The gear motor is the main element of the electric drive. Due to its operation, the speed of operation of the moving parts of the equipment mechanism is distributed. According to its design features, it consists of two components: a gearbox and a motor. The task of the gearbox is to transmit the torque of the electric motor shaft to the machine shaft.

This drive mechanism is widely used in industrial areas. This popularity is due to the fact that the gear motor has a compact size, a high level of efficiency and easy maintenance. Products are used in manufacturing enterprises to:

- belt conveyors;

- concrete mixer;

- mobile freight elevators;

- cylindrical machines.

Types of gearmotors

Depending on the type of energy transfer, this mechanism is divided into the following types:

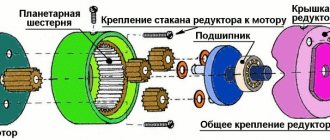

- Planetary . They are distinguished by their reliability and increased level of efficiency. The connection is represented by a rotor and an actuator using gears. The mechanism is driven by a central gear. The disadvantage of this equipment is the absence of a brake and an accelerating torque.

- Wormworms . The connection of the mechanism is represented by a combination of a worm wheel and a screw. Thanks to this, the products are able to smoothly increase and decrease the rotation speed, which has a beneficial effect on the wear of parts. The main disadvantage is the low rotation transmission number and efficiency. Such geared motors are capable of operating at medium power speeds.

- Cylindrical . They have two subtypes: coaxial and flat. In such mechanisms, motion is transmitted by cylindrical helical gears mounted on a flange or paw. The main advantages are the ability to set the desired gear ratio with an increased level of efficiency. The downside is the relatively high cost.

- Wave . The movement occurs through waves built into the flexible part of the mechanism. The models have a coaxial arrangement of axes.

Product gradation also occurs along internal axes, which can be:

- parallel;

- coaxial;

- intersecting;

- interbreeding.

The axis of the mechanism determines the type of arrangement of the input and output shafts in relation to each other. Shafts can be placed vertically, horizontally or with a slope.

For fastening gear motors the following are used:

- paws

– used for large products; - flanges

– suitable for mechanisms of small size and weight; - attachments

- the simplest method, when the gear shaft is seated on the mechanism shaft.

Chemical resistant version

When a gearmotor is intended for operation in an environment with vapors of acids, alkalis and other substances that lead to a chemical reaction of the gearbox coating or lubricant, then it is made in a chemical-resistant design. When the coating reacts with vapor, a coating based on epoxy paints is created, the layer of which does not decompose by vapor. When oil reacts with vapor, a valve breather (nipple) is installed. If vapors of substances lead to the decomposition of oil and petrol resistant rubber, then cuffs made of a polymer material resistant to these vapors, usually Viton, are installed in the gear motor.

Design features of models UHL1, UHL2, UHL3

For these models, the lower operating temperature is minus 60 degrees. Geared motors of these versions differ in the use of a different lubricant and cuff material than for the climatic version U3. In this case, the cuffs are selected in such a way that they do not crack at -60 degrees. Accordingly, the electric motor is selected as either UHL1, or UHL2, or UHL3

Also, you need to pay attention to electric motors with brakes of this climate version. The fact is that imported brakes have an operating temperature of minus 20 degrees, in extreme cases minus 40, and ours minus 60. For this reason, if such a brake is installed in the gearmotor, the brake must be heated

In this case, there are not 2 wires going to the brake coil, but 4 wires.

How to choose the best option?

Choosing a gearmotor for production is not an easy task. There are many related factors to take into account:

- Product type.

- Number of output revolutions (this parameter has an important impact on the subsequent choice of product model).

- Power.

- Features of operation.

- Working conditions.

- Mounting type.

- Structural structure of input and output shafts.

- Availability of additional functionality.

- Overall dimensions (indicators must correspond to the location of such equipment).

Gear ratio

The gear ratio is determined using a formula of the form:

Where:

- nin – input shaft revolutions (electric motor characteristics) per minute;

- nout – the required number of revolutions of the output shaft per minute.

The resulting quotient is rounded to the gear ratio from the standard range for specific types of gearmotors. The key condition for successful selection of an electric motor is the limitation on the input shaft rotation speed. For all types of drive mechanisms it should not exceed 1.5 thousand revolutions per minute. The specific frequency criterion is indicated in the technical characteristics of the engine.

How to calculate efficiency?

You can calculate and obtain quantitative values of the main operating characteristics of a geared motor using special mathematical formulas.

The first thing to do is to calculate the initial rotational power of the shafts. To find the torque value, you should take into account the size of the rated power, safety factor, operating time and efficiency.

Rated torque value "Mn2"

– this is the maximum level of safe rotation. It is calculated with a safety indicator (1) and operating time (10 thousand hours).

Maximum value "M2max"

- the limit value that the product can withstand under stable or variable types of load.

Required torque "Mr2"

- the indicator that satisfies the customer’s criteria. The value may be equal to or less than the nominal rotation rate.

Estimated number "Mc2"

- an indicator that influences the choice of product. To make the calculation, use the formula:

Mc2 = Mr2 x Sf ≤ Mn2

Designation:

- “Mr2”

– required torque; - “Sf”

– service factor; - “Mn2”

– nominal value.

Purifier management

The windshield cleaning system can be controlled in two ways - electronic and electrical. The last option involves manually changing operating modes. Under the steering wheel there is a special control lever that allows you to turn on the device, adjust the pause in the wipers and change the cleaning modes. But this option requires constant driver participation.

The electronic control system is completely autonomous and does not require human intervention. The car is equipped with a special electronic unit and a rain sensor, which analyzes the cleanliness of the glass and weather conditions. Electronic control provides a range of functions:

- automatic switching on and off;

- changing the operating parameters of the purifier;

- blocking the motor in the presence of obstacles on the windshield;

- additional cleaning with windshield washer;

- preventing brushes from freezing when the engine is off.

Drive Power

With the correct calculation of the power of the gearmotor, it is possible to overcome the resistance that occurs during linear or rotating movements. You can calculate the power “P” by searching for indicators of the ratio of force and number of revolutions in 1 minute. Formula for calculation:

P = (MxN)/9550

Designation:

- "M"

- torque; - “N”

is the number of revolutions per 1 minute.

The output power can be calculated using the formula:

P2 = P x Sf

Designation:

- “P”

- power forces; - “Sf”

is the service factor.

It is worth considering that when carrying out calculations it is necessary to take real values so that the result obtained is valid.

Calculation of coefficient of efficiency (efficiency)

Let's find this value using the example of a worm gear motor, which will be equal to the output and input power of the product. Calculation formula:

ñ [%] = (P2/P1) x 100

Designation:

- “P2”

is an indicator of output power; - “P1”

is the input power value.

It is worth considering the important fact that high gear provokes a low level of efficiency. Its high performance has a special impact and depends on the quality of the lubricant materials, as well as the operating time of the equipment itself.

Areas of use

First, you need to decide why you need it.

Since the main advantage of the gearmotor is its compactness, ease of installation and further maintenance, it is well suited for use in many industries. It is most often used in medical equipment, industrial units, special devices, miniature tracking wires and information collection and storage devices. A geared motor is the most common means of automating industrial systems, process control systems and their devices. It is increasingly used in mining, wood processing and agricultural activities.

Features of explosion-proof products

This type has its own classification. They are divided according to the type of explosion protection:

- E

– high degree of security. The models can be used in any conditions. - D

– the housing shell is explosion-proof. This will protect the motor from deformation in case of self-detonation. Such products are suitable for work with high temperatures and any types of explosive substances. - I

– protection against electrical network claims. Suitable for specially created production conditions.

Classification according to main characteristics

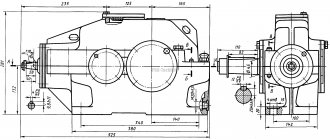

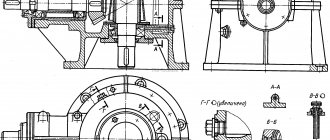

Modern engineering and technical standards provide for the classification of gearboxes according to the following criteria:

- design of the transmission used;

- spatial arrangement of elements;

- design.

Based on the spatial arrangement of key elements, these devices are divided into vertical and traditional horizontal gearboxes. The design provides two additional types: a pure mechanical gearbox, and a gearbox with a propulsion system (geared motor). However, the generally accepted classification of gearboxes is considered to be based on the type of transmission unit (gear) used.

This is interesting: Bolts - detailed classification, marking, GOST standards

Reliability table value

The tabular data shows the operating values of the gearmotor at the rated load type. The product must provide 90% operability under temporary overloads for a short time that occur when starting up the equipment or doubling the rated value.

| Data | Product types | Indicators (h) |

| 90% service life of shafts and gears | Cylindrical, planetary, conical, conical-cylindrical | 25 000 |

| 90% bearing life | Worm, wave and globoid | 25 000 |

| Cylindrical, planetary, conical, conical-cylindrical | 10 000 | |

| Worm | 5 000 |

Buying geared motors from the manufacturer of the desired size and power is quite simple. If you have any problems during the selection process or are not able to correctly calculate the main performance indicators of the product, then feel free to contact the specialists of our company: +375 (17) 513-99-93

or

+375 (17) 513-99-91

.

Introduction

The topic of recycling has always interested me, and this year I again became active in terms of my long-standing idea of “making a shredder” or, in Russian, a plastic shredder.

Among all the necessary equipment for the implementation of a small plastic processing enterprise, I chose to make a shredder first. Because a little earlier, I started sorting garbage into recyclable materials and realized that huge volumes of plastic could be stored much more profitably, and you could actually make something out of it. And then, in general, I realized that I was throwing away a lot of plastic: bumpers from cars, cases from office equipment, etc. In fact, now everything that can somehow be sold without throwing it away is either some kind of product (carrying a useful function) or scrap metal. I don't want to put up with this. Especially when the price of a roll of plastic weighing 750 g is 1000 rubles.

Previously, I could not approach this issue for several reasons:

- Complete absence of ideas and schemes for the finished project;

- Financial restrictions;

- Lack of a place to do this.

All three problems this year disappeared by themselves: I learned about the Precious Plastic project, which became a ready-made plan for implementation.

Its creator, Dave Hekkens, created the lab and the recycling community around it. Together they developed a completely open project to help create a mini-enterprise for recycling plastic waste. They have:

- A global network for finding components (flea market) and like-minded people;

- Detailed video tutorials on all topics on YouTube;

- Ready-made business plans, designs for creating your own enterprises;

- Detailed diagrams and instructions for assembling your own machines;

- Forum;

- Instructions for creating products from recycled materials;

- Well, actually a workspace in Amsterdam.

Let's move on