TECHNICAL REQUIREMENTS

1.1. Wrenches must be manufactured in accordance with the requirements of this standard and the standards establishing the basic dimensions of wrenches, and for sale through a retail network and according to samples approved in the prescribed manner.

(Changed edition, Amendment No. 3).

1.2. The hardness of the wrenches must correspond to that indicated in the table. .

Table 1

| Jaw size, mm | Hardness HRCе | |

| Row 1 | Row 2 | |

| £ 36 | 45,5 … 51,5 | 41,5 … 46,5 |

| > 36 | 40,5 … 46,5 | 36,5 … 41,5 |

Note. It is allowed to reduce the hardness of the key handles by 5 HRCe units, compared to the lower hardness limit indicated in the table. .

(Changed edition, Amendment No. 1).

1.3. The strength of wrenches is determined by the torques given in table. .

table 2

| Key jaw size, mm | Test torque, N × m, not less | Key jaw size, mm | Test torque, N × m, not less | ||||||

| Group A | Group B | Group C | Group D | Group A | Group B | Group C | Group D | ||

| 2,5 | 2,27 | 0,63 | 0,51 | 0,25 | 22,0 | 370,00 | 281,00 | 225,00 | 112,50 |

| 3,2 | 4,04 | 1,27 | 1,02 | 0,51 | 24,0 | 451,00 | 359,00 | 287,00 | 143,50 |

| 4,0 | 6,81 | 2,37 | 1,20 | 0,95 | 27,0 | 594,00 | 499,00 | 399,00 | 199,00 |

| 5,0 | 11,50 | 4,44 | 3,55 | 1,77 | 30,0 | 760,00 | 670,00 | 536,00 | 268,00 |

| 5,5 | 14,40 | 5,80 | 4,64 | 2,32 | 32,0 | 884,00 | 804,00 | 642,00 | 321,00 |

| 6,0 | 17,60 | 7,37 | 5,90 | 2,95 | 34,0 | 1019,00 | 951,00 | 761,00 | 380,00 |

| 7,0 | 25,20 | 11,40 | 9,12 | 4,56 | 36,0 | 1164,00 | 1117,00 | 894,00 | 447,00 |

| 8,0 | 34,50 | 16,60 | 13,30 | 6,65 | 41,0 | 1579,00 | 1442,00 | 1154,00 | 577,00 |

| 9,0 | 45,40 | 23,00 | 18,40 | 9,20 | 46,0 | 2068,00 | 1816,00 | 1453,00 | 726,00 |

| 10,0 | 58,10 | 36,80 | 24,70 | 12,40 | 50,0 | 2512,00 | 2145,00 | 1716,00 | 858,00 |

| 11,0 | 72,70 | 40,70 | 32,60 | 16,35 | 55,0 | 3140,00 | 2596,00 | 2077,00 | 1038,00 |

| 12,0 | 89,10 | 51,50 | 41,20 | 20,60 | 60,0 | 3847,00 | 3089,00 | 2471,00 | 1235,00 |

| 13,0 | 107,30 | 64,40 | 51,60 | 25,80 | 65,0 | 4641,00 | 3625,00 | 2900,00 | 1450,00 |

| 14,0 | 127,60 | 79,80 | 63,00 | 31,90 | 70,0 | 5520,00 | 4205,00 | 3364,00 | 1682,00 |

| 15,0 | 150,10 | 96,20 | 77,00 | 38,50 | 75,0 | 6487,00 | 4831,00 | 3865,00 | 1932,00 |

| 16,0 | 175,00 | 115,00 | 92,20 | 46,10 | 7544,00 | 5491,00 | 4393,00 | 2196,00 | |

| 17,0 | 201,00 | 136,00 | 109,00 | 54,00 | 85,0 | 8694,00 | 6200,00 | 4960,00 | 2480,00 |

| 18,0 | 230,00 | 160,00 | 128,00 | 64,00 | 90,0 | 9938,00 | — | — | — |

| 19,0 | 261,00 | 186,00 | 149,00 | 74,50 | 95,0 | 11270,00 | — | — | — |

| 21,0 | 330,00 | 247,00 | 197,40 | 99,00 | 100,0 | 12717,00 | — | — | — |

(Changed edition, Amendment No. 2, 3, Amendment).

1.4. The strength of keys for round spline nuts is determined by the torques given in table. .

Table 3

| Wrenches for nuts with diameter D , mm | Test torque, N × m, not less | Wrenches for nuts diameter D , mm | Test torque, N × m, not less | Wrenches for nuts diameter D , mm | Test torque, N × m, not less |

| 12 | 0,90 | 55 — 60 | 176,50 | 135 — 140 | 293,5 |

| 14 — 16 | 3,35 | 65 — 70 | 196,00 | 150 — 160 | 293,5 |

| 22 — 24 | 16,80 | 75 — 85 | 206,00 | 165 — 170 | 313,0 |

| 26 — 28 | 56,10 | 90 — 95 | 220,60 | 175 — 190 | 334,0 |

| 30 — 34 | 127,80 | 100 — 110 | 245,0 | 200 — 210 | 354,0 |

| 38 — 42 | 137,50 | 115 — 120 | 265,0 | 220 — 230 | 382,0 |

| 45 — 48 | 157,20 | 125 — 130 | 265,0 | 240 — 250 | 412,0 |

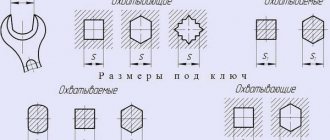

1.5. The maximum deviations of the nominal dimensions of the wrench openings must correspond to the values indicated in the table. .

Table 4

| Key size S | Maximum key size deviation | Key size S | Maximum key size deviation | ||||||

| increased accuracy P | normal accuracy N | increased accuracy P | normal accuracy N | ||||||

| no less | no more | no less | no more | no less | no more | no less | no more | ||

| 2,5 | +0,02 | +0,08 | — | — | 22,0 | +0,06 | +0,36 | +0,06 | +0,46 |

| 3,2 | +0,02 | +0,14 | 24,0 | ||||||

| 27,0 | +0,08 | +0,48 | +0,08 | +0,58 | |||||

| 4,0 | +0,02 | +0,12 | +0,02 | +0,14 | 30,0 | ||||

| 5,0 | 32,0 | ||||||||

| 5,5 | 34,0 | ||||||||

| 6,0 | +0,03 | +0,15 | +0,03 | +0,18 | 36,0 | +0,10 | +0,60 | +0,10 | +0,70 |

| 7,0 | 41,0 | ||||||||

| 8,0 | 46,0 | ||||||||

| 9,0 | 50,0 | ||||||||

| 10,0 | +0,04 | +0,19 | +0,04 | +0,24 | 55,0 | +0,12 | +0,72 | +0,12 | +0,92 |

| 11,0 | 60,0 | ||||||||

| 12,0 | +0,24 | +0,30 | 65,0 | ||||||

| 70,0 | |||||||||

| 13,0 | 75,0 | +0,15 | +0,85 | +0,15 | +1,15 | ||||

| 14,0 | +0,05 | +0,27 | +0,05 | +0,35 | 80,0 | ||||

| 15,0 | 85,0 | ||||||||

| 16,0 | 90,0 | +0,18 | +0,95 | +0,19 | +1,25 | ||||

| 17,0 | +0,30 | +0,40 | 95,0 | ||||||

| 18,0 | 100,0 | ||||||||

| 19,0 | +0,06 | +0,36 | +0,06 | +0,46 | |||||

| 21,0 | |||||||||

(Changed edition, Amendment No. 2, Amendment).

1.5.1. Unspecified maximum deviations in the dimensions of the shape and location of surfaces not subjected to machining are in accordance with GOST 7505-89, GOST 7062-90 and GOST 7829-70.

(Introduced additionally, Amendment No. 3).

1.6. The roughness parameters of key surfaces according to GOST 2789-73 should be no more than those indicated in the table. .

Table 5

| Surface name | Roughness according to GOST 2789-73 for coatings, microns | |||

| chrome | cadmium, zinc, oxide with oiling, phosphate with oiling | chrome | cadmium, zinc, oxide with oiling, phosphate with oiling | |

| Version 1 | Version 2 | |||

| Bearing surfaces for open end wrenches and round nut wrenches | Ra £ 1,25 | Ra £ 2,5 | Ra £ 2,5 | Rz £ 20 |

| External contour | Ra £ 2,5 | Rz £ 20 | Rz £ 20 | |

| Working surface of key jaws Tooth surface of keys and inner arc-shaped part of keys for round nuts | Rz £ 20 | |||

| Other surfaces | Rz £ 40 | |||

(Changed edition, Amendment No. 2).

1.7. On the surfaces of keys that are not machined, stamping marks along the parting line are allowed.

(Changed edition, Amendment No. 3).

1.8. Wrenches must have one of the protective and decorative coatings indicated in the table. .

Table 6

| Group of operating conditions according to GOST 9.303-84 | Coating | Designation according to GOST 9.306-85 (according to GOST 9.032-74) |

| 1 | Oxide with oiling | Chem. Oks. prm |

| Phosphate with oiling | Chem. Phos. prm | |

| Chrome 9 microns thick | X9 | |

| Oxide, followed by painting the handles with nitro enamel NTs-25 (or nitroglyphthalic enamel NTs-132) of different colors according to class IV and applying varnish to the lightened head | (Chem. Ox. | |

| Em. NTs-25 | ||

| diff. color IV | ||

| Varnish) | ||

| 2 — 4 | Zinc 15 microns thick, chromated | Ts15.hr. |

| Chrome 1 micron thick with a nickel sublayer 12 microns thick, applied electrolytically | H12.X1 | |

| Phosphate, followed by painting the handles with nitroglyphthalic enamel NTs-132 (or pentaphthalic enamel PF-115) of different colors according to class IV and applying varnish to the lightened head | (Chem. Phos. | |

| Em. NTs-132 | ||

| diff. color IV. Varnish) | ||

| 5 — 8 | Chrome 1 micron thick with an underlayer of electrolytically deposited nickel 14 microns thick and nickel deposited by the same method 7 microns thick | Н14.Н7.Х1 |

| Cadmium 21 microns thick chromated | Kd 21.hr. |

Notes:

1. It is allowed, in agreement with the consumer (trading organizations), to use other protective and decorative metal and non-metallic coatings in accordance with GOST 9.306-85, GOST 9.303-84 and GOST 9.032-74, not inferior to those indicated in the table. .

2. Keys produced for sale through a retail distribution network must have protective and decorative coatings of at least 2 - 4 groups of operating conditions according to GOST 9.303-84.

(Changed edition, Amendment No. 3).

1.9. (Deleted, Amendment No. 3).

1.10. The keys must be marked as follows:

manufacturer's trademark;

throat size or diameter of round spline nuts;

the word “chrome vanadium” or steel grade on chrome vanadium steel keys;

letter (on keys of strength group D

);

designation of keys (last four digits), excluding keys intended for retail sale.

1.11. Other requirements for marking and packaging of keys are in accordance with GOST 18088-83.

1.10, 1.11. (Introduced additionally, Amendment, No. 3).

TEST METHODS

3.1. Key sizes must be checked using universal and special measuring instruments.

(Changed edition, Amendment No. 3).

3.2. The hardness of the keys is determined according to GOST 8.064-94.

3.3. The surface roughness of keys is checked by comparison with roughness samples or profilometers (profilers).

3.4. The performance of wrenches is checked by strength and is determined by the torques given in the table. and table .

Strength tests of keys are carried out on a test bench or device.

Open-jaw, ring and combination wrenches must be installed with the shed on a mandrel having the cross-section shape of a regular hexagon. The nominal dimensions of hexagonal mandrels must be equal to the minimum male turnkey dimensions of normal accuracy according to GOST 6424-73.

Wrenches for round spline nuts must be installed with the jaw on a mandrel with a groove for the tooth. The outer diameter of the mandrel must be equal to the outer diameter of the nut for which the wrench is intended.

Limit deviations of the outer diameter of the mandrels according to h 8.

The hardness of the mandrels is 53 ... 57 HRC.

The strength of the mandrels should exclude the possibility of their deformation when testing keys.

When testing the keys for performance, the torque should gradually increase to the values indicated in the table. for open-end, ring and combination keys and in table. for keys for round slotted nuts. The keys must withstand at least three loads.

After performance testing, the keys should be suitable for further use.

(Changed edition, Amendment No. 1, 3).

3.5. (Deleted, Amendment No. 3).

3.6. The quality of galvanic coatings must be checked according to GOST 9.302-88, paint coatings - according to GOST 9.032-74.

3.7. (Deleted, Amendment No. 3).

Mass types of keys

Touching on the topic of wrenches, an unforgettable image of an open-end wrench appears before your eyes. The nuts are fixed using lips that look like horns. This is where the name comes from. The second name for such means is used by GOST - open-jaw wrench. The center lines of the handle and head most often intersect at an angle of 15-20 degrees. When manipulating in tight spaces, this configuration will make the work easier. The angles between the axes of the head and handle are made in different sizes; opposite heads have different slopes from each other. Horn models are typically divided into various modifications:

- Double-sided instruments have two jaws of different dimensions. Usually their size designations are adjacent (18−19 mm). The jaws can have different thicknesses: thin ones work in hard-to-reach places, while thick ones are used for loosening nuts made of soft materials.

- For one-sided ones, the body is lengthened in order to increase the moment of force when interacting with fasteners. It is used in assembly production for operations with the same type of nuts. Some models have a locking shank for tube extensions.

- High-speed with a modernized working profile and a shortened jaw for high-speed movement of the key from one element to another. The rotation changes when the tool is turned one hundred and eighty degrees.

- Profile cuts on the lips of open-end wrenches increase the number of contact points and shift the location of the boundaries of the fastening components relative to the jaw. The turning force does not damage the structure in the planes of the nut or in the heads of the bolts, and allows you to unscrew deformed elements.

- A wrench with a working profile in the form of a ring, which is put on the mounting surface, is called a spanner. They can have rings at both ends of the working plane. There are edges along the inner diameter. There are six or twelve of them. The hex power tool unscrews tight, soured connections easily and without damage. Twelve-sided is used when working space is limited. The working profile can be made elongated for the use of attachments. The undoubted advantage of the attachment tool is the permissibility of exerting a large force on the unscrewing planes and working in cramped areas. The weak point is discomfort when working with threads of increased length.

- Devices that have a horn-type head on one end and a cap or end-type head on the other are classified as combined. Their heads are the same size on both sides. The dimensions of the body length are different: when space is limited - shortened standard increasing forces - elongated ones creating the maximum peak of pressure - extra long.

- A tool with a variable working profile is called an adjustable tool. The transformation occurs due to a screw mechanism or slider, which moves the moving part to the required width. The clamping of the fixing parts is not tight, which leads to the rolling of the edges. A plus is the possibility of using it with nuts of various diameters.

Read also: How much oil is in gasoline for a Shtil chainsaw