Cast iron is used to produce manifolds, pulleys and pipes. The material is characterized by good casting qualities, which helps to produce products of various configurations. However, the alloy has a significant drawback - fragility. When struck, damage occurs, to eliminate which semi-automatic welding of cast iron is used. There are several ways to use such equipment.

Welding work on cast iron is quite complex technologically.

The problem of welding cast iron with a semi-automatic machine

It is difficult to weld cracks in parts made of such an alloy. During the work process, the welder faces the following difficulties:

- The increased fluidity of cast iron prevents the formation of a strong seam. Excessive dilution of the weld pool does not allow a thorough assessment of the quality of the joint. When welding thin plates, burns occur and drops of the melt flow out. The use of fire-resistant substrates helps prevent the development of such a situation. You can learn how to form seams under conditions of increased metal fluidity by regularly practicing on unnecessary workpieces made of a similar alloy.

- Another difficulty is the low melting point. The electric arc heats the welding site to extreme temperatures. Cast iron quickly overheats, which causes gaps to form between the edges and the filler material during the solidification process. If cast iron contains silicon or magnesium additives, hard inclusions appear in the structure of the welded joint, making grinding of the weld more difficult. Slow heating of the workpiece before welding and gradual cooling of the structure after completing the work help to avoid the formation of defects.

- It is also difficult to brew cast iron due to the presence of many pores that arise when carbon is released. Even careful processing of the seam does not improve its aesthetic qualities or increase its resistance to mechanical stress. Copper-plated welding wire is used to protect the connection. The process takes place in a protective gas environment. The filler material used must contain flux.

Cast iron has a low melting point.

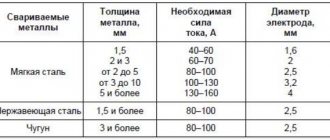

What electrodes are used

Not all types of consumables can be used for welding brittle alloy. Before starting work, you should study the basic characteristics of the electrodes.

Non-melting

You can cook cast iron parts using different types of elements:

- tungsten;

- graphite;

- coal.

Cast iron or filler electrodes containing alloying additives (copper, nickel) are used as consumables involved in the formation of the seam. The weld pool is protected with argon or borax-based fluxes. The most common technology is TIG welding with a tungsten rod under alternating current.

Simple for steel

Welding cast iron elements with conventional electrodes does not allow obtaining a high-quality seam. Such consumables are used due to their low cost. To reduce the likelihood of defect formation, filler rods of the TsCh-4 brand are used. They are designed to form the first cladding layer with further continuation of welding with simple materials.

UONI electrodes are used only to eliminate small defects in structures that do not experience high loads.

Covered with additional metal

Such elements are used for welding cast iron with an electrode at home when it is necessary to eliminate casting defects. They have the form of round bars coated with protective materials. Most often, the welding process is carried out with direct current. Variable is used less frequently. The required current strength is calculated using the formula 50-60 A per 1 mm of electrode. When electric welding with coated elements, the seam turns out to be non-uniform.

Types of welding methods available

The method is chosen taking into account the purpose of the parts being connected. The methods differ in the speed of connection formation and the cost of work.

Cold welding method

This is the simplest method of joining workpieces made of an alloy with a high carbon content. The material is not heated before starting work; it must be at room temperature. The cold method is intended for welding structures subject to minimal loads. It can be used to restore worn surfaces of cast iron products.

We recommend reading: How to work with cast iron using cold welding

Continuous supply of filler material helps to quickly form a seam and carry out large repair work in a short period of time. The connection obtained by the cold method has average performance qualities.

Cold welding is a simple joining method.

Semi-hot method

Before cooking cast iron semi-automatically using this method, the workpieces are heated to +350 °C. To do this, heat from coals is used to create the necessary conditions. Preparatory work prevents changes in the structure of cast iron during welding. In this case, under the influence of an electric arc, fewer cracks appear.

The technology is used in the assembly of structures subject to medium loads.

Hot welding method

This method is used when it is necessary to obtain a strong welded joint. Before starting work, the workpieces are heated to +600 °C. For this purpose, installations that generate inductive currents are used. Cables are connected to the part, and a measuring device monitors the temperature. After reaching the required values, an electric arc is excited, with the help of which a seam is formed.

The hot welding method is used to obtain a strong connection.

Leaving the structure in the ash until completely cooled helps reduce the likelihood of cracks. The duration of the cooling period depends on the thickness of the workpiece.

The hot method helps to obtain a strong, reliable seam, but it is associated with significant time and material costs.

Useful tips

In some cases, it is more useful to use the “old-fashioned” method of welding cast iron. This option involves the use of a “simple” electrode. First, all irregularities and roughness are eliminated using an angle grinder. The electrode must be wrapped with copper wire. “Minus” is applied to the part, and “plus” is applied to the electrode. Recommended voltage is 80 A.

It is strictly forbidden to overheat cast iron - this is even more harmful than insufficient heating. After finishing the work, tap the seam with a hammer, clean it and look at the result. The most difficult areas can be welded at 120-125 A. Welding without copper is impractical, because the quality of the seam will be too weak.

Quite often the question is how to weld cast iron to metal or, in other words, how to combine it with steel.

It also highlights the already known 3 key methods - cold, hot and intermediate modes. Preference should be given to the second type, because it allows you to achieve the highest quality connection between the welded products. However, you must understand that this is the longest and most labor-intensive process. The semi-hot method is only suitable for high-alloy alloys. And the cold method is recommended exclusively for surfacing, because in other cases it does not work.

Electrodes will help connect steel to cast iron:

- TsCh-4;

- OZCh-2;

- MNC-2.

How to cook cast iron, see below.

Features of semi-automatic welding of cast iron

With the help of such equipment you can restore metal yourself. In this case, any welding mode is selected: MIG welding (using a chemically inactive gas) or MAG welding (surfacing using carbon dioxide).

When using these technologies, the filler material is distributed evenly, and the wire is fed into the weld pool automatically. The use of spot welding on cast iron is not recommended. Due to the limited contact area, thorough heating of the part becomes impossible.

Preparing cast iron for work

The strength of the connection depends on the quality of the edges. Cracks are cut to their full depth before welding. The corners are leveled and polished. The cutting should exceed the width of the defect by 1-2 cm, the depth by 1-2 mm. The locking points are drilled, which increases the reliability of the connection. The cutting is performed at an angle of 45°. Oil stains are removed with a degreasing agent or burned. A graphite stand is placed under thin workpieces. In this case, the metal will not spread. The edges are cleaned of chips and dust, which reduce the strength of the joint.

We recommend reading: How to weld cast iron and steel

Before welding, cast iron must be leveled and ground.

Filler wire selection

Consumable electrodes are used for welding in a carbon dioxide environment. You cannot use regular wire on steel. This contributes to the appearance of a large number of cracks during the cooling process. The choice of wire for cast iron is determined by the welding mode:

- when working with the cold method, consumable electrodes PP ANCh-1 are used;

- the semi-hot method involves the use of the additive PP ANCh-2;

- when welding with heating up to +600 °C, use PP ANCH-3.

The “PP” symbols in the marking indicate the presence of a powder-filled core.

The material contains all the filler components necessary for welding (silicon, iron, copper, nickel). They make the seam stable and durable.

Necessary equipment

Semi-automatic welding is carried out using a machine that continuously supplies filler material into the weld pool. The work area must also be protected with gas or flux. Simple semi-automatic machines are represented by a single module that combines a gearbox, an engine, a feed mechanism, and a gas exhaust system. For large volumes of work, composite equipment is used. The gas burner and the wire feeder of such a unit are enclosed in separate housings. Taking into account the design of electrical circuits, devices are divided into:

- Single-phase semiautomatic devices. They are characterized by compact size and ease of connection to the network. The devices operate from household 220 V sockets.

- Three-phase units. Powered by industrial electrical network 380 V.

Welding is carried out using a semi-automatic machine.

When choosing a device, take into account the type of feeding mechanism, which can be:

- Pushing, located within the body. The device delivers the additive into the sleeve. If you use thin wire, the material may get stuck.

- Pull, built into the burner handle. It draws in the additive, feeding it evenly into the weld pool. The disadvantage is the possibility of excessive thinning of the wire.

- Combined, combining 2 types of mechanisms. The nodes work synchronously, ensuring a stable supply of consumables.

Welding process

The connection of cast iron blanks is performed as follows:

- Prepare the edges of the parts and install a backing if necessary.

- When using the semi-hot or hot method, the parts are heated to the desired temperature. When working with the cold method, this step is skipped.

- Fix the workpieces in the correct position. Start the gas supply, after 10 seconds the electric arc is ignited.

- Slowly move the torch along the seam, holding the tool at an angle.

- The seam is welded again (depending on the thickness of the metal, the action is performed 2-5 times). At this stage, transverse guidance of the electrode is allowed.

- They break the arc and turn off the gas after 30 seconds.

- Clean the seams and leave them under an asbestos or coal layer to cool slowly.

- Perform final connection processing.

We recommend reading: How to weld a cast iron vice with your own hands

The parts are heated to the required temperature.

Connecting cast iron workpieces with a semi-automatic welding machine: hot and cold methods

Cast iron, despite its relative fragility, remains one of the most popular structural metals. This is facilitated by the hardness of the material, resistance to alternating and fatigue loads, and high heat capacity.

Features of technical equipment for the process of semi-automatic welding of cast iron

Welding cast iron is difficult due to the metal's tendency to develop defects and reduce performance characteristics when exposed to high temperatures.

To connect cast iron workpieces and eliminate faults in finished products (cracks, chips, etc.), a simple and fast method of semi-automatic welding is most often used, which, however, requires special equipment. MIG and MAG technologies are acceptable, which involve the supply of inert and active gases, respectively.

Basic equipment

For semi-automatic welding, specialized electromechanical devices are used, which provide a continuous supply of a consumable electrode to the weld pool, as well as protection of the seam from the harmful effects of atmospheric air using flux or gas. Simple “semi-automatic machines” have a single-body design, when the following are combined in a single module:

- welding power source;

- motor, gearbox and passive wire feed units;

- shielding gas injection system;

- device operation control system.

The external elements of such a device include primary and secondary cables, a gas cylinder with a pressure-reducing unit and a discharge hose, and a burner.

For large production volumes, as well as complex welding work, it is advisable to use modular semi-automatic machines.

Their feed mechanism and gas system are located in a separate housing, and the welding power source with the control unit is located in the main module.

If the device is designed for intensive use, the burner can be supplemented with a forced liquid cooling system.

Depending on the design of the primary power circuits, single-phase and three-phase “semi-automatic machines” are distinguished.

The former are attractive due to their compactness and ease of connection to the network, as they operate on 220 V alternating current.

The latter are used in industrial cycles; they are powered by a 380-volt network. An equally important factor is the type of wire feeding mechanism. He can be:

- pushing – located inside the body of the device, pushes the welding wire into the sleeve, which in some cases (for example, when using thin or excessively soft material) can lead to jamming;

- pulling - located inside the torch handle, tightens the wire, ensuring its uniform feeding, which can sometimes lead to unwanted thinning of the material;

- combined - has both pushing and pulling units that act synchronously, and is characterized by stable and uninterrupted operation.

For hose lengths less than 4 meters, feed mechanisms with one pair of support rollers are usually used; for hoses longer than 4 meters, two pairs are used. If the hose length exceeds 8 meters, the only possible feed mechanism is a combination with two pairs of rollers.

Optional equipment

In addition to a semi-automatic machine, for welding cast iron you will need standard tools and materials for surface preparation and personal protection. These include:

- grinding machine (grinder);

- metal brushes;

- degreasing solution;

- dry clean rags;

- welding gloves;

- protective mask.

When welding with gas weld protection, you will need a cylinder with carbon dioxide, argon, helium or a mixture of gases. In some cases (for example, when welding cracks in cast iron crankcases), a hand drill with metal drills and other power tools can be used to pre-process the workpieces.

Filler wire

Semi-automatic welding of cast iron is carried out using a wire-type consumable electrode. The use of electrodes on steel is unacceptable, since in any case this will lead to cracking of the seam when it hardens. The choice of filler wire grade for cast iron depends on the welding mode:

- welding without heating (cold) – PP ANCH-1;

- welding with heating up to 350℃ (semi-hot) – PP ANCH-2;

- welding with heating up to 600℃ (hot) – PP ANCH-3.

The abbreviation “PP” in the wire marking indicates its powder type. This means that the material contains the necessary filler elements (Fe, Ni, Cu, Si, etc.) that provide the necessary strength and stability of the weld.

Approximate cost of cored wire on Yandex.market

Semi-automatic cast iron welding technology

When choosing a welding mode for cast iron, it is important to take into account a number of its physical and chemical features, which make it difficult to work with the material using classical methods. First of all, these include:

- low metal melting point;

- change in the structure of a substance under the influence of high temperatures (“bleaching”);

- high fluidity of cast iron , which increases the risk of burn-through and deformation of workpieces;

- the appearance of pores in the material under the influence of atmospheric oxygen.

This necessitated the use of gentle welding modes with constant protection of the seam by active or inert gas media. Cold and hot technologies for semi-automatic welding of cast iron have become widespread.

Cold way

Cold technology is used mainly in domestic conditions to create seams that do not withstand direct mechanical loads. It is simpler and cheaper, however, it does not provide a sufficiently high-quality connection of the workpieces. The algorithm of actions includes the following:

- Joint processing , edging if necessary.

- Fastening workpieces to the supporting surface with a gap of 1.5-2 mm.

- Setting the semi-automatic CA to low DC mode with reverse polarity.

- Ensuring the supply of shielding gas to the welding zone and ignition of the arc.

- Welding the seam at an angle forward (the slope is 50-60°, which is enough for visual inspection).

- The arc breaks and the supply of shielding gas stops (after 15-30 seconds).

- Cleaning the seam from slag and mechanical treatment.

Unlike MIG and MAG welding of steel, working with cast iron does not require oscillatory and transverse movements of the electrode.

In addition, cold technology allows the application of a single-layer seam at the joints of parts up to 4 mm thick.

Hot way

The best quality of welds in cast iron is ensured by the hot method of semi-automatic welding, which is widely used in repair shops and sometimes in industrial complexes. It requires the following sequence of actions:

- Joint processing , edging if necessary.

- Preparing the supporting surface , installing a graphite lining on it.

- Heating the workpieces in the oven to a temperature of about 600℃.

- Fast fixation of workpieces to the backing and early start of welding with low direct current with reverse polarity in a protective gas environment.

- Welding the seam at an angle forward (the slope is 50-60°, which is enough for visual inspection).

- Repeated welding of the seam (depending on the thickness of the metal, from 2 to 5 layers are applied), during which the method of transverse guiding of the electrode is acceptable.

- The arc breaks and the supply of shielding gas stops (after 15-30 seconds).

- Cleaning the seam from slag , ensuring a slow decrease in the temperature of the part under a layer of asbestos, charcoal or other non-combustible material.

- Final cleaning and mechanical treatment of the seam.

It is important to remember that the speed of semi-automatic welding is much higher than manual welding. If you have not worked with a semi-automatic machine before, practice on scrap cast iron before starting to weld critical joints.

How to cook malleable and high-strength cast iron

Work with these types of alloy is carried out in a carbon dioxide environment using Np-30GHSA, Sv-08G2S or Sv-08GS wire. Preheating of the workpieces is not required. During the welding process, the following rules are observed:

- To reduce the volume of additive in the weld, welding is carried out by covering 1/3 of the width of the bead. The arc should be directed towards the melt. To preserve the structure of cast iron, a method of cascade formation of a joint using annealing rollers is used.

- The use of Np-30GHSA wire promotes the appearance of inclusions in the joint, increasing the strength of the deposited layers.

- Primary welding of especially strong cast iron with steel is performed using consumable material grade Sv-08G2S. The last layer is fused using Np-30GHSA wire.

Methods

Semi-automatic welding of cast iron is possible according to various schemes. Unlike steel, however, cast iron welds very poorly. Therefore, such work must be approached as thoughtfully as possible. Welding cast iron with steel electrodes is prohibited.

Even the most careful work using this scheme inevitably leads to cracking of the seam.

The vast majority of cast iron can be cooked:

- cold;

- hot;

- semi-hot methods.

Working without preheating parts is in demand if you have to weld large structures. But in this case, you will have to use special electrodes. Consumables containing copper, iron and nickel are preferred. Such additives do not increase the fragility of the seam. However, it is still common practice to use hot and semi-hot methods.

Preheating involves the use of either ovens or inductive heaters. Such methods are widely used on an industrial scale. The most important requirement is strict compliance with the thermal regime. Heating the metal to more than 600 degrees is unacceptable. When this level is exceeded, the structure of cast iron inevitably changes and it becomes white.

The semi-hot option is heating to 350-400 degrees. Warm welding is limited to heating up to 250 degrees. When the process is completed, the metal is cooled extremely slowly, sometimes for several days, to avoid cracking of the seam. Hot methods are more labor intensive. However, only they allow you to achieve high-quality connections.

In some cases, cast iron is welded in a protective atmosphere of carbon dioxide. Such protection helps to significantly increase labor productivity.

In addition, carbon dioxide insulation from the external environment is also useful when working in particularly critical areas. For this purpose, cast iron or steel (but with a special coating) electrodes are used. Only cast iron electrodes with a thick protective coating are suitable for hot welding.

In cold mode, you can use electrodes from:

- cast iron;

- steel with a special outer layer;

- steel with copper braid;

- copper-tin mixture;

- copper-nickel composition;

- iron-nickel composition.

Correction of welding defects

The method of elimination depends on the type of deficiency:

- A crater, which is a depression at the end point, reduces the strength of the joint. It is welded again, breaking the arc at the finished section of the seam.

- Undercut - local thinning of the metal is eliminated by fusing a new layer. If the depth of the defect is small, mechanical cleaning is used.

- Lack of penetration occurs when the welding process is interrupted and resumed incorrectly. Such defects negatively affect the resistance of the connection to impacts. To eliminate lack of penetration, increase the current strength.

- Sagging is formed when the melt hits the surface of the part. To prevent its occurrence, increase the arc voltage and reduce additive consumption. Eliminate the defect mechanically.

- A burn-through is a through hole formed when the melt flows out. To eliminate the defect, the damaged areas are re-cleaned and boiled.

The strength of the finished structure depends on the quality of welding. Therefore, after completing the work, carefully inspect the seam.