GOST markings of sandpaper

In 2005, a new GOST was introduced, according to which a new marking of sandpaper was approved. However, they still use the old Soviet markings of sandpaper. The bad thing is that these markings are not only different from each other, but are even the opposite of each other. Based on the old GOST, large grains on sandpaper are indicated by large numbers. But according to the new European standard, coarse grain is indicated by a decrease in number.

There is no need to remember these markings if the sandpaper is used for household needs. You just need to know that the new marking system suggests the letter P in front of the numbers, but according to the old system, the letter N is placed after the number.

In addition, sandpaper with a numerical index of 40 is the same in both the old and new systems in its technical characteristics. It is a fairly coarse-grained sandpaper and is rarely used for household needs. But sandpaper with fine grains can be designated as follows in the old markings: 25-N, 10-N, 5-N.

And

- The largest database of foreign purchases In addition to Russian tenders, our portal can find tenders from the CIS and countries of the world with a convenient translation option.

- Property auctions and information on bankruptcies Mailings and searches for auctions on property ETP

- Access to API Integration of site data with any of your CRMs

- The ability for several users to work in one account. Additional ability to configure mailing to different addresses, including according to different parameters.

- Procurement analytics All aspects and nuances of procurement are in our analytics: Winners, competitors, contracts, protocols, procurement plans, suppliers, customers.

- Comparison of prices for purchased productsEvaluate the cost of purchased products in tenders

- Information about customers and suppliers. History of participation in procurement, arbitration, purchased products.

- Discounts and bonuses Thanks to interaction and cooperation with leading ETPs, our clients receive discounts on participation in auctions from electronic platforms, on receiving EDS from certification centers and the opportunity to open a special account for free.

- and much more…

New marking

According to the new marking, they are designated respectively as follows: P60, P150, P240. The orientation of these numbers helps in more or less accurately determining the grain size of the sandpaper.

When finishing, as well as during renovation of premises, sandpaper is often used. It can be used manually and with a variety of power tools. Despite the ease of use of this material, many people are seriously confused in its classification.

Abrasive material

I wasn’t too lazy to photograph the underside of the skin that the birdhouse was processing .

Resin bonded line - abrasive material, grinding material (according to the English - Russian dictionary of mechanical engineering and production automation)

If you look at the back of your sandpaper, you will most likely see a similar simple inscription aluminum oxide , which means aluminum oxide ( in common parlance, electrocorundum ). A possible option is silicon carbide or ceramic abrasive.

The first is a brittle material and is used for processing wood, alloy steel, and cast iron.

The second ( silicon carbide ) has high hardness and is designed to work with glass, plastic, and metal.

As a rule, this knowledge is enough for the general consumer to do housework, but for the sake of general development we suggest covering the topic more broadly:

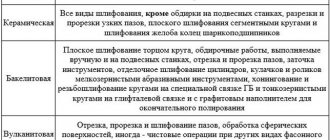

Areas of application of abrasives according to the type of abrasive material

Normal electrocorundum (93-96% Al2O3 - for example 16A) such abrasives are intended for malleable cast iron, hardened and non-hardened steels, and wood.

White electrocorundum (Al2O3 no more than 99% - for example 25A) - for processing heat-resistant and alloy steels.

Silicon carbide (for example 64C) – finishing processing of metal, cast iron, bronze, aluminum, plastic, marble, granite, glass, wood.

Flint (for example 81K) - for processing wood, plywood, leather.

Glass (for example 71C) - for processing wood, plywood, felt, felt.

Garnet – for processing hard hardwood (oak, beech, etc.).

Elbor – for polishing precision surfaces and hard-to-machine steel parts.

Diamond – for polishing and fine honing of precision parts made of carbide and cast iron.

Sandpaper markings and grit

| Purpose | Marking according to GOST 3647-80 | Marking according to ISO-6344 | Grain size, microns | |

| Coarse-grained | ||||

| Very rough work | 80-N | P22 | 800-1000 | |

| 63-N | P24 | 630-800 | ||

| 50-N | P36 | 500-630 | ||

| Rough work | ||||

| 40-N | P40 | 400-500 | ||

| 32-N | P46 | 315-400 | ||

| 25-N | P60 | 250-315 | ||

| Primary grinding | 20-N | P80 | 200-250 | |

| 16-N | P90 | 160-200 | ||

| 12-N | P100 | 125-160 | ||

| 10-N | P120 | 100-125 | ||

| Final sanding of soft wood, old paint for painting | 8-N | P150 | 80-100 | |

| 6-H | P180 | 63-80 | ||

| Fine-grained | ||||

| Final sanding of hardwood, sanding between coats | 5-N,M63 | P240 | 50-63 | |

| 4-N,M50 | P280 | 40-50 | ||

| Polishing final coats, sanding between coats, wet sanding | M40 | P400 | 28-40 | |

| M28 | P600 | 20-28 | ||

| Grinding of metal, plastics, ceramics, wet grinding | M20 | P1000 | 14-20 | |

| Even finer grinding, polishing | M14 | P1200 | 10-14 | |

| M10 | P1500 | 7-10 | ||

| M7 | P2000 | 5-7 | ||

| M5 | P2500 | 3-5 | ||

APPENDIX 2 Mandatory

METHOD FOR DETERMINING THE CUTTING ABILITY OF GRINDING FILTH

1. Essence of the method

The method is based on determining the mass of organic glass sanded off by a sample of sandpaper during the test.

2. Equipment and materials

2.1. Diagram and description of the device type MI-2 - according to GOST 426-77.

2.2. Samples of sanding paper with an outer diameter of (174±5) mm and a hole diameter of (55±3) mm.

2.3. Plates made of organic glass of the TOSN brand - in accordance with GOST 17622-72.

2.4. Linings made of rubber hardness Shore 60-80.

2.5. Adhesive grades BF-2 and BF-4 in accordance with GOST 12172-74 or other grades that ensure the strength of the connection of organic glass plates with a rubber gasket - according to regulatory and technical documentation.

(Changed edition, Amendment No. 2).

3. Preparation for the test

3.1. Glue the plates onto the rubber pads.

3.2. First grind new organic glass plates under test conditions until signs of wear appear on the entire working surface of the plates, clean from dust and weigh with a permissible error limit of ±0.01 g.

4. Conducting the test

4.1. Set the test modes indicated in the table.

| Grain | Clamping force, N | Processing time, min | Availability of airflow during processing |

| 80-50 | 98,0 | 5 | Without airflow |

| 40-25 | 72,5 | ||

| 20-6 | 40,0 | With airflow | |

| 5-M40 | 25,5 |

(Changed edition, Amendment No. 1, 2).

4.2. Install the test sample of abrasive paper, replacing the abrasive paper on the disk after grinding.

4.3. Fix the organic glass plates in the holders in the same position as during grinding.

4.4. At the end of the test, remove the organic glass plates, clean them from dust and weigh them with a permissible error limit of ±0.01 g.

5. Processing of test results

5.1. Cutting capacity ( Q

g/min) is determined by the formula

where m

— mass of ground organic glass, g;

5 — processing time, min.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Machine Tool and Tool Industry of the USSR

DEVELOPERS

E. I. Ardashev; E. S. Viksman; V. T. Ivashinnikov; N. A. Ilyina; V. A. Kvitko; L. A. Kogan; O. F. Kotlyarov; I. F. Korchmar; V. A. Morozov; E. B. Petrosyan; A. A. Pylnev; S. K. Rozin; V. A. Rybakov; N. V. Syreyshchikova; V. D. Tunikov; V. N. Tyrkov

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee on Standards dated 02/18/82 No. 735

3. The date of the first inspection is 1992.

Inspection frequency: 5 years

4. INSTEAD GOST 6456-75

5. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Number of paragraph, subparagraph, application |

| Application | |

| ; | |

| Application | |

| Application | |

| GOST 18277-72 | ; |

6. Validity period extended until 01/01/93 by Decree of the USSR State Standard dated 04/23/87 No. 1374

7. REISSUE (April 1990) with Amendments No. 1, 2, 3, approved in June 1984, April 1987, July 1989 (IUS 9-84, 8-87, 11-89)

Manufacturers of sandpaper

Among the manufacturers of sandpaper, one can distinguish domestic manufacturers (for example, Belgorod) and imported ones. It goes without saying that foreign manufacturers use European labeling standards. In addition, imported sandpaper is often sold in packages or rolls, while domestic sandpaper is sold in linear meters.

If it is necessary to perform manual work (for example, sanding some kind of wooden surface), they usually buy domestic sandpaper, when it is possible to cut off only a meter from a total roll. (For example, the cost of one meter of grade 16-N is approximately one hundred and eighty rubles, and the cost of one meter of grade 40-N is about two hundred rubles). You can check the exact markings of domestic and foreign products on the Internet by entering “sandpaper markings” into a search engine.

If we recommend any type of domestically produced sandpaper, it is better to purchase fabric-based sandpaper (it has a long service life!) or flap grinding wheels.

Features of application

Here are some tips on using sandpaper for sanding and polishing various surfaces:

- The general rule for using sandpaper is to move from coarser to finer types - from smaller to larger grain sizes.

- The coarsest grain is used for roughing wood and removing paint, and the fine grain is used for various stages of finishing sanding.

- When wet sanding, it is recommended to use waterproof paper with a grit rating of 400-600. Thus, it is possible to reduce the amount of dust and obtain a smoother surface.

- For manual processing of complex curved surfaces, you can attach the sandpaper to a thick piece of rubber.

- For ease of work, the material can be wrapped around any solid block.

Read on to find out more!

Accordion type fire curtains

How to attach plastic skirting boards in an apartment

Types of heated towel rails, which one is better to choose?

How to install an inspection hatch in an internal and external corner?

A stainless steel channel is an indispensable part of any metal structure

Stainless steel heated towel rail - a convenient solution for the bathroom

- 2.71

Rating: 2.7 out of 5 Votes: 348

- 5

Reply

6 years ago

Galina Alekseevna

6 years ago

Quote

I ran into the problem of buying sandpaper at a hardware store. Based on experience from Soviet times, my husband told me the markings and I went to the store on my own. They sold the wrong thing!!! And now I understand why. The article says that domestic and imported markings are radically different. The table is very useful, now I won’t get confused about which one to ask in the store.

Lily

6 years ago

Quote

The change in labeling has confused me more than once, but it’s not that difficult to figure out. Sandpaper is in high demand, as it is used in many areas; in everyday life, I advise you to use several types. Take from fine-grained 5-N, M50/P280 it will help to quickly correct minor errors during painting, varnishing or something else, medium-grained 8-N/P150, coarse is rarely needed for household needs.

Alik

6 years ago

Quote

I have been using Belgorod sandpaper for a long time. I like the quality of this paper. It lasts longer when you clean metal for painting. I was convinced from my own experience that Belgorod produces better quality sandpaper.

Alexander

6 years ago

Quote

In my work I rely on the ISO-6344 marking, but I’m not at all familiar with GOST standards. I mainly use P60 and P120 for sanding walls. But for polishing a car body, P40, P80, P120 and P1000 are more suitable.

ACCEPTANCE RULES

3.1. Acceptance inspection and periodic testing should be carried out to verify that the abrasive paper meets the requirements of this standard.

3.2. At least 1% of rolls of abrasive paper from the batch, but not less than 3 pieces, according to paragraph 1.4 must be subject to acceptance control for compliance with the requirements of clauses 1.2, 2.7.1, 2.7.2 and 2.7.3; 1.5; 2.12 and 2.13 - 0.1%, but not less than 3 pcs.

3.1, 3.2. (Changed edition, Amendment No. 2).

3.2.1. The batch must consist of abrasive paper of one specification, produced in one shift and simultaneously presented for acceptance according to one document.

3.3. If during acceptance control it is determined that there is non-compliance with the requirements of the standard for more than one controlled indicator, then the batch is not accepted. (Changed edition, Amendment No. 2).

3.3.1. If non-compliance with the requirements of the standard is established for one of the controlled indicators, then repeated control is carried out on a double number of rolls of skins. If there are defects in the re-sampling, the batch will not be accepted. (Introduced additionally, Amendment No. 2).

3.4. Products (one of the roll sizes) that have passed the acceptance control (according to clause 3.2) must be subjected to periodic testing for compliance with the requirements of clauses 2.8 and 2.10 0.5%, but not less than 3 pcs., clauses 2.9 and 2.11 0.5 % rolls of sandpaper, grit 40; 8; 5 and M40, but not less than 3 pcs., clause 2.9 - on all types of substrates. (Changed edition, Amendment No. 2).

3.5. Periodic testing must be carried out at least once a year. (Changed edition, Amendment No. 3).

Type of abrasive application

Sandpaper with a semi-open or open abrasive layer

The base is half closed. The gaps between the particles cover 40 to 60% of the base area. This abrasive is used for processing soft and friable materials.

No lumps are formed during operation, which prevents clogging of empty spaces with waste.

sandpaper with a closed or continuous abrasive layer

It is characterized by complete coverage of the base with abrasive material and is designed for use on hard surfaces.