Stainless steel AISI 316 in StenlisPro

StenlisPro supplies AISI 316 stainless steel sheets to the rolled metal market. The main characteristics of the products are as follows:

- Thickness: 0.5, 0.8, 4.0, 5.0 mm.

- Surfaces: matte or hot rolled.

- Size: 1000x2000 mm.

The sheets are characterized by plasticity and elasticity. The material does not require heat treatment after welding; it only needs to be cleaned of scale by chemical or mechanical means and passivated.

Selling AISI 316 stainless steel sheets, StenlisPro also provides services for cutting the material to size.

To clarify prices, standard sizes, types of additional services and other questions you may have, call: 8 (800) 333-06-56 or order a free call on the website. Our managers will contact you as soon as possible and help you place an order.

Chemical composition: find the main difference

Both grades belong to the non-magnetic, austenitic type of steel, are an iron-containing alloy and are not hardened by heat treatment. Each of these grades of stainless steel is resistant to corrosion, quite durable, and easy to form.

The difference primarily lies in the addition of molybdenum to alloy 316. Molybdenum further increases the material's corrosion resistance, making it ideal for more acidic environments. In addition, 316 steel has a longer service life than 304 steel when subjected to mechanical stress. This becomes obvious in the production of gears made from 304 and 316 steels - 316 steel is much less susceptible to wear.

| Compound | Content in AISI 304, % | Content in AISI 316, % |

| Chromium (Cr) | 18–20 | 16–18 |

| Nickel (Ni) | 8–10,5 | 10–14 |

| Molybdenum (Mo) | No | 2–3 |

| Manganese (Mn) | 2 | 2 |

| Silicon (Si) | 1 | 1 |

| Nitrogen (N) | 0,11 | 0,11 |

| Carbon (C), max. quantity | 0,08 | 0,03 |

| Phosphorus (P) | 0,045 | 0,045 |

| Sulfur (S) | 0,015 | 0,015 |

| Iron (Fe) | Remaining part | Remaining part |

Stainless steel AISI 316L analogue 03Х16Н15М3

For the manufacture of welded structures, the AISI 316 - 316L steel variety is most often used. It has a lower carbon content.

StenlisPro sells matte sheets of standard size 0.8x1000x2000. Thanks to the presence of:

- molybdenum – 2%;

- chromium – 17%;

- nickel – 10%;

the corrosion resistance of the alloy increases. Due to this, it is used in the manufacture of ventilation systems and chimneys in industries with the presence of aggressive environments.

Characteristics and properties

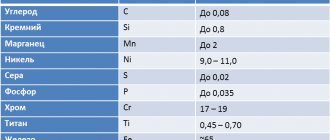

Steel 10x17n13m2t according to GOST has the following chemical composition in percentage:

- carbon – up to 0.08;

- manganese – up to 2;

- silicon – up to 1;

- sulfur – up to 0.03;

- nickel – from 10 to 14;

- phosphorus – 0.045;

- titanium – less than 1;

- iron – approximately 65;

- molybdenum – from 2.5 to 3.

This is an incomplete list of the components of this type of stainless steel; the chemical composition is indicated in more detail in the state standard reference books.

Thanks to this chemical composition, stainless steel 316ti 10x17n13m2t received the following characteristics:

- density – 8 g/cm3;

- tensile yield strength – 515 N/mm2;

- hardness – 165 (Brinell);

- fatigue strength – 260 N/mm2;

- melting point – 1440 degrees;

- electrical resistivity – 0.75 Ω mm²/m;

- elastic modulus - MPa x 10³;

These characteristics provided steel 10x17n13m2t with high resistance to aggressive environments: formic, phosphoric, sulfuric and hydrochloric acid.

Areas of application of AISI 316

AISI 316 stainless steel is actively used in such industries as:

- Food and pharmaceutical industries - due to increased requirements for hygiene and quality standards.

- Construction (facades, roofs, fences, welded structures, various architectural elements).

- Chemical industry.

- Mechanical engineering.

- Pulp and paper industry.

- Mining business.

- Shipbuilding.

- Oil and gas industry (stainless steel pipes, tanks, etc.).

Heat resistance and strength make it possible to produce tools, household appliances, equipment, and parts for mechanical engineering on an industrial scale. Another leading characteristic - oxidation resistance - contributes to the widespread use of AISI 316 steel for the production of containers for storing or transporting aggressive chemicals, pipeline elements through which not only water, but also corrosive liquids and gases are transported.

Characteristics of AISI 316 and AISI 316 Ti stainless steel

Grade 316 AISI is an improved version of 304, with added molybdenum and a slightly higher nickel content. This 316 AISI composition significantly improves corrosion resistance in most aggressive environments. Molybdenum makes steel more protected from pitting and crevice corrosion in chloride environments, sea water and acetic acid vapors. Lower overall corrosion rate in mildly corrosive environments gives good corrosion resistance in polluted and marine atmospheres.

316 is higher strength and has better creep resistance at higher temperatures than 304 AISI. 316 AISI also has excellent mechanical and corrosion properties at sub-zero temperatures. When there is a risk of corrosion in heat-affected welded areas, a low-carbon grade, 316L AISI, should be used. 316Ti AISI, a titanium stabilized version, is used to resist sensitization over long periods of time in a temperature range of 550 - 800°C.

The Russian analogue of 316L AISI according to GOST is 03Х17Н14М3, 316Ti AISI – 10Х17Н13М2Т.

Application area

Due to its outstanding corrosion and oxidation resistance, good mechanical properties and processability, 316 AISI has applications in many industrial sectors. Some of them include:

- Tanks and vessels for storing corrosive liquids;

- Specialized industrial equipment in the chemical, food, paper and pulp, mining, pharmaceutical and petrochemical sectors of the economy;

- Architectural applications in highly corrosive environments.

Chemical composition (ASTM A240)

| C | Mn | P | S | Si | Cr | Ni | Ti | ||

| 316 AISI | 0.08max | 2.0max | 0.045 max | 0.030 max | 1.0max | 16.0 to 18.0 | 10.0 to 14.0 | 2.00 to 3.00 | — |

| 316L AISI | 0.03 max | 0.5max | |||||||

| 316Ti AISI | 0.08max | 5X%C |

Typical Annealed Properties

The properties stated in this publication are typical of one plant's production and should not be regarded as guaranteed minimum values for the entire specification.

Mechanical Properties at room temperature

| 316 AISI | 316L AISI | 316Ti AISI | ||||

| Typical | Min | Typical | Min | Typical | Min | |

| Rp m Ultimate strength (tensile), N/mm2 | 580 | 515 | 570 | 485 | 600 | 515 |

| Rp0.2 Elasticity limit (yield), (0.2%), N/mm2 | 310 | 205 | 300 | 170 | 320 | 205 |

| elongation (% in L = 5.65 S0) | 55 | 40 | 60 | 40 | 50 | 40 |

| Brinell hardness - HB | 165 | — | 165 | — | 165 | — |

| Erichsen organoleptic test, mm | 8 — 10 | — | 10 — 11 | — | — | — |

| Fatigue strength, N/mm2 | 260 | — | 260 | — | 260 | — |

Properties at high temperatures

All these values apply to 316 and 316 Ti only. Values are not given for 316L because its strength decreases noticeably above 425°C.

Tensile strength at elevated temperatures

| Temperature, °C | 600 | 700 | 800 | 900 |

| Rp m Ultimate strength (tensile), N/mm2 | 460 | 320 | 190 | 120 |

| Minimum values of elastic limit (creep) at high temperature (1% deformation in 10,000 hours) | ||||

| Temperature, °C | 550 | 600 | 650 | 700 |

| Rp1.0 1.0% plastic deformation (yield) N/mm2 | 160 | 120 | 90 | 60 |

Maximum recommended service temperatures (oxidation conditions)

Continuous exposure 925°C intermittent exposure 870°C

Properties at low temperatures (316 AISI)

| Temperature, °C | -78 | -161 | -196 |

| Rp m Ultimate strength (tensile), N/mm2 | 400 | 460 | 580 |

| Rp0.2 Elastic Limit, (0.2%), (proof of yield) N/mm2 | 820 | 1150 | 1300 |

| Impact strength, J | 180 | 165 | 155 |

Corrosion resistance

Acidic environments

Examples are given for some acids and their solutions (most general values):

| Temperature, °C | 20 | 80 | ||||||||||

| Concentration, % by weight | 10 | 20 | 40 | 60 | 80 | 100 | 10 | 20 | 40 | 60 | 80 | 100 |

| Sulfuric acid | 0 | 1 | 2 | 2 | 1 | 0 | 2 | 2 | 2 | 2 | 2 | 2 |

| Nitric acid | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 2 |

| Phosphoric acid | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 1 | 2 |

| Formic acid | 0 | 0 | 0 | 1 | 1 | 2 | 0 | 0 | 1 | 1 | 1 | 0 |

| Concentration, % by weight | 10 | 20 | 40 | 60 | 80 | 100 | 10 | 20 | 40 | 60 | 80 | 100 |

| Sulfuric acid | 0 | 1 | 2 | 2 | 1 | 0 | 2 | 2 | 2 | 2 | 2 | 2 |

| Nitric acid | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 2 |

| Phosphoric acid | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 1 | 2 |

| Formic acid | 0 | 0 | 0 | 1 | 1 | 2 | 0 | 0 | 1 | 1 | 1 | 0 |

| Concentration, % by weight | 10 | 20 | 40 | 60 | 80 | 100 | 10 | 20 | 40 | 60 | 80 | 100 |

| Sulfuric acid | 0 | 1 | 2 | 2 | 1 | 0 | 2 | 2 | 2 | 2 | 2 | 2 |

Code: 0 = high degree of protection - Corrosion rate less than 100 mm/year; 1 = partial protection - Corrosion rate from 100m to 1000 mm/year; 2 = non resistant - Corrosion rate more than 1000 mm/year.

Atmospheric influences

Comparison of 316 grade with other metals in various environments (corrosion rate calculated over 10 year exposure).

| Environment | Corrosion rate (mm/year) | ||

| 316 AISI | Aluminum-3S | Carbon steel | |

| Rural | 0.0025 | 0.025 | 5.8 |

| Marine | 0.0076 | 0.432 | 34.0 |

| Industrial marine | 0.0051 | 0.686 | 46.2 |

Heat treatment

AnnealingHigh temperature from 1010°C to 1120°C and rapid tempering (cooling) in air or water. The best corrosion resistance is obtained when annealing at 1070°C, and rapid cooling.

Vacation (stress relief)

Heating to 200-400°C followed by air cooling.

Hot working (forging interval)

Initial temperature: 1150 - 1200°C. Final temperature: over 900°C.

To fail, forging must be completed between: 930 and 980°C.

Any hot processing must be accompanied by annealing.

Please note: The time to achieve uniform heating is longer for stainless steels than for carbon steels - approximately 12 times.

Cold processing

Steels 316 AISI, 316L AISI, 304 AISI, 304L AISI, being extremely strong, elastic and ductile, easily find many applications. Typical processes include bending, stretch forming, deep drawing and rotary drawing.

Stainless steel grades 304 and 316 in pumping equipment

These grades of steel are popular among pump manufacturers. However, in some cases, AISI 316 stainless steel is the only right solution. For example, for pumps that are used on ships for the purpose of sanitary supply with sea water or cooling equipment with sea water. AISI 316 is characterized by increased resistance to the formation of all types of corrosion in sea water. Also, in the petrochemical, oil refining or mining industries, when transporting aggressive liquids, it is worth giving preference to pumps with a body made of alloy 316 due to its greater durability and endurance compared to 304. Pumping equipment for the food and pharmaceutical industries cannot do without parts made of AISI 316 alloy, since upon contact with the environment, a film is formed on the surface of the metal, which prevents the appearance of rust and other defects throughout its entire service life.

So what should you choose? There is no clear answer. 304 steel is much cheaper than 316 and its choice in many cases is justified.

In what specific environment do you plan to use the equipment? If it is salty or sour, choose AISI 316. This is perhaps the main and most accurate recommendation. As mentioned, molybdenum matters. What will be the operating temperature of liquids in contact with metal? High temperatures accelerate corrosion. This means that a higher class is suitable - 316.

Cost is an important factor when choosing the right grade of stainless steel. But sometimes, having saved on equipment, you will lose more on maintenance, repairs and downtime in the future. Therefore, it is best to consult with specialists to understand which brand suits your requirements.

Difference between AISI 316L stainless steel pipe and AISI 316Ti

Round pipe AISI 316 has versions with modification of the chemical composition. These include brands AISI 316l and AISI 316Ti.

The first is characterized by a reduced amount of carbon. Its domestic analogue is 03Х17Н14М3 with a carbon content of up to 0.03%. The purpose of this modification is to increase weldability and resistance to MCC.

The second grade additionally contains titanium, its domestic analogue is steel 10Х17Н13М2Т. Titanium is one of the strongest carbide-forming elements. In this steel, it “works” in tandem with molybdenum. As already noted, molybdenum promotes the uniform distribution of carbides throughout the grain body without their concentration at the boundaries, and titanium actively captures carbon atoms, preventing the formation of chromium carbides. As a result, all the chromium remains in the iron lattice and provides corrosion resistance and MCC resistance. Steel with titanium is often called "stabilized".

This alloying allows the use of stainless steel for very critical welded structures operating under conditions of alternating mechanical and thermal loads, prolonged heating up to 600 - 6500C and corrosive effects, including in hydrogen sulfide and boiling acidic environments.

AISI 316 stainless steel pipe: characteristics and scope of application

Stainless steel pipes made of AISI 316 steel are supplied in heat-treated condition. Heat treatment consists of hardening from 1050-10800C in water or air. As a result of high-temperature heating, carbide particles dissolve (steel homogenization) and a stable austenitic structure is formed. When cooled in these environments, the structure is fixed. The high nickel content does not allow the polymorphic transformation of the iron crystal lattice to occur and the steel remains in the austenitic state. For this group, hardening is a softening treatment that reduces work hardening after cold deformation and internal stresses in the case of welding pipes from sheets.

In the heat-treated state, AISI 316 pipes have the following characteristics:

- temporary tensile strength – 550 – 700 N/mm2

- yield strength – 220 – 240 N/mm2

- relative elongation – no less than 40%

- steel has no cold brittleness limit

- weldability - no restrictions

Like all stainless steel pipes, AISI 316 rolled steel can be supplied with special surface finishing - peeling, shot and sandblasting, grinding and polishing. Surface treatment can be:

- mirror (VA)

- polished matte (2B)

- ground with different roughness (N4, SB, GRID).

Main Application:

- energy (including nuclear)

- chemical, petrochemical, food industry

- cryogenic technology

- equipment operating in aggressive environments (for example, in conditions of sea corrosion)

- boiler equipment

Considering the alloying (primarily the amount of nickel) and the complexity of manufacturing the AISI 316 pipe, its price cannot be low. It is an order of magnitude more expensive than similar carbon or low-alloy materials.

Existing analogues

When setting up production, the possibility of purchasing analogues that are cheap or have slightly more attractive performance characteristics is often considered. Analogues of steel 316l are as follows:

- SUS 316L is produced in Japan.

- European equivalent 1.4404.

- In Germany they produce an analogue under the label X2CrNiMo18-14-2.

- On the territory of the Russian Federation, in accordance with GOST, 03X17H14M is produced.

The performance qualities of analogues are similar, but the chemical composition may differ slightly. The cheapest offers come from domestic manufacturers. An analogue of AISI 316 from Russian manufacturers has become widespread, which is due to its lower cost.

Rolled metal from AISI 316 steel

In the catalog, metal products made from AISI 316 stainless steel are presented in rolled, sheet, and pipe products. Products differ in size, production method (hot-rolled, cold-rolled), as well as the method of surface treatment - polished, matte, mirror surface. Find out more details from our consultants!

Stainless steel sheet Aisi 304

Stainless steel roll Aisi 304

Welded stainless steel pipes Aisi 304