Dowels, along with anchor bolts, are the most optimal fasteners for securing household items to concrete walls. They securely hold not too heavy cabinets, shelves and other hanging structures. The article discusses what kinds of dowels for concrete there are - their features, methods of installation and dismantling of elements.

Features of dowels for concrete and brick building structures

The dowels that manufacturers produce for concrete walls and other building structures made of similar material are not the same as fasteners for hollow bricks. To perform the required work efficiently, it is necessary not to confuse these two types of fasteners. Therefore, it is important to know their features.

On a note! It is irrational to use concrete fasteners in brickwork. Such an application is absolutely unjustified when the structure is made of blocks with voids. For masonry, special fasteners with a special device are used. In addition, its installation has certain nuances.

Thus, the design of fastening elements for brickwork with voids usually contains:

- Conical rim. It is necessary to control the installation depth of fasteners.

- Special tip. Thanks to its presence, the fastener twists when a screw is screwed into it.

- Locking wings that prevent the product from turning when screwing in hardware.

An example of dowels used in hollow masonry Source stroy-podskazka.ru

A concrete wall or other similar structure made of the same material is a solid element. Special fasteners are used for it. This is exactly what a concrete dowel is. Experts have been using this fastener for a long time. The classic option is the so-called dowel-nails.

The dowel itself is a spacer element. For concrete, manufacturers make it from different plastics, nylon material and even metal. Depending on the material used, dowels have certain parameters. It is the characteristics that influence the scope of application of spacer bushings.

Each dowel in concrete has a certain load-bearing capacity. Its value depends on the design, the so-called bushing, which has notches along its entire surface. It is thanks to them that the fastening element does not rotate in the hole and does not fall out of it even when exposed to the design load.

The design of the bushing also assumes the presence of elastic whiskers. They are always in a compressed position. This feature also affects the reliability of the fastening. In particular, the whiskers prevent the element from being pulled out of the recess.

Dowel with antennae for secure fastening in concrete Source leroymerlin.ru

On a note! The expansion of the sleeve occurs after screwing in, for example, a screw. Its unclamping is carried out due to the presence of slots in the longitudinal direction.

The fastener is fixed into the hole not only mechanically. Manufacturers also produce dowels that are specially designed for porous concrete. Their fixation is carried out with the additional use of special glue. First, a hole is made into the building structure. Then it is filled with adhesive. Then the fasteners are placed. Thanks to the glue, the fastening element is securely fixed in the cavity.

A dowel nail for concrete in a classic design is a universal product. Therefore, it is used in different fields. With the help of this fastener you can solve various important tasks. It allows:

- install different frames;

- fix furniture, paintings and other similar interior elements to structures;

- secure household technical devices.

Dowel-nail for fastening frames Source stroyka-hoz.ru

Today, builders and repair teams can use steel or aluminum nails for concrete for installation processes. This fastener is simply driven, for example, with a hammer into the created holes. It speeds up installation processes. Therefore, it is widely used during construction, repair, and finishing work.

Not a simple dowel but..

Not a simple dowel but... sixbisix

April 8th, 2012The epic with cornices has already lasted about a year... It all started with the fact that I wanted to replace the cornice made in the mid-70s of the last century from scarce metal strings with a more elegant modern analogue.

For this purpose, pictures and corresponding paraphernalia were purchased. In a new panel house, the method of attaching cornices to the ceiling was tested and within three hours two cornices were firmly fixed to the ceiling. Inspired by such success, he hastened to punch holes in his place of residence, but alas... Not only was the interfloor ceiling too hollow, but also More than one dowel could not hold in the loose sand-cement composition, which over more than 40 years had become even more friable. In this regard, the search began for adequate fastening of the cornice to the ceiling... This search continues to this day. Buying fasteners of various types has already turned into a hobby, and so many different anchors, anchors and other fastening delights have accumulated that it’s time to open a museum. Initially, two thoughts came to mind to fix the screw in the ceiling: 1. using a wooden chupik.2. using cement mortar. The chip was rejected immediately because driving a wedge-shaped chupik into something hanging overhead could lead to the slab falling off. The durability of this structure, due to the drying out of the wood, also did not stand up to criticism. Traditionally, a “cement filling” was used for fastening in loose walls. To do this, I drilled a hole about 10-15 mm in diameter and filled this cavity with cement slurry. After this, drilling a 6-8 mm hole and then attaching a dowel led to the desired effect. To implement this, a super fast-setting mixture was purchased from OBI. A paste was prepared from the mixture, which was used to seal the cavity in the ceiling using a stick.

Alas, within five minutes, as promised on the packaging, complete hardening did not occur. A day later, it was possible to install a bubel into the formed filling and secure the first screw. Alas, due to the crumbling of the structure, as well as the speed of preparation and the abundance of dirt, the use of this method had to be stopped en masse. The soul demanded novelty and nanotechnology. Surfing the internet led me to liquid anchor. It's a liquid dowel. It’s also a chemical anchor. The first video inspired hope for the best. A sluggish search led to the Kashirsky yard to a shop where various fasteners were apparently invisible... Including the Fischer FIS VW 300 T (an analogue on the manufacturer’s website could not be found, so the link is to a similar product) . The tube came with two mixers.

The difference between dowels for concrete surfaces and similar elements for brick structures

Any such product allows for reliable fastening of various parts and objects only if it is correctly selected for specific conditions of use. When choosing, be sure to take into account the dimensions of the fastener and the base material where it is fixed.

Dowels for a brick wall have a different design than fasteners for concrete. For masonry, elongated products are mainly used. This is not their only difference.

Long nylon dowel Source vsmete.ru

Therefore, before fixing a dowel in a hollow brick, you need to thoroughly study its features. So, it often looks like a sleeve made of plastic or metal. Its design includes a spacer mechanism. It is double, which guarantees the fixation of at least one part of it on the material, and not in the void of the brickwork.

A threaded rod can serve as a spacer for the bushing. This is, for example, a pin whose diameter corresponds to the dowel used. Other anchors can also be used. They are selected for a specific load.

In addition, manufacturers produce special concrete nails for hammering. Their operating principle differs from similar fasteners for bricks. The nails are intended for use exclusively in non-porous materials with a hard structure. Even when using a hammer, significant efforts are made to hammer them into the created holes in building structures.

Fasteners in the form of nails for concrete surfaces Source pronailers.ru

Nails made specifically for concrete should not be attempted in brick substrates. This especially does not need to be done if the structures have a large number of air cavities. Otherwise, the holes where the so-called nails are driven will collapse.

On a note! It is impossible to reliably fix even a metal dowel for concrete in brickwork. Moreover, this cannot be done if it is made of plastic. The reason for this is the lower strength of the brick, especially if it is hollow, compared to a concrete structure.

Manufacturers still produce universal fasteners. It is mainly made of nylon. Such fasteners include:

- type N – four-spacer product;

- type S – fasteners with locking tabs;

- type U - an elastic element that twists when it enters a void;

- type K – fasteners with spacers located along its entire length;

- type T - a product with three thrusts.

Three-expansion universal dowel Source main-cdn.goods.ru

In fact, manufacturers produce a huge number of dowels in a universal design. This must be taken into account when selecting fasteners. The process must be approached responsibly. After all, structures are created from building materials of different hardness. Therefore, fixation of fasteners in them is carried out subject to certain rules.

See also: Catalog of construction companies that have their own production of materials and components for the construction of houses

Dowels and anchors for drywall: Driva screwdriver, KNAUF-Hartmut, Molly, spring

Drywall is good because it allows you to quickly and efficiently level walls or ceilings. But the material has one significant drawback: it is fragile and is not designed for the load of a wall cabinet or shelf. Traditional fastening methods in the case of gypsum plasterboard surfaces are unreliable: the material begins to crumble. In such a situation, a fundamentally different fastener is used - a special dowel for drywall.

There are several types of dowels that allow you to attach suspended structures to gypsum boards:

Each of these types of fasteners has advantages and disadvantages. To figure out which one is more profitable to use in a specific situation, let’s take a closer look at them.

Main types of dowels

Dowels are classified not only by the material used for their manufacture. They also differ in the installation method. One fastener can be installed into the created holes using only a hammer, while other dowels can be installed using only a special gun. This is exactly the tool that is used when deciding how to hammer a nail into a concrete wall.

When choosing dowels, you always pay attention to the material of the dowels. Plastic products are inexpensive. They are used when mounting non-heavy objects. For heavier structures, metal elements are used.

Plastic dowels Source tildacdn.com

On a note! Metal nails for concrete surfaces have a smooth surface. There is no thread on it. They are difficult to dismantle. They are used when it is necessary to perform fastenings for a long time.

Metal nails for concrete Source 9.allegroimg.com

Spacers are common fasteners. They have a cylindrical shape. They are driven into the created recesses. Often, the design of such fasteners contains spikes. They improve the reliability of fixation.

Dowel with a spacer structure, antennae and spikes Source dgural.ru

There is a fastener, the fixation of which is similar to the principle of operation of the “butterfly”. Such dowels are universal elements. Therefore, they are used in different designs. They seem to open up on each side.

A plastic sleeve that expands to the sides when a screw or self-tapping screw is tightened. Source wkret-met.com

Another type is façade fasteners. It is used when installing frame structures on walls. The facade fastening element has almost the same structure as the product in the spacer design. However, it is distinguished by its longer length and massive cap.

Facade extended dowel with spacer hardware Source a-krep.ru

Dowels are also made exclusively for aerated concrete. They are distinguished by the presence of wide threads. It is this that ensures their reliable fastening in a material with a porous structure. This fastener is designated by the abbreviation KVT.

Fasteners for lightweight concrete Source chelyabinsk.energogradek.ru

Manufacturers also suggest using plastic concrete dowels, used in polystyrene concrete blocks. This type of sleeve is not much different from spacer products. They have a spiral design. This dowel can withstand significant weight. It is often used during the installation of various cabinets, exhaust systems, for attaching shelves and many household items. The abbreviation GB is used to designate the product.

Fasteners for polystyrene concrete Source hubo.be

Material for making dowels

Most dowels are made from polymer materials - polyethylene, polypropylene and polyamide. Such elements are characterized by high performance, availability, ease of installation (there is no need to make significant efforts to attach them) and low cost.

Common materials for making dowels are polyethylene, polypropylene and polyamide

Products made from polypropylene are hard, wear-resistant, and resistant to high temperatures. Such elements are intended exclusively for indoor installation, which is due to their sensitivity to sub-zero temperatures. During long-term operation with temperature fluctuations, deformation of the dowels and the appearance of cracks may occur.

Polyethylene dowels are characterized by low weight, ductility, ability to operate at low temperatures and low cost.

The most reliable and durable products are dowels made of polyamide or nylon. They are characterized by high wear resistance, resistance to mechanical stress and temperature changes.

Dowels can also be made of metal. For this purpose, stainless steel, galvanization, alloys based on bronze or brass are used. Iron dowels are distinguished by high strength qualities, rigidity, the ability to withstand large mechanical loads and durability without compromising the integrity of the structure.

Important! The surface of the metal dowels has a special galvanized coating that prevents the formation of corrosion.

Metal dowel

Features of choosing the required dowel

Before purchasing fasteners, you need to know the weight of the products that will be fixed with their help. The dimensions of dowel nails for concrete and other elements of similar purposes are also taken into account. In addition, the peculiarities of the mounting location must be taken into account.

There are certain rules that are always followed when choosing dowels:

- Fastening a heavy structure is done using fasteners whose length is at least 85 mm. It is recommended to be used when fixing, for example, exercise equipment.

- If fastening is carried out in a horizontal building structure, then choose products that are placed to a depth of at least 30 mm. In this case, the diameter of such elements should be from 6 to 11 mm.

Spacer element 6*30 mm Source leroymerlin.ru

- When selecting fasteners for an already created hole, you need to select an element with a diameter no less than the same size as the drilled recess. The ideal option is if the dowel and hole have the same diameter.

- Fasteners with antennae should always be used when installing lighting fixtures and ceiling structures. After all, the load acts in the downward direction. The best option is dowels with so-called mustaches and notches.

- If fastening is carried out in hollow brick or other weak material, it is necessary to use fasteners with softening pads. Pouring them will allow you to evenly distribute the load throughout the element, and the fastening itself will be as tight as possible.

How to choose a dowel

When choosing dowels, it is important to consider the surface material. So, for fastening to drywall, Molly dowels are best suited, and for concrete walls, metal anchors

It goes without saying that when insulating a house you cannot do without umbrella dowels, and when attaching a plaster mesh to a wall, you cannot do without dowel nails (quick installation).

Also, when choosing dowels, it is important to consider whether their surface is galvanized or not. Galvanized dowels will last much longer than usual, they will not rust during operation

It is also important to consider the length of the dowels; it plays an important role when choosing them. However, here you should know not only the thickness of the wall, but also the materials used to make it, how strong and reliable they are, and whether they have voids inside.

Features of fastening dowels in a concrete wall

Of course, you need to invite a specialist to do the work. After all, the master will, at a minimum, take with him all the necessary tools, and at a maximum, he will have impressive experience in performing such operations. Professionals usually carry out the process as follows:

- Mark the installation location of the dowel after careful marking in accordance with the drawings and features of the structure being mounted.

- Make a small indentation at the marked point using, for example, a nail.

- Insert a drill of a suitable diameter into the hammer drill.

- Make a hole in the structure.

Important! The dowel must be inserted into the recess with force. This is the only way it will be fixed in the hole, which is made perpendicular to the plane of the building structure.

- Remove all debris from the recess.

- Insert the element until it stops.

- Screw a screw into the dowel (the hardware can be screwed together with some part, depending on the features of the structure being mounted).

The procedure for fixing a dowel in a concrete wall Source europartner-online.ru

On a note! Before hammering a dowel into a concrete wall, select the required fasteners. It is thicker than conventional wood hardware. It is made from special grades of steel with a massive head. In addition, it may have longitudinal or spiral notches.

Typically, craftsmen use a construction gun to drive such nails into concrete structures. However, it is often necessary to perform a small amount of work manually. This is more difficult, but the right tool may not always be nearby.

Usually they try to drive special nails into concrete surfaces without defects. There should be no chips or cracks on them. Otherwise, the hardware will not hold well.

Before the process itself, the washer is removed from the metal dowel of the nail. Then clamp the hardware in pliers. Then they install it in the desired anchored place and hammer it in with strong blows.

Types of fasteners

Construction stores offer a wide range of dowels. Photos of products clearly demonstrate the diversity of their designs, materials of manufacture and purpose.

The most common product is the universal polypropylene dowel. It has a traditional design in the form of a sleeve, into the cavity of which a self-tapping screw is screwed. This element is suitable for concrete, brick and stone foundations. The design of the product is equipped with special spacers, with the help of which the element is securely fixed in the hole.

To perform complex external work, a spacer construction dowel with a locking edge is used, which eliminates the possibility of fasteners falling into the hole.

Nylon dowels are equipped with fastening antennae, thanks to which the products are securely fixed in the holes. They can be used on any surface.

Drywall dowels are used for mounting them into porous concrete and sheets of gypsum fiber and plasterboard. They can be made of plastic or metal. The last option is called dowel molly. Before hammering in a dowel of this type, there is no need to first prepare the hole, since its tip has the appearance of a sharpened drill.

Dowel for plasterboard walls

Facade dowels are made of polypropylene or nylon. They have directional antennae for secure fixation at the base. Such fasteners can be used for any surface. They are produced without sides, which eliminates the possibility of shedding or cracking of the facing plaster.

The frame dowel is intended for installation of door and window frames, cladding through layers of thermal insulation and plaster. The products are made of metal. They are often called thermal insulation dowels, which can be of two types: for working with hard and soft materials.

Types of dowels with special design

Dowel nails are made of polypropylene, nylon or stainless steel. Thanks to the presence of knurling in the form of reverse cones, reliable retention of the product in the base is ensured. They are widely used for quick and extensive installation of skirting boards, sheathing, windows, timber, metal profiles, cable ducts, plywood to concrete, brick or stone surfaces.

Helpful advice! When deciding whether to hammer or tighten a dowel-nail, preference is given to the first installation option.

Butterfly dowel for hollow structures

The butterfly dowel is characterized by increased wear resistance and the ability to withstand high loads even in hollow surfaces. Such products are made of metal.

The adjusting dowel is used to install the sheathing under the sheathing. It has a special design containing a certain element that allows you to adjust the position of the product relative to the surface to which it is attached.

Helpful advice! To carry out large volumes of installation work, it is advisable to use dowels-screws designed for mounting guns.

The dowel-clamp has the shape of a loop with characteristic tendrils for fastening along the edges of the product. Such elements are designed for mounting electrical wiring to the base. The wire is inserted into the clamp, and its edges, in turn, are inserted into holes previously created in the wall and fixed with tendrils.

A special type of fastening element is an umbrella dowel, which is designed for installing thermal insulation made of polystyrene or mineral wool. This product has a wide round cap that holds the insulation. They produce plastic and metal dowels.

An umbrella dowel is often used to hang ceiling chandeliers

Helpful advice! The best option for loose foundations would be liquid dowels, or chemical anchors, which provide a strong and reliable connection and are at the same time able to withstand heavy loads.

The Molly umbrella dowel is a nail with metal arms that provide reliable fastening of structures to hollow surfaces with uniform load distribution.

Helpful advice! To attach the chandelier to a suspended ceiling, you should use Molly umbrella dowels.

Features of fixing fasteners in brick

Experts note that fixing fasteners in masonry is more difficult than fixing a similar element in concrete. Although professionals quickly solve this problem even when installing structures with significant weight.

First of all, before fixing the anchor in the hollow brick, the exact anchoring depth is determined. It must be no less than or maximum equal to the distance from the corner of the building structure to the installation point.

In addition, qualified craftsmen often consider the minimum length of the screw used. To do this, fold the same size dowel and the sharp part of the hardware. The last parameter is usually equal to the diameter of the screw. In addition, the thickness of the mounted part is added to the obtained value.

The value obtained as a result of addition is rounded up. In this case, they are guided by standard lengths of hardware. At the end of the entire calculation, the required depth of the hole in the brick structure is determined. It should be greater than or at most equal to the length of the selected hardware minus the thickness of the attached part.

The depth of the hole in the brick must be no less than the length of the hardware used minus the thickness of the fixed part Source sdelai-lestnicu.ru

On a note! If you decide to use a dowel or nail for brick, then it is better to use it in a solid block. In hollow material it may adhere poorly or not at all. We are talking about a plastic dowel with pointed threaded hardware. It also has a cross slot.

A high-quality installation process for fixing dowels in bricks is as follows:

- A recess is created for fixing the fastener.

Important! To drill a recess, use a power tool without impact. Otherwise, the brick may crack or break off, especially if it is hollow. In addition, due to tool impacts, sometimes the recess is larger in diameter than the dowel used. After all, brick is a softer building material compared to concrete.

Brick and other similar blocks are softer compared to monolithic concrete Source sun9-24.userapi.com

- All debris is blown out of the created hole.

Advice! To more securely secure the fasteners in the recess, tile adhesive is additionally used. It is diluted in accordance with the instructions, which are always present on the packaging. Fill the hole as deep as possible with the mixture.

- Insert the element into the recess until it stops.

- Wait for the adhesive to cure. It hardens in about 24 hours.

- Screw threaded hardware into the dowel.

The screw or pin must fit into the installed fastener with force. If the element is not installed securely, then it will scroll. With high-quality installation, such fasteners can withstand significant loads.

This method of fixing a dowel in a wall is often used if the structure is made of hollow material. It is often used in foam blocks.

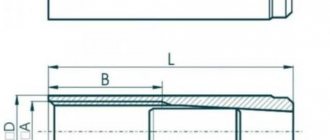

Dimensions of dowel-nails

The first number when marking a product is its diameter, and the second is its length. The parameters of such a product can vary from five by twenty-three millimeters to ten by one hundred and sixty millimeters.

The load that the dowel-nails can bear must be indicated. The most common size is six by forty millimeters. It is ideal for thin parts.

- The dimensions for the slats are six by sixty and six by eighty millimeters.

- The longer the dowel, the thicker the part can be or the further into the wall the expansion zone will be.

- Dowels begin their size range with five, six, eight and ten millimeters in diameter.

- For installation, you need to drill a hole slightly larger than the length of the nail itself.

It is advised to make the hole twenty millimeters larger. There are times when it is not known what kind of wall is hidden under the plaster. In such cases, you can try drilling a hole in non-impact mode.

It is possible that this is a weakened wall and this nail will not fit. Some manufacturers save money and make the diameter of these nails five and a half millimeters, but indicate all six.

This can be a serious problem during installation. Or you will have to look for a five and a half millimeter drill or try to expand the diameter with a five millimeter drill, which results in a loss of time and quality of work.

Features of dismantling work

During renovation work, building structures are often leveled. To ensure a high-quality process, the previously installed dowels are first removed. To dismantle them, use a regular screw or other hardware of a suitable diameter. It is screwed into the fastener by 2/3 of the length or more. It all depends on the tool that is additionally used in the work. Then the hardware is pulled out along with the plastic fastener.

To pull the dowel out of the wall, use suitable hardware Source bau-meister.ru

On a note! Usually, a steel crowbar or ordinary pliers are used for pulling out.

Sometimes a situation arises when a piece of metal hardware remains in a plastic fastener. To remove it, use a soldering iron. They first heat up a plastic dowel, and then use pliers to pull out a piece of steel fastener.

When the dowel is set very tightly, sometimes it cannot be pulled out. The fasteners are simply cut along the plane of the structure, and the hole is covered with a durable mixture.

If you need to remove a special metal nail from a structure, first loosen the hardware with hammer blows. After this, a nail puller is used for its final dismantling.

As a last resort, a hole is drilled next to the dowel-nail. It makes it easier to loosen the hardware. You can also use a grinder to simply cut off a special steel nail.

A protruding special metal nail can be trimmed with a grinder Source mcmahons.ie

How to pull a chopstick out of the wall?

Nowadays, plastic dowels are widely used, which are considered stronger, more durable and reliable. However, some people still use wooden dowels instead of plastic dowels the old fashioned way.

The difference in dismantling plastic and wooden dowels is not so great. You can also try screwing a self-tapping screw into it and pulling it out with pliers, a nail puller, or another suitable tool at hand.

Another popular way to get rid of a wooden dowel is to break it apart and pull it out piece by piece. Using a chisel and hammer, divide the dowel along the grain into several parts, then pick out the fragments using a knife or screwdriver.

You can also try drilling out the cap using a drill. However, if the chopik was made of hard wood, this process will take quite a long time. Instead of a drill, you can use a hammer drill if you have one. However, do not overdo it, otherwise you will end up with holes in the wall that are much larger in diameter than you would like.

Briefly about the main thing

A dowel for masonry or concrete is a fastener made of steel or plastic with antennae, protrusions, and spikes. Basically, it expands when the hardware is tightened.

In brick construction, elongated fasteners are mainly used. Special nails are often secured in concrete. Products with a plastic element can be driven in with a hammer, and all-metal sharp fasteners are often installed with a construction gun. It cannot be installed by hitting a brick.

Manufacturers produce spacer, butterfly-shaped, facade, wide-threaded fasteners for aerated concrete and other types of fasteners. It is selected according to the material of the wall in which it is installed. The applied load is also taken into account.

The dowel is mounted into the previously created hole. It must have a depth no less than the length of the hardware. During installation in brick, an additional adhesive mixture can be used.

Ratings 0

Fischer P.D.

One of the newest and most convenient developments in the field of drywall fasteners. The principle of operation is original in that when the self-tapping screw is screwed into the dowel, its conical shank is pressed into the plastic sleeve, forcing the stop wings to open. When the sheet thickness is small, they apply pressure from the back side. If the thickness of the drywall is significant, they will jam the dowel in the drilled hole.

Such fasteners can withstand 12–15 kg. Installing it is simple:

Step-by-step instructions for installing a dowel

- 1. Mark and recess.

Using a ballpoint pen or pencil, make a mark in the place where you plan to install the fastener. Then, using something sharp - a knife, nail or pin, make a small indentation there, which will help you position the drill correctly and drill the hole perpendicularly. - 2. The size of the dowel must match the size of the hole and the screw itself.

Prepare the “correct” dowel. It must match the diameter of our hole. The fastener should go in there with some effort. A dowel with a small diameter will dangle and fall out, while a large one may “crumple” when you try to hammer it in. Make sure that the length of the dowel matches the length of the screw you want to use. - 3. Be smart!

Did you run out of dowels? Then make them yourself! To do this, take a wooden block. Saw off a piece of it to the required length. Remember that the size of the dowel must match the size of the fastener. Use a knife to give the future homemade dowel a rounded cross-section. It is very good if it resembles a cone - slightly thickened at the top and slightly narrowed at the bottom. - 4. Control of drilling depth.

Insert a drill bit into your electric drill that is the same diameter as your fastener. It is necessary to mark on the drill the depth of the future hole, which should be slightly larger than the length of the dowel. To do this, place the fastener against the drill, as if comparing them in length, and wrap a couple of turns of electrical tape around the drill. This will be a kind of boundary that will show you how deep you need to drill. - 5. Make a hole.

Find the mark you made and make a hole in the wall. When doing this, keep the drill perpendicular to the surface and do not tilt it to the sides. Clean the drilled hole from cement chips and dust. It is very convenient to use a vacuum cleaner for this! - 6. Insert the dowel

and lightly hammer it all the way in with a hammer. Be patient and avoid powerful blows to avoid damaging the fastener. So, the dowel is installed, all that remains is to screw the screw into it and you can hang your picture!

Congratulations! You have successfully completed the installation of the dowel!

How to remove a dowel

Can't get a dowel out of the wall? Don’t despair – our publication will help you get rid of this problem.