1. Classification of gearboxes 1.1 Number of stages and shaft arrangement 1.2 Type of transmission used 1.2.1 Worm gearboxes 1.2.2 Worm globoid gearboxes 1.2.3 Helical gearboxes 1.2.4 Bevel gearboxes 1.2.5 Helical-bevel gearboxes 1.2.6 Mounted gearboxes 1.2.7 Planetary gearboxes 1.3 Methods of fastening gearboxes 2. Lubrication of gearboxes 3. Gears 4. Gearbox housings 5. Modernization of gearboxes - a stable trend

A gearbox is a composite mechanism for machine drives. Its main purpose is to reduce the speed of rotation of the driven shaft while increasing torque. The design of the gearbox can provide one or more meshing gears.

1.Classification of gearboxes

Reducer for general machine-building purposes. This type of equipment is an independent unit used in machine drives. Its technical characteristics meet common requirements for different applications. Structurally, general machine-building gearboxes may differ.

Special gearboxes are designed for automotive, aviation and other highly specialized industries. From the name it is clear that the units of this group must correspond to the specifics and parameters of a particular application.

Gearboxes can be classified according to the following criteria:

- By type of gear and number of stages;

- According to the location of the axes of the input/output shafts in space and relative to each other;

- According to the method of fastening.

Recommendations for selection

How to choose a gearbox instead of a broken one, for existing equipment and when creating mechanisms yourself. The main thing is the power on the output shaft. It is calculated based on engine speed by gear ratio.

You should pay attention to the location of the shafts; in cylindrical models it can be in one direction.

Fastening is carried out using a flange directly to the motor shaft and is installed on the platform using holes in the sole.

The marking indicates the center-to-center distance between the shafts. This size has a design significance when installing the unit and connecting it to the engine and the shaft of the working mechanism.

You should look at which pair is the first in the gearbox, its gear ratio, gearing. The choice of gearbox also includes the location of the shafts in space. They can be located at right angles and be in different planes. The type of bearings is indicated in the technical documentation. There is also a table of service life of different components.

When designing a machine, the selection of a worm gearbox is carried out based on power and gearing location. With lower engagement, the pair is well lubricated, does not require additional cooling and can operate for a long time. You should pay attention to the operating mode. The node is not always able to work for several hours continuously. The worm joint overheats quickly.

1.2.1 Worm gearboxes

Worm gearboxes are the most common type of gearboxes. The drive has compact dimensions (compared to cylindrical units). The gear ratio of the worm pair can reach 1-100 (sometimes higher).

The potential for increasing torque when reducing shaft speed is higher for worm gearboxes than for equipment with other types of gears. A gear ratio of the same order can be obtained when operating a three-stage helical gearbox. In worm units, one stage is sufficient to solve this problem. Another advantage is the simplicity and low cost of worm gearboxes. The use of a worm gear reduces the noise level of the transmission and ensures high smoothness.

The self-braking function is present only in worm gearboxes. Its principle is based on braking the driven shaft in the absence of movement on the drive shaft (worm). Self-braking in the transmission occurs at the moment when the lift angle of the drive shaft is less than or equal to 3.5 degrees.

When choosing a worm gearbox, you should take into account the fact that as the gear ratio increases, the efficiency of the worm gear decreases. Hence the energy loss due to friction of the worm on the teeth of the wheel.

The service life of worm drives is, on average, 10 thousand hours.

Design and principle of operation

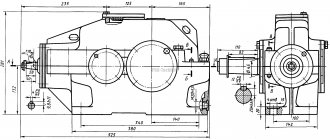

What parts does such a responsible mechanism consist of? The classic gearbox design requires the following working parts:

- body part with a cover, a hole for checking the technical fluid level;

- set of bearings;

- shafts - depending on the purpose and number of gears, in addition to the input and output, an intermediate one is added;

- parts that implement transmission between shafts - gears, worm elements.

The layout of the elements depends on the type of gearbox. In addition to the above basic elements, the device consists of additional parts - stuffing box seals, keys, adjusting rings, sealing gaskets.

Device

Gear mechanisms can be single-stage or multi-stage. An example of the simplest gearbox is the meshing of two gears or gears of different diameters, an external type of gearing. The smaller gear is the drive gear, located on the drive shaft of the gearbox. This shaft receives torque from the engine. The large gear is the driven gear and is fixed to the driven shaft. If the difference in the number of teeth between the gears is 3 times, the drive will make one full revolution, and the driven will turn the shaft only a third. The traction force on the driven shaft is 3 times relative to the output force of the engine.

The drive shaft of the gearbox is always slightly smaller than the driven one - this design feature, due to the difference in torque, helps determine its type. The use of elements such as stuffing box seals is necessary to seal the lubricant inside the gearbox housing. Keys secure gears to shafts. Gearbox diagrams are necessary for a complete display of all elements, indicating markings and dimensions.

Interesting: Metal cutting technology with gas

The gears on the shafts are located inside the housing with bearings. Lubrication is achieved by partially or completely filling the housing volume with process oil. The viscosity and composition of oil in industrial and automotive gearboxes are different. When the bath is partially filled (often found on industrial gearboxes), the gear teeth, moving down, capture the oil and thus lubricate the contact zone in the gear. The oil must be replaced: for a gearbox, the schedule is set based on the vehicle’s mileage in kilometers, for an industrial gearbox it depends on the operating time in hours.

Depending on the required gear ratio, the number of stages increases, the elements transmitting torque change. An axle in a passenger car with all-wheel drive is characterized by equal gear ratios in the front and rear mechanisms - to synchronize the rotation of the wheels.

The cover is necessary for access and inspection of the internal structure without completely disassembling the mechanism. Parts are subject to periodic inspection for wear.

Operating principle

The principle of operation of a mechanical gearbox is the interaction of the teeth of the parts that transmit torque. The power unit supplies torque to the drive shaft of the mechanism, the output shaft produces lower speeds and increased torque. If the mechanism is high-speed, then the shaft speed increases and the power torque decreases. The gearbox, as a power link, works to transmit torque to the actuator.

Marking

To designate gearbox models, combinations of letters and numbers are used to characterize the parameters and type of device. In the first place the number of stages and type of transmission are indicated:

- worm - H;

- cylindrical - C;

- globoid – G;

- conical - K;

- planetary – P.

Example of gearbox marking

For combined models, the letter indicating first gear is placed first:

- cylindrical-worm - TsCh;

- conical-cylindrical - CC;

The number of gears of a certain type is indicated by a number placed before the letter of the gear.

1.2.2 Worm globoid gearbox

The screw of a globoid worm gear has a convex shape (in other worm gears it is cylindrical). This design feature increases torque transmission and drive power.

Globoid gearboxes are designed for use in environments that require high reliability, absence of backslip and dynamic shocks on the output shaft. Most often, gearboxes of this type are used in drum drives of elevators: the globoid pair is adapted to variable loads arising during lifting and braking of the car, and is able to maintain normal reversibility during operation.

Table 2. Permissible loads for globoid worm gearboxes type ChG

| Standard sizes | Nominal gear ratio | Worm rotation speed, rpm | |||||

| 750 | 1000 | 1500 | |||||

| Rvx, kW | Tout, N m | Rvx, kW | Tout, N m | Rvx, kW | Tout, Nm | ||

| Chg-63 | 10 | 1,2 | 120 | 1,5 | — | 1,9 | 110 |

| 12,5 | 1,1 | 130 | 1,3 | 130 | 1,7 | 110 | |

| 16 | 1,0 | 150 | 1,2 | 150 | 1,5 | 130 | |

| 20 | 0,8 | 150 | 0,9 | 150 | 1,3 | 130 | |

| 25 | 0,5 | 125 | 0,6 | 110 | 0,8 | 110 | |

| 31,5 | 0,4 | 110 | 0,5 | 110 | 0,6 | 90 | |

| 40 | 0,3 | 110 | 0,3 | 100 | 0,5 | 90 | |

| 50 | 0,2 | 100 | 0,3 | 100 | 0,3 | 90 | |

| 63 | 0,1 | 90 | 0,2 | 90 | 0,3 | 80 | |

| Chg-80 | 10 | 2,4 | 250 | 2,8 | 220 | 3,1 | 170 |

| 12,5 | 2,0 | 260 | 2,4 | 240 | 2,6 | 180 | |

| 16 | 1,6 | 260 | 1,9 | 240 | 2,1 | 180 | |

| 20 | 1,5 | 300 | 1,7 | 260 | 1,8 | 200 | |

| 25 | 1,0 | 250 | 1,1 | 220 | 1,5 | 190 | |

| 31,5 | 0,7 | 220 | 0,8 | 200 | 1,1 | 180 | |

| 40 | 0,6 | 220 | 0,7 | 200 | 0,9 | 180 | |

| 50 | 0,5 | 210 | 0,5 | 180 | 0,6 | 160 | |

| 63 | 0,3 | 200 | 0,4 | 170 | 0,5 | 150 | |

| Chg-100 | 10 | 4,3 | 460 | 4,7 | 380 | 6,3 | 350 |

| 12,5 | 3,8 | 500 | 4,0 | 400 | 5,5 | 380 | |

| 16 | 3,0 | 500 | 3,6 | 450 | 4,6 | 400 | |

| 20 | 2,7 | 550 | 3,2 | 500 | 3,9 | 420 | |

| 25 | 2,0 | 500 | 2,3 | 450 | 3,0 | 400 | |

| 31,5 | 1,4 | 420 | 1,6 | 380 | 2,1 | 350 | |

| 40 | 1,2 | 420 | 1,3 | 380 | 1,8 | 350 | |

| 50 | 0,9 | 400 | 1,0 | 350 | 1,3 | 320 | |

| 63 | 0,7 | 380 | 0,8 | 320 | 1,1 | 300 | |

| Chg-125 | 10 | 8,4 | 900 | 10,4 | 850 | 12,3 | 700 |

| 12,5 | 7,1 | 950 | 8,9 | 900 | 10,0 | 700 | |

| 16 | 5,6 | 950 | 7,0 | 900 | 8,5 | 750 | |

| 20 | 5,3 | 1100 | 6,3 | 1000 | 7,8 | 850 | |

| 25 | 4,0 | 1000 | 4,6 | 900 | 5,2 | 700 | |

| 31,5 | 2,9 | 900 | 3,4 | 800 | 3,9 | 650 | |

| 40 | 2,4 | 900 | 2,8 | 800 | 3,2 | 650 | |

| 50 | 1,7 | 800 | 2,1 | 750 | 2,6 | 650 | |

| 63 | 1,4 | 750 | 1,7 | 700 | 2,1 | 600 | |

| Chg-160 | 10 | 16,7 | 1850 | 20,3 | 1700 | 28,3 | 1600 |

| 12,5 | 13,9 | 1900 | 16,3 | 1700 | 22,8 | 1600 | |

| 16 | 11,0 | 1900 | 13,7 | 1800 | 18,6 | 1650 | |

| 20 | 9,7 | 2050 | 11,9 | 1900 | 16,5 | 1800 | |

| 25 | 7,6 | 1950 | 8,6 | 1700 | 11,2 | 1500 | |

| 31,5 | 5,7 | 1800 | 6,4 | 1550 | 8,2 | 1350 | |

| 40 | 4,6 | 1800 | 5,1 | 1550 | 6,6 | 1350 | |

| 50 | 3,6 | 1650 | 4,0 | 1450 | 5,0 | 1250 | |

| 63 | 2,8 | 1550 | 3,4 | 1450 | 4,1 | 1200 | |

Purpose of the mechanism

The main purpose of the gearbox is to change the torque and revolutions received from the engine. In production processes, the gearbox is designed to implement the drive in:

- powerful processing machines;

- locking (opening) systems for heavy structures;

- lifting and holding devices.

If you touch on the design of vehicles, it becomes clear why a gearbox is needed in a car. For a car, this mechanism drives the wheels. Gearboxes can be located:

- on the rear axle of the car;

- in front as a separate element;

- integrated into the gearbox.

Gearboxes are most often used in conjunction with a gearbox in cars with front-wheel drive. The design of all-wheel drive vehicles involves 2 gearboxes on the front and rear axles with torque transmitted through a driveshaft. Having figured out what the gearbox is responsible for in a car, you need to understand its structure, basic elements and principles of operation.

1.2.3 Helical gearboxes

Spur gears are equipped with spur gears. The configuration of such drives may differ in the position of the input/output shafts and the number of stages. Single-stage cylindrical units are classified only by the location of the shafts. Gear ratios vary in the range of 1.6-6.3.

Schemes of execution of cylindrical pairs:

- unfolded narrow;

- expanded;

- forked;

- coaxial

The most common is the expanded scheme. It allows us to produce unified wheels, shafts and gears that are suitable for the production of gearboxes of different sizes. This factor is decisive for mass production, because helps reduce the cost of products.

For the same purpose, the left gear tooth direction and the right wheel direction are selected for all gear stages. When individually configuring a single gearbox, it is more advisable to use the following scheme: left direction of the gear tooth in the first stage, right direction in the second stage. This configuration will reduce the axial load on the supports.

The shape of gearboxes designed according to an expanded scheme is elongated. The weight of such a unit will be 15-20% more than drives designed using a bifurcated design.

The bifurcated scheme is applicable for low-speed and high-speed stages. In the second option, it is the most rational, since the intermediate shaft can be made according to the principle of a gear shaft, and the high-speed shaft becomes “floating”.

In a coaxial design, the axes of the high-speed and low-speed shafts coincide. The weight and dimensions of the gearbox assembled according to a coaxial design are similar to models with an expanded design. The cost of both types of units is almost the same.

One of the main technical characteristics of a coaxial gearbox is increased power of the high-speed stage, which is achieved by reducing the load on it. However, such units are structurally more complex.

The service life of the helical gearbox is 25 thousand hours or more.

Table 3. Permissible loads for CU helical gearboxes (single-stage horizontal)

| Standard sizes | Rated torque on the output shaft, Nm | Nominal radial force, N | |

| input shaft | output shaft | ||

| TsU-100 | 250 | 500 | 2000 |

| TsU-160 | 1000 | 1000 | 4000 |

| TsU-200 | 2000 | 2000 | 5600 |

| TsU-250 | 4000 | 3000 | 8000 |

Table 4. Technical parameters of helical gearboxes Ts2S (two-stage coaxial)

| Standard sizes | Nominal gear ratios | Rated torque on the output shaft, Nm | Nominal radial force, N | Efficiency | |

| input shaft | output shaft | ||||

| Ts2S-63 | 8; 10; 12,5 | 125 | 500 | 2800 | 0,98 |

Types of gear

The transmission of rotational motion is possible with different shaft arrangements, which determines the type of transmission used in it.

- If the elements are arranged in parallel, a helical gearbox is used.

- For a cross arrangement, one of 3 options can be used:

- gear-screw cylindrical mechanism;

- worm gear, which, in turn, divides the worm gear into spiroid, toroid, and a cylindrical/globoid screw;

- hypoid wheels (helical bevel gears).

- If the working bodies intersect with each other, a bevel gear drive is used (it is rarely used independently).

Depending on the number of connected gears, a cylindrical or worm gearbox can be one-, two-, three- or multi-stage. Its first type is used infrequently, but mechanisms with two or more stages, in turn, are also divided into single-type and combined. In the first case, gears of the same type are connected to the housing, in the second, systems of different classes are combined (worm-cylindrical or bevel-cylindrical, for example).

1.2.5 Helical-bevel gearboxes

This type of mechanism is a hybrid of a single-stage cylindrical and bevel gearbox. Accordingly, this group of equipment has all the advantages and disadvantages of both types of units.

All bevel-helical gearboxes have a high-speed bevel stage. This design feature is explained by the low load capacity and, accordingly, the large dimensions of the unit. In order to reduce the size of the drive, a high-speed conical stage is used.

Bevel gears can be used in low-speed and intermediate stages, which is justified by the need to reduce its sensitivity to errors during production and installation, minimizing their impact on the mechanism as a whole.

The direction of the tooth in a helical cylindrical pair must be chosen taking into account the possibility of subtracting axial forces on the intermediate shafts.

Table 5. Operating mode coefficient of bevel-helical gearboxes (two-stage and three-stage)

| Character of the load mode | Daily duration of operation | ||

| 3 hours | 8 ocloc'k | 24 hours | |

| Calm | 1,25 | 1,0 | 0,8 |

| Moderate tremors | 1,0 | 0,8 | 0,65 |

| Strong tremors | 0,55 | 0,65 | 0,5 |

Types of gearboxes

A gearbox is a mechanism that transmits torque. The simplest mechanical components that transmit torque are belt and chain drives. They transmit rotation from one part to another and at the same time change the angular velocity.

The largest group of gearboxes, which are widely used in all mechanisms, from coffee grinders to blast furnaces, are mechanical gear reducers. They are divided into groups according to several parameters:

- type of gearing;

- number of gears;

- installation method;

- spatial position of axes and gear connections.

Usually the drive shaft of the gearbox is high-speed. It is rigidly connected to the engine and rotates at the same speed, up to 1500 rpm. In the opposite case, when the wheel is the leading one and the output rotation speed increases and the torque decreases, the unit is called a reducing unit.

According to the type of gearing and gear shape, they are divided:

- cylindrical;

- conical;

- worm;

- planetary;

- combined;

- wave

Combined models can have different types of gearing.

Cylindrical

The largest number of helical gearboxes are produced. The working surface of the wheel and gear has the shape of a cylinder. The models are distinguished by high efficiency, ease of execution and a wide variety of parts. Single-stage units are called transmission gearboxes. It is compact, reduces rotation speed and transmits torque at the same time.

Cylindrical models are divided according to tooth shape:

- straight teeth;

- helical;

- chevron

According to the kinematic scheme, they can be rectilinear or branched.

A straight tooth has a rounded surface to promote the largest possible contact area. When engaged, the teeth contact along their entire length. Friction is reduced to a minimum. The efficiency of spur gearing is the highest, 99%.

The advantages of spur gears include minimal load on bearings, low friction, and the mechanism does not heat up.

The disadvantage is loud noise during operation and low power. In order to exert great force, the wheels must be made wide and large-sized.

An oblique tooth is located at an angle. It has a larger contact area with the same wheel rim width. The teeth engage gradually. The helical pair operates quietly, smoothly and can withstand heavy loads.

The friction area along the involute is larger, the parts heat up. The efficiency of helical gearing is 98% or lower. Making parts with helical teeth is more difficult, especially milling the teeth. Greater precision is required when setting the cutting tool. The inclined position of the tooth creates additional axial loads on the bearings and shortens their service life.

To compensate for the negative axial forces of helical gears, chevron gears were created. They represent two wheels on one shaft with teeth inclined in the opposite direction. This increases the power even further.

Chevron gears operate quietly. The disadvantage is the complex and time-consuming technology of cutting teeth.

There can be any number of gears. The arrangement of the shafts is parallel, horizontal and vertical in the same plane. With a large number of gears in one housing, a double-row arrangement of shafts is possible.

Cylindrical models are widely used in all areas. From household appliances, coffee grinders, drills, to the metallurgical and mining industries. Each machine has one or more gearboxes. In particularly difficult conditions, chevron gears are used.

Conical

The gear and wheel have a conical surface. The shafts are located at an angle. The tooth on the gear is straight and radial. Often bevel gears are used in combined or reduction units. The direction of rotation is possible in any direction. A wheel can act as a leader.

The number of gears in a bevel gear depends on its purpose. Usually alone. The most famous example of helical gearing is the rear axle differential, a torque-reducing unit. From one wheel, 2 gears rotate synchronously in one direction.

Worm

Instead of a drive gear, there is a threaded worm in the gearing. There are 1, 2, 4 threads. No other number of passes is made. The shaft axes are located perpendicularly in different planes.

When rotating, the worm interacts with several teeth of the wheel. Strong friction at an angle creates a braking torque. It prevents the wheel from turning and moving the worm. Self-braking is used in lifting mechanisms. A suspended load will not be able to go down. A worm gear can move a wheel and its associated mechanism with great precision. This is used in instruments and machines to fine-tune the position of the tool.

Worm gearboxes are created with one and two gears. Often they are combined with conical gears.

The worm gearbox has a quiet and smooth operation, the highest gear ratio of one pair is up to 80 units.

The disadvantage is low efficiency and high heat during operation. it is necessary to make a cooling system.

Planetary

Planetary models are structurally different from all others. Their wheel is fixedly fixed in the body. Meshed with it are 4 satellites - gears that rotate synchronously from the central gear.

The carrier, connected to the output shaft, rotates around the sun gear. The satellite shafts are fixed in it through bearings.

The complex design of the planetary gearbox is compensated by its high power, compact dimensions and quiet running. Planetary models are used for work in mines, metallurgy, and the mining industry.

Combined

Gearboxes in which gears of different types are installed are called combined. Most often, cylindrical pairs are combined with worm or conical pairs in one housing.

Geared motor – a motor and a transmission unit assembled in one housing. The drive is usually manufactured with bevel or worm pairs. Number of gears one and two.

In wave models, vibrations of a gear located inside the wheel are used for rotation. The model has not yet received wide distribution.

1.2.6 Shaft-mounted gearboxes

Mounted gearboxes are units with a hollow output shaft. They are mounted directly on the shaft - without additional connections or gears. The advantage of mounted gearboxes is their more compact dimensions and relatively low weight.

The mounting method is usually applicable to worm gearboxes and some other types of gearboxes. The exception is a cylindrical coaxial group of equipment, the design features of which make such installation difficult.

When the load on the output shaft suddenly changes (most often in emergency situations), the absence of a coupling can cause premature failure of the drive equipment. Therefore, the operation of the gearbox requires the creation of operating conditions with a uniform load. As an option - additional drive protection.

Stages of work to create this device

- Installation of drive sprockets on the input shaft. In this case, installation can be done by spot welding, flange or key connection;

- Assembly of driven shaft axles;

- Installation of the driven sprocket;

- The case can be picked up from disassembly and adjusted or made by yourself. At the same time, it is necessary to make technological holes in it for oil seals and bearing connections;

- Installation of closed type ball bearings. An excellent option would be cylindrical ones. Their installation is carried out by tension;

- The drive shaft is mounted on eccentric bearing supports with the ability to adjust the chain tension by at least 15 degrees;

- At the final stage, a lid with a sealing gasket is installed.

Having decided to do this, it is better to first assess your strengths, knowledge and skills in handling the tool, so as not to get into trouble by spending a decent amount of money, a lot of time and effort, and at the same time, without creating the necessary device, but if you are an existing or former mechanic, you can safely get down to business.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

1.2.7 Planetary gearboxes

Planetary (differential) gearboxes consist of a central gear (sun gear) located in the center of the gearbox, auxiliary gears of the same size (satellites) installed around the central gear, and a retainer (carriage) that ensures their secure fastening. The design of the planetary gearbox also includes a ring gear that looks like a gear wheel. Its purpose is to provide traction with the satellites. The central gear is the driving element, the satellites are the driven elements. The ring gear is always stationary.

The design of planetary gearboxes may differ. Models are classified by the number of stages (one-, two- and three-stage), and the kinematic scheme of the planetary gear. The type of bearings is also different. Rolling bearings are designed for low speed operating conditions. In turn, plain bearings are designed for high speed conditions. The main area of use of planetary gearboxes is mechanical engineering.

MPO planetary units are classified as universal drive equipment. They are widely used in drives of mixing mechanisms in the medical, chemical, microbiological industries, as well as in drives for general industrial purposes. Gearboxes of the MPO series can be operated 24 hours a day under constant and variable loads.

Strict requirements are imposed on planetary gearboxes. The production of such equipment requires high precision so that the teeth are in close contact with each other, but are easily set in motion.

Table 6. Technical parameters of Pz planetary gearboxes (single-stage gearboxes)

| Standard size | Carrier radius, mm | Gear ratios | Torque on the output shaft, Nm | Cantilever force, N | Efficiency | Input shaft speed | ||

| input shaft | output shaft | maximum | minimum | |||||

| Pz-31.5 | 32,35 | 8, 10 | 125 | 80 | 140 | 0,96 | 3000 | 500 |

| Pz-40 | 40 | 6,3 | 250 | 120 | 200 | 0,98 | 3000 | 500 |

| 8, 10, 12,5 | 0,97 | |||||||

| Pz-50 | 50 | 6,3 | 500 | 170 | 280 | 0,98 | 3000 | 500 |

| 8, 10, 12,5 | 0,97 | |||||||

| Pz-63 | 63 | 6,3 | 1000 | 240 | 400 | 0,98 | 3000 | 500 |

| 8, 10, 12,5 | 0,97 | |||||||

| Pz-80 | 80 | 6,3, 8, 10, 12,5 | 2000 | 340 | 560 | 0,97 | 1500 | 500 |

| Pz-100 | 100 | 6,3, 8, 10, 12,5 | 4000 | 480 | 800 | 0,97 | 1500 | 500 |

| Pz-125 | 125 | 6,3, 8, 10, 12,5 | 8000 | 680 | 1130 | 0,97 | 1500 | 500 |

| Pz-160 | 160 | 6,3 | 16000 | 960 | 1600 | 0,97 | 1000 | 500 |

| 8, 10, 12,5 | 1500 | |||||||

| Pz-200 | 200 | 6,3, 8, 10, 12,5 | 31500 | 1340 | 2240 | 0,97 | 1000 | 500 |

Gear reducer designs

The vast majority of cylindrical, conical, conical-cylindrical devices operate on involute gearing. The peculiarity of this mechanism is the use of wheels with a toothed profile. Its advantages include simplicity of design (manufacturing gears and wheels takes a minimum of time and requires a simple tool, regardless of the gear profile) and high reliability. The engagement profiles themselves are:

- straight teeth;

- chevron;

- helical.

Our catalog also presents designs of gear reducers with combined straight and helical gears. In particular, bevel and bevel-cylindrical devices operate on hypoid gears and profiles with straight, oblique, and curved teeth.

Operating principle of elvovent gearing:

- The mating wheels slide smoothly over each other everywhere except the contact patch, at low speed.

- In the area of the gear coupling, rolling occurs with a large radius.

- Due to the low sliding speed of the profiles and large swing radii at the engagement point, high efficiency indicators are achieved. At the same time, the wear of the coupling elements is significantly reduced, which determines the durability of their service.

Gearbox lubrication

In order to prevent premature wear of gearbox components and reduce power losses as a result of friction, lubrication of bearings and gears is used.

In gearboxes of low power and low meshing speed, lubrication is carried out by splashing or using an oil bath. The worm, wheel (geared or worm) and spray ring are partially immersed in the same oil that is poured into the housing.

To lubricate high-power high-speed equipment, oil is supplied to the engagement zone by a pump from an oil bath. For bearings, lubricant of a liquid or thick consistency is used.

Gearbox malfunctions

Gearbox malfunctions include:

- wear of teeth in the gear;

- bearing wear;

- depressurization of stuffing box seals;

- overheating due to insufficient lubrication level.

The gearbox in a car most often suffers from untimely replacement of process fluid and operation in difficult conditions. In particular, operation in winter conditions with oil of inappropriate viscosity is harmful. All this leads to rapid wear of the main pair transmission, the appearance of backlash and breaking of the bearings in the housing.

Gear housings

The main requirements for the gearbox housing are rigidity and strength, eliminating the possibility of shaft misalignment. In modern gearbox production, two types of housings are produced - split and one-piece.

The split housing design includes a base and a removable cover. Some models of vertical helical gearboxes have connectors along 2-3 planes. To prevent oil leakage, the gear housing connectors are treated with sealant. It is not recommended to install gaskets between the cover and the base, since they are deformed when fixing the mounting bolts. As a result, the bearings may not fit properly.

The one-piece housing is more often used for worm gearboxes and other types of equipment that are lightweight. This design includes a removable lid.

For the production of gearbox housings, mainly cast iron grades SCh 10-15 are used. Sheet steel is used less frequently, as a rule, when completing large-scale drive equipment for individual orders. The welded steel housing has a wall thickness that is approximately one third less than that of cast iron gearboxes. Recently, aluminum alloys have been increasingly used for the production of housings.

Worm type gearboxes

This category includes worm and worm-cylindrical mechanisms. The main type of transmission in devices is a worm gear, which was previously called a gear-screw. The moment of force is transmitted when the gear and trapezoidal screw (worm) engage. Products are made from wear-resistant materials. In industry, 3 types of worm gearboxes are often used:

- single-pass;

- two-way;

- four-way.

The number of thread channels on the mechanism determines the number of starts. In worm-type devices, the screw engages with a wheel of the same name, which is shaped like a gear. The teeth on it are replaced with threads, which are shaped to fit a trapezoidal screw. In worm devices designed to transmit high torque, the wheels are made of different materials. For wheel hubs, cast iron or inexpensive steel is used, and the teeth are made of anti-friction materials.

The most significant advantage of using worm gearboxes is high efficiency. They are installed in equipment in which the moment of force is large and the angular velocity is small. The main driving element of the mechanism is a trapezoidal screw. It begins to move when the output shaft rotates.

Helical type gearboxes

The purpose and design of the gearbox are always closely interconnected. Cylindrical products are used more often than others in industry. They are installed in lifting mechanisms, metal-cutting machines and other high-performance equipment. Cylindrical devices can be installed vertically or horizontally. The advantages include a wide range of powers and gear ratios, which makes these products universal. They are classified by:

- the distances between the input and output shafts are parallel, coaxial;

- number of stages - one, two, multi-stage;

- installation method - horizontal, vertical.

When produced to order, the mechanism can be equipped with additional flanges, claws and other elements.