GOST 2839-80* (ST SEV 1287-84)

Group G24

STATE STANDARD OF THE UNION OF THE USSR DOUBLE-ENDED OPEN SPANNERS Design and dimensions Double-ended open spanners. Construction and dimensions

OKP 39 2651

Date of introduction 1981-01-01

By Decree of the USSR State Committee on Standards dated June 16, 1980 N 2800, the validity period was established from 01/01/81 to 01/01/91**

________________

** The validity period was removed by Decree of the USSR State Standard dated July 24, 1989 N 2426 (IUS N 11, 1989). — Note. INSTEAD GOST 2839-71 * REISSUE (September 1986) with Amendments No. 1, 2, approved in March 1982, April 1985; Fast. N 1203 dated 04/25/85 (IUS N 6-82, N 7-85) An amendment was introduced, published in IUS No. 2, 1990. The amendment was made by the legal bureau “Code”.

1. This standard applies to open-end wrenches with dimensions from 2.5x3.2 to 75x80 mm, manufactured for the needs of the national economy and for export.

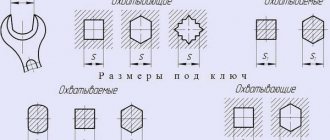

2. The main dimensions of the keys must correspond to those indicated in the drawing and in Table 1.

Drawing. Basic key sizes

Table 1

mm

| Key designation | Applicability | Jaw sizes | (limit shutdown according to h15) | ||||||

| 1st row | 2nd row | Prev. off 17 each | Nom. | Prev. off | no less | ||||

| 7811-0451 | — | 2.5x3.2 | 3,0 | 7 | 8 | 65 | ±1,9 | 4 | 4 |

| 7811-0452 | 3.2x4 | — | 8 | 10 | 5 | ||||

| 7811-0453 | — | 3.2x5.5 | 8 | 13 | 80 | 6 | |||

| 7811-0001 | 4x5 | — | 10 | 12 | 5 | ||||

| 7811-0005 | 5x5.5 | — | 12 | 13 | 95 | ±2,2 | 6 | ||

| 7811-0002 | 5.5x7 | — | 3,5 | 13 | 15 | 100 | 7 | ||

| 7811-0454 | — | 6x7 | 14 | ||||||

| 7811-0006 | 7x8 | — | 4,0 | 15 | 20 | 110 | 7 | 8 | |

| 7811-0455 | — | 8x9 | 4,5 | 20 | 21 | 8 | 9 | ||

| 7811-0003 | 8x10 | — | 22 | 120 | 10 | ||||

| 7811-0456 | — | 9x11 | 21 | 24 | 125 | ±2,5 | 9 | 12 | |

| 7811-0457 | 10x11 | — | 22 | 10 | |||||

| 7811-0004 | — | 10x12 | 26 | 13 | |||||

| 7811-0458 | — | 10x13 | 5,0 | 28 | 140 | 14 | |||

| 7811-0459 | — | 11x12 | 24 | 26 | 125 | 12 | 13 | ||

| 7811-0461 | 11x13 | — | 28 | 140 | 14 | ||||

| 7811-0462 | — | 11x14 | 5,5 | 30 | 15 | ||||

| 7811-0007 | — | 12x13 | 5,5 | 26 | 28 | 140 | ±2,5 | 13 | 14 |

| 7811-0021 | — | 12x14 | 30 | 15 | |||||

| 7811-0027 | — | 13x14 | 28 | 14 | |||||

| 7811-0463 | — | 13x15 | 6,0 | 32 | 160 | 16 | |||

| 7811-0008 | — | 14x15 | 30 | 15 | |||||

| 7811-0472 | 13x16 | — | 6,5 | 28 | 34 | 14 | |||

| 7811-0464 | — | 13x17 | 35 | 17 | |||||

| 7811-0022 | — | 14x17 | 30 | 15 | |||||

| 7811-0473 | — | 16x17 | 7,0 | 34 | 16 | ||||

| 7811-0474 | 16x18 | — | 7,5 | 39 | 175 | 18 | |||

| 7811-0023 | — | 17x19 | 35 | 42 | 17 | 19 | |||

| 7811-0465 | — | 17x22 | 8,5 | 46 | 180 | 21 | |||

| 7811-0475 | — | 18x19 | 7,5 | 39 | 42 | 175 | 18 | 19 | |

| 7811-0476 | 18x21 | — | 8,5 | 45 | 205 | ±2,9 | 20 | ||

| 7811-0024 | — | 19x22 | 42 | 46 | 19 | 21 | |||

| 7811-0466 | — | 19x24 | 9,5 | 50 | 23 | ||||

| 7811-0477 | — | 21x22 | 45 | 46 | 20 | 21 | |||

| 7811-0478 | 21x24 | — | 50 | 220 | 23 | ||||

| 7811-0025 | — | 22x24 | 46 | 21 | |||||

| 7811-0467 | — | 22x27 | 10,5 | 55 | 230 | 26 | |||

| 7811-0026 | 24x27 | — | 50 | 250 | 23 | ||||

| 7811-0468 | — | 24x30 | 11,5 | 62 | 260 | 28 | |||

| 7811-0041 | 27x30 | — | 55 | 26 | |||||

| 7811-0469 | — | 27x32 | 12,5 | 65 | 270 | 30 | |||

| 7811-0042 | — | 30x32 | 62 | 280 | ±3,3 | 28 | |||

| 7811-0479 | 30x34 | — | 70 | 32 | |||||

| 7811-0471 | — | 30x36 | 13,5 | 62 | 75 | 310 | 28 | 34 | |

| 7811-0481 | — | 32x34 | 65 | 70 | 30 | 32 | |||

| 7811-0043 | — | 32x36 | 75 | 34 | |||||

| 7811-0482 | 34x36 | — | 70 | 32 | |||||

| 7811-0044 | 36x41 | — | 15,0 | 75 | 85 | 350 | 34 | 38 | |

| 7811-0045 | 41x46 | — | 15,5 | 85 | 95 | 380 | ±3,8 | 38 | 42 |

| 7811-0046 | 46x50 | — | 17,0 | 95 | 102 | 420 | 42 | 46 | |

| 7811-0047 | 50x55 | — | 18,0 | 102 | 112 | 460 | 46 | 51 | |

| 7811-0048 | 55x60 | — | 18,5 | 112 | 122 | 500 | 51 | 55 | |

| 7811-0049 | 65x70 | — | 21,0 | 132 | 142 | 580 | ±4,5 | 60 | 65 |

| 7811-0050 | 75x80 | — | 23,0 | 152 | 165 | 670 | ±5,0 | 68 | 72 |

Note. The sizes of the pharynx along the 1st row are preferred for use. An example of a symbol for a key with jaw dimensions of 17x19 mm, increased accuracy P, strength group C, with surface roughness version 1 according to GOST 2838-80, with a chrome coating 9 microns thick:

Key 7811-0023 P S 1 X9 GOST 2839-80

The same, normal accuracy:

Key 7811-0023 C 1 X9 GOST 2839-80

(Changed edition, Amendment No. 2).

3. Keys must be made of strength groups C and D according to GOST 2838-80 from the steel grades indicated in Table 2.

table 2

| Jaw size, mm | Steel grade for keys of strength group | |

| WITH | D | |

| Up to 36 | 40HF A* | 40Х* |

| St. 36 | 40Х* | 45** |

______________ * According to GOST 4543-71 ** According to GOST 1050-74 ______________ GOST 1050-88 is in force on the territory of the Russian Federation. — Note. It is allowed to use steel of other grades with mechanical properties in a heat-treated state not lower than those of the steel grades indicated in Table 2.

4. Keys of strength group C must have hardness according to the 1st row, and group D - according to the 2nd row of GOST 2838-80.

5. Technical requirements - according to GOST 2838-80.

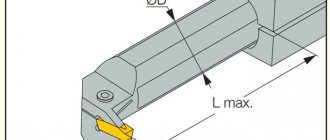

6. The dimensions of the heads and handles of the wrenches are indicated in the recommended appendices 1 and 2.

Wrenches

Wrench

A wrench is a tool for creating a large torque (a pair of forces) on a nut or screw head. This facilitates either tightening or unscrewing the threaded connection. The first nuts were square, but then the shape of a regular hexagon at the base was taken as a basis. This reduced the angle at which the wrench bar (lever) can be held while working. If for a square nut it was 90 degrees, now it is 60. Wrenches are divided into three main types.

Types of keys and geometry

Open-end wrenches

The most familiar to us and, most likely, the most commonly used type of wrench. The ends of this key resemble “horns,” hence the name. There are two sizes on the ends of these keys, for example, 10 by 12, 13 by 15, and so on. They have a wide range of sizes: from the smallest 4mm to the largest 55mm. You can purchase such keys either individually or in sets of several pieces.

Single-sided open-end wrenches

A rather rare key in the household, it is mainly used in industry. Hence their sizes: the smallest is 36mm, and the largest is 95mm. A very important advantage is the ability to put a metal pipe on the handle, which will increase the leverage and significantly increase the tightening force.

Double-sided spanners

It differs from an open-end wrench in that the ends of these keys are made in the form of rings. This allows the key not to break off and allows for torsion without repositioning the key. The sizes at different ends of the key are different, for example 10 by 12, or 17 by 19. Sizes vary from 6mm to 55mm.

Single-sided spanners

Like single-sided open-end wrenches, single-sided spanners are not very common in households. Its dimensions range from 30 to 50mm. You can increase the tightening force by putting a metal pipe on the handle.

A type of single-sided socket wrench is the impact socket wrench. Outwardly similar to a single-sided spanner, but much thicker and equipped with a special platform for striking with a hammer or sledgehammer. This wrench is used for powerful tightening; its dimensions vary from 27 to 105 mm.

Combination keys

These wrenches are a combination of an open-end wrench and a socket wrench: on one side there is an open-end wrench of a certain size, and on the other hand there is a socket wrench of the same size. The sizes of such keys vary from 5 to 32 mm.

Socket wrenches

Such keys are also called tubular. This type is familiar to any motorist - this is the key used to unscrew and tighten the wheels. The main purpose of such a wrench is to unscrew recessed nuts or bolt heads when no other wrench can be used. They can be made simply in the form of a tube - such a key is rotated using any lever threaded through a special hole at the end, or have an L-shape - it is simply rotated by hand or a pipe (to increase the force).

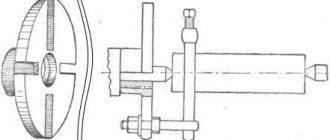

Adjustable wrenches

This is the most common type of key in the household. Equipped with adjustable jaws, this wrench easily adjusts to the size of the nut. Adjustable wrenches are small - up to 20mm, medium - up to 30mm and large - up to 46mm.

When choosing such a wrench, make sure that the jaws move easily and smoothly when moving apart, and also that there is no play. Buy a wrench with a rubber-coated handle - this will prevent your hand from slipping. Some adjustable wrenches have digital markings on them, allowing you to set the wrench to the required size and even measure the size of the part instead of using a caliper. As a rule, adjustable wrenches have a small allowance, so if the maximum size is specified as 19 mm, then when fully extended, you will almost certainly be able to unscrew a nut with a size of 20 mm.

Pipe wrenches

People sometimes call them gas keys. These keys are universal. They can be used to unscrew both regular nuts and parts that do not have special grips (couplings, pipes, etc.). The key expands to different diameters of the parts to be grasped. Depending on the maximum diameter, keys are divided into the following categories in the Russian classification: No. 1 (from 10 to 36 mm), No. 2 (from 20 to 50 mm), No. 3 (from 20 to 63 mm), No. 4 (from 25 to 90 mm), No. 5 (from 32 to 120mm). In the Western classification, keys are marked by inches: 1, 1.5, 2, 3 inches.

Pipe wrenches also differ in the shape of their jaws. Jaws can be L-shaped - well suited for unscrewing regular nuts and S-shaped for unscrewing round workpieces.

Non-sparking keys

If you come across a yellow or red (copper) key, then this is a non-sparking key. Such keys are used in explosive industries; they do not produce a spark when hitting metal or falling. When working with gas, it is imperative to use just such keys.

Key dimensions and material

Keys in continental Europe are numbered by the distance between parallel edges, expressed in millimeters. In the Russian Empire, and later in the USSR, German technology mainly predominated, and the influence of German engineers was stronger than the influence of the British. Therefore, millimeters took precedence over inches; Soviet GOSTs were based on German standards. Keys can be divided into three groups: small, medium and large.

Small wrenches are designed to work with nuts up to 10-12 mm in size. Medium keys occupy a range from 12 to 22 mm. Large keys - from 22 onwards. This division is quite arbitrary and depends on the equipment being assembled or repaired.

To ensure that mechanics and electricians do not interfere with the work of related specialists, which helps prevent accidents, a rather nice move was made: “mechanical” keys have even numbers, and keys for electrical connections have odd numbers.

The material for wrenches is high-strength carbon alloys, the so-called tool steel. The ideal keys are those that are made from tool steel on milling machines and blued ("black" keys). Military-type firearms are often made from this steel. The main attention should be paid to the edges - the accuracy of their processing is crucial. Only this will allow the greatest torque to be applied to the nut without damaging (“collapsing”) the shape of its edges. Such a key is worth any money, since it is an eternal key, in the literal sense, if you protect it from rusting by lubricating it and storing it in a dry place. Unfortunately, such keys are now rare. Cast and stamped keys that shine like silver may be beautiful, but from a specialist's point of view they are just junk. Do not try to purchase sets - it is expensive and not optimal. Even if the wrenches are good, select the tool strictly individually for your job.

Wrench selection

So, before you pay for wrenches, evaluate them for the job they require. The previous sections should help you with this. For tight nuts, buy only the best wrenches. If the nut is available, choose a wide wrench with strong arms - it will not break. If the geometry of the mechanism is complex, a useful tip is to make a model of the key from plasticine and evaluate it for accessibility of the operation. Be a little bit of both a designer and a technologist. When purchasing, choose a wrench: 1) from the best grades of steel; 2) with the most precise and cleanly processed edges and the most suitable edge height.

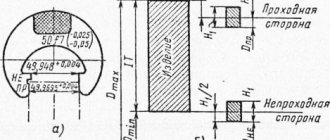

APPENDIX 1 (recommended). WRENCH HEAD SIZES

APPENDIX 1 Recommended

| With 10 mm | With 10 mm | ||

Note. The middle of the radius arc should be at the intersection of the axes of the handle and jaw.

| 2,5 | 7 | — | 4 | 0,5 | 5 | 1 | 9 | 10 | 3,0 | — | — | 10 | 5 |

| 3,2 | 8 | 5 | |||||||||||

| 4,0 | 10 | ||||||||||||

| 5,0 | 12 | 6 | |||||||||||

| 5,5 | 13 | 6 | 10 | 14 | 4,0 | 14 | 7 | ||||||

| 6,0 | 14 | 7 | 2 | 11 | |||||||||

| 7,0 | 15 | 12 | |||||||||||

| 8,0 | 20 | 8 | 1,0 | 7 | 13 | 15 | 4,5 | 15 | 8 | ||||

| 9,0 | 21 | 9 | 15 | 17 | 5,0 | 17 | 9 | ||||||

| 10,0 | 22 | 10 | 8 | 3 | 16 | 19 | 6,0 | 19 | 10 | ||||

| 11,0 | 24 | 19 | 12 | 9 | 17 | 21 | 7,0 | 13 | 6 | 21 | 11 | ||

| 12,0 | 26 | 20 | 13 | 10 | 19 | 23 | 8,0 | 14 | 23 | 12 | |||

| 13,0 | 28 | 21 | 14 | 20 | 24 | 24 | |||||||

| 14,0 | 30 | 22 | 15 | 11 | 4 | 21 | 26 | 9,0 | 15 | 26 | 13 | ||

| 15,0 | 32 | 24 | 16 | 12 | 23 | 27 | 10,0 | 17 | 7 | 27 | 14 | ||

| 16,0 | 34 | 26 | 13 | 24 | 28 | 18 | 28 | 15 | |||||

| 17,0 | 35 | 27 | 17 | 25 | 29 | 29 | |||||||

| 18,0 | 39 | 29 | 18 | 14 | 27 | 28 | 11,0 | 19 | 31 | 16 | |||

| 19,0 | 42 | 31 | 19 | 28 | 32 | 12,0 | 20 | 32 | |||||

| 21,0 | 45 | 33 | 20 | 15 | 5 | 34 | 14,0 | 21 | 8 | 34 | 17 | ||

| 22,0 | 46 | 34 | 21 | 31 | 35 | 15,0 | 22 | 35 | 18 | ||||

| 24,0 | 50 | 38 | 23 | 16 | 33 | 38 | 16,0 | 24 | 9 | 38 | 19 | ||

| 27,0 | 55 | 41 | 26 | 2,0 | 18 | 38 | 41 | 17,0 | 26 | 10 | 41 | 20 | |

| 30,0 | 62 | 46 | 28 | 19 | 6 | 42 | 44 | 19,0 | 28 | 11 | 44 | 22 | |

| 32,0 | 65 | 48 | 30 | 20 | 45 | 47 | 21,0 | 29 | 12 | 47 | 24 | ||

| 34,0 | 70 | 51 | 32 | 22 | 7 | 48 | 50 | 22,0 | 31 | 13 | 50 | 25 | |

| 36,0 | 75 | 54 | 34 | 23 | 50 | 52 | 33 | 52 | 26 | ||||

| 41,0 | 85 | 61 | 38 | 26 | 55 | 60 | 24,0 | 36 | 14 | 60 | 30 | ||

| 46,0 | 95 | 68 | 42 | 29 | 8 | 62 | 65 | 26,0 | 40 | 15 | 65 | 32 | |

| 50,0 | 102 | 74 | 46 | 31 | 67 | 72 | 28,0 | 43 | 16 | 72 | 36 | ||

| 55,0 | 112 | 81 | 51 | 3,0 | 34 | 9 | 73 | 77 | 32,0 | 47 | 18 | 77 | 38 |

| 60,0 | 122 | 88 | 55 | 37 | 81 | 83 | 37,0 | 51 | 20 | 83 | 42 | ||

| 65,0 | 132 | 95 | 60 | 40 | 10 | 88 | 90 | 43,0 | 55 | 22 | 90 | 45 | |

| 70,0 | 142 | 102 | 65 | 42 | 95 | 97 | 48,0 | 58 | 24 | 97 | 48 | ||

| 75,0 | 152 | 109 | 68 | 45 | 11 | 103 | 100 | 53,0 | 62 | 26 | 100 | 50 | |

| 80,0 | 165 | 116 | 72 | 48 | 112 | 110 | 58,0 | 66 | 30 | 110 | 55 | ||

| 85,0 | 175 | 123 | 77 | 51 | 120 | 120 | 63,0 | 70 | 34 | 120 | 60 |

(Changed edition, Amendment No. 1, 2).

Appendix A (mandatory)

Protective and decorative coatings

Table A.1

| Group of operating conditions according to GOST 9.303 | Name of coating | Designation by GOST 9.306 |

| 1 | Chemical oxide, oil impregnated | Chem. Oks. prm |

| Chemical phosphate, oil impregnated | Chem. Phos. prm | |

| Chrome 9 microns thick | X9 | |

| 2 — 4 | Chrome 1 micron thick with a nickel sublayer 12 microns thick | H12.X |

| Zinc 15 microns thick chromated | Ts15.hr | |

| Chemical phosphate, followed by painting the handles with nitroglyphthalic enamel NTs-132 (or pentaphthalic enamel PF-115) of different colors according to coating class IV and applying polyacrylate varnish AK-113 to the lightened surfaces of the head | Chem. Phos. (Enamel NTs-132 different colors GOST 6631 . Varnish AK-113 GOST 9825 . IV) | |

| 5 — 8 | Chrome 1 micron thick with an underlayer of electrolytically deposited nickel 14 microns thick and nickel deposited by the same method 7 microns thick | N14.N7.X |

| Cadmium 21 microns thick chromated | Kd21.hr | |

| Notes 1 It is allowed, by agreement with the consumer, to use other metallic and non-metallic coatings according to GOST 9.306 GOST 9.303 GOST 9.303 | ||

Figure 2

Version 2

Figure 2

Note: Drawings do not define the design.

Table 1

In millimeters

| Key designation | Combination of throat sizes | Outer diameter of the head, no more | Handle length, not less | ||

| Version 1 | Version 2 | ||||

| 7812-0601 | — | 17x19x22x24 | — | 38 | 355 |

| — | 7812-0602 | — | 12.5x17x19x22 | ||

| 7812-0603 | — | 19x22x24x27 | — | 42,5 | 450 |

| — | 7812-0604 | — | 12.5x19x24x27 | ||

| 7812-0605 | — | 22x24x27x32 | — | 49,5 | 630 |

| — | 7812-0606 | — | 20x24x27x32 | ||

| 7812-0607 | — | 30x32x36x41 | — | 63,0 | 700 |

| — | 7812-0608 | — | 20x32x36x41 |

An example of a key symbol with a combination of jaw sizes 17x19x22x24, version 1, normal accuracy N, strength group A, with a chrome coating 9 microns thick:

Key 7812-0601.N A X9 GOST R 51981-2002

The same, execution 2:

Key 7812-0602. N A X9 GOST R 51981-2002

Test methods

7.1 The sizes of keys are checked using universal and special measuring instruments.

7.2 The hardness of the keys is determined by

GOST 8.064

.

7.3 The surface roughness of keys is checked by comparison with roughness samples or profilometers (profilers).

7.4 The strength of the keys is controlled on a test bench.

Socket wrenches with internal hexagons are installed with their jaws on a mandrel having the shape of a regular hexagon in cross section. The nominal dimensions of hexagonal mandrels must be equal to the minimum turnkey female dimensions of normal accuracy according to GOST 6424.

The hardness of the mandrels is 52 ... 56 HRC.

The strength of the mandrels should exclude the possibility of their deformation when testing keys.

Load application diagram F

indicated in Figure 3.

Material and hardness

| Jaw size, mm | steel grade | Hardness, HRC | Key strength group according to GOST 2838-80 |

| up to 36 | 40HFA GOST 4543-2016 | 45,5…51,5 | C |

| St. 36 | 40Х GOST 4543-2016 | 40,5…46,5 | |

| up to 36 | 40Х GOST 4543-2016 | 40,5…46,5 | D |

| St. 36 | 45 GOST 1050-2013 | 36,5…41,5 |

—

Figure 3

Figure 3

To avoid deflection of the key, which may occur when load F

on the length between the load application point

F

and the mandrel, it is necessary to use a stop, as shown in Figure 3.

During testing, the torque value must gradually increase to the values specified in GOST 2838. The keys must withstand at least three loads.

After testing, residual deformations of the keys (cracks, changes in jaw dimensions) that reduce the strength of the keys and the accuracy of the jaw dimensions are not allowed.