A grinder with a cutting disc for metal has long ago almost completely replaced the hacksaw from use. This tool has no equal where, without high precision, it is necessary to quickly and accurately cut off excess reinforcement, divide a pipe into two parts, or prepare dimensional parts from rolled stock for further welding of three-dimensional structures. The main working tool for an angle grinder when cutting metal is a thin disk made of an abrasive mixture based on resins and reinforced with a fiberglass mesh. Despite the very high cutting speeds, these products are much safer than monolithic grinding wheels. The reinforcement does not allow large parts to break off, and the destruction of the disk, as a rule, occurs only due to violation of operating rules and non-compliance with cutting conditions.

Types of cutting discs for metal

The technical characteristics of cutting wheels (or otherwise disks) for working on metal are regulated by GOST R 57978-2017, which provides for two types of this tool: flat (ISO 41) and with a recessed center (ISO 42). The same GOST establishes size ranges and other standardized parameters for both types. Structurally, a metal cutting disc is a sandwich-type structure consisting of alternating layers of reinforcing mesh and cutting composite into which a metal sleeve is pressed (see figure below).

Reinforcing meshes are usually made of fiberglass and, depending on the conditions of use of the tool, can have different thicknesses and cell sizes. The cutting composite consists of abrasive powder and a binder. For cutting metals, powders from various types of electrocorundum and silicon carbide are used as an abrasive, and bakelite resins are usually used as a binder (although GOST also provides for the use of vulcanites).

The structural and physical properties of cutting discs depend on the type of metal being processed. On this basis, international standards provide for four types of tools: for work on structural steel, cast iron, stainless steel and non-ferrous metals. The latter have many variations in hardness, brittleness and toughness, so manufacturers often indicate in their catalogs what specific type of metal a particular type of disk is intended for. In addition, there are cutting tools for manual and machine work, in particular, metal discs intended for grinders must contain the code “Рд” in the marking.

In addition to reinforced abrasive wheels with resin bonds, there are carbide discs for cutting metal on stationary pendulum and miter saws. Such a tool is usually used in the procurement shops of metalworking enterprises; it has a highly specialized application and belongs to circular saws. Another type of cutting tool is diamond discs, but in accordance with GOST 32833-2014 they cannot be used for cutting metals. Sometimes saw blades used in woodworking on circular machines are also classified as cutting blades. Outwardly, they are somewhat similar to cutting wheels for wood processing. But in fact, such saw blades have a different purpose, and are classified by GOST as “circular saws”.

Pros and cons of carbide wheels for metal

I would like to immediately note that carbide discs have quite a lot of advantages over abrasive discs, but the price of the equipment and the discs themselves hinders the popularity of their use. Let's get everything straight!

The advantages include:

- Cutting accuracy. In order to maintain precision when cutting metal workpieces, a carbide blade on a pendulum saw is one of the best options for working.

- Speed of work. You will be surprised at how fast a carbide blade cuts.

- Huge disk resource. On average, the disk life is 5000 cuts. Compared to abrasive, it is immortal.

- No harmful emissions. When working with abrasives, a cloud of small particles is formed in the work area, which negatively affects human health.

- The metal does not heat up. After you cut the workpiece, you can safely handle it; it will be cold. The main advantage is that the properties of the metal do not change without exposure to temperature.

There are also disadvantages:

- Price. The cost of a carbide disc is tens of times more than an abrasive one. At home, with rare use, such a disk will not pay for itself.

- Loss of metal. Since the disc is thicker than an abrasive one, it is worth considering that the cutting line will be thick.

- Afraid of rust. If you decide to saw metal with rust, remember that this will wear out the disc faster.

Concluding all of the above, we can say that carbide wheels are more professional consumables. They have fewer disadvantages than their competitors, but the price makes them inaccessible for home use.

Markings of circles for cutting metal

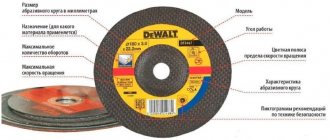

The content of markings applied to the surface of metal cutting wheels is regulated by GOST R 52588-2011 and GOST R 57978-2017. The first determines safety-related labeling data (including operating limits) and information about the manufacturer, and the second determines the physical and technical characteristics of the product. Both GOSTs were developed on the basis of specialized international ISO standards, so the markings of foreign manufacturers are practically no different from GOSTs.

The photo above shows a metal cutting disc from the Luga Abrasive Plant, marked in accordance with state standards. The following fields are indicated by numbers:

- Construction type (ISO 41, flat).

- Geometric characteristics (diameter, thickness, mounting hole). Below, under the red stripe, they are indicated in inches.

- Physical characteristics: type of abrasive (A – electrocorundum); grain size; degree of hardness (Latin T - very hard); bond type (BF – reinforced bakelite).

- Maximum rotation speed.

- Maximum permissible peripheral speed.

- What material is it intended for?

- Safety pictograms.

- Link to regulatory documents.

- Manufacturer's logo.

In addition, GOST P 52588-2011 and international standards oblige manufacturers to apply color markings to their products in the form of a continuous horizontal stripe with a width of 5 to 20 mm, indicating the maximum peripheral speed. For metal cutting discs, this is usually a red stripe corresponding to 80 m/sec (see photo above). Some manufacturers additionally mark their products with color fields in accordance with the group of materials (metals, stone, ceramics, etc.) for which a particular type of wheel is intended for cutting. Such markings in the ANSI and ISO systems only partially coincide, so it is better to focus on signs in the form of inscriptions and pictograms.

Features of aluminum cutting discs

Due to their increased viscosity, non-ferrous metals are difficult to cut with discs designed for working on steel and cast iron.

This occurs due to the fact that during operation, the chips are not removed from the cutting zone, but clog (salt) the space between the abrasive grains and the filler. Therefore, for cutting pure aluminum and its alloys, special discs with a softer bond that is more prone to chipping are used. With this configuration of components, the cutting edge is better self-sharpening, although this increases the wear rate of the tool. Special blades for cutting aluminum are produced by only a limited number of manufacturers; the rest usually indicate a broader purpose in the type of material, for example, “for working on non-ferrous metals.” In general, cutting aluminum with a grinder makes sense only for some one-time work. And for large volumes of aluminum workpieces, cutting and cutting machines with special saw blades for aluminum are much better suited. In the photo below: a disc for working on aluminum from Metabo. Pay attention to the hardness class markings (O means “medium hard”) and compare with the markings of the Luga disk.

Meet me! Carbide blades for metal cutting

The components of all carbide discs are the base and cutting teeth. The number of cutting segments ranges from 24 to 100; the greater the number of teeth, the faster the workpiece is cut. A distinctive feature of the segments is the presence of special solders, which play the main role in cutting. Alloys of cutting teeth can be different, it mainly depends on the manufacturer. In most cases, tungsten-cobalt alloys or tungsten carbide cemented with cobalt are used. Carbide cutting segments are secured by soldering with electrolytic copper solders with the addition of nickel alloys. On many wheel models, you can see slots made to dissipate heat, which extends the life of the carbide wheel.

Such discs are used on pendulum, miter and hand-held circular saws for metal. Of course, there are friction saw blades, which can also be classified as carbide, but this will be the topic of a separate article. Speaking about the distinctive characteristics of carbide discs for metal, each type of metal has its own disc. There are discs for aluminum, discs for high-carbon steel, for low-carbon steel, for thin sheet metal, for sandwich panels, for stainless steel. The most important criteria when choosing are: the diameter of the disk and the diameter of the mounting hole. The most popular diameters are from 200 to 355 mm, the most important thing here is what tool you need the disc for. The same applies to mounting holes, their range is from 20mm. (for hand-held circular saws) up to 30 mm. (for pendulum saws). The number of teeth on the disk is directly proportional to the speed of cutting the material; you should know this when choosing.

You should always check the required number of revolutions, which is indicated on the packaging or on the body of the disk with the passport data of the tool used.

How to choose the right cutting disc

When purchasing a cutting wheel for metal work, you first need to pay attention to its diameter, since it must exactly match the type of grinder on which it will be used.

In addition, you should choose the correct diameter of the mounting hole (22 or 22.2 mm). There is no need to worry about maximum revolutions and peripheral speed, since they are standard for each size. On all cutting discs for angle grinders, in addition to sizes and speeds, it is always indicated in the most visible place (in text or pictogram) what material this sample is intended for cutting. When it comes to metals, there are usually four types: steel, stainless steel, cast iron and non-ferrous metals. In addition, discs are produced for both combined use (usually steel + stainless steel) and for cutting individual non-ferrous metals, in particular aluminum. You definitely need to pay attention to the expiration date (it is stamped on the rim of the sleeve), since bakelite resins are used as a binder in such products, which dry out over time and lose their elasticity. You also need to understand that metal cutting discs of the same type, but from different manufacturers, behave differently during operation. Therefore, in order to avoid surprises, in addition to analyzing standard data, you must definitely look for additional information in customer reviews, on specialized forums, etc. The video below explains how several almost identical disks from different brands differ.

What is important to know about saw blades for aluminum (plastic), steel and multimaterials.

What is important to know about saw blades for metals (aluminum and steel)

A lot of different information can be easily found about saw blades for wood (this is the most popular material for sawing). But, for example, for sawing metals (non-ferrous materials and steel), unfortunately there is not much information. We decided not only to inform you about the main points when choosing or using a saw blade for aluminum, but also to test them and compare them with each other.

Let's start with the fact that saw blades do not have strict standards, unlike other consumables. Tool manufacturers rule the roost here, and the sizes and types of saw blades “dance” from them in the first place. So, metal saw blades can be used on hand-held circular saws, on cross-cutting machines and on stationary or portable sawing machines. Since sawing metals is mostly the job of professional users, accordingly, other requirements are imposed on the size and quality of sawing. It is in the category of saw blades for aluminum that European and world brands and a limited list of Russian brands enjoy the greatest demand and the best reputation. Here is not a complete list of them.

To be precise, there are no more than 5-10 companies in the world that can actually produce high-quality saw blades on a regular basis. Well-known brands, as a rule, are produced at these factories, which almost 100% guarantees consistently high quality of the product.

We published an article about saw blades and their features in one of the previous magazines; it is important to note that practically production is located either in Europe or in China. The quality of saw blades of the same type according to the standard is almost the same, however, they can be easily distinguished, primarily by the quality of welding of carbide plates to the body of the blade itself. This is visible to the naked eye, however, this does not greatly affect the quality of the connection; our tests show this.

Material for sawing. Aluminum, hard plastic, plastics, and plexiglass differ minimally in their structure, so aluminum saw blades are excellent for sawing these materials. However, when choosing, it is important to understand what we want to saw – a hollow piece or a massive one.

Accordingly, some manufacturers indicate on the packaging for which workpieces (hollow or solid) a particular saw blade is best suited. For example, TM ProfOsnastka indicates that for massive workpieces you can use saw blades with the smallest number of teeth, and vice versa; for sawing hollow and thin-walled workpieces, saw blades with the largest number of teeth are best suited. The quality of sawing will depend on this.

Number of teeth. This is an important point, which is a simple standard logic - the more teeth, the higher the quality of the cut, and accordingly the higher the cost of the saw blade, since the cost of the saw blade itself is formed, first of all, by carbide plates - they differ in cost depending on the manufacturer and on their size. In standard logic, the thicker the plate, the greater the number of cuts it will be enough for, provided that the saw blade itself is designed for the corresponding resource. Many people sharpen saw blades. It is important that this can be done efficiently only on appropriate machines, but usually the cost of sharpening is almost close to the cost of a new saw blade (except for large diameter circles for industrial sawing).

Angles and types of teeth.

The result of sawing depends on simple factors: tooth shape, inclination angles, number of teeth. There are no other options, depending on the choice of combinations of three factors - we get the output results. The tilt angle can be negative N (-), positive P (+) and zero, without tilt. Saw blades with a negative angle give the cleanest, high-quality cut in combination with the maximum number of teeth, and vice versa, a positive angle gives the maximum sawing speed when sawing, but together with the smallest number of teeth, the quality of the cut will be significantly worse.

You can read the full article about saw blades in the ProfiToolInfo magazine

Comparison of consumables from popular manufacturers

The main manufacturer of cutting wheels in Russia is the Luga Abrasive Plant, which produces its products under the Luga-Abraziv brand. Its metal cutting discs belong to the lower and middle price categories and occupy the lion's share of the Russian market for this tool. In the same segment and at approximately the same prices, Russian and foreign brands specializing in power tools and gardening equipment offer their Chinese-made abrasive wheels. Global giants like Bosch and Metabo order wheels under their own brands from EU factories. Their products are of high quality, but are much more expensive. The table below provides a small overview of prices for abrasive wheels for cutting metal in the usual series Ø125 mm and 1 mm thick.

| № | Trademark | Bore hole diameter (mm) | Average price (RUB) | Country of Origin |

| 1 | "Bison" | 22,2 | 25 | China |

| 2 | "Luga-Abraziv" | 22, 22,2 | 30 | Russia |

| 3 | Gigant | 22 | 30 | China |

| 4 | Sturm | 22,2 | 32 | China |

| 5 | Stayer | 22 | 36 | China |

| 6 | Fit | 22 | 42 | China |

| 7 | Hitachi | 22,2 | 45 | Russia, "Luga-Abraziv" |

| 8 | Bosch | 22,2 | 85 | EU |

| 9 | Metabo | 22,2 | 90 | EU |

In addition to abrasive metal cutting wheels for grinders, you can find similar products on sale intended for other power tools. These are cutting discs with a diameter of 350÷400 mm for Husqvarna rail cutters and the like, as well as mini-discs Ø32 of the “Dremel” type for mounting on equipment with a cylindrical shank.

Diamond blade manufacturers

The following companies are deservedly popular among manufacturers:

- Bosch. German leader in the production of power tools and related materials.

- FIT. The Canadian company produces tools for professional and household use.

- Dremel American company producing high quality power tools.

- Husqvarna. A Swiss company that is known for its high performance and level of durability.

- MESSER. A Korean manufacturer that produces a wide range of attachments for grinders.

- Zubr. Russian company producing power tools and cutting equipment.

- Hitachi Power Tools, Luga Abrasiv Extra. Has excellent value for money.

Diamond cutting discs are an effective tool with high productivity and provide comfortable conditions when performing work. Do you have experience working with them? Be sure to share it in the comments to this article.

How to calculate the consumption of a cutting disc

There are no modern centralized regulatory documents regulating the consumption of cutting wheels for metal.

Therefore, to solve this problem, you can go in two ways. The first is to use the developments of Soviet times, for example, the departmental standards of the USSR Ministry of Installation and Special Construction VSN 434. In this document, in section 5 “Method for calculating consumption rates of reinforced abrasive wheels”, you can find tables that provide standards for the number of cuts with one wheel and their consumption per shift for each standard sizes of rolled ferrous metals and pipes. The main disadvantage of this method is the problem of non-repeatability of the parameters of cutting wheels of the same type purchased by users on the modern Russian market. Therefore, it is best to adopt your own standard for each batch of purchased disks by carrying out test cutting with several of them on certain types of metal workpieces (sheet, pipe, fittings, etc.). In this way, over time, you can accumulate a sufficient database, analyze patterns and develop your own standards with correction factors.

There is often a statement that stone cutting wheels can be used to cut non-ferrous metals without any problems. What do you think about this? Please share your opinion in the comments.