The pipe design includes various flange connections, tees, bends and other products. To seal joints in such structures, steel gaskets are used, which contain a minimal amount of carbon.

Christmas tree fittings are designed to solve many problems. In particular, one of these tasks is the installation of piping of pipelines for various purposes. The use of this equipment allows you to control the movement of the working environment and ensure the execution of processes that control production. The devices are used to seal branches from main pipelines.

Purpose of fountain fittings

Devices of this class are responsible for solving the following engineering and technical problems:

- ensuring well sealing;

- diversion of products transported through the pipeline system;

- to adjust and maintain well flow;

- when providing access to the well bottom;

- to ensure sampling without stopping production processes.

Products of this class are used at high pressures arising under the influence of loads. Fittings are used when there is a possibility of exposure to aggressive environments inside the well. Quite often it is used if the liquid contains a large number of impurities of different origins and sizes.

When using such a system, it is necessary to take into account that this equipment must have a long service life and the necessary margin of safety. The main consumers of these products are enterprises engaged in the production and transportation of hydrocarbons, as well as the construction of pipeline transport systems.

Types of fittings

GOST, which are in force in our country, define the following types of Christmas tree fittings:

- Tee (cross) - the scheme allows you to connect taps to prefabricated and metering installations using flow lines.

- Double-row (single-row) - it is equipped with valves or taps. The former are used to work in oil wells, the latter - in gas wells.

In addition to the classification described above, the following is also used:

- By pressure. Typical equipment operates at pressures from 7 to 105 MPa. Valves that are designed to operate at high pressure are used for working in deep wells. In addition, it is installed in wells in which the presence of dangerous formation pressure has been noted.

- According to the size of the barrel passage. This size ranges from 50 to 150 mm. Devices with working diameters from 100 to 150 mm are installed in oil and gas wells with high flow rates.

The designer, when selecting material for the production of reinforcement, must take into account the properties of the environment. By the way, to install products in an explosive environment, it is not advisable to install components and assemblies made of cast iron.

Typical fittings include different types of gate valves, valves, etc. Special piping includes pressure reducing valves, gates and valves for supplying catalysts and operating backup fittings.

Water shut-off valves for distribution networks

Such products of various types and purposes are intended to deliver water from the supply tank to the final point of consumption.

Its main purpose is to close or open the flow of liquid in a pipeline, as well as regulate pressure in the network. Simply put, any of these mechanisms, be it a tap or a valve, allows you to cut off or restore the water supply. The design of the shut-off valve is quite simple. The basis is a cast iron or brass pipe. A valve is inserted into it, which can partially or completely block the lumen in the pipe, which leads to a change in pressure in the pipeline or a cessation of flow. The mechanism is controlled using a lever tap of any shape.

Xmas tree design

GOST 13846–84, implies the use of tee and cross type circuits. Typical fountain fittings include the following components:

- pipe head;

- fountain tree;

- manually controlled locking devices;

- chokes.

The pipe head is designed to hang tubing in several rows on it and ensure their tightness. In addition, it takes part in some technological processes associated with the development, operation and maintenance of the well.

This device, if necessary, replaces the side valves installed on it. For this purpose, blind plugs are used, installed in threads cut in the body.

The fountain tree is designed to solve the following problems:

- sending finished products to the line;

- taking part in the installation of additional devices;

- performing measurements of pipeline network operating parameters;

- ensuring the lowering of devices for cleaning well pipes.

Locking devices are represented by plug valves and gate valves with supplied lubricant. Their main task is to block the movement of the working environment.

Specifics of shut-off valves - general information, classification and types

Shut-off valves are special devices that are used in pipelines. Their design is made in such a way as to reduce the diameter of the pipe lumen, or completely block it. This is used to regulate the circulation of the internal flow, as well as to distribute or mix it.

For certain types of work, a certain design of devices is selected. Therefore, in order to understand the specifics of their work, we will consider the types and classification of shut-off valves for pipelines.

In essence, shut-off valves are just a large water tap Source kurganfm.ru

There are 6 groups of shut-off valves, the difference of which is their purpose:

- General purpose devices . They are usually used in urban networks and gas and water supply systems.

- Special devices for difficult working conditions . Used at high and low temperatures, toxicity and radioactivity, etc.

- Target . For cases where the use of a pipeline requires certain technical regulations that differ from standard requirements.

- Plumbing . Used in domestic conditions.

- Ship's . This group is developed for specific operating conditions on ships for various purposes.

- Unique . Such devices are produced only for experimental purposes according to orders from specific manufacturing organizations.

Variety of shut-off valves Source bud-material.com

Although each group differs in purpose, the design of the devices has common features. All of them are manufactured in a sealed case, inside of which there is a locking unit (it is from this that the devices received their common name).

According to the method of blocking the flow, pipeline fittings are divided into the following 5 types:

- cast iron valves - such valves are equipped with a stainless steel body;

- shut-off valves - devices of this type are also divided into shut-off and control valves;

- safety – these products are designed for a protective function;

- taps – suitable for use in various types of water supply systems;

- Butterfly valves - inside such a device, the locking unit is made in the form of a disk.

Shut-off valves with various methods of fastening Source ndt.ee

The main task for the design of shut-off valves is to close the pipeline by moving the internal unit. This can be either a screw or various special valves.

It is important to know ! Despite the differences in design, the internal assembly has a similar schematic structure. Typically this is a part consisting of two elements. The first (fixed) is called the saddle, and the second is called the mechanism. The operation of the unit is based on the contact of the mechanism with the sealing surfaces, which are usually located on the seat - it is this action that blocks the flow of liquid.

What are shut-off valves for pipelines: classification by application

One of the most numerous classes of devices is shut-off valves for household pipelines. The group represents various valves and taps used by all people in everyday life. This includes shut-off valves for heating, kitchen pipelines, etc.

“Home” shut-off valves are divided into those used for cold and hot water Source gazton.ru

See also: Catalog of companies that specialize in the design and installation of water supply and sewerage systems

There are also other types of pipeline fittings:

- Safety . If, as a result of a failure in the system, the pressure increases, the safety valves are activated automatically and balance the indicators.

- Protective . Similar in functionality to the previous one. But if the safety one is triggered by the release of the internal environment, then the second one acts directly with the liquid inside - its operation does not require emptying the contents of the pipeline.

- Control valves . It includes in its group various valves responsible for the pressure level (the design of such valves in itself is not capable of performing a regulatory function, so it is supplemented with various valves);

- Distribution and mixing . The name speaks for itself - this is the mixing and distribution of liquid;

- Control . Used for the manufacture of measuring instruments;

- Phase separation . Separates several types of working media (for example, oil separator, etc.).

It is important to know ! Most often, the design of shut-off valves is designed to operate in open or closed positions. If you “force” it to perform other functions (for example, open it halfway to reduce water pressure), then faster abrasion or deformation of the internal elements will occur.

Ball shut-off valve - designed for open/closed positions Source klinger-spb.ru

In drainage systems, two types of shut-off valves are used. The first is directly a shut-off valve, and the second is used for adjustment. For a long service life it is important to use them for their intended purpose, i.e. Do not close the control valve, and do not adjust the shut-off valve.

On a note! Types of fittings also include wedge, disc and parallel. The first are intended for sewers, the second for large pipes, and the third can withstand high pressure and high temperatures.

Features of shut-off pipeline valves: differences in connection methods

Another criterion that divides pipeline fittings into two large groups is the design - flanged and wafer-free.

In the first group, for attaching to pipes, there is already a ready-made part, which is made in various shapes - most often a circle and a square are used, less often a triangle.

Flanged shut-off valves are secured with a bolted connection Source otvod.net

Technical requirements for design

GOST 13846–89 determined that Christmas tree equipment is designed to seal wells, block the movement of the working medium and perform other technological procedures. In accordance with the standards regulated in GOST 15150–69, these devices can operate at temperatures from -60 to +40 degrees.

GOST 51365–2009 defines the technical conditions and requirements for the specified fittings. Designers involved in the design of equipment should be guided by the requirements of this document.

Marking of fittings

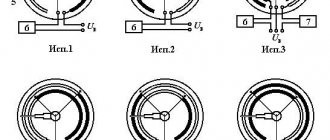

To mark this type of product, alphanumeric abbreviations are used, which are designated as follows: AFKh or AFKH, where AF indicates the type of fittings, in this case the fittings are fountain, the letter “K” indicates the method of hanging the pipeline. The letter X (from 1 to 6) indicates the diagram in accordance with GOST 13846–84. In addition, the product labeling may indicate numerical parameters showing the working diameter and pressure, climatic version and some others, in particular, the corrosion resistance class.

Functional purpose of devices

Fittings for the water supply network are installed not only in every house, but also in every apartment. It serves to regulate the pressure in the internal water supply system and distribute water throughout all rooms of the apartment, where it is provided for by the project.

Watch the video

Educational film about shut-off valves » All about gas transport

Such devices are also installed in industrial buildings and premises where the use of water is provided for by production technology, as well as for sanitary needs. For this purpose, pipes made of special materials different from those used in residential construction are used.

Shut-off valves for water supply are functionally designed to lock liquid in a pipe and, if necessary, supply it to its destination in the required quantity.

The material for the manufacture of locking mechanisms can be various substances, but most often they are:

- Cast iron of various modifications.

- Brass.

- Stainless steel is capable of painlessly passing chemically active liquids, which are also often pumped through pipelines.

Installation and dismantling of fountain fittings

During the operation of an oil or gas well, the structure is installed. Column heads are used for connection. The holes located in the upper flange allow you to fix parts of different sizes. The equipment installation process is carried out in several steps.

A gasket made of low-carbon steel and having an oval shape is placed in the space between the flanges. Using an elevator, the pipe string is lowered to the installation site. After this, the pipes are assembled together using threaded connections. By the way, it makes sense to coat the threads with a protective lubricant before assembly. After completing assembly of the installation, it is necessary to carry out pressure testing.

Repair of this equipment must be performed only at special enterprises. Before sending it for repair, the unit must be disassembled. The tree must be washed and at this time the remaining components must be examined.

The Christmas tree fittings and their piping scheme are designed so that they can protect the environment from the influence of the working medium supplied in the pipeline system.

Briefly about the main thing

The pipeline has long come into use, becoming a basic part of the life of all people. One of the parts that is of key importance in pipeline structures is shut-off valves. The device is a kind of regulator with movable valves. Being inside the pipeline, they direct, stop, and mix the liquid or gas passing through it.

Shut-off valves for pipelines are divided into many types and types. Such a multifaceted classification is due to a wide range of body materials, connection methods, shape, etc. Also, the operating conditions for which the part is intended play a big role here.

When choosing a device, it is important to pay attention to the type of pipeline and the parameters of the part itself. They must correspond with each other. It should be remembered that the most important condition for the functioning of this part is tightness. And for this you need a flat surface (if you install the device into a pipe with defects, the tightness will be broken).

Each device has its own specifics and is characterized by certain features. To install/dismantle and repair such devices, you must have certain knowledge, abilities and acquired skills. Therefore, it is not recommended to do such repair work yourself.

Ratings 0