The cutting tool becomes dull during operation. This is a natural process. The quality of the metal of the cutter or saw can only affect the rate of wear, but in any case, sharpening cannot be avoided. It is for this procedure that there are special diamond grinding wheels. They are mounted on a sharpening machine or angle grinder.

The designs of sharpening discs are different, for example, there is a diamond plate, a tool in the form of a cup, just a flat disc or any other shape. All this variety of configurations is due to the goal of making it convenient to grind or sharpen various tools.

Diamond wheels are most in demand for sharpening circular saws. They are designed to work with hard pobedite tips, which are difficult for a conventional sharpening tool to handle. Let's try to understand the questions of how diamond wheels are structured, what they are, and what exactly this or that type of product is intended for.

Signs that the drill is dull

Before sharpening the drills, you need to make sure that they are actually dull. What signs does this show:

- the cutting tool gets very hot;

- metal shavings flying out from under the edge have a fine fraction;

- the noise of operations increases.

We especially note the last sign, because the friction force between the dull edge of the drill and the plane of the workpiece increases. Therefore, as soon as there is an increase in noise during drilling, work must be stopped immediately. If work is not stopped, the cutting tool will overheat greatly, the structure of the metal will change, which will lead to the complete loss of the tool. After which there is no point in sharpening it.

Edges and rear planes of an overheated drill Source podshipnik-servis.ru

How to choose a drill

Before deciding how to sharpen a drill correctly, I would like to dwell a little on the cutting tool itself.

Let's start with the fact that drills on the construction tools market are presented in a fairly wide range. Since we are only interested in metal equipment, it should be noted that there is a choice here too.

First, you can select by tool color:

- Black is an oxide film, the function of which is to protect the base of the drill from corrosion and high temperatures. Therefore, this variety has high strength and wear resistance.

- Gray – this tool can easily be classified as low quality equipment.

- Bright golden. This color indicates only one thing – the steel from which the tool is made contains titanium.

- Dark golden. The same as the previous option, only there are no internal stresses inside the steel rod. Hence its high qualities.

Types of metal drills Source rozetka.com.ua

It should be noted that most metal drills are rods made of tool steel. But to increase their cutting performance, you need to strengthen the cutting edge. Therefore, today you can buy four types of equipment with different coatings:

- Still the same black oxide film.

- TiCN is titanium carbonitride.

- TiAIN is titanium aluminum nitride.

- Titanium nitride itself.

- Ceramics.

Attention! The last two coatings cannot be re-sharpened.

Mainly in everyday life, and many craftsmen use twist drills to drill holes in metal. This is a steel cylindrical rod in which grooves are cut in the form of a spiral. Hence, in principle, the name.

The smaller part of this tool is occupied by the shank, which is clamped in the chuck of drilling equipment or in a drill or hammer drill. The main part is occupied by a cylinder with grooves. Grooves are cut for one purpose - to create a space through which metal shavings will leave the drilling site without interfering with the main process.

Twist drill: its parts and elements Source studfile.net

Spiral equipment also has a small classification, where there are three positions:

- Classic drill.

- Left-handed. It is used when it is necessary to drill out a broken fastening element from a hole: a bolt, a screw, etc.

- High precision. If the task is to drill a hole with minimal errors, then use it.

So, having sorted out the assortment of equipment, we move directly to the main question - how to sharpen a drill for metal.

Sanding wheel grit

When purchasing an emery grinding wheel for their machines, consumers pay attention to such a characteristic parameter as grain size. It can take the following values in the standard version - 8, 12, 16, 25, 40. It is clear that 8 are products with the smallest grains, and 40 are, accordingly, the largest.

The choice of grain size should be carried out exclusively professionally. Otherwise, either the sharpening work will be done poorly, or the emery wheel itself will not last long. Fine grit is great for jewelry sharpening, while coarse grit is great for heavy, large tools that do not require high precision.

There is another important parameter that concerns grain - its resistance to abrasion. There are so-called medium-soft products (they are labeled SM), as well as medium-hard ones (respectively, ST). The first option in our country, and throughout the world, has become quite widespread. This is due to the relatively low cost of the product, as well as acceptable characteristics. It works for a long time even under fairly heavy loads. As for medium-hard grain, it is even more resistant to mechanical stress, including abrasion. However, such a product costs many times more, which significantly reduces the economic feasibility of the purchase.

From this perspective, we can consider some examples of product labeling and their appropriateness for use in a given situation. So, for example, an emery wheel marked 150x8x32 12-CM is often used to sharpen skates. What does it mean?

- The disc has a medium-soft grain, which is relatively cheap and allows for high-quality sharpening.

- The grain size is 12-H - 12 microns in diameter, if we take the average.

- 32 mm is the fitting diameter, which is standard for many equipment.

- 8 mm is the thickness of the product itself. This is a very small indicator, which does not ensure structural strength when working with a large tool under high loads, but it is quite suitable for the intended purpose.

- 150 diameter sanding wheel.

Let's look at another small example. For everyday life and production, abrasives 150x20x32 25-CM are installed on emery surfaces. In this example, in comparison with the previous one, the width of the product is increased to 20 mm, and the grain diameter is increased to 25 microns. In fact, this turns out to be a fairly universal machine that will allow you to work not only with small tools, such as scissors, knives, screwdrivers, but also with fairly large devices, such as axes and some saws.

Rules for sharpening drills

Firstly, to carry out this process you will need either special equipment or special devices in the form of attachments for drills or hammer drills. The first group includes a sharpening machine on which a sharpening stone is mounted. A thrifty owner will always have such a small machine in his garage or shed.

It should be noted right away that the sharpening technology depends on the type of drill. It can be conical, helical, cylindrical, or one- or two-plane. But you need to understand that in any case only the rear edges of the tool need to be sharpened. In this case, each edge must be sharpened equally. It is clear that it is almost impossible to do this manually. But craftsmen sharpen small-sized drills by hand, which requires some experience in carrying out this type of work.

Screw drill for metal Source besplatka.ua

See also: Catalog of companies that specialize in the installation of metal structures and utility networks

There are some differences in sharpening different types of drills. For example, a single-plane drill differs from others in that its back wall of the pen has only one plane. And the angle of inclination of this plane varies in the range of 28-30°. It is this plane that needs to be sharpened. Here it is important to bring the drill to the rotating sharpening stone parallel to this back plane. In this case, the tool cannot be rotated; even a slight deviation will lead to an incorrect operation.

Double-plane drills are sharpened in the same way. You just have to sharpen two planes separately. The same requirements apply here.

As for conical models, the main task is not to disturb the taper of the structure of the edge being sharpened. Therefore, the tool is brought to a rotating grindstone, the drill is pressed and oscillating movements are made along the cone. The important thing here is not to tear the rig away from the stone. That is, the process is carried out in one touch.

And one more wish - to strictly adhere to the shape of the edge. It is clear that this is not always possible, especially if the drill is up to 10 mm in diameter. But for this variety you can only maintain the back angle. And that's enough. As for large-diameter drills, experts recommend, in addition to sharpening the edges along planes and accurately maintaining the angle, sharpening the front plane, thereby improving the design. These drills are more efficient when drilling.

Sharpening should be done with one touch Source novate.ru

Why is it necessary to sharpen the front plane? The thing is that by decreasing the angle of inclination of the front plane, the angle of the cutting edge increases. And this increases the resistance of the tool to chipping of metal from the plane of the cutting edge. In addition, it should be added that the length of the transverse edge decreases sharply. That is, it turns out that the edge of the cross member does not cut, but scrapes the metal workpiece. Or rather, the central part of the drilled area.

After sharpening the drill, it is also recommended to carry out fine-tuning. That is, the nicks left by the grindstone are removed. This is a mandatory procedure in factory conditions. This is what allows you to increase the wear resistance of the tool. If it is possible to carry out fine-tuning at home, then it must be done.

Usually other stones are used for finishing:

- made of silicon carbide, it is green, grade 63C, and it is better to use a wheel with a grain size of 5-6 and a hardness of M3-SM1;

- from CBN, a grit size of 6-8 is required here.

Please note that these stones must be made in a Bakelite bond.

Stone for sharpening drills Source i.ytimg.com

Marking of grinding wheels

Content

Wheels for sharpening and grinding machines are used for a wide variety of jobs. One removes paint and rust from metal workpieces. Others are needed for sharpening knives, ax blades, saw chains and discs. The third ones carry out finishing treatment of the surface. How to understand the variety of equipment and choose the right one? Let's decipher the symbols and read the markings that the manufacturer places on the packaging or the product itself.

How to decipher the markings of grinding wheels

At first glance, everything is simple. You need to look at the parameters of the equipment, and it will be clear what equipment is suitable for it. The type of work to be done is also taken into account. However, it must be borne in mind that manufacturers use two labeling systems. Some are guided by the Soviet GOST, others by the modern GOST R. We will describe each marking point for grinding wheels separately and indicate how it is designated in different GOSTs.

Circle size

Indicated in the name of the grinding wheel and duplicated on the packaging. For example, in the name of a grinding wheel 175x20x32 mm, the numbers mean the following: 175 mm is the outer diameter, 20 mm is the height of the wheel, 32 mm is the internal landing diameter. The machines are designed to work with circles of certain sizes. These requirements, as a rule, are in the instructions for the equipment, and they must be taken into account first.

Rotational speed

Depends on the strength of the circle. It must withstand the speed that the grinding or sharpening machine will give it. If the equipment is not strong enough, it will wear out quickly, and very soon you will have to buy a new one. Manufacturers indicate on the wheels the maximum permissible rotation speed of the equipment in two units of measurement - m/s and rpm.

How is the speed of rotation indicated in the markings of circles?

Circle shape

Determines the nature of the work that can be performed with this equipment. The knife blades are straightened in a circle with a straight profile. A conical profile wheel is needed for saw chains and discs. There are 14 forms of equipment. According to old standards, the shape of a circle is indicated by letters and numbers; according to modern standards, only numbers. One of the labeling options is most often in the name. Example of numerical marking: grinding wheel 1 – a product that has a straight profile.

Shapes of grinding wheels and their markings

Type of abrasive

Abrasive material is a tiny grain with sharp edges that removes layer by layer from the workpiece. The properties of the particles determine whether the surface will become smooth or rough after treatment. The main qualities of abrasive materials are hardness, resistance to mechanical stress, high temperatures and chemicals.

Types of abrasives, their properties and markings

Each material has subspecies that differ from each other in parameters and manifest themselves differently in operation. For example, normal electrocorundum consists of 93–96% aluminum oxide, and its variety, white electrocorundum, contains up to 98–99% of this substance. Therefore, it is harder and has increased abrasive ability and fragility. Grinding with such equipment is better and there are fewer burns to the metal. This material is designated as 22 A or otherwise - 23A, 24A or 25A. The higher the numerical value, the stronger and better quality the grain.

Marking of abrasives

Grinding wheel grit

Shows the size of abrasives and is measured in microns. The more uniform the particles are in size, the better the surface is processed. There are two systems for marking grinding wheels according to this parameter. The Soviet GOST 3647-80 uses a numerical notation system. The number 1 indicates a grain size of 10 microns. If the wheel grit is 40, then the grain size is 400 microns. The new GOST R 52381-2005 repeats the FEPA marking system adopted throughout the world. In it, grain size is designated by the letter F with a number. The higher the number, the finer the abrasive particles. For example, the marking F70 means that the grain size is 200 - 250 microns, and F40 indicates that the size is 400 - 500 microns.

Typically, the grain size is selected depending on the material being processed, the desired roughness of the workpiece, and the thickness of the layer being removed. For example, first rough grinding is carried out with a wheel with a coarse grain, then finishing is carried out using equipment with a fine grain.

Wheel hardness

Indicates the ability of the bond to resist chipping of grains and indicates the wear resistance of the equipment. The grain must completely exhaust its resource and only then fall out of the bundle, revealing the next layer of abrasive.

The degree of hardness in the markings of grinding wheels

The most common wheels are medium hard. But still, the choice depends on the task ahead: what equipment and what material will be processed. An error in selection will affect the quality of work. Insufficiently hard equipment will quickly exhaust its service life. If the hardness is too high, cracks or burns will appear on the treated surface.

Grinding Wheel Structure

Shows the mixing proportions of abrasive and binder. The more grains, the higher the density. The larger the bond, the more space between the abrasive crystals and the more porous the wheel structure will be.

Types of circle structure in markings

The choice of equipment for this parameter depends on the material to be processed. Equipment with a dense structure is used to grind hard materials and carry out abrasive trimming. Non-ferrous metals and alloys with high viscosity are processed using wheels with a highly porous structure.

Type of bundle

The bond can be bakelite, ceramic and vulcanite. The composition of the binder affects the characteristics and scope of application of grinding equipment.

Types and properties of ligaments

Designation of the bond in the marking of grinding wheels

Accuracy class

Shows the degree of compliance of the equipment with the declared geometric shape and dimensions. Here the uniformity of abrasive grains, their grade and the balance of the working surface are assessed. There are three accuracy classes, which are indicated in the markings of grinding wheels.

Devices for turning drills on a machine

It is difficult to hold a drill in your hands and sharpen it on a machine on which the stone is spinning at high speed. You need to have a lot of experience so as not to screw up the instrument. Therefore, there are special devices on sale that make this operation easier.

Simple devices can be purchased on the market. There are also quite complex ones with electric motors that not only hold the drill in the required position, but also feed the tool to the grindstone automatically. The latter are more often used for sharpening twist drills. But such devices cost a lot of money, so they are purchased by professional sharpeners.

Characteristics of sanding wheels

The classification of emery wheels is based on their geometric shape. Based on this feature, products can be cylindrical (CC) and conical (CC) cups, disc-shaped (T) disks and others. In everyday life, a flat disk shape with a straight profile (PP) is most often used. Abrasives with a double-sided conical profile (2P) are less relevant in the home workshop, but they are still in demand for sharpening the teeth of saws and other tools.

The next most important parameter of an abrasive disc is its geometric dimensions. It includes diameter, thickness and fit. The latter indicates the size of the mounting hole in the product and in most cases is equal to 32 mm. Exotic abrasives with mounting diameters of less than 10 mm, used for machinist finishing of precision parts, as well as discs with a 76 mm mounting, used for cylindrical and flat grinding, are typical for industry and are difficult to adapt to economic needs. Therefore they are not considered here.

For the same reason, this publication does not focus on discs whose width is not included in the range of 10, 16, 20 and 25 mm. These sizes are optimal for use in private households.

Video description

The video shows how the master made a device that helps to properly sharpen a drill for metal:

How to sharpen a drill using a drill

If a sharpening machine is not available, you can adapt a drill with a grinding wheel mounted on the shaft. There are two options for the process:

- hold the drill in a vice and bring the drill to the stone with your hands;

- Clamp the cutting tool in a vice and bring the stone with the drill manually.

Both options are not easy, but the second is easier than the first.

How to sharpen a drill correctly in this case:

- the cutting tool must be installed in a vice in a vertical position;

- using a circle mounted on a drill, the trailing edge is removed, the goal is to remove signs of wear;

- then sharpening is carried out at the required angle - usually 120°.

Attention! To prevent the edge from overheating, the sharpening process should be carried out for no more than two seconds. That is, the metal is removed in layers.

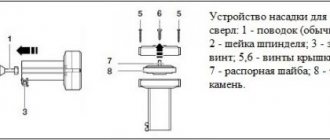

But there is an easier way. To do this, you need to purchase a special nozzle. It is installed on a drill and a drill is inserted into a special groove. The latter, relative to the rotating sharpening tool, is located at a certain angle equal to the sharpening angle. This can be clearly seen in the photo below.

Sharpening a drill using a drill and a special attachment Source yandex.net

Material used

Sanding attachments are made from different materials. You need to select them depending on the surface being treated and the work being carried out. For example, to remove rust and paint you will need a hard attachment, for polishing - a soft one.

3 types of materials are used:

- Soft. They remove primer and putty, traces of rust, and are used for polishing and removing dirt. Thanks to the soft action, the metal does not heat up or deteriorate during operation, which improves the quality of grinding.

Soft Source ebayimg.com

- Emery cloth. The most popular drill attachment for sanding wood. It varies in grain size and roughness, which allows it to be used for different types of work - from rough surface cleaning to finishing details.

- Grinding stones. These are special abrasive stones that are harder and more durable. With their help you can eliminate defects from the surface. They are usually used for preparing and leveling concrete, glass, and ceramics.

When choosing, it is important to focus not only on the material, but also on its hardness and grain size. For example, felt can be used to polish a car.

Sharpening accessories

It is difficult for beginners to carry out the sharpening procedure efficiently. Therefore, manufacturers of construction tools have been producing special attachments for drills for a long time. This is actually a nozzle. It must be installed on a drill, insert a drill into the hole from the end and turn on the power tool.

Then the drill is pulled out, rotated 180°, reinserted into the drill sharpener, and the drill is turned on again. That is, the second plane of the cutting edge is sharpened.

Device for sharpening a drill mounted on a drill Source yandex.net

Sharpening small drills

Unfortunately, it is impossible to sharpen a tool with a diameter of less than 4 mm using an attachment or on a machine. Therefore, such drills are sharpened by hand using a file or needle file. As for the latter, it is better to choose one with diamond coating. Even if a file was used, the edges must be finished with a file.

The complexity of the operation lies in the fact that the cutting tool has a small plane and edge. Therefore, it is recommended to purchase glasses with four times magnification for this, and also use a lamp with a good luminous flux.

The principle of sharpening is exactly the same. But there are some recommendations:

- grinding off a layer of more than 1 mm is not recommended;

- The sharpening angle of the metal drill is standard, but is maintained by eye;

- As practice shows, you will definitely ruin the first drill, don’t despair, skill comes with experience.

Types of sharpening

Some types of sharpening have already been mentioned above, but we will repeat it again. So, there are five types of sharpening, which are selected based on the type of material and the specifics of the work associated with drilling.

The first of them is normal under the title “N”. This variety is universal, but is used only if it is necessary to sharpen a drill with a diameter of no more than 12 mm. Essentially, two cutting edges and one transverse edge are formed on the tool. To do this, you have to maintain an angle within 118-120°.

And the rest:

- NP – sharpening is done with a short crossbar to reduce the load on it;

- NPL - in addition to the transverse edge, the width of the ribbon is also reduced, the goal is to reduce the friction force that is created between the drill and the workpiece;

- DP is the so-called double sharpening, where in addition to the transverse edge, four more edges are formed, which are broken lines;

- DPL is the same previous version, only the ribbon is additionally sharpened.

Attention! Why are four edges needed? This is an opportunity to reduce the angle between sections of the peripheral planes of the edges. Thus, an increase in heat removal from the drilling site is achieved. And this increases the service life of the tool itself.

Correctly carried out sharpening of a drill Source tehnomuza.ru

Sharpening angle

As mentioned above, before properly sharpening a drill for metal, you need to choose the right sharpening angle. Firstly, this parameter is tabular. Secondly, it depends on what kind of metal needs to be drilled. If this:

- cast iron or steel workpiece, then the angle should vary from 116° to 118°;

- if it is brass or bronze, then from 120° to 130°;

- if the workpiece is made of copper, then 125°;

- aluminum – 140°.

An incorrectly sharpened drill leads to overheating of the tool itself. But, as practice shows, it is the incorrectly chosen sharpening angle that leads to a decrease in the quality of the process.

Briefly about the main thing

You can sharpen a dull drill using different devices: a sharpening machine, a drill on which a whetstone is installed, or a drill attachment.

Small drills are sharpened by hand with a file or needle file.

The main sharpening parameter is the angle that forms the edges. The sharpening angle is selected taking into account the metal that is to be drilled. This parameter is tabular.

To increase the wear resistance of the drill, the sharpening configuration is changed, using five options for edge formation as a basis.

Ratings 0

What to look for when choosing a diamond blade

The convenience and speed of working on a sharpening machine directly depends on the correct choice of diamond blade. In some cases, the wrong choice can cause deformation of the disc or damage to the cutter. Here's what you need to analyze before choosing a specific drive:

- the grade of metal that will be sharpened or the type of carbide;

- revolutions and power of the sharpening machine;

- shape of the surface being treated;

- degree of permissible roughness.

The diamond blade you purchase must strictly comply with all these parameters.

If you are a professional who works with turning equipment or someone who has experience using diamond grinding wheels, take part in the discussion of the topic in the comments. Expert knowledge is always valuable!