The construction of building structures requires accurate determination of the diameter of the reinforcement. People who are not familiar with the nuances of carrying out such work imagine reinforcement as an ordinary rod. The corrugated surface causes difficulties when measuring parameters. In addition, there are no special places where accurate measurements can be taken.

For this reason, it is worth taking measurements taking into account certain features. This indicator of reinforcement can be measured using available means. Auxiliary tools are used when it is not possible to study the documentation.

Detailed documents are usually attached to the metal shipment. In them, the manufacturer indicates the nominal values of the parts. For example, the number of the fittings must be indicated. Studying this documentation will help you accurately determine the diameter, but if it is not at hand, then you need to use available tools.

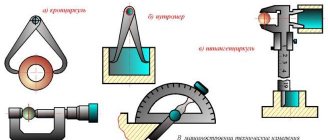

Measurements during the design and manufacture of threaded connections

The “bolt-nut” type connection is one of the most common in mechanics. When designing and manufacturing structures, the problem of how to measure a bolt with a caliper is often difficult.

Before starting work, it is worth remembering that the main dimensions of a bolt/nut are the length of the product and the diameter of the thread. A standard bolt of any design does not require such measurements. It’s a different matter when the bolt is made at home, or you need to measure the fastener without dismantling the connection. The following situations are possible here:

- Between the head and the opposite end of the rod there is a plane or part/plate, the dimensions of which do not allow the insertion of the measuring jaws of a caliper. In this case, using the main measuring scale and a depth gauge (sometimes called a “Columbic”), the height of the head, the thickness of the washer (if any), the thickness of the intermediate element and the height of the part protruding from the opposite side of the joint are determined. The obtained result is added up, and then, according to the tables of correspondence between the lengths of the rod and the “turnkey” dimensions that the bolt has, the standard size of the fastener is determined.

Measuring internal threads and imprinting threads

Linear dimensions measurements

How to measure linear dimensions using a caliper? It all depends on the material of the part/workpiece. For rigid elements, the product is pressed tightly against some support plate, after which the measurement is taken with the external measuring jaws of the tool. You must first determine the suitability of the existing type of caliper for use. For example, the main measuring scale on the rod should be less than 25...30 mm longer than the part (taking into account the own width of the jaws). When using a depth gauge, this value is even smaller, since the length of the frame should also be taken into account (for the most common tools 0-150 mm and an accuracy of 0.05 to 0.1 mm, this parameter is taken to be at least 50 mm).

Less accurate, but very fast method

However, if there is no need for overly complex and precise calculations, then you can determine the diameter simply by applying an ordinary school ruler to the diameter of the pipe. You will only need to hold the ruler so that its scale coincides with the imaginary line of the pipe diameter. Small deviations in one direction or another are quite acceptable. After all, in stores, pipes, as a rule, are offered in standard sizes. If necessary, the sales consultant can adjust the diameter of the required pipe.

An ordinary ruler can help if there is no professional tool for measuring the diameter of the pipe, but do not forget about the error.

If you need to measure a very small pipe

It is usually recommended to measure the diameter of small objects using a caliper. This method is suitable when working with pipes up to 15 cm. One end (leg) of the device is pressed against one edge of the pipe, and the other against the other. In this case, special indicators on the caliper will show the outer diameter of the pipe.

A caliper is a universal tool for measuring internal and external dimensions, as well as hole depth, with an accuracy of 0.1 or 0.01 mm.

If you need to use it to measure the internal diameter, then you can press the edge of the pipe, the one that is “responsible” for its thickness, between the legs of the caliper. The pipe wall thickness is then subtracted from the outside diameter. This will be its internal diameter.

Read also: Construction of a cyclone for woodworking

Calculations of equal strength replacement of plastic reinforcement

For the ratio of fiberglass reinforcement and steel reinforcement used in construction, such an idea as an equal-strength replacement has emerged. Any reinforcement used to strengthen a concrete product works in tension. It is also used to prevent concrete structures from cracking.

The tensile strength of reinforcement, measured in megapascals, is called tensile strength. If it is exceeded when tensile stresses are applied to the reinforcement, it will break. It should be borne in mind that when steel and fiberglass reinforcement reach tensile strength, they do not fail in the same way, since under load they have a distinctive type of behavior:

- Steel reinforcement is represented in a curved line, under the load of which there is a horizontal section of the graph.

- Non-metallic reinforcement is represented in a straight line, under the load of destruction of which there is an elastic-linear relationship.

Yield is a term that means the rupture of steel reinforcement at some stage.

Basics of calculating strip foundations

The most common type of foundation in individual construction is monolithic strip. It is easy to construct, quite durable and has the necessary rigidity. It is arranged in the form of a shallow or recessed structure.

The depth of placement, effective loads and the width of the working section of the base are important for calculating the reinforcement for the foundation.

Strip foundation Source eurohouse.ua

Determination of depth

The mark of the base of the base is selected depending on the type of soil:

- in clayey, silty and fine sandy soils, the foundation is supported on a non-freezing layer below the groundwater level;

- for non-heaving and slightly heaving soils, the level of the base should not be lower than 0.5 m from the top of the existing ground level;

- if there is a basement, the strip base is buried 0.5 m below the floor, the columnar base - 1.5 m.

The type of soil, the position of the groundwater level and the presence of weak lenses - quicksand - are determined by drilling or digging holes. The depth of soil freezing in each region is indicated in SNiP “Building Climatology”.

Load collection

At this stage of the calculation, all possible loads acting on the foundation are summed up:

- own weight;

- the mass of walls, floor slabs, roofs, roofing, floors and finishing;

- impact from people, plumbing equipment, furniture, partitions located inside the building;

- standard snow load.

All information is contained in the tables of SNiP 2.01.07-85* “Loads and impacts”.

The total value is divided into linear meters in strip foundations, and by the number of supports - in pile or columnar ones.

Outsole width

Reinforcement of a strip foundation Source guru-remonta.ru

The width of the sole is a value that helps to calculate the reinforcement for a strip foundation. For massive brick walls, T-shaped strips are used, the overhangs of which, due to the larger support area, reduce the pressure on the soil. Lighter frame and foam concrete structures are erected on bases with a rectangular cross-section.

When calculating the size of the sole, the maximum pressure on the ground and the load from the structure on the load-bearing sections of the foundation beams are taken into account. In low-rise construction, as a rule, structures with a width of 20-40 cm are used.

See also: Catalog of companies that specialize in foundation repair and design.

We want to know how to measure the diameter of the reinforcement ourselves, with our own hands?

Round rod photo

Strictly speaking, the idea of measuring the diameter of reinforcement with your own hands is usually based on somewhat incorrect approximate ideas about reinforcement as a round smooth rod. Which just looks a little #171;off. And when a person who has little to do with rolled metal starts measuring, he is overcome by bewilderment, where exactly is the diameter of the reinforcement measured, in what place? There is no such clear, defined, one place where you can measure the diameter of the reinforcement on a reinforcing bar.

Table of deviations of dimensions of corrugated reinforcement

After determining the minimum and maximum values, you need to refer to the table given in GOST 5781-82. It shows the corresponding values for each nominal diameter based on the “edge-to-groove” principle.

| D nominal, mm | Dmin, mm | D max, mm |

| 6 | 5,75 | 6,75 |

| 8 | 7,5 | 9 |

| 10 | 9,3 | 11,3 |

| 12 | 11 | 13,5 |

| 14 | 13 | 15,5 |

| 16 | 15 | 18 |

| 18 | 17 | 20 |

| 20 | 19 | 22 |

| 22 | 21 | 24 |

| 25 | 24 | 27 |

| 28 | 26,5 | 30,5 |

| 32 | 30,5 | 34,5 |

| 36 | 34,5 | 39,5 |

| 40 | 38,5 | 43,5 |

For example, consider measurements of reinforcement with a diameter of 18 mm. When taking measurements, the minimum value for the specified profile should be 17 mm (maximum deviation upward +0.3 mm, and -0.5 mm downward), maximum 20 mm, we get (17+20)/2=18.5 mm.

Correct determination of the diameter of the rod will allow accurate calculations of the cross-sectional area of the reinforcement. This is an important parameter that is taken into account when calculating the reinforcement of columns, floors, foundations and other reinforced concrete structures.

Scope of application, features of fittings: diameter, classes, markings, compliance with GOST

Reinforcement is an important component in the general list of building materials. It is characterized by a wide range of applications at various stages of building construction. Not a single reinforced concrete structure can do without it, serving as reinforcement and support both in the foundation of a small house and in the construction of a large-scale railway bridge or overpass. Reinforcement technology is even used to strengthen glass structures.

Reinforcement is used in construction at various stages of construction.

Even at the initial stage of developing design estimates, every self-respecting engineer and architect has at hand a special table of the ratios of weight and footage of reinforcement, as well as cross-sections of reinforcing bars in accordance with established state standards. The main one among them is GOST 5781-82. Also, products must comply with GOST 52544-2006, STO ASChM 7-93, TU 14-1-5254-94. The standards regulate the requirements for a specific type of reinforced products. Their totality corresponds to the term – reinforcement assortment.

The fittings are round metal rods with a smooth or corrugated surface. They are made from several types of steel. The diameter of the rods ranges from 4 to 80 mm. The product range is divided into classes A1 – A6.

I-beam: assortment, dimensions, technical characteristics of profiles (read more)

Diameter, that is, the cross-sectional size of a reinforcement bar or wire, is the main indicator underlying the product range. Hence the corresponding terms: reinforcement 8 mm or weight 1 m of reinforcement 12. These products are classified according to other properties, including strength, wear resistance, specific gravity and other characteristics, which we will consider further.

Pipe diameters external and internal

Before you find out how the diameter of a pipe is calculated, you need to determine what diameter you need to calculate. All pipe products that are used for gas and water supply, as well as for sewage disposal, are classified by internal diameter. This indicator is also called conditional passage, since the throughput of the entire system depends on it. The inner diameter is designated Dу, the outer diameter is Dн, and the wall thickness is h. Such designations allow you to conveniently carry out calculations and design a wide variety of pipelines for residential and commercial premises.

With the same outer diameter, the inner diameter can vary depending on the wall thickness. The last indicator is selected based on the required mechanical strength of the product. For more precise standardization, GOST 355–52 was introduced, which regulates the nominal flow rate of pipe products. Each subsequent standard nominal diameter provides approximately 50% greater pipe capacity than the previous one.

Nominal or nominal diameter is a term that is often used instead of the concept of nominal bore. Often the internal diameter of the pipe and its nominal bore are different. The difference can be from 1 to 10 mm. The conditional or nominal diameter is the main characteristic of the product. It is this parameter that is decisive for the design and installation of any type of pipeline.

The diameters of pipes for water and gas are usually calculated in inches. Due to the fact that the metric measurement system is widespread in the post-Soviet space, difficulties often arise with the correct calculation of the width of pipes. Such situations arise when connecting pipelines made of different materials. To avoid mistakes, you should use special tables that are created specifically for quick and accurate calculation of sizes. Next, we will learn how to measure the diameter of a pipe using available tools.

Calculation of reinforcement for the foundation

To reinforce the bases, corrugated and smooth rolled steel of class A400 or A500 is used for working rods, A240 for structural elements.

The calculation is carried out according to the standards of SNiP 52-01-2003 and the updated rules of SP 63.13330.2012, taking into account all types of loads acting on the foundation and the type of foundation.

SNiP 01/52/2003 Source meganorm.ru

Reinforced with spatial or flat frames made of longitudinal, transverse and connecting rods. The former perceive the tensile load along the upper part and sole, the latter distribute it between horizontal and vertical elements. For stability during manufacturing and installation, structural connections are used.

Basic methods for determining the diameter of reinforcement

To set the exact diameter of metal rods, you can use two main methods. One of them involves the use of a tape measure, the second - a caliper. They are used when it is not possible to view the technical documents attached to the rolled metal.

Read also: How to recognize a manipulator?

- Measuring with a tape measure. Using this tool to measure the diameter of rebar is not easy. Especially when it comes to thin rods with an elliptical cross-section. In fact, you can only get an approximate cross-section value. If you ordered standardized reinforcement, it is worth measuring the diameter, and then refer to the characteristics of the reinforcing bars, see which parameters the values obtained from your measurements are closest to.

- Measuring with a caliper. This method helps to obtain more accurate results. To correctly take measurements, measurements should be taken at the minimum (at the narrowest point of the bar) and maximum (at the widest) diameter. After this, you should look at the special table presented in the current state standard. The diameter of the reinforcement and data on its maximum and minimum values are indicated there. For example, if the minimum value obtained as a result of measurements is 15 mm, and the maximum is 18 mm, you have 16 mm reinforcement.

Determination methods

There are 2 ways to measure reinforcement.

In the first case, a caliper is used, and in the second, a tape measure. Both methods are instrumental. They are resorted to in cases where it is not possible to refer to the documents attached to the rolled metal upon purchase.

- Measuring with a tape measure

It is quite difficult to carry out such operations using such a tool. The fact is that a tape measure is not the best solution for measuring thin rods, whose cross-section is not a circle, but an ellipse. You will only receive approximate values. For an experienced specialist, such data may be quite sufficient. If there is very little knowledge in this area, it is better to use another technique. - Measuring with a caliper

You can correctly measure the diameter of the reinforcement using this tool. As a result, you will get 2 values - minimum and maximum. Next, you need to refer to a special table. For each nominal diameter of reinforcing bars, values from the current state standard are also indicated. For example, let’s take 16 mm reinforcement and look at the table. We see 2 physical measurements. For the minimum, this value will represent the measurement between the ribs of the steel bar. The indicator is 15 mm. As for the maximum, this figure is 18 mm.

How to measure the diameter of STEEL reinforcement

With measuring the diameter of steel reinforcement, everything is simple; here GOST 5781-82 (Hot-rolled steel for reinforcement of reinforced concrete structures) comes to our aid. It contains two drawings that show the profiles of all the reinforcement used and indicate the diameters and other dimensions. Further, under the drawings there is table No. 2 and table No. 3, of which the dependence of the profile number on the internal and external diameter of the reinforcement follows. It is worth remembering that when integers are mentioned that describe the diameter of the reinforcement, we are talking about the so-called NOMINAL (average) diameter of the reinforcement, which is also referred to as the PROFILE NUMBER. In this case, the real diameters (internal - measured along the body of the bar and external - measured along the ribs) differ from the nominal diameter and are fractional numbers.

EXAMPLE: Let's take for example steel reinforcement of class A-III (A400), which is referred to everywhere as “twelfth”. We look at table No. 2 GOST 5781-82 (Hot-rolled steel for reinforcement of reinforced concrete structures) and find the number 12 in the first column of this table. As can be seen from the name of this column of this table, 12 is not the real diameter, but the so-called profile number (or nominal diameter dн) . In this case, the real outer diameter d1 of this reinforcement is equal to 13.5 mm (indicated in the 6th column of the table), and the inner diameter d is equal to 11.0 mm (indicated in the 2nd column of the table).

Therefore, you need to be especially careful when purchasing steel reinforcement with a profile number of 16 and higher. Starting from this number, the outer diameter begins to significantly exceed the profile number and is often equal to the next profile number. Dishonest sellers can take advantage of this. So, for example, for steel reinforcement with profile number 16, the internal diameter d is 15.0 mm, and the real outer diameter d1 is 18.0 mm, and this fact can be used to sell the “sixteenth” reinforcement under the guise of “eighteenth” .

How to avoid being scammed when purchasing steel reinforcement? Download GOST 5781-82 (Hot-rolled steel for reinforcement of reinforced concrete structures). We look in it for the value of the outer diameter for the reinforcement with the profile number that you need. We take a caliper with us and go for the fittings. The outer diameter is measured 300 mm from the edge of the rod (the edge itself can be deformed during loading/unloading or cutting).

How to measure the NOMINAL diameter of reinforcement?

So we come to the very root of the problem - the measurement of the NOMINAL diameter.

With steel reinforcement, everything is clear, since the types of steel are known in advance, the density is known, the profile options, the pitch of the ribs are known, the types of reinforcement are also known in advance, regulated and tabulated. Therefore, for steel reinforcement, it is enough to measure the external diameter along the ribs, the internal diameter along the body of the rod and, depending on the type of reinforcement, determine the nominal diameter according to tables No. 2 and No. 3 from GOST 5781-82.

With composite reinforcement everything is complicated. In Russia there is traditionally a legal vacuum; GOST 31938 leaves a bunch of questions unanswered. Of course, armed with a caliper and holding a composite reinforcement rod from any manufacturer in your hands, you are simply not able to measure the nominal diameter! Why? Because, according to the methodology mentioned above, the method for determining the nominal diameter of composite reinforcement is based on determining ( based on the results of hydrostatic weighing ) the volume of a sample cut from the controlled product to a given length and subsequent calculation of the nominal diameter!

What to do? It is enough just to remember that the NOMINAL diameter of the reinforcement is a certain average value between the outer and inner diameters of the reinforcement. In this case, the sparser the winding of the ribs is located (the greater the distance between the turns of the ribs), the closer the value of the NOMINAL diameter will be to the value of the INNER diameter of the reinforcement.

A500S fittings: GOST, key parameters and characteristics

Since the third category is the most common, which class of reinforcement (A400 or A500) to choose is up to the designers, who take into account all the nuances of construction work. Speaking about the structural features of this type, you should pay attention to GOST reinforcement A500. It regulates the production of a round profile having two ribs along the rod and parallel rows of crescent-shaped protrusions across. Moreover, they do not intersect with paired ribs along the body of the rod.

Reinforcement class A500 is the most universal, it is produced in coils and rods.

The profile has high ductility and strength characteristics during the rolling process. A500 reinforcement bars have a minimum length of 6 m, and a maximum length of 25 m. The optimal length of the rods is 12 m. According to the assortment table, A500S reinforcement is made from high-quality marked steel St3SP, St3PS and St3GPS. The material has excellent weldability, but this is not its only advantage.

On a note! A500C fittings can be connected using electric arc welding machines. This advantage is indicated by the letter C in the profile marking. The quality of welding is reduced by the minimum presence of alloying elements.

The positive properties of such fittings are as follows:

- increased degree of strength and flexibility, absence of weak points that could lead to destruction of the reinforcement;

- relatively low production cost and, as a consequence, affordable cost of reinforcement per ton;

- the specific gravity of A500 reinforcement implies significant savings in steel volumes during the manufacturing process.

Class A500 is used not only in residential construction, but also in commercial and industrial construction.

How to measure the diameter of reinforcement, if necessary, yourself; with your own hands? Methods

There are two ways to measure the diameter of the reinforcement with your own hands if you do not have the opportunity to look at the documentation included with the batch of reinforcement. Both of these ways to measure the diameter of reinforcement #8212; instrumental. You can try to measure the diameter of the reinforcement with a tape measure or caliper.

How to measure rebar photo

Measuring the diameter of reinforcement with a tape measure #8212; bad idea. The tape measure is not suitable for measuring diameters with a small radius for objects that have an ellipse rather than a circle in cross-section, like reinforcement. Although, by taking measurements with a tape measure at the end of a reinforcing bar, you will get approximate, estimated values, which are quite sufficient for a professional who is accustomed to working with reinforcement. But you're clearly not a professional, are you? So we immediately forget about roulette.

How to measure rebar photo

The tape measure will only help us when measuring the length of the reinforcement; here it does an excellent job.

How to choose fittings of the required diameter

The cross-section of rolled metal of this type is far from the only parameter for selecting rods. However, in construction it is important. The choice of rebar depends on where it is planned to be used. So, for example, when carrying out construction work, rods with a cross-section of 12 mm are used as the main steel frame. For tying structures, products with a diameter of 6 to 8 mm are more suitable.

If the construction of structures that will be subject to high loads is required, or the object itself is located in an area where it will be affected by extreme (both low and high) temperatures, thicker rods with a cross-section from 14 mm to 40 mm inclusive should be ordered.

Remember that reinforcement of the required diameter is supplied in bars of measured and unmeasured lengths. The latter option is cheaper, but in operation it is only suitable for filling small areas in order to reduce the need to tie together too short pieces of metal.

Reinforcement range: additional marking options

To determine more specific characteristics of the reinforcement, a special additional marking system has been created. For example, the abbreviation A5K means that these are class A5 profiles, and the letter K indicates the presence of additional corrosion protection. To do this, the material is treated with special agents that ensure its durability.

The presence of the letter C in the marking indicates that the reinforcement can be welded. It must be taken into account that not all products belonging to different classes can be welded together, especially in the absence of the C mark in the designation.

If the marking contains the letter K, this means that the reinforcement has additional corrosion protection.

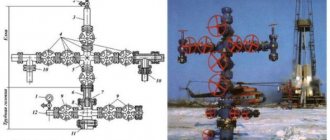

Speaking about the range of fittings, we should mention such a term as shut-off (or pipeline) valves. These types of profiles are used in plumbing work. Accordingly, as a separate subtype of material, this reinforcement has its own classes and markings. In this case, the main parameter of choice is tightness. This criterion indicates the quality of the assembly in the pipeline, without which it is impossible to assemble it. The tightness indicator is indicated in the characteristics on the packaging of the material.

On a note! It is better to connect reinforcing bars with different markings and in the absence of the letter C in the designation, using special couplings and wire.

home

Strictly speaking, the idea of measuring the diameter of reinforcement with your own hands is usually based on somewhat incorrect, but rather approximate ideas about reinforcement as a round smooth rod. Which just looks a little "off". Well, kind of a little embossed. And when a person who has little connection with rolled metal starts measuring, he is perplexed: where should the measurements be taken? How to correctly measure the diameter of the reinforcement, in what place on an uneven rod is it best to do this? There are so many different grooves and ridges that it is completely unclear where to measure and which of the different values to choose as the correct one. There is no such clear, definite, one place where you can correctly measure the diameter of the reinforcement on a reinforcing bar. And it shouldn’t be “by definition.” After all, REINFORCEMENT IS NOT A SMOOTH ROD . Now I will explain this “phenomenon” in more detail.

Measuring the diameter of reinforcement

Request a call back

The manager of our company “GreenRiver” will call you back for consultation.

Why is it necessary to correctly measure the diameter of the reinforcement?

Manufacturers of steel corrugated reinforcement, in most cases, use worn-out equipment, and, in connection with this, the steel reinforcement obtained is slightly larger than the required diameter. According to the tolerances (GOST of the Russian Federation), the reinforcement passes, and the total tonnage corresponds to the declared one, but when converted to linear meters, a shortage of reinforcement occurs.

When determining the diameter of corrugated reinforcement, it should be understood that the cross-sectional shape of the reinforcing bar is more reminiscent of an ellipse (for example, A500C reinforcement) than an even circle - when measuring the reinforcement bar in different places, you get several non-matching numbers - the discrepancy in measurements is several millimeters.

Question: How to correctly measure the diameter of reinforcement?

The size should be viewed in the accompanying documents. In them, manufacturers indicate the so-called nominal diameter of the reinforcement; it is called the reinforcement number or profile number. The profile number of the original workpiece is comparable to the nominal diameter of the finished product.

So how, in the end, can you correctly measure the diameter of the reinforcement? (you will need a caliper):

1. Measure the diameter of the rod body

2. Measure the diameter of the protruding ribs

3. Sum up the indicators and divide the result in half

For such calculations, the following expressions are appropriate: “maximum diameter of reinforcement” and “minimum diameter of reinforcement.”

These are the indicators that were obtained by measuring the body of the reinforcement and the edge of the reinforcement bar. Using the obtained figures, a table was developed that specifies the minimum and maximum dimensions and what nominal diameter of the reinforcement they correspond to.

Rib depression. This is how you should correctly measure the diameter of the reinforcement.

2 Independent calculation for all products - how to cope?

If suddenly you don’t have the Internet, which is now practically indispensable, at hand to find out the size of the cross section from reference books, then you can calculate it yourself.

First we find out the diameter of the reinforcement. That is, we measure it, and for products with a periodic profile (corrugated) we use the recommendations of the previous chapter. Then we calculate using the following formula: S = π * R 2, where

- S is the required cross-sectional area in mm 2, cm 2 or m 2;

- π is the so-called number “pi”, which is a constant mathematical constant (coefficient);

- R 2 is the square of the radius of the reinforcement, that is, the radius multiplied by itself.

To calculate the radius, you need to divide the diameter (in mm, cm or m) by 2. And the number “pi” (π) is equal to 3.14…, where “…” means an infinite sequence of decimal places. And by and large, for any calculations it is always enough to assume that π = 3.14. For more accurate calculations, it is enough to use 10 signs of this constant, that is, assume that π = 3.141592653.

Share the link - this is the best motivator for us

Measure the diameter of the reinforcement?!

Very often, when constructing a reinforced concrete structure, the question arises of how to measure the diameter of the reinforcement. And here a lot of questions arise about how to do this correctly. Most people have a misconception about a reinforcing bar as a round rod. But the relief surface of the reinforcement bar is puzzling, because it is completely unclear at what point the diameter should be measured. Alas, there is simply no specific exact place where the diameter of the reinforcement should be measured.

So how do you measure the diameter of a reinforcing bar?

It turns out that it is almost impossible to measure the diameter of a reinforcement bar using physical methods. Due to the fact that the reinforcement is not a smooth rod, as most people understand, but a special rolled metal product with a complex configuration and relief. Therefore, by measuring the diameter of a reinforcement bar in different places on its surface, you will obtain different data. When working with reinforcement, specialists take data on the diameter of the reinforcement from projects and accompanying documents in which the manufacturer indicates the diameter.

Methods for measuring the diameter of reinforcement.

If you need to measure the diameter of the reinforcement yourself, you can resort to one of 2 methods:

Using a tape measure.

- using a tape measure. Take measurements at the end of the rebar and you will only get an approximate value. An error of up to 0.5mm is allowed. Keep in mind that if you are not an expert, you will not be able to do this more accurately.

Here's our advice:

Using a caliper.

Only with the help of a caliper can you find out the diameter of the reinforcement without much effort. To do this, you need to measure the minimum diameter along the body of the rod and the maximum along the cross section with corrugation. Having this data, refer to the GOST table. In this table, find the minimum and maximum diameter; in the third column, the diameter of the reinforcement will be exactly.

Possible mistakes

Beginners begin to make a lot of mistakes during their first measurements and subsequent work. Examples can be given when beginners begin to measure the internal diameter with their upper lips, which are intended for measuring the surfaces of the part. Also, beginners do not always watch the locking screw: it moves freely. But it is this part of the device that securely fixes the part in a vice, which gives the most accurate measurements.

Everything comes with experience, and there is no way to learn all the intricacies of a caliper without using it, so the most important prevention against mistakes is practice.

To learn how to use a caliper correctly, watch the following video.