Advantages of wood cutting machines

The presence of professional equipment radically changes the entire production process, including in the field of carpentry. The advantages of purchasing a machine include:

- Possibility of unique wood processing. Using the machine, you can give any shape to the processed base.

- High equipment performance. All professional machines have sufficient power to ensure long-term uninterrupted operation.

- Precision performance with proper handling of the equipment.

- High quality. Just after a little training and “breaking in” of the tool, you can produce interior items and souvenirs for sale or to order.

- All models from a quality manufacturer are safe to use. If the device overheats, the automatic shutdown system is activated. This feature significantly extends the service life of the machine.

- Most woodworking equipment does not require complex maintenance; just regular inspection of components and cleaning of the working part from shavings and dust is enough.

- Low noise level.

The advantages also include a large selection of woodworking machines, each of which is designed for specific tasks. The future owner should only indicate the scope of work and, in accordance with this, select the most suitable equipment model.

Equipment design

The professional wood milling machine is designed according to the most modern kinematic schemes. It is equipped with complex mechanical connections and state-of-the-art electronics. The main elements of such devices are:

- powerful frame;

- a special table called a milling table;

- caliper;

- spindle having a special shape;

- workpieces are moved along the machine using special slides;

- spindle launch panel;

- control adjustment system;

- set of cutting tools.

Some manufacturers equip their 220 V wood milling machine with an additional carriage. It turns the milling machine into a unit with advanced capabilities. It has the ability to process parts at any angle.

The frame of such a unit is made of a thick piece of steel or cast iron. Due to its mass, it gives the machine increased stability. It allows you to dampen vibrations during operation.

A special shaft is attached to the caliper. Its upper part rises above the table through a special hole. All units provide the ability to adjust the shaft lifting height. An insert spindle with a cutting tool is installed on top. An industrial wood router is a device capable of performing a large number of operations. This is achieved through the use of a variety of cutting tools. The main types of equipment are: cutting disc, knife, cutters of various configurations.

To carry out milling strictly in a straight line, a special guide bar is used. Thanks to a special fastening unit, it can be moved to the required length. High spindle speed significantly improves processing quality.

Modern professional machines are equipped with powerful industrial vacuum cleaners. They allow you to create comfortable conditions during work. Thanks to the powerful suction system, construction dust is removed.

Types of sawing machines

There are many areas of use for woodworking machines, and many types of equipment. One of the most common types is the sawing machine.

Such devices are designed for sawing logs and timber. Depending on the operating principle, the following types of machines are distinguished:

- Sawmills, which refer to stationary equipment that makes longitudinal and transverse cuts using a linear saw. The installed saws perform reciprocating movements, and the master only guides the working part. Such devices were among the first to be developed, are large in size, and are quite difficult to maintain.

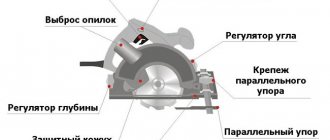

- Sawmills have now been replaced by circular saws. Depending on the model, such designs can be manual or automatic. Circular saws cut logs in a vertical and inclined plane.

Also included in sawing machines are band models. The working part is presented in the form of a rotating belt.

Such designs are quite cheap, but are intended primarily for harvesting primary material, since they do not have sufficient accuracy.

Types of milling machines

Devices in this direction are divided into three categories:

- professional (serve for mass processing of workpieces using a wide range of cutting tools);

- household (intended for a household workshop);

- manual devices.

The first category includes units used in various industrial enterprises. They have increased productivity and versatility. They have large dimensions and weight. Large workpieces are processed on these machines.

Of all the variety, the most popular are:

- a standard turning and milling machine with a classic design;

- copy machine;

- machine for processing workpieces in a vertical plane;

- horizontal professional milling machine;

- for double-sided processing of a wide range of workpieces;

- equipped with modern CNC systems.

A wood milling machine for a home workshop has small weight and size characteristics. It is capable of performing basic processing functions efficiently. Such machines include:

- desktop household appliance;

- manual milling unit.

A simple turning and milling machine is used for standard machining operations. Thanks to its equipment, a wide range of operations can be performed. It allows you to give the part the required configuration. Depending on the tasks being solved, various cutting tools are used. These include cutters, drills of various diameters, and special turning knives.

The copying machine is used to carry out artistic types of milling work. Such work includes: applying complex patterns, designing ornaments, transferring a sample to various surfaces that require precise execution.

To ensure the identity of even small parts, pre-prepared templates are used. They are made from wood boards, plywood, thin metal or plastic. Precise drawing is carried out by fixing the workpiece using the vacuum fastening method.

To process the workpiece from top to bottom, that is, in the vertical plane, special wood milling machines are used, which are called vertical. Grooves of the required width and depth are cut out on them, fastening elements are prepared, and the workpieces are cut to the required length.

The horizontal machine differs in the processing method. This is due to the special placement of the spindle. To solve the required problems, its axis is located horizontally relative to the floor plane. This machine is equipped with end and cylindrical cutters. Additionally, you can expand the range of equipment.

A double-sided wood milling machine is a universal unit for performing a large number of operations. It processes profiles of various configurations. Such a stationary machine is used in industrial enterprises for the production of various furniture elements. For example, chair legs, decorative supports, stands and much more. The advantage of the machine is the ability to carry out processing on both sides simultaneously.

Milling devices equipped with CNC are becoming increasingly popular in modern production. It includes an electronic unit based on a special microprocessor. The program embedded in it establishes the sequence of operations. This improves the accuracy and quality of processing. Thanks to this, it is possible to reduce processing time and significantly increase labor productivity.

Small workpieces are processed using hand tools. With its help, miniature grooves are prepared that are necessary for the articulation of individual elements. They are widely used to create decorative furniture sets, couplers, and various fastening elements. Equipping a hand-held milling unit with the appropriate tool turns the unit into an electric cutting device. Sawing tools can be special cutters.

The desktop wood milling machine is structurally similar to a professional machine. It is easier to operate and maintain. With good preparation, it is possible to make not only simple wooden parts, but also the most complex decorative elements.

Any milling machine for household use is used in personal carpentry workshops to perform small amounts of work. It is chosen to perform basic milling operations. These include: planing boards, drilling various holes, grinding surfaces, various types of sawing.

Types of planing machines

Another variation of woodworking equipment is planing machines. Such structures are designed to remove the outer layer of wood. In this case, the cutting part is located deep in the material being processed.

The following types of planing equipment are distinguished:

- One-sided models that process only one plane of a wooden workpiece.

- Double-sided models capable of removing both the top and bottom layers of wood from a part.

- Often special rimming machines are used that process 3 or 4 edges of the workpiece.

There are also jointing machines that remove a layer of wood at a given angle.

Types of tables

- Tabletop (portable) table.

These tables are compact in size, light weight and can be installed on any work surface. For example: American portable milling table Kreg PRS 2100. Has a steel base

English Milling table Trend CraftPro

Homemade versions of these tables can be of various types, ranging from a simple tabletop with a router and a side support made of plywood:

and simple cabinet tables with a router:

Often, plexiglass is used as a plate for installing a router into a table.

- Stationary milling table (personal, non-portable)

These tables have a working height that provides comfortable standing work - 800-900 mm. In some cases, tabletops may be height adjustable. Serial samples usually have an aluminum base (for example, such as INCRA):

or steel base (as in Craig milling tables):

The base can be made from furniture panels (professional table CMT):

A special place among milling tables is occupied by the Festool milling table with a universal removable plate and mount for any Festool router. In essence, this is a lightweight, but at the same time well-equipped version of a milling machine for both work in the Workshop and on the road.

With folded legs, the festul table turns into a tabletop version:

Wide range of equipment and quick setup make it an indispensable assistant for many professional Craftsmen.

Homemade stationary options sometimes look no worse than factory tables:

Custom milling tables can be made using standard elements from serial tables: milling plate, profiles and tires, table tops, stops. For example, based on Kreg components:

Examples where the KREG Combo-Trak guide profile (combined rail) and KREG pressure combs are used Table with a KREG plate

or INCRA (profile guides, router lift) Positioner INCRA M-LS25SYS:

In some cases, industrial tables are also modified, improving their functionality. KREG PRS 1045: The simplest and most useful improvement is, of course, the integration of drawers for cutters, tools and other accessories.

You can also use the side surfaces of the table to secure on their outside the tools or accessories necessary for work.

Admirers of the INCRA brand also try to improve the useful properties of the table. Milling table INCRA M-RT COMBO 3

Multifunctional (not just a router) table A stationary table can simply be a router table, like the ones shown above. But it can also be multifunctional, universal, combined with a workbench, assembly table, stationary saw, etc.

INCRA and KREG accessories are actively used in the design of tables. For example: stop and positioner Incra

The large working surface of such a universal table, on the one hand, expands possibilities, and on the other hand, saves both space and resources.

Features of using lathes

Lathes are used to remove a piece of wood in a circular manner. Similar designs have found their application in the furniture industry, and are intended for the manufacture of decorative cases, facades, and fasteners for sets.

All known models differ in engine power, housing size, installation method and degree of automation:

- Manual models are purchased, as a rule, for home use. Using this design, you can successfully produce a small furniture set for your home or to order. On the case there are power buttons, speed controllers and other technical parameters. All changes are made manually.

- Automated equipment has a template for producing specific parts. The specified parameters are entered into the machine operating program, but control and maintenance are performed by humans.

There are also automatic designs that are widely used in furniture production. These machines operate according to specified algorithms and are not used in everyday life.

Wood drilling machines

In furniture cases or facades, many interior items require through or blind holes. Woodworking drilling machines are used to perform this task.

Distinctive features of such devices are the ability to drill to a given depth and maximum accuracy.

The following types of drilling machines are distinguished:

- With vertical type of action. The spindle has a vertical direction.

- There are spindles with horizontal direction.

- Spindles are available for deep drilling.

Some modern machines can operate on an inclined axis, which is used for the manufacture of complex wooden structures.

Today, drilling equipment is often replaced by milling machines, which greatly facilitate the work of the master. Such devices are more convenient in practical use, which determines the buyer’s choice.

Milling table with built-in router for the workshop

The most popular and least expensive option for use in a wide variety of workshops (home and small industrial) is the option of a manual router built into a special work table. The versatility and quick reconfiguration for manual milling with a sufficient level of quality and individual solutions have made such milling machines extremely popular both among home craftsmen and among small production workshops.

Some of the milling cutters already have a built-in microlift, which simplifies its use and is extremely convenient to use.

Using such a table in combination with a manual router when processing wood products allows you to achieve excellent results, with quality at the level of professional milling machines.

Wood bending machines

Interior styles such as Baroque require not simple furniture, but furniture with relief facades and details. Woodworking bending machines were developed specifically to solve such problems.

- The main purpose of such structures is to give the wooden surface the desired shape.

- The device is equipped with special clamps and forming heads.

In appearance and principle of operation, a bending machine resembles a hydraulic press, which gives the workpiece a complex shape, relief or imprint.

Equipment for assembling parts

Woodworking machines also include assembly structures. Such devices are capable of fixing adjacent parts using screws or nails.

Also on the list of tasks performed you can find the processing of fixation points, upholstery work for future furniture, and the application of various decorative coatings.