The use of a concrete vibrator during laying is a necessary condition for obtaining the design characteristics of the material.

Regardless of the mixing method, freshly poured concrete contains air bubbles, “excess” moisture, and heterogeneous fragments. You can give a monolith density and brand strength using different compaction methods, one of them is vibration.

Purpose

Even a solution thoroughly swirled in a stirrer cannot be 100% homogeneous. In theory, an uncured monolith is a “skeleton” of crushed stone, evenly covered with a wet cement-sand mixture. In reality, the contents of the formwork (form) include:

RECOMMENDED ON THE TOPIC

- Penetrating waterproofing for concrete

- How to choose impregnation for concrete

- air bubbles;

- water unbound with cement;

- undistributed aggregate or additive particles.

The risk of stratification and airing of the mortar increases with a long time interval between mixing and installation, incorrect pouring (from a great height or in thick layers) or transportation.

Liquid and air “pockets” impair the adhesion of the crushed stone frame to the binder. Having gained strength, uncompacted concrete quickly cracks and crumbles.

To achieve uniformity when pouring into formwork, the concrete solution must be fluid (plastic). At the same time, the correct proportions of heavy concrete exclude a consistency convenient for laying. The use of a deep vibrator for pouring concrete can temporarily increase the fluidity of concrete and prevent the mixture from separating.

After the “correct” vibration compaction:

- the volume of concrete poured into the formwork is reduced by a third - due to the removal of gas and liquid sinks, compaction of sand and crushed stone;

- Cement laitance and fine sand fractions float to the top, the surface becomes smooth and glossy.

During hardening, the “vibrated” monolith reaches high density and maximum (for the design grade) strength.

Vibrator device for concrete

More often, vibrators for deep (internal) type concrete are used on construction sites. Therefore, the design and general principle of operation should be considered using the example of a submersible model.

Main components of vibrating tools:

- drive based on an electric (usually) motor - creates torque on the rotor shaft;

- flexible shaft – transmits the rotation of the motor through the coupling to the shaft (spindle) of the vibrating tip. The flexible shaft is attached to the spindle using a thread;

- vibrating tip (mace) - a rigid body with a spindle located inside and a mechanism that converts the rotational movement of the rotor into vibrations (vibration).

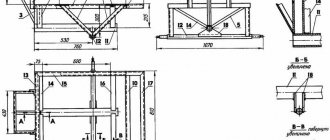

A more detailed drawing of a needle vibrator for concrete is shown in the figure.

Based on the type of rotation conversion mechanism, vibrating tips are distinguished between pendulum and eccentric types.

In the first case, the runner attached to the shaft rolls inside or outside the cone (core or sleeve).

To start a tool with a “pendulum”, it is not enough to turn on the engine - you need to hit the tip on a hard surface to initiate oscillations.

Inside the tips of the second type, vibration is created by an eccentric unit, similar to a crank.

Also, the eccentric mechanism can be implemented in the form of a shaft with a load to shift the center of gravity.

The most common drive option is an electromechanical motor operating from a standard network (220 or 380 V at a frequency of 50 Hz).

High-frequency deep vibrators operate at a frequency of 200 Hz and a voltage of 42 V.

Types of deep concrete vibratory compactors

There are four types of power plants that activate vibrations of the vibrating tip: an electric motor, a gasoline and diesel engine, and an air compressor.

Electric deep vibrators are used more often than others, since most construction sites have a central power supply.

Electric depth compactor with a set of vibrating tips

Gasoline and diesel submersible vibrators are completely autonomous and indispensable at sites located far from power lines.

Gasoline deep vibrator

Pneumatic installations are not widely used in private construction.

In recent years, battery-powered immersion vibrators have appeared on the market. They are not inferior to gasoline ones in terms of autonomy, but are much lighter and more compact.

Cordless deep vibratory compactor

During the Soviet period, vibrators operating in the same frequency range were used on construction sites. Today on sale you can find devices that create vibration vibrations of low, medium and high frequencies, as well as multi-frequency installations. This gradation is due to the fact that the concrete mixture contains particles of different weight and size. They require different vibration frequencies for optimal compaction.

Based on the type of alternating voltage used, electric concrete deep compactors are divided into two types: three-phase and single-phase. The first ones are more powerful and belong to the category of professional tools. The latter are indispensable in individual construction, where there is no three-phase power line.

Types and characteristics

Vibration compaction of poured concrete is possible in three ways - immersion (c), smoothing (a) and vibrating together with the formwork (b).

Depending on the dimensions and other features of the compacted mass, three types of vibrators are used. Having a similar operating principle, different types of vibration compactors differ in design.

Deep vibrator

Also called submersible or internal concrete vibrator. Compaction occurs when the vibrating tip is immersed in the solution.

Depending on the shape, a vibrating attachment can also be called a vibrating bayonet, vibrating shovel or vibrating rod.

Based on the location of the engine, there are: