Characteristics

| Standard | EN 10253-4 - Butt welded pipe fittings. Part 4: Forged austenitic and austenitic-ferritic (duplex) stainless steels requiring special inspection EN 10222-5 - Steel forgings for pressure vessels. Part 5: Martensitic, austenitic and austenitic-ferritic stainless steels EN 10253-3 - Pipe fittings for butt welding. Part 3: Forged austenitic and austenitic-ferritic (double) stainless steels without special testing requirements EN 10216-5 - Seamless steel tubes for pressure service. Technical delivery conditions. Part 5. Stainless steel pipes EN 10217-7 - Welded steel pipes for pressure applications. Technical delivery conditions. Part 7. Stainless steel pipes | |

| Other names | European | X5CrNi18-10, 1.4301 |

| Classification | Elements for pipelines, welded pipes, seamless pipes, steel forgings | |

Stainless steel characteristics

Does your company produce various stainless steel tools? Then you need specialized material. These can be carbon hot-rolled and cold-rolled steels, as well as their alloyed analogs with the addition of chromium, manganese, vanadium, molybdenum and tungsten. Depending on the alloying material, it is possible to achieve heat resistance at temperatures up to 700 - 800°C, as well as wear resistance.

Each brand has its own characteristics. For example, AISI 304 has special characteristics. It is capable of withstanding short-term temperature increases of up to 800 - 900 ° C, which is inaccessible to many analogues. It also does not react with liquid media, including food products (milk, sour cream, honey, etc.). This allows it to be effectively used in the food industry, medicine, and pharmacology. There is a thin oxide film on the surface of the material.

Mechanical properties

According to EN 10216-5, EN 10217-7, EN 10253-4 +AT

| Elongation, min., % | Transverse samples | 35 | |

| Longitudinal samples | 40 | ||

| Impact work KV at 20°C, min., J | Transverse samples | 60 | |

| Longitudinal samples | 100 | ||

| Minimum absorbed energy at 0°C [32°F], J (J) | Transverse samples | 35 | |

| Longitudinal samples | 47 | ||

| Impact work KV at -196°C [-320°F ], min., J | Transverse samples | 60 | |

| Brinell hardness, HB max. | 200 | ||

| Ultimate strength (temporary tensile strength), min., Rm, MPa | 500-700 | ||

| Yield strength, min., ReH, MPa | 195 | ||

| Nominal thickness, (mm) | < 60 | ||

According to EN 10222-5 +AT

| Elongation, min., % | Transverse samples | 35 | |

| Longitudinal samples | 45 | ||

| Impact work KV at 20°C, min., J | Transverse samples | 60 | |

| Longitudinal samples | 100 | ||

| Impact work KV at -196°C [-320°F ], min., J | Transverse samples | 60 | |

| Yield strength, min., ReH, MPa | 200 | ||

| Ultimate strength (temporary tensile strength), min., Rm, MPa | 500-700 | ||

What is “medical” steel 18/10

What is “medical” steel 18/10.

Stainless steel is considered the best material for kitchen utensils today, and almost every family now has stainless steel cutlery

The most popular grade of steel used for making cutlery is marked 18/10. Moreover, such markings appear on very inexpensive Asian cutlery and on products from leading European manufacturers. What do these numbers mean?

Steel 18/10 - according to the German DIN standard it is X5CrNi18-10, according to the European EN standard it is 1.4301, according to our GOST it is grade 12Х18Н10. This alloy contains, in addition to iron, 0.12% carbon, 18% chromium, 10% nickel and up to 1% other impurities. That's where the numbers 18 and 10 come from, they indicate the content of chromium and nickel. Steel density - 7.8 g/cubic. cm.

In advertising, such steel is often called “chrome-nickel” , “medical” , “space” and some special properties are attributed to it. Indeed, such steel is used for the manufacture of medical instruments, this is due precisely to the properties of the material, primarily due to its density. The fact is that 18/10 stainless steel is optimal in its density and hardness for use in medical institutions; such steel produces fewer scratches where dirt would accumulate, providing a favorable environment for the proliferation of microbes. This steel is resistant to acids and alkalis, including at high temperatures. This is why 18/10 stainless steel is used in medicine. This steel does not have any other special properties.

Yes, 18/10 stainless steel is quite expensive; cutlery made from such steel can rarely be classified as cheap. For inexpensive cutlery, corrosion-resistant steel is most often used. This steel is marked 08Х13.

If on the back of the cutlery you saw the designation 08X13 or 12X13. You should not be afraid of such a product; on the contrary, this is a big plus for the manufacturer for his honesty. The fact is that GOST 27002 “Cookware made of corrosion-resistant steel” indicates that “for the manufacture of bodies and lids of dishes and cutlery, steel grades 08Х13, 12Х13, 12Х18 should be used.” The only visual difference between this steel is the shine of the product; it gives off a slightly gray tone. Some advise using a magnet, they say 12X/18 does not magnetize, but 08X13 does, but practice has shown that such advice does not work accurately.

Unfortunately, some, especially Asian manufacturers, are disingenuous, putting the 18/10 mark on cutlery of unknown steel. I emphasize some, because many Asian factories make high-quality and high-end cutlery from 18/10 stainless steel….

Stainless steel cutlery >>>

Tests at elevated temperatures of material X5CrNi18-10 - 1.4301

| Temperature, °C | Ultimate strength (temporary tensile strength), min., Rm, MPa | Yield strength, min., Rp0.2 in N/mm3 |

| 550 | — | 90 |

| 500 | 360 | 92 |

| 400 | 380 | 98 |

| 350 | 380 | 104 |

| 300 | 380 | 110 |

| 250 | 390 | 118 |

| 200 | 400 | 127 |

| 150 | 420 | 142 |

| 100 | 450 | 157 |

| 50 | — | 180 |

Steel and stainless steel (differences)

There are many types and grades of steel. Sometimes analog brands can have huge differences in strength, corrosion resistance and other parameters. A common service is electrochemical polishing, which gives stainless steel characteristics suitable for certain applications:

- Making tableware;

- Pipelines;

- Mechanical engineering, etc.

For example, stainless steel 316, the characteristics of which are close to AISI 304, thanks to molybdenum (an alloying additive), has received greater resistance to high temperatures, chemical influences (alkali and acid), and rust. This grade of steel performed well even with constant use in cold and salty sea water. In the post-Soviet space, an analogue is produced, marked 08Х17Н13М2.

No less interesting is stainless steel 321, the characteristics of which allow it to be used in the manufacture of pipes, fittings for furnaces and boilers, and welding equipment. The material shows high resistance to temperatures and exposure to particularly aggressive environments.

12Х18Н10Т 12Cr18Ni10TiCharacteristics of the material Art. 12Х18Н10Т.

| Substitute: | 06ХН28МДТ 12Х18Н10Т 08Х18Н10Т 10Х17Н13М2Т |

| Classification: | Structural cryogenic steel |

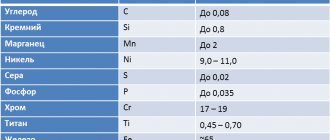

Chemical composition in % of material 12Х18Н10Т

| C | Si | Mn | Ni | S | P | Cr | Cu | — |

| up to 0.12 | up to 0.8 | up to 2 | 9 — 11 | up to 0.02 | up to 0.035 | 17 — 19 | up to 0.3 | (5 C - 0.8) Ti, the rest Fe |

Mechanical properties at T=20 °C of material 12Х18Н10Т.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Forgings | up to 1000 | 510 | 196 | 35 | 40 | Quenching 1050 - 1100 °C, water, | ||

| Thin sheet | 530 | 205 | 40 | Quenching 1050 - 1080 °C, Cooling water, | ||||

| The sheet is thin and hardened. | 880-1080 | 10 | ||||||

| Variety | up to 60 | 510 | 196 | 40 | 55 | Quenching 1020 - 1100 °C, Air cooling, | ||

| The leaf is thick | 530 | 235 | 38 | Quenching 1000 - 1080 °C, Cooling water, | ||||

| Cold-deformed pipes | 549 | 35 | ||||||

| Hot deformed pipes | 529 | 40 |

| Hardness of material 12Х18Н10Т, Forgings | HB 10 -1 = 179 MPa |

Physical properties of the material 12Х18Н10Т.

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 1.98 | 15 | 7920 | 725 | ||

| 100 | 1.94 | 16.6 | 16 | 462 | 792 | |

| 200 | 1.89 | 17 | 18 | 496 | 861 | |

| 300 | 1.81 | 17.2 | 19 | 517 | 920 | |

| 400 | 1.74 | 17.5 | 21 | 538 | 976 | |

| 500 | 1.66 | 17.9 | 23 | 550 | 1028 | |

| 600 | 1.57 | 18.2 | 25 | 563 | 1075 | |

| 700 | 1.47 | 18.6 | 27 | 575 | 1115 | |

| 800 | 18.9 | 26 | 596 | |||

| 900 | 19.3 | |||||

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

Technological properties of material 12Х18Н10Т.

| Weldability: | steel with unlimited weldability. |

| Flock Sensitivity: | not sensitive. |

Designations:

| Mechanical properties : | |

| sв | — Short-term strength limit, [MPa] |

| sT | — Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | — Elongation at break, [%] |

| y | — Relative narrowing, [%] |

| KCU | — Impact strength, [kJ/m2] |

| HB | — Brinell hardness, [MPa] |

| Physical properties: | |

| T | — Temperature at which these properties were obtained, [degrees] |

| E | — Modulus of elasticity of the first kind, [MPa] |

| a | — Coefficient of thermal (linear) expansion (range 20o - T), [1/degree] |

| l | — Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | — Material density, [kg/m3] |

| C | — Specific heat capacity of the material (range 20o — T), [J/(kg deg)] |

| R | — Electrical resistivity, [Ohm m] |

| Weldability: | |

| no limits | — welding is performed without heating and without subsequent heat treatment |

| limited weldability | — welding is possible when heated to 100-120 ° C and subsequent heat treatment |

| difficult to weld | - to obtain high-quality welded joints, additional operations are required: heating to 200-300 ° C during welding, heat treatment after welding - annealing |

Application of stainless steels 08x18n10 and aisi 304

Since the main characteristics of 304 and 321 are similar (with minor differences), their areas of application are the same.

They are used to make structures, parts and components in construction, mechanical engineering and the chemical and petrochemical industries. These are welded equipment, devices, mechanisms, the operation of which takes place in conditions of increased aggressiveness - heat exchangers, muffles, pipes, etc.

At the same time, 08x18n10 is advisable to use for assemblies, parts of units, devices that operate at high temperatures, or with requirements for increased strength.

Properties 08x18n10 analogue of aisi 304

Titanium in alloy 08x18n10 makes it more durable compared to steel 304. But alloying steel with titanium increases the price of the structures in which it is used, and therefore of the entire construction. But the demand for products made from 08x18n10 is not decreasing.

The choice between steel aisi 304 and 08x18n10 is simple, since they are practically interchangeable.

Of the same properties: both alloys are characterized by good weldability, with a slight difference - titanium requires an increase in temperature during welding. But it also promotes slow burnout of carbon and increases resistance to the formation of intergranular corrosion. The welds of both steels are not treated during welding.

Since both steels are non-magnetic, they do not require hardening.

Steels aisi 304 and 08x18n10, due to the combination of strength, ductility and elasticity, are perfectly processed by any means (cold and hot). They are subjected to annealing, tempering, tensile deformation, drawing; amenable to drawing, bending and forging.

The basic properties of steels are the same:

- corrosion resistance;

- durability (even at high temperatures);

- heat resistance and resistance to high temperatures (although 08x18n10 can withstand higher temperatures, up to 850°C);

- plasticity and easy machinability (although there is a difference, unlike aisi 304, in 08x18n10, due to the presence of titanium, a matte surface is formed during grinding; it is impossible to achieve a mirror finish);

- environmental Safety.

The conclusion is simple - 08x18n10, an analogue of AISI 304, differs slightly from steel 304, and can completely replace it.