| Place | Name | Characteristics in the rating |

| The best household compressors |

| 1 | Wester W 006-075 OLC | The best technical characteristics for painting small parts |

| 2 | Fubag Air Master Kit | The best package. Maximum range of work. Easy maintenance |

| 3 | Denzel RS 1/6-180 | The most inexpensive and small-sized compressor. Quiet operation |

| The best semi-professional compressors |

| 1 | ABAC Montecarlo L25P | Improved piston head. High working pressure |

| 2 | Aurora GALE-50 | Reliability in operation. Availability of 2 outputs for equipment |

| 3 | Quattro Elementi KM 50-380 | The best balance between performance and efficiency. Double cylinder group |

| The best compressors for professional use |

| 1 | FIAC AB 100-360 | Minimal oil carryover. Quiet operation. Availability of all spare parts |

| 2 | Remeza SB4/C-100.LB75 | Lacme three-cylinder piston block. Starting at reduced mains voltage |

| 3 | ABAC 6000/270 CT 7.5 | 2-stage compressor unit. Increased air flow and increased operating pressure. |

| 4 | Bezhetsk plant ASO S-416M | A stationary unit recognized as the best product in Russia. Powerful electric motor |

The best household compressors

T.n. Garage compressors are designed for short, small jobs. They cannot be connected to pneumatic equipment with high air flow rates, for example, spray guns with HVLP technology. Painting a car for such a unit is a feasible task, but it takes 2–3 times longer. This is explained by the fact that the duration of its continuous operation usually does not exceed 10–15 minutes, otherwise it quickly overheats and, in the absence of a thermal relay, fails. Hence the conclusion - even a high-quality household compressor must be used carefully and requires competent selection of pneumatic tools based on power indicators.

Kinds

To decide which compressor you need for painting your car, you should study the range offered.

There are several categories of compressors.

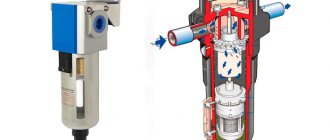

- Piston type devices. The most common types that are most often found on sale. The work is carried out using an electric motor or internal combustion engine. Air is forced through the valve using a receiver. The main disadvantages of piston compressors are considered to be low performance, high noise levels and fairly rapid wear of elements. But the design is very light, it can be repaired with your own hands, and the compressors themselves are affordable.

- Screw type compressors. Here the work is based on the interaction of a pair of screws. There are no valves here, which significantly reduces the noise level during operation. At the same time, the resource has increased. Screw models can work for a long time, even if they are constantly turned on. But you won’t be able to repair such a device yourself.

- Spiral type models. Their operating principle is in many ways similar to the operation of screw compressors. Only the arrangement of the spirals is not parallel, as is the case with screw ones, but at a given angle. It is small in size with a more complex design. It is also impossible to repair the device with your own hands, despite the fact that the price is much higher than competitors.

The types of compressors considered are also divided into oil-free and oil-based. If you take oil-type screw and piston devices, then there will be difficulties with maintenance, although the service life and safety margin are impressive. The main disadvantage is that it is necessary to clean the air from dust and contaminants with oil impurities.

The best semi-professional compressors

Semi-professional compressor equipment in most cases is represented by European and domestic manufacturers and is distinguished by a number of characteristics. They provide a flow rate of over 270 l/min. and pressure 8–12 atmospheres. To support optimal operating mode, the volume of the receiver increases and is approximately 50–100 liters. Non-stop operation of such compressors should not last more than 40 minutes, but this is enough to use them for small service stations and tire shops, car services, and small industries.

Design and principle of operation

The name of the mechanism in question determines that it works based on the supply of compressed air, which is mixed with a dye. That is why such a device also has a compressor with a receiver. When choosing a compressor for a spray gun, you should pay attention to the following points:

- The spray gun itself is represented by a spray nozzle, which is designed in the form of a pistol. At the top or bottom of the structure there is a place to install a tank for storing the dye.

- The receiver is connected to the sprayer using a special rubber hose. It has fairly high strength, is flexible, and is designed to supply air under a certain pressure from the generator to the actuator.

- In the sprayer, air is directly mixed with the dye, which is broken into small particles. This results in a high-quality coating.

- The shape of the mechanism is created in such a way that the air flow spreads like a torch, diverging at a certain angle in all directions.

Particular attention is paid to the fact that devices must be manufactured using high-quality materials.

How long they will last depends on this moment.

The sprayer has a rather complex design. It consists of the following elements:

- Pendant.

- Channel for supplying substance.

- Nozzle.

- Channels designed for air supply.

- Air type head.

- Tank for storing dye.

- A regulator that allows you to change the parameters of the resulting torch.

- A regulator responsible for the direct supply of paint.

- Air supply regulator.

- Lever.

- Connection for direct hose connection.

A fairly simple principle of operation determines that the mechanism can last for a long period.

The best compressors for professional use

If you paint passenger and truck cars professionally, you will have to forget about inexpensive direct-drive compressors. Car painters need high-power units with a belt drive that do not overheat. They are equipped with similar engines, but due to the difference in pulley diameters, the crankshaft turns much more slowly, therefore, the air injection part does not overheat, and the compressor group has time to be well lubricated. This allows compressors of this category to be used in a more intensive mode, but it must be taken into account that continuous operation is still unacceptable.

Additional recommendations

There are a few more points that not all motorists pay attention to. As a result, this results in some difficulties and problems in the future. It’s better to plan everything in advance so that you don’t have to return the compressor to the store or buy new equipment for painting the vehicle.

- Drive unit. Modern compressors that are used for servicing and working with cars have two drive options. These are straight and belt. Direct transmission of torque directly to the crankshaft. Belt ones use a slightly different principle. The torque goes to the driven pulley from the drive pulley using a belt. If you are interested in painting a car, then it is better to stick to belt compressors. They are more expensive in price, but have a wide range of advantages. The main advantage can be considered the absence of disadvantages characteristic of direct drive compressors. They have increased speed, which, when using air cooling, provokes rapid overheating of the heads and cylinders. This significantly reduces the service life of the equipment. Plus, direct drive leads to overload of the motor at the moment of starting. Belt models do not have such problems.

- Cylinders. The buyer should be interested in the number of cylinders that are used in the compressor. It is generally accepted that the more there are, the better. In most cases, this statement is correct. But since we need a compressor for painting, not only the number of cylinders, but also the volume plays a big role. Here experts advise buying models that have a paired number of cylinders. Their advantage is that they do not provoke excessive vibrations, thereby ensuring the durability of the device.

- Portability. Compressors can be divided into stationary and mobile. If you are sure that the compressor will always be in one place and will not need to be moved, you can take a stationary model. But practice shows that compressors have to be rearranged at least periodically. Even in such a situation, it is already correct to take equipment that is equipped with a special trolley on wheels.

Considering these additional recommendations, it will not be difficult for you to determine the optimal characteristics and required parameters.

Why do you need a receiver and how to choose its volume

The receiver is represented by a vessel with air, where it is under pressure. The main purpose is to equalize the pressure when air enters the compressor. Otherwise, a situation may arise where the air mass is transported by pulsation. Due to this, the operational characteristics of the mechanism are significantly reduced. In addition, you can eliminate the possibility of condensation.

When choosing, pay attention to the following points:

- Volume.

- Equipment performance.

- The type of material used in the manufacture of the case.

Do not forget that the mechanism must be securely connected to the system. Otherwise, there is a possibility of a leak occurring, which will cause a decrease in pressure.

Main blower power supply type

Industrial installations in most cases operate on a voltage of 380 V. This is due to the fact that such installations are characterized by high productivity. For home workshops, a design option is suitable that can operate on a 220 V network.

The type of power supply largely depends on the power of the equipment used. Do not forget that three-phase equipment places a serious load on the electrical supply cable.

In conclusion, we note that when choosing a compressor, you should pay attention to the popularity of the brand. Some manufacturers use high-quality materials when producing their products, others try to save money. The resistance of the mechanism to environmental influences will depend on this.

Equipment options for various fields of activity

You can get lost in the numerous variations and sets of components for building an effective air supply system. Therefore, it is worth giving a few simple recommendations and templates for average solutions.

- For domestic use in periodic mode, a piston oil compressor is perfect. Today there are many options for ready-made stations on sale that supply air with a pressure of up to 8 bar. Such kits are equipped with a receiver with a volume of 6 to 100 liters (it is recommended to choose at least 50 liters), and are capable of operating for 20 minutes every hour.

- Semi-professional class compressor stations are built on oil piston compressors with coaxial or belt drive and are equipped with a receiver with a volume of at least 50 liters. They also cannot be operated continuously, but the effective operating time is up to 40 minutes every hour. The average maximum pressure is up to 16 bar.

- Industrial (professional) equipment does not have a clear gradation of parameters. As a typical feature, we can note the huge volumes of receivers - up to 1 cubic meter. Such stations can operate continuously, and you can purchase equipment with characteristics that satisfy any need.

For purely one-time garage work, you can assemble a compressor station with your own hands. To do this, you will need to purchase moisture and oil traps, a reducer, a pressure switch and find an empty gas cylinder in good condition. The main supercharger in a homemade station is a compressor from a refrigerator. This device belongs to the piston oil class.

After dismantling the refrigerator, the old oil is drained from the unit and modern synthetics are filled in. After this, the output tube is connected to the receiver, and the power system is switched through a thermal relay. A mini compressor of this class is capable of satisfying minimal garage needs.

What you should pay attention to when painting with water-based emulsion with a compressor.

During painting, enough paint dust or microscopic droplets fly in the air, they settle on the floor like coarse flour. This is better than drops, but the surface, like any painting, needs to be protected, for example, linoleum or laminate. Everything turns out neatly, but paint is paint.

Also, if you overexpose the spray gun, the paint begins to flow down the wall. There is nothing scary about this, you can get it wet with a cloth or spray it while passing over the area.

Also, an important point is that you will need to paint it 2 times, i.e. The paint is runny and cannot be applied in a thick layer the first time. But even when painting with a roller, a second layer is often unavoidable.