Purpose

Mostly milling machines are designed for metal processing. Various parts of various profiles and sizes, including complex ones, with straight and curved contours, are cut from blanks using mechanical processing.

In addition to mechanical processing, various metal parts are made in other ways: casting into molds, stamping on presses, punching, cutting, forging. But these methods are not always technologically possible or justified. For example, stamping, gas or laser cutting cannot create a three-dimensional part or a high-precision part.

Sometimes heat treatment (high heating) is unacceptable for an alloy, since this changes the properties of the metals. Then the only way to produce parts is mechanical processing - milling.

In addition to milling, there is another type of mechanical processing of metals - turning. The process is similar to milling, but round parts are cut with cutters. As a separate type, there are combined turning and milling machines, which perform both processing along diameters and along straight lines - grooves, recesses, channels, splines, etc.

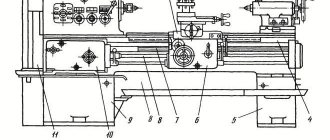

Turning and milling machine:

What can you do with a milling machine?

A wood router can be a great tool in your home workshop. You can perform a lot of different actions on it:

- ✓make panels for doors and kitchen facades;

- ✓make tenon joints in wooden door or window blocks;

- ✓cut mini-spikes on the edges of the parts;

- ✓make legs of various shapes for tables, poufs, etc.;

- ✓perform high-precision drilling of holes;

- ✓apply a pattern of varying complexity to a wooden plane;

- ✓process the edges of products in order to round them;

- ✓copy products according to an existing template;

- ✓grind the ends and bring the products to the required shape.

Based on the possibilities described above, we can conclude that a milling machine is an extremely necessary thing for a home, since it can easily replace a whole “fleet” of machines in a carpentry workshop.

Device

The simplest diagram of the traditional (classical) layout of two main types of milling machines:

A) a horizontal milling machine, with a horizontal spindle that rotates the cutter.

Numbering of main nodes:

- Stand (the main load-bearing part of the bed).

- Access panel (hatch) to the gearbox.

- Trunk, upper part of the supporting frame.

- Workpiece clamping vice.

- Headstock for fixing the horizontal spindle shaft.

- Work table slide for moving a vice with a workpiece.

- Console.

- Worm or screw mechanisms located inside the console move the table with the workpiece forward/backward, left/right and up/down.

B) Vertical milling machine. The spindle is positioned vertically, like a drilling machine.

Numbering of main nodes:

- Stand (the main load-bearing part of the bed).

- Access panel (hatch) to the gearbox.

- Trunk, upper part of the supporting frame.

- The spindle on which the cutter is mounted.

- Workpiece clamping vice.

- Work table slide for moving a vice with a workpiece.

- Console.

- Worm or screw mechanisms located inside the console move the table with the workpiece forward/backward, left/right and up/down.

The electric motor is located at the back of the machine or inside the rack, from the model. From the engine, through the V-belt pulleys, rotation is transmitted to the gearbox. On different machines there can be from 6 to 19 or more speeds. For processing different alloys and operations, the optimal spindle speed is selected.

Machines with a horizontal spindle are better suited for longitudinal cutting of grooves, niches, and splines.

Vertical milling cutters are better at cutting along the walls of tall workpieces, inside workpieces, and processing deep internal cavities.

The range of capabilities is evidenced by the power of electric motors on different machines - from 0.75 kW to 14 kW or more on special machines.

Principle of operation

The processing method on such machines is simple - the cutter removes “everything unnecessary” from the workpiece, creating a part with dimensions that exactly match the drawing. To do this, several conditions must be met:

- The cutter alloy must be significantly stronger than the metal or alloy of the workpiece.

- The profile (shape) of the cutter and the number of teeth must be selected correctly.

- By switching spindle rotation speeds, the optimal processing speed is selected.

- The workpiece must be absolutely precisely positioned and moved relative to the cutter. In this case, the fastening of the workpiece must be strong enough.

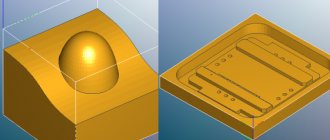

Milling process:

Any deviation will lead to sampling in the wrong place, and the workpiece will be rejected.

Therefore, desktop settings are of great importance. The spindle and mechanisms for feeding the workpiece to the cutter should have no backlash. The slide should move without the slightest deviation. The accuracy class of the machine depends on how accurately these components work. In metalworking there are 5 accuracy classes for machines:

- N – normal accuracy.

- P – increased.

- B – high-precision machines.

- A – increased high accuracy.

- C - master machines, the most high-precision.

Milling machines of classes B, A, C are used in workshops with constant temperature and humidity, since a large temperature variation leads to a narrowing and expansion of the metal parts of the machine by minimal amounts, but this is no longer acceptable for ultra-high-precision machines, the tolerances on which are hundredths of mm .

The accuracy of processing on old-type machines depended not only on the machine, but also on the qualifications of the milling operator. Then auxiliary mechanisms and devices began to appear, machines with semi-automatic and automatic feed, with CNC (computer numerical control).

Modern machines that use computer programs have a different operating principle. The workpiece can be fixed motionless, and its processing is carried out by a milling cutter movable in three coordinates. Such machines operate with minimal human intervention (software loading, workpiece positioning, switching on and control) and can make a part of any complexity with high accuracy. This brought metal milling technology to a new level.

Parameters to consider when choosing a milling machine

1. Size of workpieces to be processed: the part must fit completely on the work table. Therefore, we advise you to pay attention not only to the width and length of the part, but also to its height so that it does not touch the spindle. 2. Electric motor power: a parameter that must be taken into account when choosing a unit. If you are going to work on the machine regularly, for example, several hours a day, then it is better to purchase a more powerful device. Of course, in this case, the price of a milling machine will be higher than an analogue with a weaker engine, but you are guaranteed to be able to complete the planned amount of work. 3. Installation and connection of the machine: when purchasing a machine for use in a home workshop, you must pay attention to the voltage at which the unit can operate. If you have the ability to connect to a three-phase network with a voltage of 380 V at home, then it is better to take a machine specifically for such conditions, otherwise only machines operating on 220 V will suit you. Also pay attention to the overall dimensions of the machine. Of course, if you are buying equipment for a spacious workshop, then this nuance is not so important, but many craftsmen try to place the machine even in an apartment, and then the issue of the size of the machine comes first. 4. Maximum drilling diameter: this parameter is indicated in the technical characteristics of the machine and indicates the maximum drilling diameter in the steel part. For wood and plastic, this figure will be at least twice as large. 5. Weight: the heavier the machine, the higher its rigidity will be, and this parameter, in turn, will guarantee the absence of vibrations and, accordingly, improved quality of part processing. A professional milling machine weighs from 300 kg. Such units are often used only in production. The price of a professional-level wood milling machine, as you understand, is also not cheap, so it makes no sense to purchase this device for home purposes. For rare home use, it is enough to take a simple desktop model weighing about 50 kg.

Types and classification

The first primitive milling machines appeared in the 17th century. The prototypes of modern machines are in the 19th century. To date, dozens of varieties of such machines have been created and are in use.

Horizontal milling

Horizontal spindle position. The machines are used for shallow sampling of long parts, described above.

Vertical milling

Vertical spindle arrangement. The machines are better suited for deep sampling inside workpieces and processing of part walls, also described above.

Universal

These are machines with a cutter that moves on a support, which makes it universal for processing different parts. Can process horizontal, vertical and inclined planes of workpieces. Work with turning and drilling cutters. Modern machines of this type are CNC and operate with minimal participation of the machine operator.

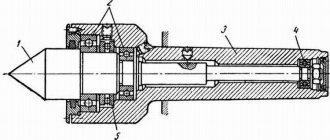

Universal router:

Drilling and milling

Machines of this type are similar in design to a vertical drilling machine. There are desktop models of low power, and industrial ones for processing large parts.

Their main difference from a conventional drilling machine:

- more powerful engine;

- the presence of a work table, like a milling machine, screw feed in three planes on a slide, a vice for fastening the workpiece on the work table slide;

- powerful chuck for mounting various cutters and cutters.

It can be used as a regular drilling machine, if instead of cutters you put a drill of the required diameter in the chuck.

Widely versatile

Compared to simply universal milling cutters, they have expanded capabilities. Equipped with two spindles, horizontal and vertical. The work table not only moves left/right, back/forward and up/down, like all routers, but can tilt at the desired angle.

Such machines can perform a wide range of different operations - milling in different planes, drilling, threading, etc., which makes them highly versatile. Modern industrial models can be equipped with CNC.

Consoleless

On console machines, the work table is located on the console and is significantly raised relative to the workshop floor. This makes it difficult or impossible to process large workpieces. They either simply do not fit in the workspace under the cutter, or they weigh too much. To process such workpieces, non-cantilever machines are used.

Their work table is located much lower, right on the base of the machine, and can withstand a lot of weight.

Industrial machines of this type can process workpieces weighing several tons.

Longitudinal milling

These are powerful industrial machines designed for processing long parts. For example, the MS64OGMF4-16 K machine is capable of processing workpieces up to 17 meters long. At the same time, the workpiece has a significant height (up to 3.5 m) and width (up to 5 m). However, it is the significant length of the work table that gives such machines the name – longitudinal.

The mass of the workpiece can be over 200 tons, and it is difficult to move it relative to the cutter with high accuracy. Therefore, the machines are structurally designed as a stationary work table and milling heads that move relative to the workpiece.

At the same time, the machine makes not only longitudinal selections, but also any others according to the drawings of the future part. The video shows a demonstration of such a machine:

Copying

There are many types of milling machines that operate on the principle of mechanical copying, that is, using templates. CNC machines can also copy blanks, that is, make many parts of the same size. But we are talking about mechanical, not digital copying.

In metalworking, this principle is practically not used, since metal is a hard material and it is problematic to determine the precise movement of a cutter or workpiece using a template.

Copying machines are used mainly in woodworking. As an example, in the video there is a demonstration of a WoodTec copy-milling machine:

Keyed

These are specialized machines designed for selecting keyways in shafts.

There are both the simplest small models and powerful industrial machines with two spindles for simultaneous cutting of two grooves at the ends of the shaft, hydraulic feed of the workpiece.

When working, a measuring tool is practically not used, since the width of the groove is set by the diameter of the cutter. Although there are machines with eccentric rotation of the cutter, when it selects a groove wider than its diameter, the width of the groove is known in advance.

Only the length and depth of the keyway are controlled. Keyways and keys for them come in different sizes and shapes. As an example, a classic connection with a closed (blind) groove that does not extend to the end of the shaft and a groove on the gear:

Keyways are also selected in other ways on different machines. We are talking about specialized ones, created specifically for such operations in large production lines.

Tabletop

Benchtop milling machines work on the same principle as all others. The difference is in small dimensions and weight.

These can be horizontal, vertical or drilling and milling machines. Engine power, from 0.75 kW to 1.5 kW. As an example, NGF 110 (desktop horizontal router).

Models of machines NGF 110 Sh3, NGF 110 Sh4 could be found in many schools. They were used for labor training. The letter Ш in the marking of the machine means “school”.

The machine has 6 spindle speed modes and a 0.75 kW motor.

Despite its small dimensions, power and educational focus, the NGF 110 is a fully functional machine that copes well with processing small parts. Accuracy class – N (normal).

Tabletop machines also include modern small milling and turning machines. An example of such a machine in the photo:

The machine has a 300 W motor and is designed for the manufacture of small products with complex profiles from soft materials.

CNC

Punched cards and punched tape were used to program the first CNC machines.

The first domestic 6N13 CNC milling machines appeared in the mid-60s. The machines were controlled by the Kontur-ZP system. With the advent of modern computers, the capabilities of such machines have become an order of magnitude higher.

Today there are fully robotic complexes that, according to a given program, without the participation of a machine operator, can create any part of the most complex shape with high precision. They are controlled using the following chain:

- Microcontroller or microprocessor.

- Controller with programming capability (logic).

- Control computer.

All the data about the parameters of the required part are stored in the control computer program, and then the machine does everything itself. The operator's actions are as follows:

- Loading data into the machine computer.

- Correct positioning of the workpiece.

- Process control.

On fully robotic lines, the workpiece is moved without operator intervention along a conveyor and manipulators, and the program can be created remotely via an industrial network.

There are 3, 4, 5 and 6 axis CNC milling machines, 6 axis are the most complex and expensive, and are less common. The number of axes of movement of the cutter determines how complex a part can be processed at one time, without changing the position of the workpiece or using another machine.

Another model line is medium and small CNC machines, including tabletop ones. They can be placed in a small carpentry or home workshop.

As an example, an average CNC milling machine for making wooden balusters in the video: