In construction, when constructing foundations or monolithic walls with high-quality concrete, it is necessary to lay it without voids. For this purpose, special mechanisms have been created, called concrete compactors or vibrators. According to the principle of operation of the drive, there are 3 types of design:

- pneumatic,

- electrical and

- internal combustion engines (ICE).

According to the transmission of vibration to the solution - deep and surface.

Pneumatic units

There are two types: working on the principle of a pneumatic hammer and rotary turbines. In the first case, the working element receives vibration from the impacts of the driving hammer on the strikers. In the second, a flexible drive is attached to the tip of the rotor, which is connected to the club. The rotor receives rotation from the compressed air created by the compressor.

Electrical

in turn, they are divided into stationary and portable. Stationary ones are produced driven by electric motors, which are installed on platforms or skids and have a limited ability to move. The motors are mounted on stands and remain motionless when the vibrator is operating. Portable (manual) driven by electric drills or hammer drills.

Internal combustion engines (ICE).

When driven by an internal combustion engine, the flexible shaft receives rotation from the clutch through a mechanical connection to the output shaft.

Flexible drive of the working body (club)

For this purpose, the industry produces an attachment - a concrete vibrator for a drill at a low price, which is available in household and professional versions. Vibrators produced for professional use: have a specific design depending on the type of work and drive power. Household: for simple home work on pouring concrete floors or grillage foundations. The article will consider only household devices for compacting concrete mixtures

Vibrator device

The vibrator consists of three components:

- directly from the vibrator itself;

- drive to the executive body - vibrating beater;

- drive mechanism. This device can be any engine: pneumatic, electric or internal combustion engine.

Flexible drive device

The connection between the motor and the actuator is a flexible drive. Drives can be of various designs: flexible, metal, short, long, closed type, rigid mounting and are selected for a specific type of work. The outer diameter of the flexible drive can be in a wide range from 15 to 35 mm, length from 0.5 to 15 m. The most universal is a flexible shaft with a length of 2.5-3 m.

The drive consists of an outer hollow shell with an internal passage hole for a flexible steel cable or coiled spring. One end of the steel cable is connected to the motor shaft, the other end is connected to the “beater” drive. The connection is made with a classic hexagon or clamp clamp.

Tip (vibrator) device

The vibrator is used to create high-frequency mechanical waves and transmit them into the concrete solution. The designs of the tip are varied, but the purpose is the same - to create high-frequency vibration in the tip and transmit vibrations to the building mixture.

An eccentric shaft is used to create vibration. Eccentricity creates an additional load at the end or middle of the rod attached to one side. The rod itself is located inside a hard shell, usually metal and made of pipe. The rotation of the eccentric shaft is ensured by bearings, the outer races of which are installed in guides, which serve as the housing, and the inner races are installed in the eccentric rod.

The body of the “beater” is hermetically sealed at one end; the end of a flexible shaft, which connects to a vibrating rod, is connected to the second. As the eccentric of the rod unwinds, it begins to vibrate. Vibration is transmitted through the bearings to the handpiece body. The oscillation frequency depends on the drive speed and the diameter of the shaft on which the eccentric is located. The larger the shaft diameter, the greater the amplitude and the lower the oscillation frequency.

External sealing devices

In addition to deep compactors for concrete mortar, the industry produces external ones. External fixtures are used for the manufacture of small, narrow or deep products, for example, monolithic walls or columns. In such devices, the principle of transmitting mechanical waves into the solution is transmitted through the shells of the formwork in which the mixture is located. Small parts of the same shape or the same size are placed on a single-multi-level pedestal, vibrations are transmitted through a common vibrating table driven by a single mover. External vibrators are also widely used to help unload solution from large containers: car bodies or concrete mixers and accelerate the movement of the mixture in trays.

The design of such devices is simple, usually it is a single or three-phase motor with elongated shafts on which unbalanced bushings are mounted. When the shaft rotates, these bushings create vibration, which is transmitted through a rigid mount through the table to the products.

To further increase the vibration power, the extreme ends of the unbalanced bushings can touch the base of the table pedestal, creating additional shock amplitude. In addition to those described above, there are molding and compression molding machines for working with concrete mixtures.

General characteristics of vibrating devices for compacting concrete solutions

| Parameter | Meaning | Note |

| type of drive | Electric | The most common vibrators, since the power of the electric motor can vary from 7 kW to 100 kW. Modern battery power sources make the electric drive operational in stationary conditions and suitable for any conditions. Electric vibrators are lightweight, cheap and versatile. |

| ICE | Use with high-performance stationary or professional devices. | |

| Pneumatic drive | The use of stationary compressor units is due to large production plants of reinforced concrete products. | |

| Performance | Household | The so-called domestic or household is used in home construction for the construction of light one-time work on the construction of foundations, pouring in formwork or laying floors in apartments. |

| Professional | Reliable equipment with a power of more than 2 kW and above. Made for constant work with concrete mixtures of any fraction. | |

| Vibration | Low frequency | Low frequency (up to 4) thousand vibrations/min. and the large amplitude determines the use of large filler fractions with concrete. |

| Mid frequency | The most widely used option (10 thousand vibrations/min.) It is used with concrete with an average filler fraction and degree of mobility. | |

| High frequency | Vibration frequency more than 10 thousand vibrations/min. The optimal choice for working with thick mixtures of fine fillers. | |

| Weight | up to 10 kg | In this case, the weight of the device cannot be equated to its power, since the main mass is taken by the flexible drive of the mace. The weight of the actuator depends on the diameter and length. The minimum weight of the vibrator is 7 kg. Industrial stationary ones can weigh up to 200 kg. |

| 10-25 kg | ||

| more than 25 kg |

Dynamic concrete vibrator

“Dynamic” is a well-known brand of Chinese companies producing tools, including construction and hand tools. The official name is Dynamic Construction Machinery Co., Ltd. A flexible drive with a mace produced by this company can be purchased separately. One of the popular ones is the EN brand model. The diameter of the mace is available from 25 to 58 mm, the length of the flexible drive is from 2.5 to 9 m. This product can also be used as an internal vibrator for concrete for attaching to a drill, or you can select an individual working motor for it, depending on the volume of work.

Concrete vibrator model ZPND

Produced by the same company, the differences are that the ZPND model is more focused on professional work, has a more powerful fastening tip and a wide range of club diameters.

Note to craftsmen

When compacting concrete with an internal vibrator, you must adhere to the appropriate recommendations.

- The freshly poured solution may contain about 50% air. The percentage depends on the brand of cement and the degree of its mobility. These voids must be eliminated using a deep vibrator.

- The battery-powered vibrator must reach all places in the poured foundation, otherwise the remaining voids will cause trouble in the future.

- Remember that under no circumstances should you stop pouring the foundation, so you must constantly monitor the operation of the vibrator so that it does not break at an unforeseen moment.

- To avoid the formation of air voids in the solution, the foundation must be poured from a low height.

- It is recommended to immerse the tip of the device into the solution only vertically and not make horizontal movements.

- You must always monitor the distance between dive points. It should not exceed 10 sizes of the diameter of the tip itself.

- When pouring a layer-by-layer foundation, the tip must be immersed in each previous layer by at least ten centimeters to ensure the strongest possible adhesion of all layers.

- If you hold the vibrator at one point for too long, the concrete may delaminate. The operating time of the device is from 5 to 15 seconds. The frequency depends on the brand of cement and the power of the vibrating device.

- The working tip should not touch the walls of the formwork or reinforcement structure.

- The tip must be removed carefully, making slow “up and down” movements so that street air does not enter the place where it was located.

- If there are no bubbles on the entire surface of the concrete, then the work was done correctly.

- A factory vibrator cannot be turned on “idle”, as this will damage the device and shorten its service life.

Other options for making your own vibrator at home

Although making it from a drill or hammer drill is the most common, there are other options for assembling an internal vibrator at home. It is enough to select the appropriate vibration source and adapt a suitable vibrating tip to it.

Video: deep vibrator from a water pump motor

The main advantage of concrete vibrators made from improvised tools is that you do not have to spend money on the device, and after finishing the work it is dismantled, and the components can be used for their intended purpose.

Video: deep vibrator from a trimmer

In order to pour a monolithic foundation yourself, a vibrator made from a drill or hammer drill, assembled at home from improvised materials, is perfect. Such a tool is not suitable for large-scale construction, but will be simply irreplaceable in the construction of structures for a summer house or country house. It should be noted that if the length of the device exceeds one meter, you will need an assistant to work. When assembling a vibrator at home, you need to make all joints as reliable as possible, since the concrete solution creates strong pressure on the device and is able to actively counteract vibration vibrations.

Drive models

The DYNAMIC DV-230 model (in the picture) is represented by one of the many models of flexible shaft drives for stationary vibrators for sealing

shade of the concrete mixture. DYNAMIC DV has a range of engines of varying power and speed. The DV-230 model is positioned as a professional tool with a power of 1.5 kW and a speed of 12 thousand rpm.

There is no time limit for work. Power supply: alternating current 220V, frequency 50 Hz. It has a waterproof housing made of high-strength polystyrene, a high degree of protection against electric shock. Application conditions are limited by the length of the supply wire and power. Capacity 15 m3 per hour.

The “Caliber” VER-1500 drive is produced as a lightweight portable model based on a drill. Supplied without accessories. The manufacturer positions it as a device for household use. The hand-held portable motor is made on the basis of drills made without a speed controller. The main advantage is mobility, lightness and ease of use. Can be used for home laying of floors or compaction of poured strip or grillage foundations for buildings. Productivity 5-7 m3 per hour.

The characteristics of the presented models can be seen in the table

| Parameter | Meaning | |

| Characteristics | Caliber VER-1500 | DYNAMIC DV-230 |

| Type | deep | deep |

| Power | 1500 W | 1500 W |

| Nutrition | 220 V | 220 V |

| Flexible shaft length | depending on model | depending on model |

| Possible vibrator tip diameters | 25,35,45,52 mm | 28,38,48,58 mm |

| Revolutions | 9000 rpm | 12000 rpm |

| Weight | 3.2 kg (+3-4 kg) components, delivery only drive | 5 kg (+3-4 kg) components, delivery only drive |

| Price | 5000 rub. | 9000 rub. |

How to make a vibrator for concrete with your own hands

The first group includes compact units. They are light in weight. The length of the hose on which the vibrating tip is attached can reach 2.5 m. To facilitate operation, a small-sized motor is provided. The cost of such basic units does not exceed 3,700 rubles.

Portable ones differ in design. Main components: motor, vibrating tip and flexible shaft. If portable units propagate vibration waves due to the imbalance of the motor, then in portable devices the motor is stationary. The operating principle of such devices is based on the ability to propagate vibration waves through a flexible shaft.

Portable units can be used in the construction of structures of significant dimensions. The length of the flexible shaft reaches 10 m. The price of devices of this type is 5,500 rubles.

How to choose

First of all, you need to determine for what design you plan to purchase a vibrator. Its dimensions and concrete composition are taken into account. In this case, the most important parameter is the type of filler (fraction size). If it is not possible to connect the unit to a power source at the construction site, models with an internal combustion chamber should be considered.

In domestic conditions, it is better to use devices designed for 220 V. To connect three-phase structures, it is necessary to provide a dedicated line with the appropriate parameters (network voltage 380 V, significant power).

Other criteria:

- the diameter of the area where compaction will be performed, or the radius of action of the unit;

- shaft oscillation frequency, which determines the efficiency of the unit;

- diameter of vibrating nozzle;

- length of flexible shaft/hose.

How to use

A vibrator is used to increase density, which is achieved by ensuring a uniform consistency of the solution. If you use an unsuitable unit for the parameters, the mixture will delaminate, and this may cause a deterioration in the properties of concrete.

It is necessary to maintain the distance to the walls of the formwork. The vibrator does not need to be brought closer than 10 cm to the wooden structure. In addition, the unit must be rearranged correctly. The step in this case is 1-1.5 times the size of the club.

A homemade unit is less efficient than professional equipment, but it will cope with light tasks. Such devices can be made from an electric drill or other improvised tools with a similar operating principle.

This mechanism itself works on the beating principle. When the working peak is immersed in the solution, vibration waves will propagate, and their intensity is quite high. You can increase the range of the tool. To do this, metal rods are welded to the working peak.

If you install a hammer drill on a scoop or trowel, you get a surface type of vibrator. However, due to the small size of the working platform, it is permissible to use the unit to compact a layer of concrete of small thickness.

You can purchase a mace attachment separately. This will make things easier. To secure such a nozzle, a hexagon is required. Some models have it. Then you can simply attach the attachment and start working. When a hexagon is missing, an adapter is used. It is fixed in the drill chuck.

You can make the nozzle yourself. A metal tube is used for this. A bearing is fixed on it, through which a rod is passed. There must be a load inside the cylinder. It is pre-fixed to a metal rod.

In this case, any engine is taken as the basis. A load is fixed on it, which will serve as an eccentric. The resulting structure is connected to the bar. A handle is provided to move it. When the engine is turned on, the force is transmitted to the bar using an eccentric.

Overview of autonomous drives based on internal combustion engines

Grost VGB 4000 W.

The drive is based on a four-stroke gasoline engine with a power of 4000 W. (China) Autonomous sources manufactured on the basis of internal combustion engines, in addition to the main drive for the flexible shaft of the concrete compactor, have additional features

and devices for connecting additional devices, for example, a current generator, universal couplings for connecting other machines, with standard shafts.

In addition to its main purpose, the Grost VGB 4000 W internal combustion engine can be used as an additional source of electricity with a power of up to 4 kW. The versatility of the engine makes it indispensable in facilities that do not have a constant power supply.

CHAMPION CVG424

This is another universal drive from the Chinese company, having the same power as the one described above, but cheaper. The model is 4 kg heavier due to the stand, as it is made of thick-walled metal sheet. Has a smaller fuel tank capacity. Engine characteristics are presented in the table

Basic characteristics of autonomous vibrator drive models | ||

| Parameter | Meaning | |

| Model | Grost VGB 4000 W | CHAMPION CVG424 |

| type of drive | Flexible vibrator | Flexible vibrator |

| Power | 4100 W | 4000 W |

| Nutrition | petrol | petrol |

| Max. rev. | 4000 rpm | 3600 rpm |

| Flexible shaft length | Not included | Not included |

| Recommended vibrating tip diameter | 28,32,38, 50 mm | 28,32,38,45,50,60,70 mm |

| Dimensions | 550x410x430 mm | 550x410x430 mm |

| Weight | 21.2 kg | 23.6 kg |

| Price | 17,000 rub. | 13000 rub. |

Industrial devices for compacting concrete are expensive, and their purchase is advisable for large volumes of work. If working with concrete is intermittent, and your home workshop has a drill with a power of 1 kW or more, then it makes sense to make an internal vibrator for concrete with a drill attachment yourself.

Making a "beater"

A “beater” is a working element that creates vibration to transmit it into the working concrete mixture.

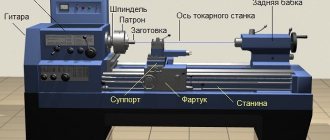

Vibrations are created by an eccentric rod that rotates in bearings. To make the rod, you will need a 12-20mm steel rod (depending on the internal diameter of the selected pipe for the housing). By turning the eccentric on a lathe, or by welding an additional weight on the side of the rod. Before making the eccentric itself, it is necessary to select the bearings in which it will rotate. On the shaft itself it is necessary to prepare seats for the bearing. The length of the shaft is calculated depending on the diameter and length of the rod. The more powerful the drill, the longer or larger in diameter the eccentric.

Selecting a bearing

The type of load on the bearing is rotation with variable radial load. The radial load is transferred from the rod to the body. Additional load is carried by the bearing at the end of the shaft, which is under radial contact load.

Types of bearings that accept radial load

a-c) single-row radial ball bearings, respectively, types 0000, 60000 and 80000 (without, with one, two protective washers);

a-c) radial roller bearings with short cylindrical rollers, respectively, types 2000, 32000, 42000, 52000, 92000, 62000;

e-f) single-row angular contact ball bearings type 36000; angular contact rollers with conical rollers, single row, type 7000.

Having analyzed a number of standard bearings, we can conclude that the most budget option is to choose the radial single-row type 0000. These bearings have the simplest design, but they also have the lowest degree of protection. If the responsible master is used to doing everything as needed, it becomes clear that this option is not optimal. If you choose a single-row radial ball bearing, then it is best to take the option with two protective washers; it is protected from dirt getting into the balls and does not require lubrication because it is included during manufacture.

Even better, variable radial loads can be withstood radially - roller bearings have load distribution over the entire area of the roller, and accordingly, the load concentration is distributed over the entire area of the cages. Considering the operating conditions of the bearing at the end of the shaft, which is not only under radial load, but must also withstand the weight of the entire structure, a thrust roller bearing with short rollers, or radial thrust roller bearings with a tapered roller type 7000 (e) are best suited. on the image.

Bearing seating

In order to correctly install the bearing, it is necessary to prepare the appropriate place on the shaft for landing the bearing races; for the external one, you need to make an axle box, the outer diameter of which must correspond to the inner diameter of the “beater” pipe. The inner race is pressed onto the shaft. First of all, the seating surface must be smooth and parallel and made to an accuracy class of at least 5. The end bearing shank must have a thread with a bearing fixing nut.

The bearing can be seated on the prepared shaft surface either hot or cold. When shrink-fitting, the inner diameter of the bearing should be approximately 0.07 mm smaller than the shaft diameter, and before landing, it should be heated in oil to a temperature of 80°C.

Cold fit - the diameter of the seating surface of the race must exactly match the bearing. In this case, it is allowed to place the clips on a special glue. The permitted tolerances for bearing fit on the shaft can be seen in the figure.

Attaching the vibrator to the drill

The design of fastening an in-depth vibrator for concrete when attached to a drill can be imagined by looking at the figure. The mount consists of a clamp attached to the protruding part of the spindle. Stretches are welded to it, which hold the protective pipe and the entire structure. And although this is not the best option, the principle itself is simple and clear.

Conclusion

In order to fill a monolithic base or process a large volume of solution, it is recommended to use flat equipment. In order to be able to perform such work, it is important to have a high-power hammer drill, as well as a steel frame on which it will be mounted. We must not forget about preparing a special platform made of stainless metal.

A vibrator made by yourself, of course, cannot be used during large construction projects, but in private or personal use it is quite possible. The financial savings are absolutely obvious.

Tags: concrete, vibrator, deep, homemade

« Previous entry

Conditions for successful operation of the structure

Bearing operation

If the bearing is correctly selected for the load and all landing conditions are met, long-term operation is guaranteed, since by standard all bearings are designed to operate up to 5 million revolutions. The standard also provides for the permitted bearing heating temperature. The heating temperature during operation should not exceed 35°C in front of the environment, the maximum heating should not exceed 80°C.

Work of the entire assembly

Prompt operation of the bearings will be guaranteed if the entire structure is used correctly.

Especially when starting the assembled mechanism. The fact is that if the torsional resistance of the “mace” drive cable is high, the engine protection system may be triggered. In industrial versions of the vibrator manufacturing, protection is provided by the design; in home-made ones, when the hammer drill chuck is rigidly connected to the drive, the entire load falls on the gearbox and the protection provided in the drills may be triggered (slippage of the protective clutches - ratchets, or power failure). Therefore, it is best to start with minimal resistance of the drive cable, positioning it strictly in a straight line.

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: +7 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru

Drill as a basis for a concrete vibrator

After the vibrator circuit for functioning in concrete has been prepared, you can begin installing the equipment based on the hammer drill. To construct this device, you will need some tools and materials:

- a hammer drill with a minimum power of about 2 kW;

- steel washer;

- peak.

An in-depth tool for mixing concrete mortar is installed in several stages. The most important thing is to use a hammer drill with a power of at least 2 kW. The use of the tool will be performed in a percussion system and this is worth learning during the preparation process.

It is advisable to use a lance as a nozzle for the equipment. It is necessary to construct some kind of base for the peak during operation. To accomplish this task, you can install formwork. You can create the required adhesion between these two elements by using a steel washer.

Equipment for mixing concrete mortar created independently, under conditions of a small volume of the mixture, can be made using bayonet technology. This technology requires mounting one nozzle onto an existing nozzle.

Diagram of a deep vibrator with a flexible shaft.

For this technology, it is important that the length of the entire nozzle bayonet of the equipment corresponds to the depth of the container. The nozzle will need to rest against the bottom of the container and change its position from time to time. The advantage of this technology is that it is possible to mix a large amount of concrete mixture in a short period of time.

The methods described above make it possible to create deep-depth equipment with the lowest financial costs. It is important to take into account that all the components and components used during the creation of the tool can be changed to different analogues. Replacements will be no less functional. In order for the replacement to be equivalent, it is important to study the principles of operation of the equipment.

General recommendations for use

- If you need to mix a large volume of concrete solution, for example, to install a monolithic base, you can use a vibrator based on a hammer drill. Nevertheless, it is important initially for such purposes to create a metal frame to secure the hammer drill, and also to mount a special steel platform.

- To install a vibrating tool, you must remember that its length should not exceed 100 centimeters. You also need to know that all connections must be designed especially carefully, because they will be subject to heavy loads and vibrations.

Return to contents

Tips for using a homemade vibrator

Professionals recommend adhering to the following recommendations when using a homemade vibrator for pouring concrete from a hammer drill.

- The device is immersed vertically in the solution; horizontal movements should not be made.

- When pouring layer-by-layer, a vibrating tip for concrete from a hammer drill is immersed in each layer to ensure reliable adhesion to the previous one.

- When pouring layer-by-layer, it is not recommended to keep the device in the solution for a long time - it can delaminate the concrete.

- The tip should not come into contact with the walls of the formwork or reinforcement included in the structure.

You can make an internal vibrator for concrete with your own hands in a few hours from raw materials purchased for a hundred rubles at a metal collection point. It can work with both a drill and a hammer drill. A surface vibrator for concrete is made in five minutes from a piece of metal and a drill shank; it only works in impact mode on a hammer drill.