General description of the key

Currently, it is quite difficult to imagine carrying out any repair work that could be done without such devices. The thing is that bolted connections are one of the most common today. Naturally, for each connection a nut and bolt with a certain size are used, which means that wrenches with different sizes must be used. In addition to the fact that the instruments differ in this parameter, they also come in different types: carob, cap, ratchet, etc.

It is precisely because in different situations it is necessary to use different types of these devices, sets of combination wrenches were invented. Having such a kit on hand, you can unscrew almost any bolted connection without any significant problems.

Types and types of keys for the lock

There are a great variety of keys for locks. It is quite difficult to distinguish between them, so in order to successfully classify them, you must first define the types of keys. The division of keys into types will correspond to the typology of locking devices. It is this approach that we will follow when studying unlocking devices for locks in this article.

Keys for cylinder locks

Let's start looking at the typology of keys with unlocking devices for cylinder locks. Cylinder locks differ from all others by a specific secret mechanism, which is represented by a small cylinder with a keyhole in the center. Precisely because the cylinders of such locks are small and the keys to them are also small in size. That's what they are like.

- A key with one bit (another name for an “English” key). Once upon a time, such a key could be seen on every second person in Russia and the CIS countries. English locks were often installed in wooden entrance doors, although their secrecy, to put it mildly, leaves much to be desired. The key of such a lock has teeth on one edge of the working surface, the second edge remains smooth. There is a groove in the center of the working part.

- Key with two bits. Businessmen call it a key to a lock with high or increased secrecy. In fact, such a lock can be opened easily using the most ordinary available tools. The teeth on the key to such a lock are located on two edges of the working surface, and there is also a groove in the center.

- Cross key. A lock of this type will not create a barrier for a burglar. You can open it with a screwdriver, using it as a roll. And the secrecy of the mechanism leaves much to be desired.

- Key for disk locking device. This is a unlocking device with a rounded working surface and intricate grooves and teeth of different thicknesses. It is difficult to open disc locks using the manipulation method, but it is very easy to use the rough method.

- A key unique in appearance, called “Finnish” (in other circles “Swedish”). The working surface of such a key is complex, as is the lock to which it fits. Both edges of the working surface of the key have teeth of different shapes and thicknesses; in the center there is a groove with special recesses. The Finnish lock's secrecy is quite good, as is its resistance to burglary.

- Key with perforated surfaces. Its peculiarity is that it does not have teeth along the edges of the working surface, but its planes are covered with many recesses - perforations. Such keys are most often used for locks made in China, Turkey and Italy. Locking devices of this type have average resistance to burglary and average secrecy.

Important! Having learned to distinguish the secrets of locks by their keys, if you find yourself in an unpleasant situation with a breakdown of the locking device, you can quickly determine the cause of the breakdown, and therefore carry out the opening faster.

Keys for lever locks

Keys for lever locks differ from each other in the area of the working surface and the number of teeth and grooves on its edges. In addition, such keys may have one or two longitudinal projections on the plane of the working surface. The more protrusions and teeth such a key has, the higher the real security of the lock it fits. Well, resistance against rough hacking of the lever will be determined by other factors:

- strength of crossbars;

- the presence of additional protective elements of the housing;

- the strength of the fastening elements of the lock;

- correct installation, etc.

The key to the pump-type lever lock stands somewhat apart. This key has a working surface that looks very similar to a regular key for a lever locking device. However, the teeth are not located on the right and left edges of the work surface, but on the leading edge. To open the lock, you need to press the key into the depth of the keyhole and turn it.

Keys for other types of locking devices

The types of keys are not limited to those we discussed above. There are much more of them, as well as types of locks. Within the framework of this paragraph, we can give only a few examples so that it is clear what we are talking about.

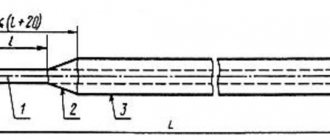

- Keys to rack locks. The key to the rack lock is a pin with oblique grooves cut into it. To open the lock, you need to insert the key into the keyhole and press it firmly. Rack and pinion locks work reliably in both heat and cold, and their service life is estimated at tens of years. However, you can open such a lock using simple tools in a few minutes.

- Electronic key for electromagnetic locks. A device familiar to everyone, because every resident of an apartment building that has an iron door with an intercom has such a key. This electronic unlocking device contains in its memory the code for opening the lock. By attaching the key to the reader, we send a request for code verification. If the code is correct, the door will open.

- Chip keys for car locks. Their peculiarity is that they unlock locks with mechanical and electronic security. The memory of such a key stores an individual code from the ignition switch of a specific car.

If you try to start the engine with a key that is not the original one, the security system blocks the ignition, simultaneously transmitting information about an attempt to start the engine without permission to the owner or law enforcement agencies.

Delving deeper into the study of information about keys, we will be surprised how many of their varieties have been invented by man. The development process has not stopped yet. With the introduction of digital technologies, a large number of different keys have appeared that unlock electronic locks. There are electronic locks for which the keys are parts of the human body: fingers, palms, eyes, etc. Whatever keys are jingling in your pocket, the main thing is not to lose them and then everything will be fine.

Brief characteristics of the set and scope of application

Naturally, a kit can only be called a kit whose contents will allow you to easily carry out operations such as tightening or unscrewing bolts and nuts of various sizes. Such a set should consist entirely of combination wrenches. The main requirement for such a kit was that the keys contained in it must correspond in size to all the main categories of bolts and nuts. If we touch on the topic of the type of combinations, then there are no specific requirements; the types can be very different. However, as practice shows, the most popular are those sets that contain wrenches with a combination of open-end and socket heads.

If we talk about the scope of use of combination wrenches, it is almost limitless. It would take a very long time to list all the categories in which this type of tool is used. It’s easier to say that it has found its application in any work that requires a process such as unscrewing or tightening bolted connections. For these purposes, horn, cap or ratchet types of combinations are used.

The most common options

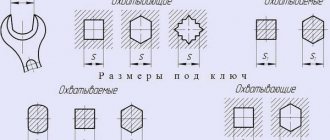

First, let's look at the open-end wrench. In principle, when many of us take the first association to the phrase “wrench”, then in front of them, as in the photo, appears a picture of an open-end wrench. With such a tool, the nut is fixed between jaws , which can resemble horns.

This is where the name of this type of wrench comes from. In these types, the longitudinal axis of the head and the longitudinal axis of the handle are usually at an angle and this angle is 15 degrees. There are other options for a similar tool with a different angle relative to the head and handle; the options can be combined in one key. In principle, this solution is used to facilitate the work of tool owners in limited space.

Such wrenches are used almost everywhere and there is an explanation for this in their simple design and relative versatility. However, such keys also have their significant disadvantages. The most important thing is that such a tool has only two small contact zones, which are located close to the corners of the nut itself. Pressure on these areas often tends to compress the corners of the nut and, as a rule, this occurs when the size of the throat is slightly larger than the size of the nut. With a little force in this case, the corners will wrinkle. If the size of the hole exactly matches and fits the nut, then creasing can also occur, only with a little more force.

If you reduce the thickness of the wrench lips, the likelihood of damaging the nut increases.

A socket or ring tool is a more advanced way to work the way you want. Its design eliminates the two small contact patches described in the previous paragraph. The socket tool covers the entire nut or bolt . Thus, the number of contact spots increases to six (along the edges of the bolt). Moreover, they are all located a little further from the corners, which prevents them from creasing. The head has a slightly smaller size; in general, it is much more convenient to work with such a tool.

The ring can lie in the same plane as the handle (the so-called flat key), or it can be at a certain angle (this is called a tool with a bent head). Typically the angle is 15 degrees. It is also possible that there is a bend. Some options allow an articulated head. When servicing hydraulic or pneumatic installations, situations arise when it is impossible to put a tool on top and for such cases, slots are made in the ring , transferring it to the open category.

Combination instruments usually combine horn and cap instruments. On one side there is one ring, on the other there is another. This allows you to create a tool that is devoid of the disadvantages of any of the individual types. However, manufacturers do not limit themselves to combining only these two options. More modified versions have an angle of 90 degrees at which the head is rotated and in this case the palm rests on a wide plane when working, which is convenient.

Set selection. Main criterion

If we talk about how to choose the right set that contains a certain type of combination wrench, then it is worth saying that there is quite a large number of approaches. However, among the many, there is one that is considered the most optimal in order to select the most suitable set for a certain type of work.

Naturally, the main selection criterion will be the type of keys. Currently, the most common type is the wrench. This type is presented in almost all sets, which means you need to start from the fact that one head will always be of the horn type. The essence of the choice comes down to selecting the type for the second head. Combination wrenches can have either an additional ratchet type head or a socket head. It is important to note here that the operating principle of both heads is the same. The only difference is that you don’t have to remove the ratchet every time after cranking and put it on again. Therefore, if there is a choice between a horn-cap and a horn-ratchet, then it is better to take the second option.

Creating a universal master key

Any magnetic key can break or a person may lose it. It is important to have with you a duplicate master key or a universal key suitable for each intercom. To create such a device, you need to understand calculus systems (program code) and write a special code into the device command that is capable of transmitting the necessary impulses to the intercom chip, opening a secure door. For such purposes, one of the following types of codes can be used:

- Factory.

- Service.

Factory code

Typically, during the process of creating a key, experts enter the necessary code into its memory. But in addition to the number, there may be empty cells in memory with zeros or other characters written in them. Such cells are needed if you need to program another code. Previously, factory devices were produced into which all keys could be entered, that is, any factory key was able to open any intercom with 100% probability. But technology has constantly developed and models have improved. Now intercoms have become better in terms of security - not all factory codes are able to open the door (the percentage of operation is no more than 50).

Service code

Universal keys for intercom can be programmed. Special service keys are recorded in them, which can be used by service center employees or a person installing and repairing intercoms. During the installation process of the device, a specific key is entered into it. This process is quite complicated, because it takes a lot of time if, for example, you need to program universal keys for intercoms of an entire city.

On video: How does it work and how to make a universal intercom key with your own hands?

Additional criterion for choosing a tool

An additional selection parameter will be the size of the keys themselves. Currently, this parameter is measured in millimeters. Based on this, any good set should contain a minimum of 6 keys, with sizes ranging from 8 to 19 mm. However, there are also extended versions of the sets. In this case, the number of keys increases to 12 or 15 pieces. Thus, the tools will have additional sizes with 6, 7, 15, 22 mm, etc. Concluding, we can say that an additional selection criterion will be deciding whether a set of six keys will be enough for the job or is it better right away purchase the extended version.

How does an intercom key fob work?

The key to the entrance intercom works simply: put it on it and the door opens. Or it didn’t open if the key fob was from the wrong entrance. This article will tell you how it all works inside, how much data is stored there, and why these key fobs don’t need batteries. Just for perspective.

Intercoms and access code

In general, what we call an intercom works like this:

- there is a strong magnet that keeps the door closed;

- there is a panel where you can attach the key;

- at this moment the intercom receives a certain code from the key and compares it with the codes that are stored in its memory;

- If the intercom does not have this code in its memory, the door does not open, but if it does, it opens.

It turns out that the only thing needed from such a key is to transmit the required sequence of bits, which is already in the intercom’s memory.