very comfortably.

3 meters

For a small surcharge you can order a cut in half of a standard 6-meter profile. In this case, three-meter sections of profile pipe can be placed in any passenger car with a hatchback or station wagon body. The rear 5th door remains open; we place a dimensional load sign on the end of the pipe.

The organization from which you will purchase can offer additional services:

- Cut to size

- Drilling holes

- Bending to radius

It is very tempting to get the necessary blanks right away, but there will definitely be an error. In our case, on each pipe the size was a plus by 15-20mm and we still had to trim it ourselves with a grinder.

How we bent a corrugated pipe last summer to then build a greenhouse

We completed the bending task using a homemade pipe bender.

Read more >>> Using a pipe bender and a professional pipe, we assembled the greenhouse with our own hands. To view the progress of work in detail, click here >>>

Product advantages

The main advantage of rectangular profile pipes is their significant spatial rigidity compared to products with a round cross-section. For example, if such a corrugated pipe is used as a load-bearing beam and the load is at an angle of 90 degrees to any plane, the bending resistance of the profile will be approximately 35% greater than that of other products. This indicator is close to the characteristics of a solid steel rod.

Due to their flat surfaces, rectangular products are easier to process. Painting and priming them is much easier, and protective coatings adhere better to such surfaces. Unlike a channel or an I-beam, such products do not have hard-to-reach places for processing. This improves corrosion resistance.

Also, the flat edges of rectangular corrugated pipes provide good ergonomics. The profiles are firmly connected to any structural elements. They are convenient to install on load-bearing surfaces. Also, such products take up minimal space and do not create dead zones at the base.

The presence of planes guarantees high resistance during storage and transportation.