When actively working on trimming dead wood or expanding the area of a personal plot, the home workshop must have a chainsaw. Chainsaw teeth, even from a trusted brand (for example, Stihl), periodically wear out and therefore require high-quality sharpening. In the absence of special devices, a properly selected file for sharpening a chainsaw chain will help solve this problem.

External signs of a dull chainsaw tooth

Among the most popular chainsaws are rightfully the tools of the Austrian company Stihl, in particular, Stihl-180 (to be precise, Stihl MS-180-14''). With such a chainsaw you can trim branches and deal with medium-sized branches - a power of 1500 W allows this quite well. Despite the high-quality steel that this brand (we don’t consider Chinese counterfeits!) uses to make the teeth, self-sharpening will require skill and time.

You should pay attention to the following external signs of a dull cutting chain:

- A conical section appeared on the working angle of the tooth.

- When moving from the working corner to the top edge, the radius rounding is visually different.

- At the moment of the initial feed, even at a relatively low intensity, the penetration of the working edge of the tooth into the thickness of the wood is carried out with great resistance.

- At the stage of a steady cut, the chainsaw chain begins to vibrate, and the noise level of the chainsaw increases noticeably.

- When sawing in the longitudinal direction, the cutting surface has rough cuts and chips of wood. The chips themselves become significantly smaller in size.

The trial test is carried out on dead wood, and in no case on wood with high humidity. The frequency of sharpening depends on the main cutting direction. If it is performed predominantly in the axial direction, then sharpening will have to be performed much more often.

What is included in the sharpening kit?

In the absence of a special machine, you will have to make do with a file to sharpen the chainsaw chain (more precisely, not one, but two). You also need a special template with which you can check the current value of the sharpening angle. Thus, the basic set of sharpening equipment includes:

- Round file with a cross-sectional diameter of 4.5…5 mm.

- A holder with special positioning lines, with the help of which the tool can be placed on the top face with the required accuracy. The holder is equipped with a section that rests on the surface of the cutting depth limiter.

- A flat file used to sharpen the limiter itself.

- A hook that removes sawdust generated during the sharpening process.

It should be noted that manual sharpening is effective only when the signs of dullness of the chainsaw are established very quickly, and the wear is relatively small. Otherwise, more complex and expensive specialized machines will be required. Manual machines in the FUG size range are also suitable for working with Shtil-180 chainsaw teeth. Their advantage is that it is possible to qualitatively sharpen teeth whose wear turned out to be sharply uneven.

Experts advise purchasing sets of such files at the same time as purchasing the saw itself, or, in extreme cases, in the same store. Because there is no universal file for sharpening chainsaws from different manufacturers.

In addition to the length, it is important to correctly determine the type of notches available. They can have cut or notched teeth. For sharpening, notched ones are better, because otherwise the cutting angle fluctuates in a wider range of values (70±10 0), which is unacceptable for processing a chainsaw tooth.

The file material for sharpening a chainsaw chain should be U13 or U13A tool steel according to GOST 1435. Other options for sharpening chainsaw teeth are not suitable.

The domestic tool industry produces a special sized line of “Zubr” metal files, which are designed specifically for manual sharpening of chainsaw teeth. The price of the required tool numbers ranges from 300...350 rubles.

Storage rules

Files are made from hard but rather brittle tool steel. Storing and transporting several copies in one box may affect their performance parameters.

As part of the factory kits, files are provided with optimal storage conditions. It is recommended to keep a set of several individual tools in a sectional case such as a bandoleer.

The functionality of files with a dirty or oily cut can be restored by cleaning with a stiff brush and rinsing in a solution of dish grease remover, acetone or unleaded gasoline.

Sequence of operations when sharpening

High-quality sharpening of teeth requires strict adherence to the following rules:

- A file for sharpening a chainsaw should be placed strictly perpendicular to the direction of movement of the saw teeth in the vertical direction, and at an angle of 15...20 0 in the horizontal direction. The latter is controlled using a holder.

- The round file in the tooth mouth must be located slightly above its edge (for file No. 5 this is approximately 1...1.5 mm).

- A holder is installed on the tooth, the lines of which will show the exact direction of movement of the file in the horizontal plane.

- After several movements of the file, the sharpening surface is covered with magnetized shavings, which should be immediately removed with a hook.

- Sharpening begins in the direction away from you, without using excessive force: the notches should gently enter the metal of the tooth. It is recommended to make several movements and then turn the file by 20...30 0 so that the wear of the notches occurs more evenly.

- It is recommended to sharpen “through the tooth”: first sharpen the teeth in one direction, and then in the other.

- The pressure on the file during sharpening should be constant, as should the number of reciprocating movements on the tooth being sharpened.

Read also: Pinout of socket for truck trailer

When sharpening the depth limiter, proceed as follows. A template is applied to the limiter. When the stopper slot fits into the template groove, set the height of the worn area, which is removed using a flat file. The template is installed on one of two sides - Hard or Soft, which corresponds to hard or soft wood.

Sharpening will be easier if the chainsaw bar is clamped in a bench vise. The intervals between sharpenings can be increased if you promptly monitor the correct chain tension, monitor the condition of the limiter, regularly lubricate all moving elements, and periodically replace the drive sprocket.

“A lumberjack working with a blunt ax was advised: “Sharpen the ax.”

He replied: “There is no time.” The forest needs to be felled. »

Hello to all readers!

Today I decided to tell you about an instrument that, it seems to me, is simply impossible today. A good tool should work well, and this largely depends on its owner.

Cleaning the autumn garden, preparing firewood for winter, building a bathhouse, and repairing a wooden fence will require not only time and desire, but also the availability of a “cutting” tool. If this is a chainsaw, then it must be properly sharpened.

Of course, there are paid specialists, and you, for example, have extra money... But we know that such a procedure is performed periodically and therefore a natural question arises: how to sharpen a chainsaw chain at home? I’ll tell you about that. Go!

From this article you will learn:

Choosing a tool class for use at home and in the country

A chainsaw is an indispensable assistant in the home and countryside. With its help, you can easily clear a log of knots, cut down a dried tree, take care of a garden, prepare firewood for the heating season, and perform other activities related to wood cutting.

In order to understand which chainsaw to choose, you need to know the operating principle of a technically quite complex tool, and navigate the variety of models offered on the modern construction market. In this case, it is necessary to decide on the expected scale of work, as well as with what intensity and frequency the unit will be used; even the gender of the employee should be taken into account.

So which chainsaw is best for the home? To choose the right unit, you should start by assessing the power of the tool and the duration of continuous operation. According to these parameters, chainsaws are divided into the following classes:

- Household tools. They are not designed to perform large volumes of work and are not very powerful. Using units of this class, it is possible to produce seasonal firewood in small quantities; thick logs cannot be cut. But they are light in weight and have minimal fuel consumption; they are easy to hold and carry. The duration of continuous operation is from forty minutes to an hour per day. This is the kind of chainsaw you can choose for your home.

- Semi-professional class units. With their help, you can saw fairly thick logs lengthwise and crosswise, but carrying the tool is already quite difficult. The engine is of average power and fuel consumption is not very high. The duration of continuous operation in a daily cycle reaches up to ten hours. Such a unit can be chosen for subsidiary farming.

- Professional grade devices. They are characterized by high power, weight and fuel consumption. With the help of chainsaws of this class, you can cut down forest for twenty hours without a break. The materials from which they are made are distinguished by their durability and quality. Such equipment is expensive, so for household work it is better to rent it.

First about the horror stories

If you cut with a dull chainsaw, you will get three negative factors:

- Reduce the efficiency of your process. For example, instead of two cubes, cut one (in the same time);

- You will subject the mechanism to intense wear, with the risk of destruction of the drive sprocket and tire;

- Get increased fuel consumption;

There is also a fourth, perhaps not so significant factor – a “ragged” cut of the saw cut.

And of course, you will be more tired, you will (possibly) be angry with yourself, like “why am I stupid, didn’t I sharpen it in advance, now suffer…”

Here's a test question for you (photo on the right). Guess what chips “came out” from under the sharp and blunt chain? (the answer will be below).

How to tell if a chain is dull

- Increased physical effort;

- Sagging (stretching) of the chain;

- Vibration and “slow” cutting;

- Inaccurate cutting and changes in the appearance of sawdust (they become uneven with sharp “needle-like” edges, small and dusty). This is already the answer to the test.

“According to experts and in my opinion too: well-sharpened teeth are more important than engine power.”

Why is it dull? The reasons are generally known, but I will name the main ones:

- Intensive or extensive work;

- Accidental contact with stone, earth, hard knots, etc.;

- Mishandling (broad concept).

About chainsaw teeth

Chainsaw teeth have a specific geometry. You need to understand and know which part of them needs to be sharpened. In general, the “logic” of cutting wood resembles a plane.

The cutting surface consists of two edges. One is lateral, the other is slightly beveled. The cutting depth limiting element regulates the thickness of the chips. Let's take a closer look. The elements of the cutting-working link are arranged as follows:

- Base with holes for the axle;

- Tooth blade;

- Cutting depth limiter;

- The end edge of the blade (placement – vertical);

- The upper edge of the blade (placed horizontally);

Sharpened edge Blunt After touching the ground

After sharpening, the height of the stop and the angle of the sharpened working edges should not differ greatly from the parameters specified by the manufacturer. This is an important condition and you need to keep an eye on it. Otherwise, the saw will not work as expected.

Do not excessively grind or change the location of the links. The normal operation of the instrument depends on the identity of their location. Otherwise, increased loads on the body, tire and engine are likely. The cut may be crooked. There is also a small chance of the chain breaking.

Possible ways and methods of chain sharpening

Working with a file

The best solution is simple “bells and whistles” for sharpening work. This set includes a round and flat file, special holders, a gauge template, a hook for removing chips, etc. Structurally, the “devices” may differ, but the functionality has a common logic.

The diameter of the round file directly depends on the size of the chain:

- — Chains with ø 1.3 – require a file ø 4 mm (used much more often);

- — Chains with ø 1.6 – require a file ø 5.2 mm;

- — To sharpen the depth stop, use a flat file.

Sharpening process

- Having previously “turned on” the chain brake, firmly clamp the chainsaw bar in a vice (a tightly clamped saw is the key to successful sharpening)

- Position the template so that the “arrow” points toward the “nose” of the tire. Be sure to mark (you can use chalk) the tooth from which you started sharpening, otherwise you can go around the second round;

- Sharpen in the direction indicated by the arrows. Remember, each tooth of the chain has a special factory notch. It indicates the maximum sharpening angle.

- In addition to the cutting tooth, there are limiters on each link. They are sharpened as needed. This is necessary in the case when, as a result of sharpening, the height of the tooth decreases and problems arise in the operation of the chainsaw. As a rule, the limiter is sharpened after 2-3 sharpening of the teeth;

Read also: Program for calculating transformer windings

“If you don’t have sharpening skills, it’s better to start with inexpensive chains.”

Recommendations:

- The file should not extend beyond the top of the cutting edge, more than 1/5 of the working part of the file. The pressure is applied with the same force;

- The movement of the sharpening tool is performed in one direction “away from you”, and the number of movements for each tooth should be equal;

- To sharpen a vertical plane, the position of the file should be at a right angle;

- For sharpening on a horizontal plane, file position at an angle of 20-30°

- If there are teeth of different heights, the reference point is the smallest one.

Advantages: Ability to “charge the saw” in the field. At the same time it’s cheap.

Disadvantages: Takes time and effort. At the same time, the file quickly “kills”. By the way, about files: it’s better to pay a little more and get a quality product than to buy it for 40-50 rubles and throw it away after the first sharpening (tested in practice). And also, if the chain has “plowed” the soil so well that its cutting edge has changed its original shape, sharpening with a file is difficult and not at all quick.

Sharpening with a grinder

Professionals consider this work to be primitive. There is a risk of tire damage, and not only that.

Process (looks easy, but is actually difficult)

- The chain also remains on the bar;

- We attach a cutting disc for metal with a thickness of 1.5-2 mm to the grinder. It is advisable to take something that is not new, that is, with a reworked edge;

- We put a barrier in front of the chain and tire (a sliver will come off);

- We sharpen at the desired angle;

- Upon completion of the work, the chain must be properly tightened.

With a professional approach and a “full hand”, the number of sharpenings in this case can be more than 7.

“For a beginner, it’s better not to “experiment” with a saw, chain, etc. with your body parts!”

Advantages of the method: Fast, cheap and does not take away strength;

Disadvantages: Requires special skills, a steady hand and the ability to follow safety precautions.

Electric sharpening machines

They are equipped with special adjustment functions that help position the chain at a certain angle. At the same time, it is possible to accurately and accurately bring the disc to the chain teeth. There are machines equipped with automatic vices. They turn on when the disc is brought to the edge being sharpened. Convenience and functionality are of course high. You can also find models at “increasing” prices.

Manually driven machines

The design of such a machine is similar to a bow saw. Only, where the saw blade is located, there is a round file. With this machine you can sharpen and straighten teeth, adjusting the proportionality of the upper edges to the smallest (control) size. The mechanism allows you to accurately set the parameters. After adjustment to the “control” tooth, sharpening is carried out in two or three movements. And then move on to the next tooth.

When it is necessary to sharpen the limiter, replace the round file with a flat one.

Advantages of the method: Allows you to sharpen teeth efficiently, conveniently and without great physical effort, including those that have lost their original shape.

Disadvantages: Price of the tool and distance from the possible area where the saw will be used.

“After completing the “sharpening procedures,” blow the chain with compressed air (from a compressor or pump) and put it in clean engine oil for a while. Of course, almost no one does such events, but for the chain they will only be beneficial.”

What to choose for sharpening is up to you. This has to do with how often you use the chainsaw. From handling it carefully. From the quality of the purchased chain. And, of course, from the opportunity to spend a certain amount. It is impossible to compare methods, because as the German proverb says, “apples must be compared with apples.”

Features of care and maintenance of saw sets

The service life of removable equipment equally depends on the quality of the material, the design features of the lubrication system, and the qualifications of the workers and maintenance personnel.

During operation, it is recommended to periodically check the tension of the saw chain and the supply of chain oil to the working cutting area. Filling the system with waste and cheap oil substitutes is strictly not recommended.

The wear rate of the chain and bar increases sharply with excessive tension, sand and other abrasive materials getting into the set, or poor condition of the drive sprocket crown. A nail not detected in the wood in a timely manner can ruin a new chain beyond any possibility of repair.

After work, the headset must be cleaned of sawdust; during long breaks in work, it must be dismantled, lubricated and stored in a dry place.

Files and accessories

The main one used to sharpen the working saw tooth is round. Flat is used to adjust the height of the tooth - limiting the depth of cut.

Round file

Round ones vary in diameter. The main diameters are:

Depending on the size of the tooth, it is necessary to choose the optimal diameter. To facilitate the process, special file holders or support rollers with an indication of the tooth sharpening angle can be used.

Flat file

The flat one should have a width of no more than 1 cm. It is convenient to sharpen the stop tooth using a special bar (filing gauge), which is installed on the chain and shows to what maximum depth the tooth needs to be ground in order to achieve optimal performance of the chainsaw.

Read also: How to cut slate for garden beds

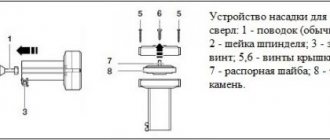

File holder

A round file is installed in a holder and fixed with special clamps. On the plane of the holder there are several markings indicating a specific sharpening angle. When straightening a chain with a file with a holder, the markings on the device are placed parallel to the chainsaw bar, which allows you to accurately maintain the required angle.

Using the holder all the time is quite inconvenient. You can use this device from time to time to check the correct angle of the tooth.

Filing gauges

These devices are used to control the sharpening angle of the teeth, as well as the distance to the depth stop in conjunction with a flat file.

Sharpening device

Manufacturers of equipment for chainsaws make special guide machines for installing a file in them and sharpening them. The machines are mounted on the chainsaw bar and are adjustable in height and angle of location to the chain. The use of such equipment is relevant for those who are just trying to learn how to sharpen a Stihl chainsaw chain with their own hands.

Clamp

This device allows you to hold the chainsaw bar while sharpening. To use it correctly, the process must take place directly at the cutting site. The clamp is hammered into a tree or board, then the tire is clamped into it and securely fixed from displacement. The device can be used for all types of tires, regardless of size.

In some cases, for example, in garage conditions, instead of a clamp, you can use a regular vice; the tire is clamped in them in such a way that the jaws of the vice do not interfere with the free movement of the chain. Next, sharpening is carried out according to the usual scenario.

How to properly sharpen a chainsaw chain with your own hands. Step-by-step instruction

Bringing a chain into working condition has its own characteristics.

They are determined by the configuration of the tooth. It includes two edges, located - one at the top and the other at the bottom. Moreover, the edge located towards the top has a slope at a given angle. In fact, the tooth, both in geometry and in its operating principle, is similar to the blade of a carpenter’s plane. Manual chain sharpening diagram

For competent sharpening, the master must understand the structure of the tooth.

Teeth parameters

The tooth structure consists of:

- grounds;

- shoulder blades;

- limiter.

Two cutting edges are formed on the blade, one is placed on a horizontal plane, the other at an angle. To obtain the required parameters, the blades are sharpened at the angle specified in the technical specifications. The rake angle is sharpened in the range from 60 to 85 °.

The clearance angle indicates the backward tilt of the upper blade. It lies in the range of 50 to 60°. The blade located on top is considered the main one; the rear angle in this design is very important. It is difficult to measure; if the sharpening rules are followed and the geometric parameters are observed, it is formed in the specified range.

Teeth

The corners are sharpened depending on the use of the tool. The main rule is that the larger the angle, the greater the efficiency when processing soft wood; the smaller the angle, the easier it is to operate the saw with hard wood. That is, the smoothness of operation improves and the vibration of the tool decreases.

Meanwhile, the situation of sharpening the angle greater than 35 and less than 25° should be avoided. This rule does not apply to rip chains.

Angles change when editing the tool

They have an important impact on cutting parameters, so all technical requirements must be carefully followed

Description of the sharpening process

Let's take a closer look at how to sharpen a chainsaw chain. The first thing you need to do is prepare a place for installing a clamp, or if the process takes place without it, then it is convenient to use an ordinary log as a stop for fixing the tire in a horizontal plane. The chainsaw is placed on a flat surface, a log is placed under the tire, and the brake is applied.

To avoid injury when sharpening your chainsaw, be sure to apply the saw chain brake.

The next stage is the actual sharpening of the tooth. To do this, use a round file to make movements from the inside of the tooth to the outside.

It is very important at this moment to maintain the correct sharpening angle. The standard angle is thirty degrees from the perpendicular location of the file to the plane of the bar. How to position it correctly is shown in the photo below.

In the process of sharpening a chainsaw for a non-standard cut, for example, longitudinal. The sharpened angle changes to a less acute one. As a rule, it is no more than 10°. It is in such cases that a holder, hand-held machines or filing gauges are used to control the sharpening angle.

Some manufacturers of chainsaw chains, to facilitate sharpening, as well as to indicate the maximum possible sharpening, make a special mark on the upper surface of the tooth.

By holding the file parallel to the mark, you can be sure that the correct angle is maintained.

The number of working movements with a file should be the same for each tooth. This will allow all teeth to be ground evenly.

In the process of straightening the chain, it is customary to sharpen the teeth on one side first, and then on the other; this is convenient because there is no need to constantly change its location in relation to the chainsaw.

After the working teeth have been sharpened, it is necessary to adjust the height of the limiting tooth with a flat file. To do this, the filing gauge is placed on the chain so that the limiting tooth coincides with its slot, after which the protruding part is ground off with a file. This procedure is performed on all restrictive teeth.

Application of roller device

The sharpening device, with which you can quickly and efficiently correct teeth, consists of a small guide template on which two rollers are mounted.

By installing the device on the tire, you can sharpen the teeth of a chainsaw, even without experience in such operations.

How to sharpen cutting equipment using a grinder and a screwdriver

There are videos online that show the process of sharpening chainsaw chains using a tool such as an angle grinder or simply an angle grinder. The principle of the procedure is similar to the actions when using the machine. However, its only difficulty is that the master needs to independently choose the sharpening angle, and at the same time control the tool, holding it in his hands. It is quite difficult to do this, and even more difficult to carry out the procedure to obtain a high-quality sharpening angle. That is why it is not recommended to implement the process in this way, because it has many disadvantages:

- complexity - what is associated with holding the tool in your hands and simultaneously controlling the sharpening angle;

- there is a high probability of damaging the equipment, since if the teeth are incorrectly sharpened, the chain will cut with less efficiency, or will not cut at all;

- increasing the speed of tooth dulling - the disk on the sharpening machine rotates at a lower speed than the wheel on the grinder. With short contact with the edge, the metal manages to heat up significantly to high temperatures, which leads to its hardening and tempering, and therefore it is possible that a chain sharpened in such conditions will become dull faster (this will lead to accelerated wear).

Using a grinder to restore the quality of teeth sharpening is far from the best option. And resorting to its implementation is not recommended at all. You can watch the video to see how masters do this at home.

As an alternative to using a grinder for sharpening chainsaw accessories, a screwdriver is used. The principle of its implementation is to perform the following actions:

- Clamp a round file in the tool chuck (screwdriver).

- Perform movements with a file, as in the case of the manual method, only additionally rotate it using a screwdriver.

- Pass the rotating file several times, increasing the pressing force when moving away from you, and loosening it, returning it to its original position.

This method cannot be called effective, since there is no question of maintaining the sharpening angle. It has only one advantage - it takes half as much time to implement. It is suitable when you need to quickly complete the procedure. The video below shows how to sharpen a chain on a chainsaw using a screwdriver.

Based on the instructions presented, each sawyer can draw appropriate conclusions about the rationality of each method. Based on the description, you can always keep your instrument in good condition.

Adviсe

For those who are just learning how to sharpen a chainsaw chain themselves, it will be useful to take into account a few basic tips for carrying out this process correctly.

- Whenever manipulating the chain, the engine must be turned off; under no circumstances should you sharpen the chainsaw chain while the saw is running.

- Before sharpening, the chain must be tightened to normal working condition.

- The saw chain brake must be set to the working position when straightening it.

- When sharpening the chain, gloves must be used to protect against cuts from the sharp edges of the teeth.

- Maintaining the same number of file movements is guaranteed to ensure uniform grinding of all teeth.

Below you can see how to sharpen a chainsaw chain with a file in the video; it describes in detail what files you need to use. How to best position the chainsaw. And of course, how should the sharpening tool be positioned in relation to the saw bar.

Finally, I would like to note the main advantages of sharpening with a file, compared to straightening the chain in a machine.

Benefits of sharpening a chain with a file

- The service life of the chain is significantly increased.

- There is no risk of ruining it.

- Editing can be done anywhere, wherever you are, regardless of the availability of electricity.

For sharpening chainsaws on construction sites, as well as in places where wood sawing is carried out, it is most convenient to use a file. Thanks to the presence of numerous devices to facilitate the process, even a person with no experience can straighten the chain; the main thing is to remember safety precautions when working with a chainsaw and follow the recommendations received in the article.