Design Process of Single Stage Helical Gearbox

Before starting to manufacture this device, a design calculation is made:

- selection of materials;

- selection of the maximum permissible rolling voltage;

- calculation of net useful shaft torsion.

As part of the work, the preliminary design of the gearbox is prepared.

The calculation of the shaft dimensions of this device is carried out in 2 stages:

- approximate calculation of the number of revolutions of pure torsion;

- accurate calculation of strength indicators of bending and torsion stress.

For the production of such units, it is recommended to use heat-treated alloy steel. The calculation of shafts when drawing up a project is carried out depending on the torsional stress, stress concentration, and its cycles. If you plan to install high-speed shafts, then smaller values are taken into account for the calculation, while low-speed shafts - larger ones.

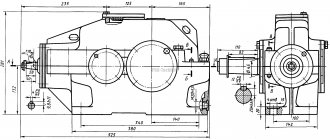

At the final design stage, an assembly drawing of this device is created. It includes all previously developed drawings of each of the gearbox elements separately. In this case, a drawing of the finished device is created, in longitudinal and transverse sections.

To achieve balance and coaxiality in the arrangement of the various elements of this device, kinematic diagrams of single-stage gearboxes are being developed. They are images in different sections of the body and parts that make up the gearbox, reflecting their relative position, proportions, mating points, etc.

Gearbox: definition, purpose, device, types

A gearbox is a mechanism that changes the torque and power of an engine and is present in almost any machine. It is part of the car's transmission and regulates movement in precision instruments with high precision. What is a gearbox from a technical point of view? This is one or more gears that interact with each other and reduce the engine speed to an acceptable rotation speed of the operating unit. Instead of a drive gear there may be a worm.