Want to create a site? Find Free WordPress Themes and plugins.

Stainless steel products have long been an indispensable household item. So, in almost every kitchen you can find stainless steel dishes - pots, cutlery, graters, thermoses and much more. Sinks, elements of boilers and chimneys, ventilation systems - stainless steel is used everywhere.

However, few people think that the excellent characteristics of stainless steel have found their way into industry. Containers for transporting food products, pipes, pipeline fittings, sheet metal and much more are made from stainless steel.

What is the reason for such popularity of stainless steel?

Types of stainless steel

Stainless steel is an attractive material for use in modern industry. It consists of iron and chromium impurities.

Attention: In order to ensure the longest possible protection of iron from corrosion, it is necessary to add at least ten percent chromium to it during the production of stainless steel.

Also, other elements are added to the mixture for the production of stainless steel, which are presented:

- nickel,

- niobium,

- molybdenum,

- titanium.

They are necessary for the material to acquire its physical and chemical qualities and become more durable.

Thanks to the mixture of iron and other elements, a material is created that can resist corrosion. Depending on the proportionality of the added elements, the stainless material becomes durable and can withstand even high temperatures. Due to its ductility, stainless steel is used in a wide variety of industries.

Iron itself becomes rusty quite quickly. If you mix it with chromium and other elements, an invisible film is formed on its surface, which prevents the flow of oxygen to it. As a result, no oxidation occurs. This layer is quite durable. Which makes the material more resistant to the formation of cracks, dents and many other defects. Steel can repair itself over time.

Areas of use of alloys - difference between aisi 304 and 316

Considering the peculiar properties of aisi 316, steel 304 and 316 have differences in application. Although under normal operating conditions they are completely interchangeable.

Due to its resistance to the formation of all types of corrosion in sea water, first of all, alloy 316 is indispensable in shipbuilding and the transport field - containers, units and installations on ships, elements of marine instruments. It is also widely used in the petrochemical industry, oil refining, mining, chemical and mining industries. It is advantageous to make tanks and containers from this alloy for storing and transporting aggressive liquids, since they are the most durable.

In all areas in which both steels are used, there is no need to decide whether aisi 304 or aisi 316 is better, since in all other performance indicators they are similar.

- Pipelines

- Metal constructions

- Elements of technology

- Units and parts in mechanical engineering

Stainless steel grades and their characteristics

In the modern world there are more than two hundred and fifty types of stainless steel. They differ in their series or brands and in their properties. The most popular grades of stainless steel currently are those types that belong to the 300 and 400 series. They have a high level of resistance to corrosion. In addition, their layer of protective film is quite durable due to the optimally selected proportionality of the elements used in production. Stainless steel of these series has high strength and ductility. It is actively used for the production of various items in modern industry. Soon, these series may be competed by the 200 series of steel, which, according to consumers, has the optimal combination of cost and quality.

Characteristics of AISI stainless steels

In the modern market, stainless steel of the 300 series is in great demand. It is divided into several types depending on the chemical composition:

- austenitic,

- austenitic-ferritic,

- austenitic-martensitic.

These types of steel contain different amounts of nickel and chromium. carbon.

AISI stainless steel grades:

AISI 304 stainless steel

aisi 304 (08Х18Н10) is widely used in the food industry. It is excellent for welding and to resist rust.

AISI 316 stainless steel

aisi 316 (10Х17Н13М2) is formed if an element such as molybdenum is added to aisi 304 (08Х18Н10) steel. This grade of stainless steel is widely used in the shipbuilding, oil and gas and chemical industries. It is resistant to aggressive environments.

AISI 316T stainless steel

aisi 316T (10Х17Н13М2Т) has a high level of strength due to the fact that it contains more titanium than previous brands. It has found wide application in the creation of equipment for the chemical and food industries.

AISI 321 stainless steel

aisi 321 (12-08Х18Н10Т) has the largest amount of titanium among all brands of the three hundredth series. Able to withstand heating temperatures up to 800 degrees Celsius.

AISI 430 stainless steel

Among the brands of the four hundredth series, the most widely used brand is aisi 430 (12X17). In general, the entire series is characterized by the fact that it includes stainless steel grades that are created with a high chromium content. The characteristic feature of the aisi 430 brand is that the material bends well and is subject to welding. This steel can be used for places with high temperature changes. Most often it is used for decoration of buildings and in the oil and gas industry.

Stainless steel AISI 201

The 200 series of stainless steel also has worthy brands that you should pay attention to.

Among them, the most prominent steel is AISI 201 (12X15G9ND). It differs from more expensive brands from other series in that it uses a mixture of elements such as nitrogen and manganese instead of nickel. Due to its chemical and physical properties, it is widely used in the food and medical industries. It is also suitable for the production of various types of fences and pipes. Table of stainless steel grades and their compliance with chemical composition

| Stainless steel standards | Content of alloying elements, % | |||||||||

| * | DIN | AISI | GOST | C | Mn | Si | Cr | Ni | Mo | Ti |

| C1 | 1.4021 | 420 | 20Х13 | 0,20 | 1,5 | 1,0 | 12,0-14,0 | |||

| F1 | 1.4016 | 430 | 12Х17 | 0,08 | 1,0 | 1,0 | 16,0-18,0 | |||

| A2 | 1.4301 | 304 | 12Х18Н9 | 0,07 | 2,0 | 0,75 | 18,0-19,0 | 8,0-10,0 | ||

| 1.4948 | 304H | 08Х18Н10 | 0,08 | 2,0 | 0,75 | 18,0-20,0 | 8,0-10,5 | |||

| 1.4306 | 304L | 03Х18Н11 | 0,03 | 2,0 | 1,0 | 18,0-20,0 | 10,0-12,0 | |||

| A3 | 1.4541 | 321 | 08Х18Н10Т | 0,08 | 2,0 | 1,0 | 17,0-19,0 | 9,0-12,0 | 5xS-0.7 | |

| A4 | 1.4401 | 316 | 03Х17Н14М2 | 0,08 | 2,0 | 1,0 | 16,0-18,0 | 10,0-14,0 | 2,0-2,5 | |

| 1.4435 | 316S | 03Х17Н14М3 | 0,08 | 2,0 | 1,0 | 16,0-18,0 | 12,0-14,0 | 2,5-3,0 | ||

| 1.4404 | 316L | 03Х17Н14М3 | 0,03 | 2,0 | 1,0 | 17,0-19,0 | 10,0-14,0 | 2,0-3,0 | ||

| A5 | 1.4571 | 316Ti | 08Х17Н13М2Т | 0,08 | 2,0 | 0,75 | 16,0-18,0 | 11,0-12,5 | 2,0-3,0 | 5xS-0.8 |

| 1.4845 | 310S | 20Х23Н18 | 0,08 | 2,0 | 0,75 | 24,0-26,0 | 19,0-21,0 | |||

Properties of 304-316 steel

And yet, despite seemingly insignificant changes in the chemical composition of the alloy, the properties of 316 differ significantly from 304 in some respects.

Thanks to alloying with molybdenum, alloy 316 acquires the ability to resist corrosion damage such as crevice and pitting. Especially with direct contact of structures made of this alloy in such aggressive environments as acidic vapors, chlorine compounds, sea water (cold). It is well known that pitting corrosion, which selectively affects hard-to-reach places, is especially dangerous for structures. Therefore, for structures that are operated in such conditions, the question does not even arise - aisi 304 aisi 316 which is better, it is so obvious. The same applies to structures and products whose operation takes place in contact with vapors of many acids - formic, phosphoric, acetic, boric, oxalic, sulfuric or lactic.

When comparing AISI 304 to 316 steel, it is clear that AISI 316 alloy has significantly high performance properties and technological characteristics, including strength indicators. Moreover, what is especially important when operating structures made of 316, these properties are maintained throughout the entire service life and do not change even at temperatures tending to zero ˚C.

Steel 316 has greater strength than 304, as well as much greater creep resistance at higher operating temperatures. This difference between 316 and 304 is due to the addition of molybdenum.

Due to the high level of resistance to corrosive formations and non-susceptibility to oxidation, aisi 316 is characterized by physical properties that are practically no different from the properties of aisi 304 (a slight increase in density has little effect on performance properties).

Stainless steel standards

There are state standards for different types of stainless steel in our country. They determine the quality of products made from this material. Stainless steel has different GOST standards. Certain quality standards are developed for thin sheets, for wire, for thick sheets and for stainless steel pipes.

Stainless steel has different characteristics. Thanks to its chemical and physical parameters, it easily resists the formation of corrosion plaque. This material was developed for use in places where there are different environmental conditions. Due to its heat resistance and strength, steel does not react with substances in the environment.

Usage. 304 or 321 steel which is better

The presence of titanium in the AISI 321 alloy makes it advisable to use it for the production of structures, their components, elements of installations or assemblies, the operation of which will take place at elevated temperatures, or with requirements for increased strength.

Typically this is:

- fittings for furnaces;

- heat exchangers;

- housings and parts of steam and thermal boilers;

- containers for storing or transporting gases under pressure.

In most cases, 304 and 321 stainless steel can be used in a very wide range of industries - in construction, mechanical engineering and the chemical and petrochemical industries. In the food industry, paper industry, etc.

Application of stainless steel

Modern industry cannot do without the use of stainless steel. It is not only a high-strength material, but also has an attractive appearance. It was because of its beauty that steel began to be used for the decoration of buildings and their individual elements. In particular, fencing and railings for staircases are made from stainless steel.

In the food industry, rolled steel is very popular. Cooking equipment and utensils are made from steel materials. They are able to withstand high heating temperatures and are not susceptible to rust.

The use of stainless steel in the chemical industry began in the middle of the last century. The most durable types of steel material are used here so that equipment or devices do not fail under the influence of various reagents.

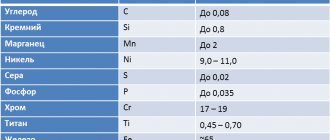

Characteristics AISI 321

Grade AISI 321 belongs to the class of heat-resistant stainless materials and is classified as structural cryogenic steel. It is an austenitic, non-magnetic metal, which makes it in demand everywhere.

Chemical composition:

- carbon – up to 0.080%;

- silicon – less than 1%;

- manganese – no more than 2%;

- phosphorus – up to 0.045%;

- sulfur – up to 0.030%;

- chromium – 17-19%;

- nickel – 9-12%;

- titanium <0.5%;

- iron - the rest.

The titanium content prevents or reduces the precipitation of chromium carbides and increases strength characteristics.

Mechanical properties:

- fluidity – 205 MPa;

- Brinell hardness – 163 HB;

- temperature limit – +850°C;

- strength – 515 MPa;

- density – 7.79 g/cm3.

Advantages:

- resistance to normal and intergranular corrosion;

- easy weldability and forging;

- plastic;

- increased strength.

Heat treatment is carried out by annealing with rapid cooling (+1050°C – +1150°C) and tempering (+450°C – +800°C).

AISI 321 is in demand everywhere, due to its heat resistance and anti-corrosion properties.

Areas of use:

- mechanical engineering;

- aviation;

- heating equipment;

- pipeline accessories;

- food industry;

- automotive industry, etc.

Steel is used for the manufacture of welded pipes, boilers, furnace fittings, exhaust manifolds, rotors, heat exchangers and other parts.

Application difference

Both brands are non-magnetic, low-carbon materials that do not require hardening. They are characterized by environmental safety, elasticity and pliability to any processing method while maintaining the structure. They are neutral to most environments and, in principle, can be used interchangeably.

At the same time, AISI 321 is more durable due to the titanium in its composition, and therefore is used for the production of structures operating at extreme temperatures and pressures. But such a metal is not suitable for use in an oxidizing environment, even despite its resistance to MCC. In such cases, it is better to use AISI 304.

ASTM Steel Markings

The designation of steels in the ASTM system includes:

- letter A , meaning that we are talking about ferrous metal,

- serial number of the ASTM regulatory document (standard)

- the actual designation of the steel grade.

Typically, ASTM standards adopt the American system of notation for physical quantities. In the same case, if the standard contains a metric notation system, the letter M .

ASTM standards, as a rule, define not only the chemical composition of steel, but also a complete list of requirements for metal products. To designate the actual steel grades and determine their chemical composition, both ASTM’s own designation system can be used (in this case, the chemical composition of steels and their markings are determined directly in the standard), as well as other designation systems, for example AISI - for rods, wire, etc. , or ACI - for castings made of corrosion-resistant steels.

Example: A 516/A 516M-90 Grade 70 the letter A indicates that we are talking about ferrous metal, 516 is the serial number of the ASTM standard ( 516M is the same standard, but in the metric notation system); 90 - year of publication of the standard; Grade 70 - steel grade. In this case, ASTM's own steel designation system is used, here 70 defines the minimum tensile strength of steel.

As you can see from the example, in order to fully understand the steel grade, it is necessary to use tables describing ASTM standards.

Series 200

Stainless steels, in which expensive nickel is partially replaced by manganese and nitrogen to stabilize the austenitic structure, have long established themselves as an effective substitute for standard chromium-nickel steels. These steels have proven themselves as a material for the manufacture of metal utensils, household kitchen utensils and apparatus.

In conclusion, we note: Steels of the 300 series are gradually losing ground to the more cost-effective austenitic steels of the 200 series and chromium steels of the 400 series. A change in priorities is clearly observed in the world.