SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

From this article you can learn the features of such a tool as a disc cutting machine for metal: types of designs, advantages and disadvantages, technical characteristics. Here you can get acquainted with the products of the most popular and sought-after manufacturers. The article examines in detail the technical and operational features of machines designed for cutting metal, and also provides a comparative description of market prices.

Disc devices for cutting metal have many configurations and can be used both in industry and in a small home workshop

Disc cutting machine for metal: scope of application

A cutting machine designed for working with metal is an electric tool with a high level of performance. This type of equipment is used for cross cutting of rolled metal blanks, as well as products made from metals and various alloys.

Disc machines are used to form workpieces from materials such as:

- corner;

- metal strip;

- rod;

- I-beam;

Disk equipment is considered the most popular among metal cutting devices

- profile pipe having a round or square cross-section;

- channel;

- other rolled metal elements.

Note! Disk equipment is considered the most popular. Band saws and hacksaw machines are also used for cutting metal, but they are less popular.

Disk equipment is used at metalworking industry facilities, as well as at factories involved in the manufacture of metal structures. A circular saw is used as a cutting element.

Machine designs have many advantages:

- simple structure;

- high-quality metal cutting;

- ergonomic control;

- ease of operation.

The equipment can be operated by an operator who does not have special qualifications.

Automatic Disc Cutting Machine

Band-cutting machines for metal use a long toothed saw as a cutting element, which has the appearance of a closed band. The material for the manufacture of this part is high-speed steel. Thanks to the minimum cutting width, material loss is reduced and an accurate cut is obtained. This type of equipment is most often used in large and serial production.

A hacksaw blade is used to cut metal workpieces in hacksaw units. It is mounted on the saw frame. Such machines can have a manual or electromechanical operating principle. Hacksaw machines are used in small enterprises and in procurement shops.

The device of a disc cutting machine for metal

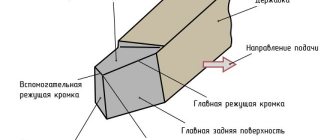

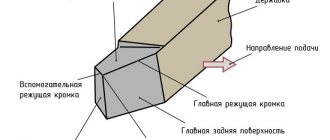

The equipment is assembled on a platform. This structure can have a metal or rigid base. Moreover, the placement of the machine components is not stationary, but removable. The tool is equipped with a vice with a reliable stop, thanks to which workpieces with different types of configuration are firmly held during the cutting process.

For cutting metal, a disk made of high-speed or carbide steel is used. Instead, a circle made of material with an abrasive hard surface can be used.

The rotational motion is transmitted to the cutting element from the electric motor through a gear or belt drive. The first option is installed on stationary equipment with a high power reserve, the second is suitable for compact tools with a portable design.

Disc cutting devices use wheels made of carbide steel or abrasive material as a cutting tool.

Note! There are modifications of machines where the disk is connected to an electric motor without a drive (directly). Household units with low power have this structure.

Classification of cutting machines for cutting metal

Disc equipment for cutting metal is divided into 4 classes. A tool belonging to the first category is considered universal. With the help of such machines you can process any metal products, and in large quantities. The fourth class of equipment includes household tools.

Tool classification based on the number of cutting edges:

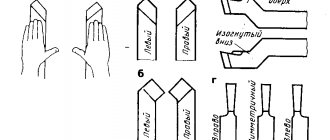

- Single-head - the design has one disk, so the equipment has low efficiency. The tool can be used exclusively to perform one operation, for example, cutting a workpiece intended for a frame profile.

- Double-head - the tool is equipped with 2 cutting elements, which allows you to perform several operations with metal simultaneously. One of the heads is rigidly fixed, and the second moves. Cutting a frame profile requires only one operation, so double-head machines can be used automatically. Thanks to this, the efficiency of the tool is doubled.

An example of a wire straightening machine. Model I6119K-SERVO

Classification of equipment according to the method of feeding the cutting element:

- pendulum cutting machines for metal;

- tool with front disc feed;

- machine with bottom feed of the cutting element.

Types of machines:

- straight-cutting;

- abrasive cutting;

- cutting saws.

Helpful advice! Equipment should be selected taking into account the tasks for which it will be used. Only in this way can the capabilities of the tool justify the cost of its purchase.

Design Features

All industrial processes related to metal processing are inevitably associated with its cutting.

To cut rolled metal quickly and efficiently, use an abrasive cutting machine. Vulcanite is used for processing workpieces made of various types of metal. At an affordable price, it has a number of design features that provide advantages during operation.

One of the features that an abrasive cutting machine has is that it can cut workpieces at an adjustable angle. The cutting angle is set not only directly at the place where the workpiece is installed, but also by rotating the cutting disk itself. This is especially convenient in cases where the size of the workpiece does not allow it to be rotated without difficulty or the room allocated for metal processing is too cramped. The rotation angle is 45 in one direction from the central axis and 45 in the other. For this purpose, a model is used in which a pendulum mechanism and a rotating head are installed. This system allows you to control the cutting angle without changing the position of the workpiece.

The bed that the abrasive cutting machine has is strong and rigid, since a large load can be placed on it during operation. The blanks are attached to the table in one of two ways:

- Foot method - this allows you to do cutting much faster, since fixing before cutting takes less time.

- The traditional method is using a clamp or vice. This method of fixation is slower, but when working with small workpieces it is much more convenient.

Vulcanite works by using electricity. Depending on the needs of the buyer, various modifications can be equipped with engines with power from 2.2 to 5.5 kilowatts. The belt drive ensures the transmission of force from the motor to the cutting shaft. The number of belts at different capacities can range from two to four.

The abrasive cutting machine is started and stopped using a control unit equipped with “START” and “STOP” buttons. Rolled metal is cut using a cutting wheel. Its diameter is 400 millimeters.

Dimensions allow you to carry out cutting even in small spaces, and if necessary, move it to a convenient place. Dimensions are 710 by 910 by 145 millimeters, and the total weight is only 75 kilograms.

Indispensable in a variety of industries that have one or another relation to metal processing. Factories and workshops cannot do without cutting rolled metal. Can be used both in closed areas and in open spaces.

Manufacturers of pendulum saws

The safest and most technologically advanced models are produced by the following companies:

- Makita;

- Corvette;

- Bosch;

- DeWALT;

- Hitachi;

- Metabo.

Pendulum saws are usually characterized by a fairly small cutting width. To increase this parameter, professional saws have a special traction function. On these machines, the working unit is mounted on rods.

Many manufacturers can expand the basic configuration by offering a wider table, however, if you need to work with larger materials, additional supports will not be superfluous.

1. For example, the Makita LF1000 miter saw has special folding stands that make it easier to work with.

The stable frame of pendulum saws holds the moving part. The bed itself has a round section for more convenient setting of the cutting angle.

If aluminum or magnesium alloy was used to make the frame, then such models are more reliable by default. These elements are not only highly durable and reliable, but also lightweight, so this miter saw is mobile.

Video:

2. The Corvette miter saw boasts the following advantages, which distinguishes it favorably from tools produced by competitors. The advantage of the Corvette is the presence of a laser pointer and longitudinal broach.

The latest models are even more improved, since they can increase the cut to 43 cm.

Video:

3. Pendulum saws from DeWALT, in turn, also offer an interesting solution - the unique XPS system.

It boils down to the fact that a shadow will be projected from the disk during operation, acting as additional lighting. Thanks to this, cutting is more accurate.

Video:

Device

The design is stationary. It has a rigid metal base and is installed on a platform that provides stability on the floor. Some parts of the housing can be removed in order to, if necessary, gain access to repair and maintenance of various equipment components. The clamping device is equipped with a foot drive, which allows you to quickly and reliably fix the workpiece. If necessary, the foot drive can easily be replaced with a classic screw-type vice. Metal cutting is done using a hard cutting disc.

Choice

In order to choose an abrasive cutting machine in a suitable modification, it is extremely important to know which characteristics need to be given the most attention. One of the most important selection criteria is power. Power determines how fast the disk can operate, and therefore performance. It is also important to take into account what size workpieces you will need to work with. Equally important are the metals that need to be processed. This determines which disk is suitable for the job.

Among the most popular models of vulcanite is STEC-5. This is a fairly mobile structure that can be moved around the workshop or site quickly and easily. STEK-5 is also distinguished by high power, which allows you to speed up the production process. It is easy and convenient to work with, and cutting is done quickly and efficiently.

With the right choice of blade, you can cut not only metal, but also other materials:

- Various types of steel.

- Other ferrous and non-ferrous metals.

- A natural stone.

- Ceramics.

- Polyvinyl chloride.

If a significant load on the device is not planned, you can choose simpler and less powerful models, STEC-2 or STEC-3. They are suitable for moderate loads. The STEC series is distinguished by a high level of operator safety. Operator contact with the disc is prevented by a special protective metal casing. The working tool can be changed quickly and easily thanks to the convenient fastening.

Self-production of a cutting machine

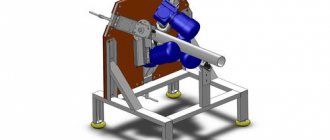

A homemade cutting machine can be made using the following tools and materials:

- steel corner;

- drill;

- electric motor;

- starting circuit;

- wooden shield;

- channel;

- welding machine;

- bearing pair;

- switch;

- coil;

- box to ensure the operation of the electrical circuit.

Instead of a wooden board, you can use a steel sheet, which will be used to make a working surface. Once all the tools are prepared, a frame or frame of suitable dimensions can be made. For this, corner No. 25 is usually used.

The design blanks according to the drawing must be cut with a grinder, and then you can start welding. The finished frame is mounted on vibration supports of the legs, which facilitate the operation of the equipment. The legs can be made from tubes of small diameter or profile. When automatic cutting machines are manufactured, channel No. 10 should be welded to the table; it will serve as a guide axis. This part will act as the basis of the structure for fixing the cutting part of the equipment and connecting it to the engine. At the next stage, the main parts are fixed to the channel, this should also include two vertical posts that can be secured with bolts.

Scope of application

The abrasive cutting machine is used to carry out several types of metal processing:

- When cutting large workpieces into smaller ones.

- Removing excess from finished metal products.

- Cut the metal blanks to the required node.

It is important to remember that when working at high power, vulcanite must be attached to the floor. For this purpose, special holes are made on the legs to allow fixation using anchors. Otherwise, it may vibrate excessively and pose a hazard to the operator and other personnel, and the cut will not be made with the required accuracy.

Purpose of cutting machines

Cutting machines are used to form sections of angles, pipes, channels and other copper products. An electric motor is installed on the base during the manufacturing process of the device; it is connected to the drive shaft using a gear system. Compact and household models are characterized by the installation of a system for fixing the disk on the motor shaft.

There are also cutting machines, which are entire production complexes; they have high productivity, which is why the devices have gearboxes. The material is cut using the method of lowering the disk onto the surface, which leads to the formation of a cut.

Operating rules

Before you start working, it is important to familiarize yourself with the operating rules and safety precautions. So, the room should have:

- High-quality lighting, both natural and artificial.

- Exhaust hood or at least good ventilation to remove abrasive metal dust generated during work.

- Controlling the absence of flammable and combustible substances that could flare up when struck by a spark.

- Reliable clamp for securing workpieces during work.

Any work can be carried out only after it has completely stopped and turned off. This is especially true for the blade for cutting workpieces - changing it while the power is on can be extremely dangerous. In addition, it is necessary to provide reliable protection against moisture entering the engine and damage to its parts by corrosion.

Important! Under no circumstances should you install unsuitable discs. Before installation, you must know the exact size of the disk and determine its suitability for the materials being cut.

The field for placing the disc must have a rigid base and a durable surface. It is important that during operation the vibration that occurs does not cause deformation of structural elements. In addition, it is necessary to comply with standard requirements for the load level in the network, the presence of grounding and residual current devices.

Safety precautions at work

A pendulum saw is a tool that has a cutting block and operates at high speed. Therefore, in order to avoid injury during work, it is necessary to follow safety measures.

- Before turning on the tool, you must check it and the electrical cord for external defects, as well as the rated voltage of the network.

- The device should be placed in a well-lit and ventilated room, away from fuels and lubricants.

- It is necessary to install disks of the appropriate mounting diameter on the saw.

- Do not use discs that are mechanically damaged or poorly sharpened.

- If the blade jams, the saw must be turned off by turning off the start switch.

- Do not touch the rotating disk, much less try to stop it.

- The cutting unit must be protected by a special casing.

- You should use personal protective equipment, such as glasses, gloves, earplugs.

- Do not stand in front of the cutting line while working.

- The disc is not allowed to go beyond the edge of the table.

Compliance with these minimum requirements will help prevent injury.

Useful tips

The disk type of drive that has an abrasive cutting machine requires a special approach to work, and the following rules will help reduce the cost of consumables:

- Long pieces need to be cut at the edge. If you start cutting between the support points, this may cause the blade to jam and break.

- You can start cutting metal only after waiting for the disk to spin up to the maximum number of revolutions.

- It is important to regulate the pressure on the disc. If the speed decreases, it is necessary to slightly reduce the degree of pressure. If there is no resistance, the pressure increases.

- Cutting does not begin abruptly, but gradually. A sharp beating of the disk against the edge of the workpiece causes its premature wear.

- When cutting heavy material, it is necessary to slow down the work, periodically bringing the workpiece to the disk, touching it and moving further.

- The corners are cut in two separate passes. Each line is cut separately; do not rotate the workpiece 90 degrees to achieve the desired result. The same rule should be followed when cutting a profile.

It is better to take short breaks while working to maintain accuracy of vision and not get tired ahead of time.

Let us add that our abrasive cutting machine is characterized by a high degree of reliability. It also has a very reasonable price, which allows you to buy vulcanite at a profit for the buyer.