DIY electric spark pencil

Often there is a need to make an inscription or drawing on the metal panel of the device being created. There are many ways to make inscriptions or drawings on metal: chemical etching, mechanical engraving and a number of others. We will talk about one of them - electric spark engraving.

This method will require an alternating current source with a voltage of 18-20 V, preferably adjustable, and an electrode holder - an electric spark pencil.

A transformer with a power of about 200 W can be used as a current source. One of the terminals of the secondary winding of the transformer is connected using an alligator clip to the workpiece or part on which the inscription needs to be applied. The other terminal is connected to an electrode clamped in an electric spark pencil. Connections are made with an insulated stranded wire with a cross-section of at least 1.5 mm2, ensuring operation with currents of more than 10 A. The connection diagram is shown in Fig. 1.

Fig. 1 Connection diagram of an electric spark pencil to a 220 volt network

An electric spark pencil is a simple clamp for an electrode, the basis of which can be used as a regular collet pencil (Fig. 2). However, due to the high degree of heating during engraving, its plastic body must be replaced with another made of heat-resistant insulating material, for example, PCB or ebonite. The wire coming from the transformer is passed through a hole in the housing and soldered to the collet.

Rice. 2 Electric spark pencil based on a regular collet pencil

The electrode can be a pointed metal rod with a diameter of 02-3 mm, preferably made of a refractory metal, for example, tungsten. But you can use rods from other materials, say, from less scarce graphite. The engraving end of the rod is a cone with an apex angle of about 30°.

When the transformer is connected to the network according to the diagram above, voltage appears on the electrode. Touching the end of the electrode to a metal surface causes a spark discharge to appear, which, melting the metal surface, leaves a noticeable mark on it.

Experience shows that the highest quality inscriptions are obtained at an operating voltage for a tungsten electrode - 8-10 V, for a graphite electrode - 16-18 V. Before applying an inscription, the metal surface must be cleaned of dirt and degreased. Inscriptions and drawings are applied with separate points and tangential movements.

'If desired, an electromagnetic breaker can be introduced into the electrical circuit of the “electric spark pencil”, connected in series to the circuit it breaks, and the pencil can be equipped with a solenoid (in the core of which the collet is fixed) and a spring that returns the collet with the electrode to its original state after opening the circuit. This will somewhat simplify the engraving process, but will complicate the design of the electric pencil.

When operating the described device, it is necessary to observe electrical safety measures, especially when using LATR as a voltage source. To protect your eyes, you must always use safety glasses. Do not allow the transformer to overheat, take breaks during operation.

S. IVANOV, Kursk

Device characteristics

An electric metal marker (EM) has been used in production practice for about 40 years. It is known by many names:

- electric spark marker;

- electrograph;

- electric pencil;

- arcograph.

EM is often used for marking:

- metalworking tools;

- measuring instrument;

- cutting tool;

- printed circuit boards;

- all kinds of tags or nameplates;

- surgical instrument;

- dental instruments;

- all kinds of metal parts.

Structurally, the electric marker is a system of 4 parts:

- Portable power source (usually designed for power from a regular household electrical network with a voltage of 220 V and a frequency of 50 Hz ).

- A vibrator handle with a built-in light filter (it has a regulator of the vibration frequency of the working part of the device).

- Replaceable tips made of spring steel or tungsten wire (diameter from 0.5 to 1 mm)

- Clamp and cable for connecting to the metal surface being processed.

The physical principle of operation of EM is the rapid erosion of the surface of the metal product being processed by breaking down the gap between the electrodes. Their role is played by the working part of the device (cathode) and the metal surface of the product (anode). The treated surface is covered with a series of small holes, with a diameter of 0.1 to 2 mm.

Advantages of electric markers and their standard sizes

An electric marker for metal has a number of advantages over other devices for applying information to metal surfaces:

- the product is not subject to mechanical stress; it can be any thin-walled or complex configuration.

- Attention! The operation of the EM is relatively simple, but still requires a certain skill and careful preliminary calibration of the device

- the treated surface is not subject to corrosion and has a clearly visible matte finish.

- ability to work with various metals and their alloys: steel, titanium, zirconium, iron, copper, aluminum and many others.

- ease of removing the applied pattern - to do this, you just need to re-polish the metal in this place (since the depth of the holes does not exceed 1.5-2 mm ).

- comparative efficiency of the device - at maximum settings it consumes no more than 30-50 W.

- Possibility of long-term continuous operation of the EV - it has built-in overheating protection.

Most EVs have small overall dimensions (on average about 160x130x90 mm) and low weight (from 1,000 to 1,500 g)

Let's start experiments

Decorative patterns using the engraving method are applied to plates, knives, pistols, sabers, medals, cups, and apartment numbers. All patterns and inscriptions are preserved almost forever and do not require expensive and rare consumables or special equipment for execution. The design can be applied to steel, aluminum, brass, copper, and metal alloys. The method does not pollute the environment. It is impossible to wash off or erase the drawing using conventional methods and means.

It is recommended to start by applying simple inscriptions on cutlery. Relatives and friends may appreciate such a gift. You need to prepare for work (photo No. 4).

Photo 2. Engraved wedding rings, the wedding date and the initials of the bride and groom are usually written on them.

- Nail polish that my wife doesn't really need.

- Toothpick with sharp tips.

- You may need an ordinary match.

- Salt.

- Charger for car battery. It can be successfully replaced by charging from a mobile phone.

- Glass or porcelain dishes in the form of a glass, mug or jar.

- Nail polish remover.

The work is done in this order:

- Take a spoon and cover it with nail polish. The entire surface must be varnished very carefully, otherwise there will be defects in the work.

- Using a match or toothpick, a pattern, name, or other image is scratched through the layer of varnish.

- Pour 2 tablespoons of salt into a glass glass or jar. Some people add a spoonful of salt and a spoonful of soda.

- Water is poured into the vessel, the salt is thoroughly stirred until completely dissolved.

- We connect a car or other charger with the positive terminal to the product being processed, and the negative terminal to any metal object that will be placed in a vessel with water. This item could be another spoon, a piece of thick wire, or a metal plate.

- The rectifier is connected to the network. Almost immediately, an etching reaction will begin in the glass with darkening of the liquid. It lasts 1-5 minutes. It depends on the magnitude of the current. The product is checked periodically. After reaching the desired etching depth, it is removed from the container.

- The varnish is washed off with nail polish remover. The result should look something like this (photo No. 3).

Photo 3. Personalized engraved spoons and, interestingly, engraving can be done on various metal objects in a simple home environment.

In this way you can process any metal objects at home. If you make an inscription with varnish, it will be convex on the etched background. For better quality work, it is recommended to purchase a special tool - an engraver. It can operate from the electrical network and from built-in batteries. The kit usually comes with drills of different shapes. They can work on glass, plastics and other materials. Engraved wedding rings are an excellent gift for newlyweds (photo No. 2). But you can do this yourself only when you are completely confident in the result of the work.

The best models. How to choose

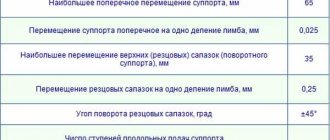

Currently, there are five EV models that are most common on the market. We present their characteristics in the table below.

| Model name | Manufacturer, Country | Size of the applied hole, microns | Maximum character size, mm | Operating voltage, V | Operating current, mA | Power, W | Average price, according to at the beginning 2022 |

| EVZ-021 | Josef Solnar (Czech Republic) | 10×10 | Up to 50 | 220…230 | 200 | 20 | 15000 |

| Progress-001 | (Russia) | 10×10 | Is not limited | 220…230 | 400 | 50 | 8000 |

| EVZ-022 | Josef Solnar (Czech Republic) | 20×50 | Is not limited | 220…230 | 450 | 50 | 20000 |

| AG25/3 | Arglo AG (Switzerland) | 20×20 | Is not limited | 4 | 5000 | 25 | 20000 |

| AG50/6 | Arglo AG (Switzerland) | 20×50 | Is not limited | 6,5 | 6500 | 50 | 25000 |

When choosing an EV, they are usually guided by the ratio of the parameters price - performance - maintainability. Therefore, in our country they usually choose a device produced in St. Petersburg - the Progress - 001 electric metal marker.

Engraving in production

The process is no different from working at home.

Before proceeding, the object is polished and then degreased. Before preparing for the process, the product is tinted with a sulfur solution, which is distributed evenly over the part. The drawing is traced using a metal needle on glued tracing paper. The drawing and shadows are done as realistically as possible to obtain a high-quality result.

Laser engraving in production

Next, the main process occurs; a special engraver produces the drawing and other strokes.

After work, the drawing is covered with a protective layer of colorless varnish or wax. Then the product is wiped dry and polished to obtain shine.

Tools and materials

Engraving involves the use of various equipment. You can find specialized metal engraving machines on sale. They are used to decorate jewelry, tokens, bracelets, and pendants. A milling machine with special cutters is suitable for engraving. It is desirable that they have diamond coating on them.

However, it is better to use a laser machine. This is expensive equipment that allows you to quickly create beautiful drawings.

Engraving tool.

Watch this video on YouTube

How to choose equipment

When choosing laser equipment for metal engraving, you need to pay attention to a number of factors:

- The material from which the guides, bed and working part are made. The structure should not be bent, have cracks or dents.

- Check the operation of the laser upon purchase.

- Control Panel. It is better to buy a machine equipped with a CNC system.

What can a Cheap Laser Engraver with a Power of 1000 mw do? Parcel from China

Watch this video on YouTube

Metal Engraving Tips

Metal cutting is done only with high-quality tools. Equipment and accessories must be purchased in special stores with a quality guarantee. Making a tool at home will require choosing reliable materials. The graver and engravers must be perfectly sharpened to achieve the desired end result. A dull tool can damage the product and injure the craftsman; when working with cutting surfaces, you should follow safety precautions.

In order to engrave metal with your own hands, there are enough methods and technologies. A large number of metals that are engraved make it possible to bring the most creative ideas to life.